Starch mold-based jelly drop casting device

A soft candy and starch technology, applied in confectionary, confectionery industry, food science, etc., can solve the problem of inability to effectively control product pouring back absorption, inability to achieve optimal product pouring, and pouring quality not reaching the expected effect, etc. problem, achieve the effect of shortening product replacement time, facilitating replacement, and eliminating tails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

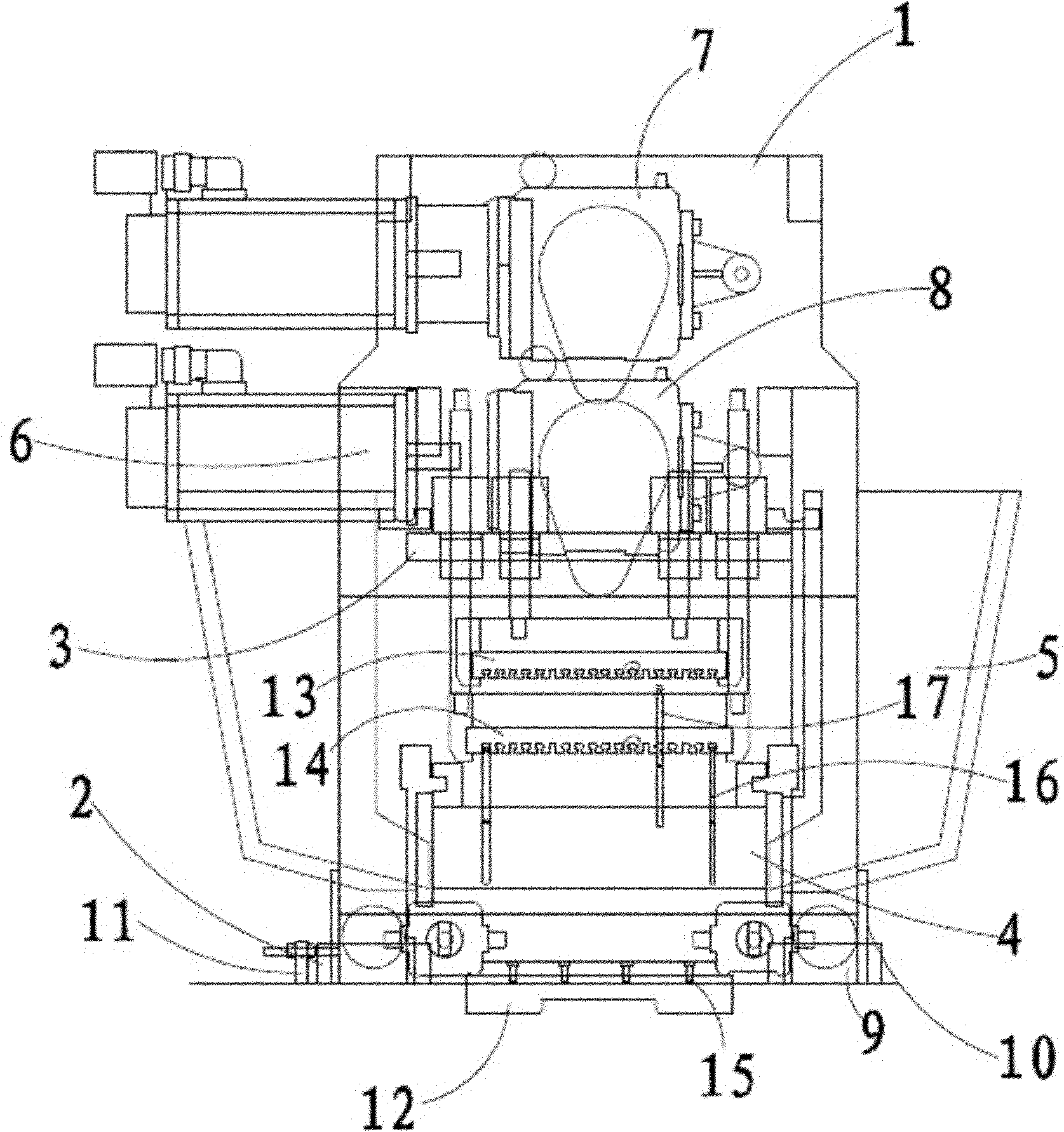

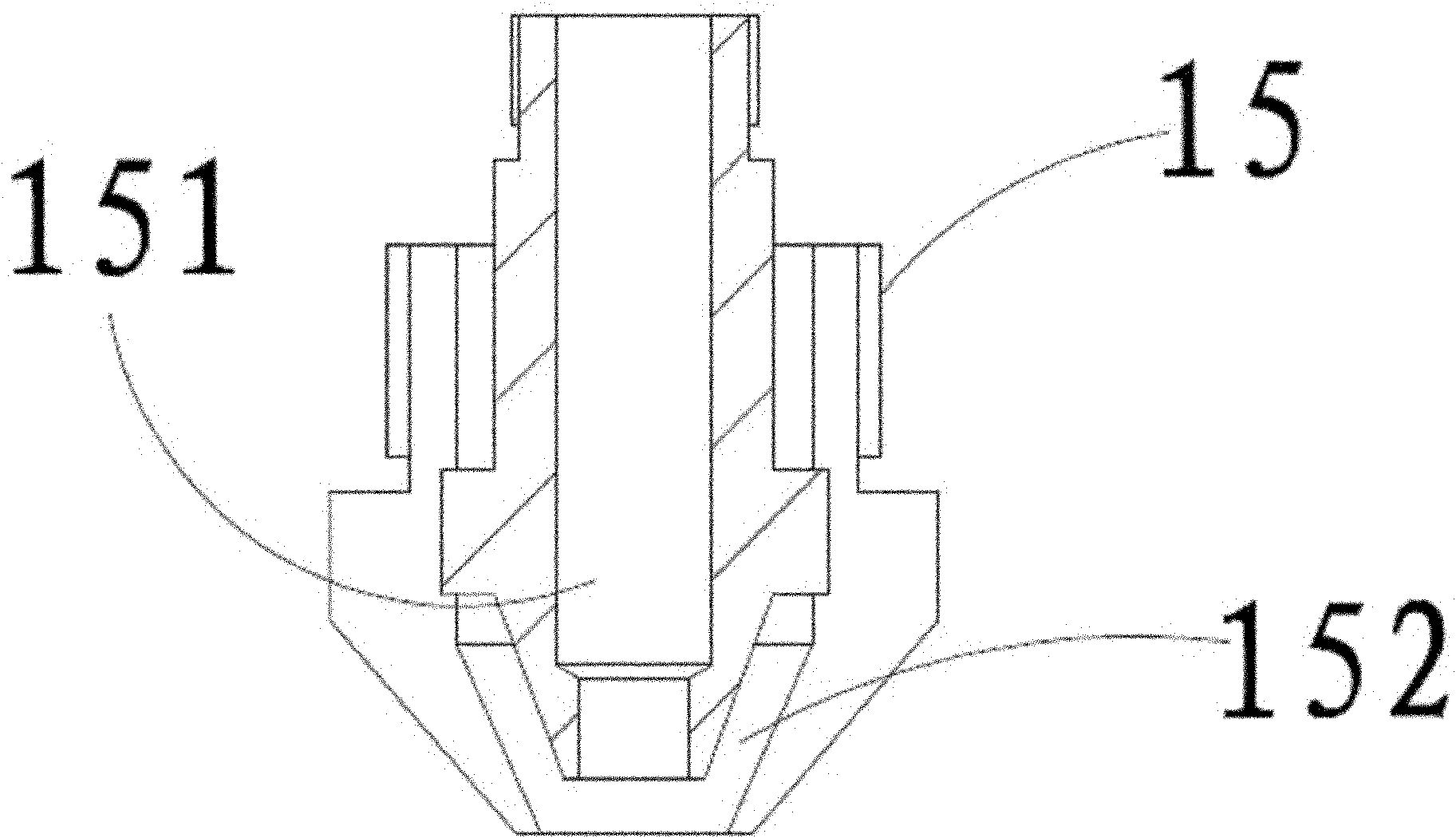

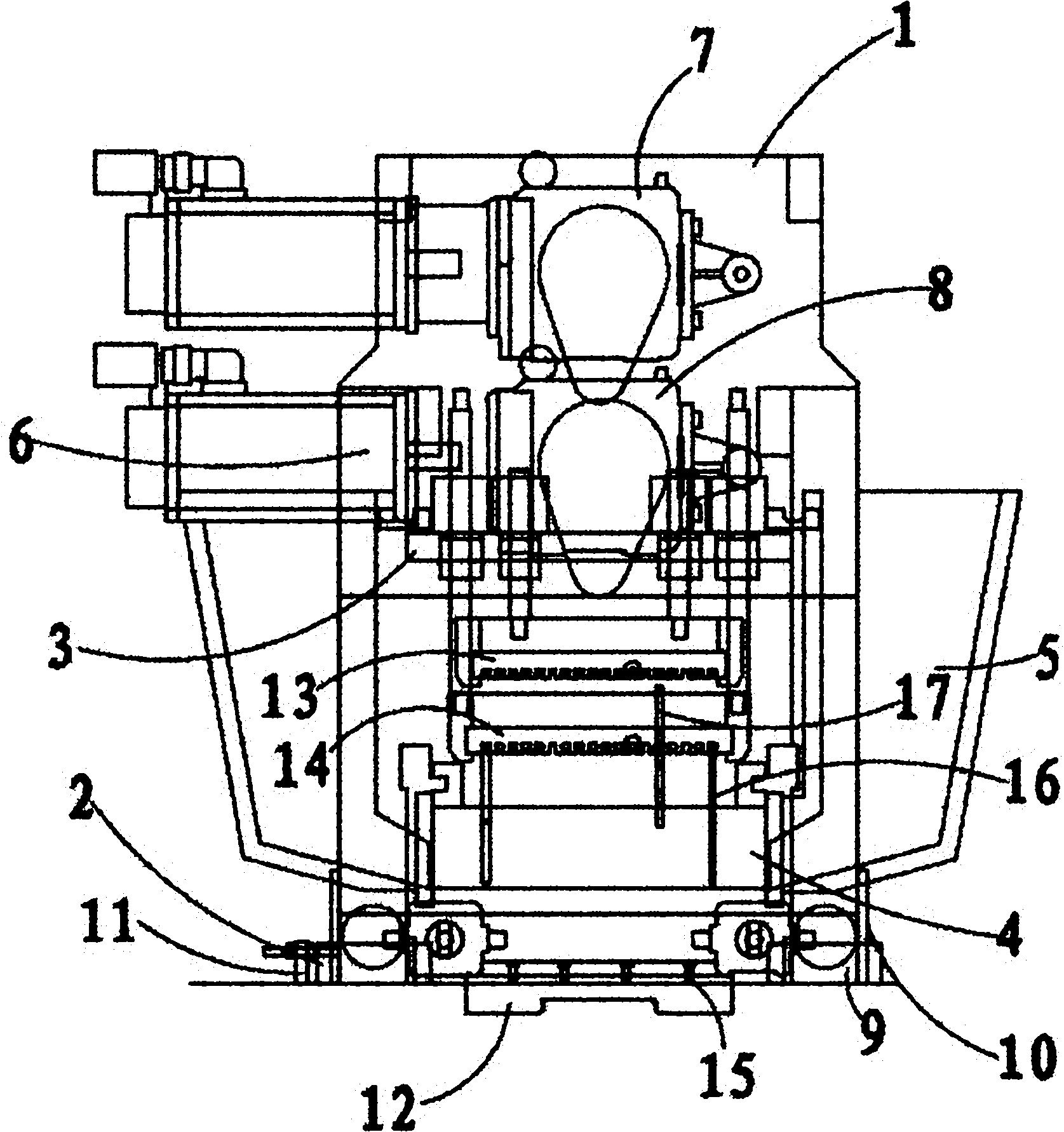

[0015] Such as figure 1 As shown, the starch mold soft candy depositing equipment described in this embodiment includes a housing 1, which is characterized in that the upper pouring drive system assembly 7 and the lower pouring drive system assembly 8 are installed inside the housing 1, and the upper pouring drive system assembly 7 The pump rod is connected with the syrup suction and release assembly 13, and the down pouring drive system assembly 8 is connected with the sandwich suction and release assembly 14 through the pump rod. The sandwich pouring frame 6 is installed on the down pour drive system assembly 8; A feed funnel 5 is installed on the side, and the feed funnel 5 communicates with the sandwich pouring assembly 4 inside the shell 1, and the sandwich pouring assembly 4 is arranged below the sandwich suction and release assembly 14; at the bottom of the shell 1, the rotary valve drives the system assembly 9. The track plate 2 and the adjustment seat 11 form a discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com