Metalaxyl-M and azoxystrobin sustained-release agent and preparation method and application thereof

A technology for metalaxyl and azoxystrobin, applied in the field of pesticides, can solve the problems of poor efficacy, difficult control, and short duration of effect, and achieve the effects of reducing production costs, excellent control effects, and delaying drug resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

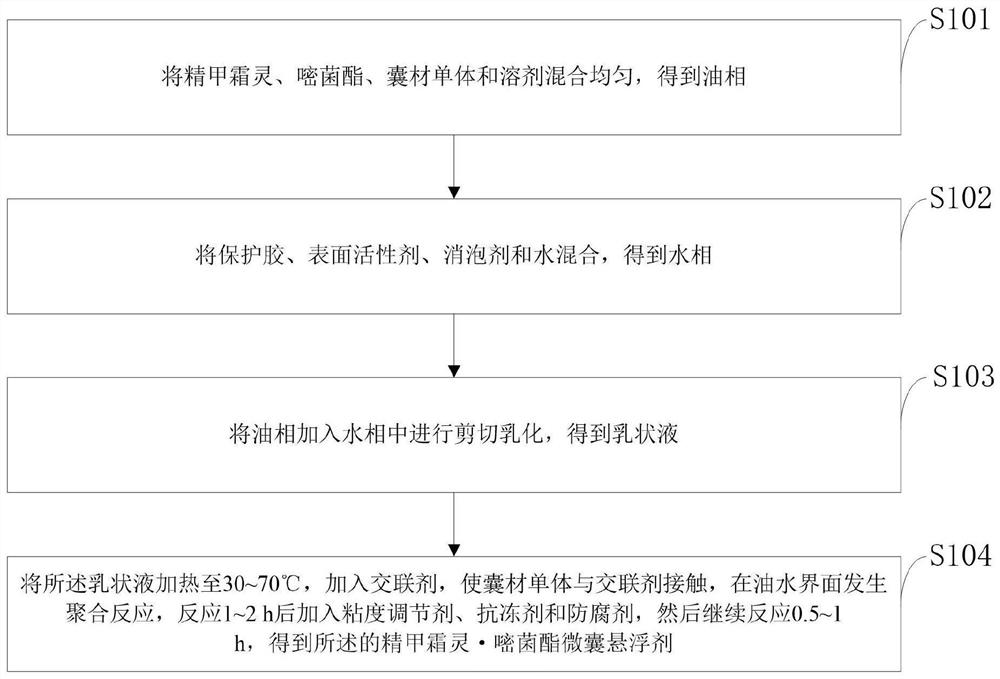

[0044] Such as figure 1 As shown, a kind of preparation method of metalaxyl-ethyl and azoxystrobin microcapsule suspension provided by the embodiment of the present invention comprises the following steps:

[0045] S101: uniformly mixing metalaxyl-ethyl, azoxystrobin, capsule material monomer and solvent to obtain an oil phase.

[0046] S102: uniformly mixing the protective glue, surfactant, defoamer and water to obtain a water phase.

[0047] S103: adding the oil phase into the water phase for shear emulsification to obtain an emulsion.

[0048] S104: Heat the emulsion to 30-70°C, add a cross-linking agent, make the monomer of the capsule material contact with the cross-linking agent, and polymerize at the oil-water interface, react for 1-2 hours, then add a viscosity modifier and an antifreeze agent and preservatives, and then continue to react for 0.5 to 1 hour to obtain the metalaxyl-azoxystrobin microcapsule suspension.

[0049] In S101 provided in the embodiment of th...

Embodiment 1

[0066] Preparation of 60% metalaxyl-azoxystrobin microcapsule suspension, metalaxyl (active ingredient, calculated by 100%) 58.5%, azoxystrobin (active ingredient, calculated by 100%) 1.5%, 200# Solvent oil (oil phase solvent) 5%, isophorone diisocyanate (capsule material monomer) 3%, ethylenediamine (crosslinking agent) 0.5%, gum arabic powder (protective glue) 5%, lignin sulfonate Sodium acid (surfactant) 1%, silicone defoamer (defoamer) 0.1%, xanthan gum (viscosity modifier) 0.5%, glycerol (antifreeze) 1%, Kathon (preservative) 0.1%, deionized water (water phase solvent) make up 100%.

[0067] Step 1: Weigh metalaxyl-fine and azoxystrobin respectively, add 200# solvent oil and isophorone diisocyanate, and stir evenly as the oil phase;

[0068] Step 2: Weighing gum arabic powder and dissolving it in deionized water, adding sodium lignosulfonate and organic silicon defoamer, stirring evenly as the water phase;

[0069] Step 3: Slowly add the oil phase prepared in step 1 t...

Embodiment 2

[0072]Preparation of 42% metalaxyl-azoxystrobin microcapsule suspension, metalaxyl (active ingredient, in 100%) 40%, azoxystrobin (active ingredient, in 100%) 2%, 200# Solvent oil (oil phase solvent) 25%, isophorone diisocyanate (capsule material monomer) 0.3%, ethylenediamine (crosslinking agent) 0.1%, gum arabic powder (protective glue) 1%, lignin sulfonate Sodium acid (surfactant) 0.2%, silicone defoamer (defoamer) 0.1%, xanthan gum (viscosity modifier) 0.1%, glycerol (antifreeze) 4%, Kathon (preservative) 0.1%, deionized water (water phase solvent) make up 100%.

[0073] According to the formula in Example 2, weigh metalaxyl-ethyl, azoxystrobin and other materials, and operate with reference to the preparation method in Example 1 to obtain 42% metalaxyl-azoxystrobin microcapsule suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com