Construction method of lifting casting wall and droping casting floor

A construction method and floor slab technology, which is applied to formwork/formwork/work frame, preparation of building components on site, construction, etc., can solve problems such as longer construction period, heavy workload and troublesome assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

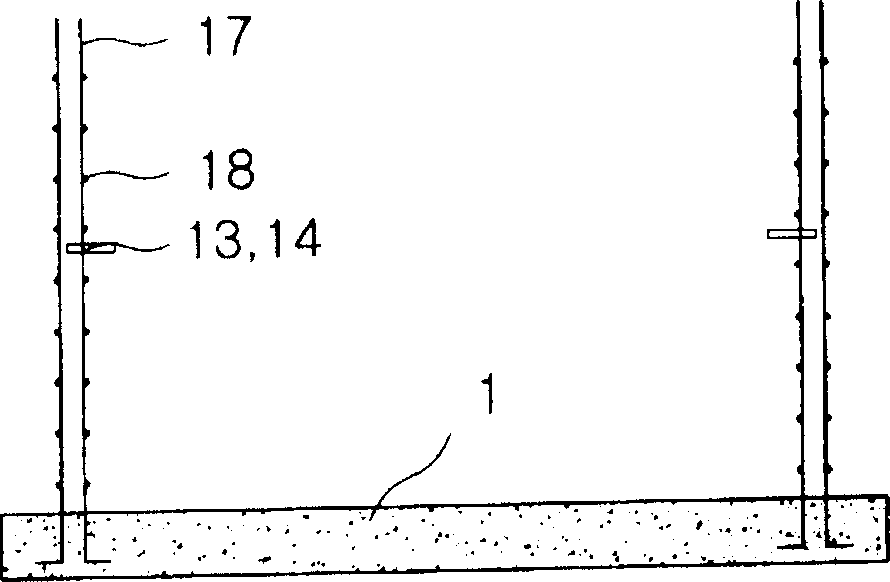

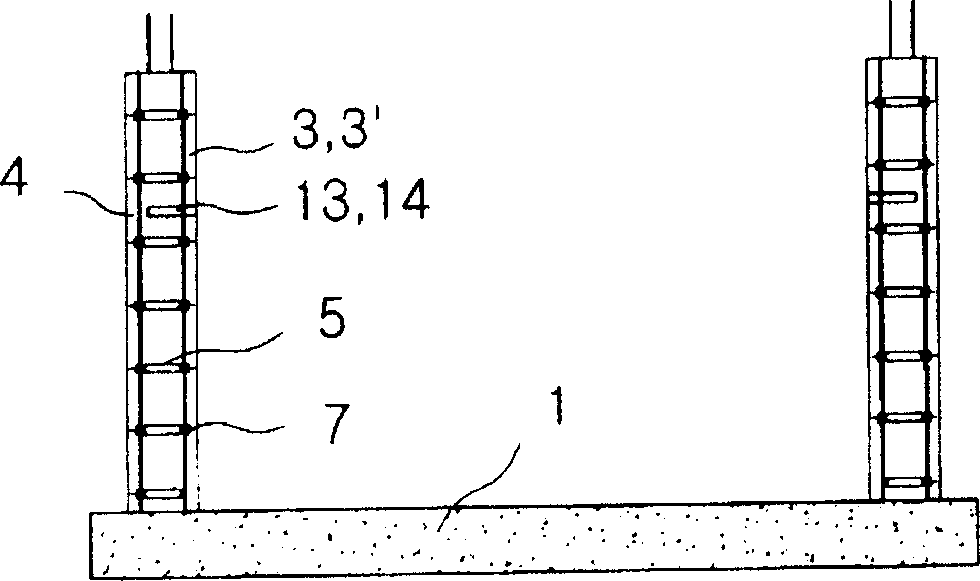

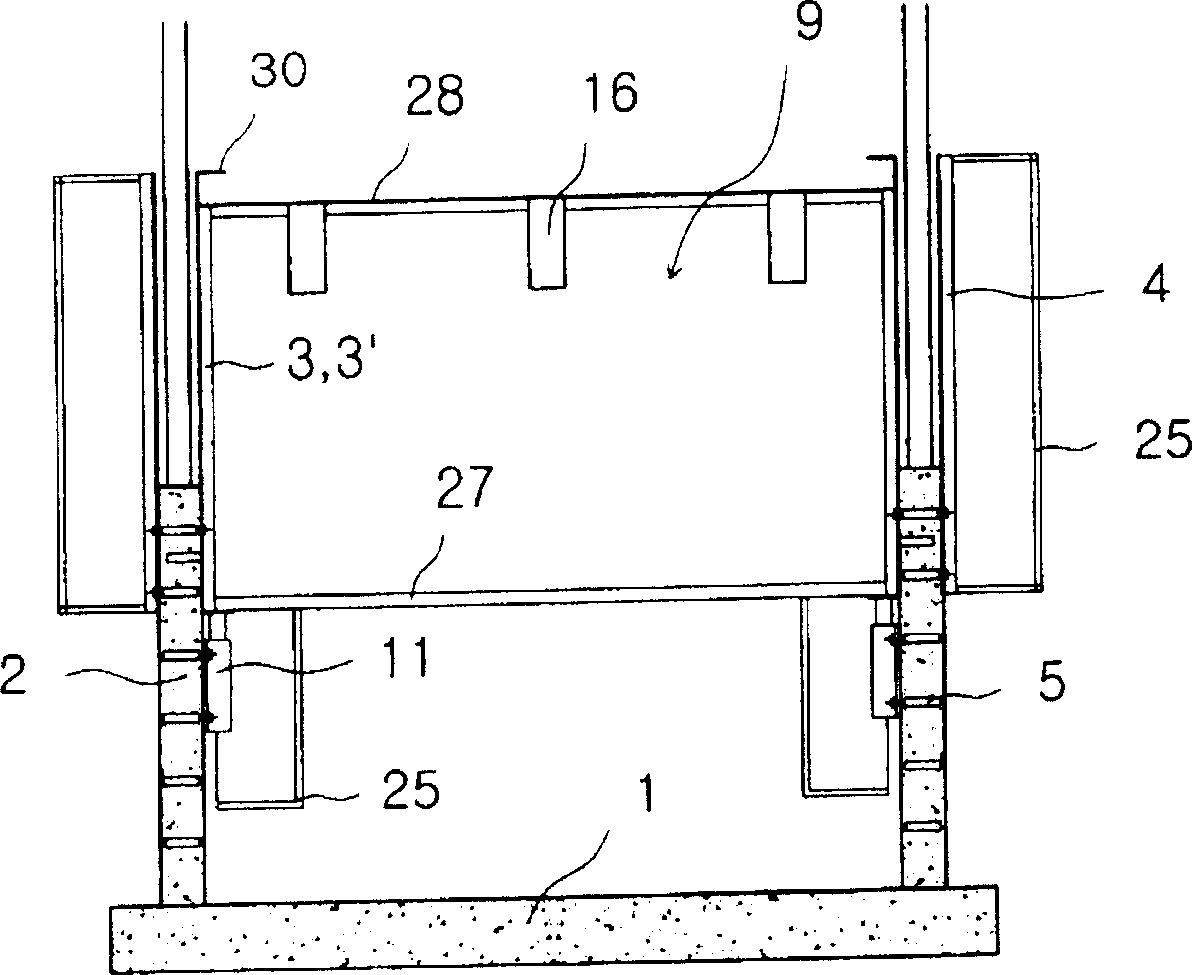

[0049] The first process step, as in figure 1 As shown in , the vertical steel bar 17 and the horizontal steel bar 18 net forming the skeleton of the wall body 2 are arranged on the foundation 1; at the position of the first floor slab 12, the outer wall steel bar is connected to the elastic sleeve rod 13 ' or the inner wall steel bar is connected to the elastic sleeve Rod 14 is fixed on vertical steel bar 17 and horizontal steel bar 18; On foundation 1 bottom surface, install the position of interior wall formwork 3,3 ' and exterior wall formwork 4, mark with ink. One end of the outer wall reinforcement connecting the elastic sleeve rod 13 has a hole, and a thread is formed in the hole, and it is fixed on the steel bar bent into a "" shape; Threads are formed in the holes. The second process step, as in figure 2 and Figure 7As shown in , use a crane to lift the inner wall formwork 3, 3' and the outer wall formwork 4, and fix the bottom, put the rubber ring 6 on the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com