A kind of process of metal mold centrifugal casting composite high and low carbon manganese steel hammer head

A centrifugal casting, metal mold technology, applied in the field of large crusher hammer, can solve problems such as low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

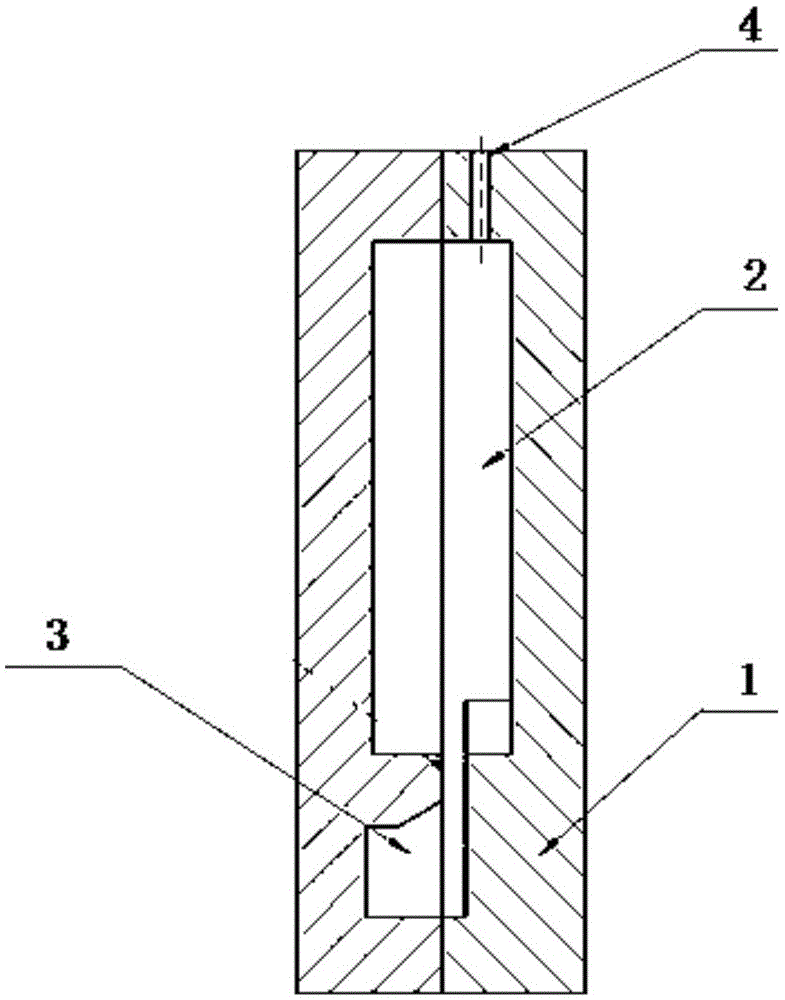

[0005] Referring to the attached drawings, a process for a metal type centrifugal casting composite high and low carbon manganese steel hammer head includes a hammer handle and a wear zone hammer head. The hammer handle and the hammer head use two carbon-manganese steel materials with different compositions. Use the bottom injection metal hammer mold to shape, and then install it on a vertical centrifuge. Use two intermediate frequency furnaces to smelt two-component carbon-manganese steel at the same time, and then cast them in sequence. Under the action of centrifugal force, the two-component carbon-manganese steel is completed. Steel composite casting; specifically includes the following steps: (1) First, design a bottom injection metal type hammer head mold according to the size of the hammer head. The bottom injection type metal hammer head mold is a mold body composed of two metal mold bodies. 1. A hammer head cavity 2 is formed in the middle of the mold body 1. The lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com