Rheology and thixotropy integrated casting and forming machine

A molding machine and an integrated technology, applied in the field of casting, can solve the problems of anodic oxidation, the limited use of alloy materials, and poor dimensional accuracy of products, so as to save production and operation costs, improve mechanical properties, and high dimensional accuracy of products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

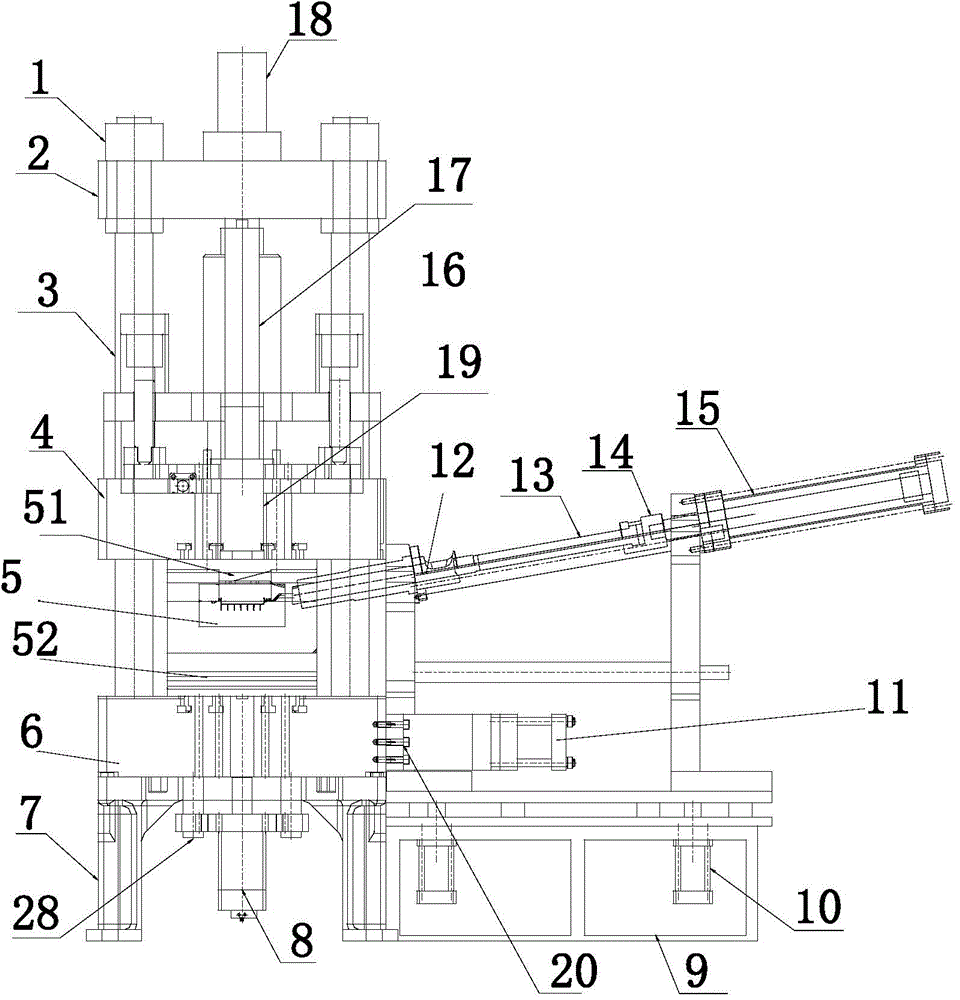

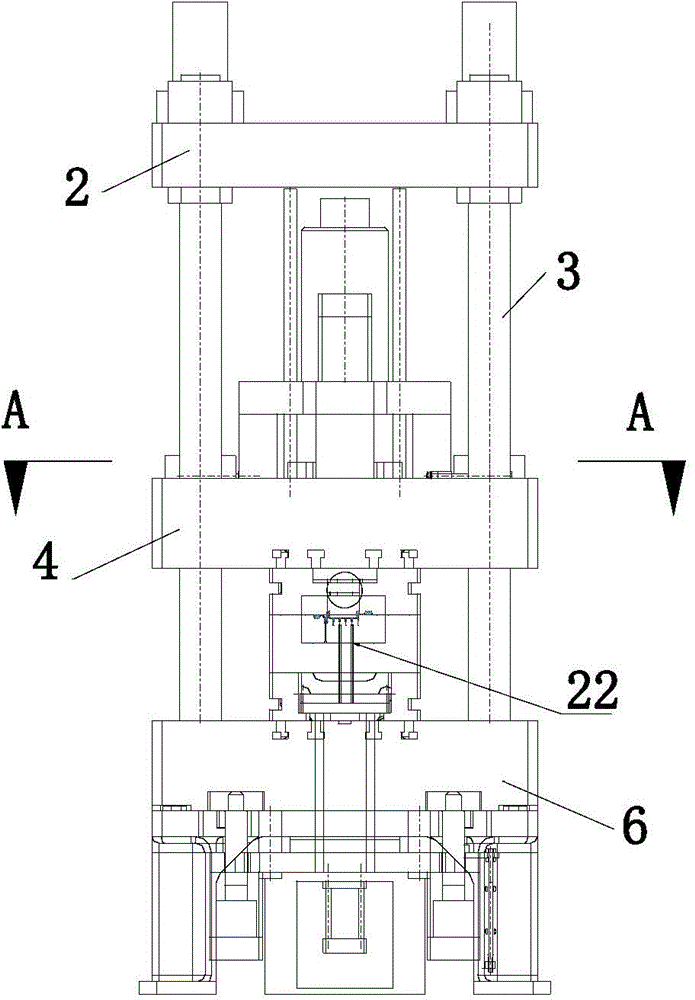

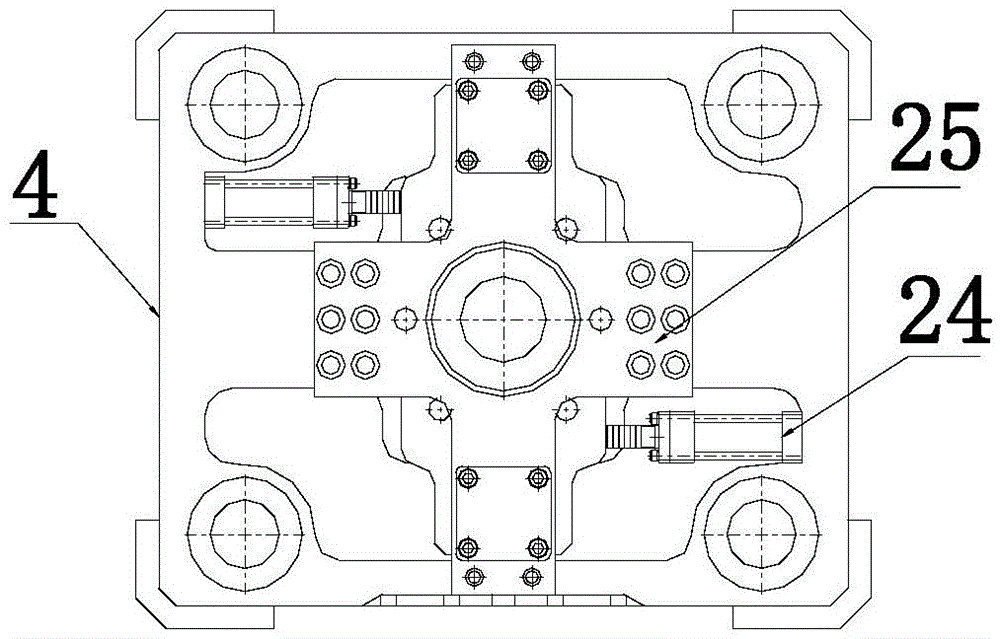

[0029] Embodiment 1, with reference to Figures 1 to 3 , figure 1 It is the front view of the preferred embodiment of the rheological and thixotropic integrated casting molding machine of the present invention, figure 2 It is the left view of the preferred embodiment of the rheological and thixotropic integrated casting molding machine of the present invention, image 3 for along figure 2 Cross-sectional view of line A-A in.

[0030] Such as Figures 1 to 3 As shown, the rheological and thixotropic integrated casting molding machine is a vertical rheological and thixotropic integrated casting molding machine, including a machine base 7, a machine tool head plate 6, a machine tool middle plate 4, a machine tool tail plate 2, and a product molding model 5 , clamping device, injection device and forging hammer device.

[0031] The machine tool head plate 6, the machine tool middle plate 4, and the machine tool tail plate 2 are successively installed above the machine base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com