Method for preparing low-cost centimeter-sized zirconium-base amorphous alloy by adopting industrial sponge zirconium

A zirconium-based amorphous alloy and zirconium sponge technology, which is applied in the field of preparation of zirconium-based amorphous alloys, can solve the problems of high production costs, achieve the effects of reducing production costs, excellent mechanical properties, and eliminating nucleation particles of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

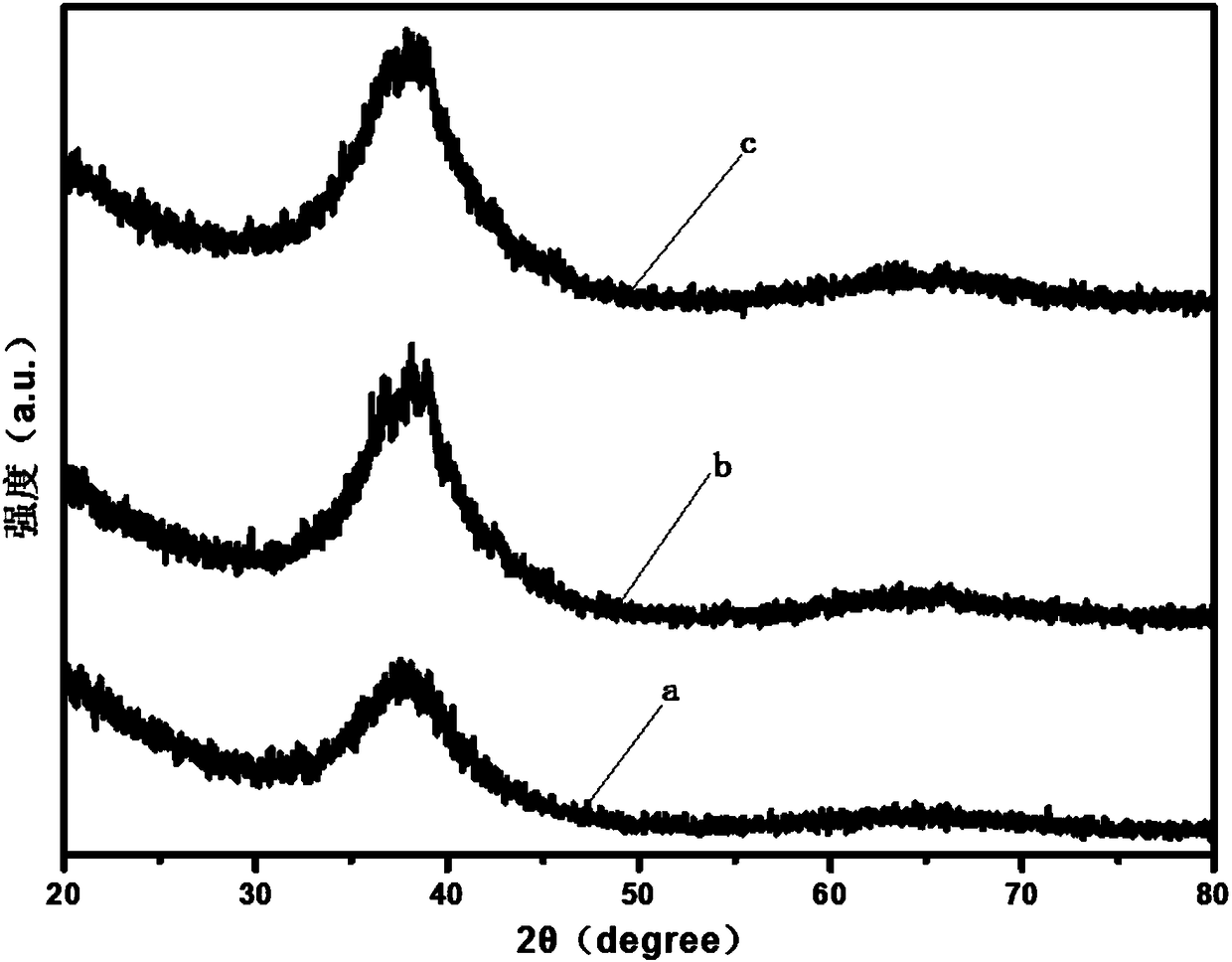

[0026] Specific implementation mode 1: In this implementation mode, the method for preparing a low-cost centimeter-level zirconium-based amorphous alloy using industrial-grade zirconium sponge is carried out according to the following steps;

[0027] 1. According to the atomic percentage, Zr: 50-51%, Cu: 27-29%, Ni: 8.5-9.5% and the rest of Al weigh industrial-grade sponge zirconium, metal copper, metal nickel and metal aluminum as raw materials;

[0028] 2. Vacuum the electric arc furnace to a vacuum degree of 6.6×10 -3 Below Pa, fill with protective gas;

[0029] 3. Carry out titanium smelting in the electric arc furnace after vacuuming for 2 to 3 minutes;

[0030] 4. Place the raw materials weighed in step 1 in the crucible in the electric arc furnace, set the melting current of the electric arc furnace to 300-350A, and melt the raw materials in the crucible for 3-5 minutes to obtain an alloy melt. During the melting process, the crucible Electromagnetic stirring is perfo...

specific Embodiment approach 2

[0037] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, Zr: 50%, Cu: 27%, Ni: 8.5% and the remainder of Al weigh industrial grade zirconium sponge , metal copper, metal nickel and metal aluminum as raw materials. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0038] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: in step one, Zr: 50.7%, Cu: 28%, Ni: 9% and the balance of Al weigh industrial grade Zirconium sponge, metal copper, metal nickel and metal aluminum are used as raw materials. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com