A precipitation-strengthened high-entropy alloy without sigma phase precipitation tendency and its preparation method

A technology of precipitation strengthening and high-entropy alloy, applied in the field of high-entropy alloy preparation, can solve problems such as the decline of comprehensive mechanical properties, and achieve the effect of eliminating the tendency of precipitation and improving the application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The molecular formula of the high-entropy alloy prepared in this example is MnFeNiCu. Preferably, the purity of the constituent elements is above 99.9%, so as to reduce the introduction of impurities as much as possible.

[0031] The Fe, Ni, and Cu materials used are weighed with a precision balance, and the weighed raw materials are put into absolute ethanol for ultrasonic cleaning and fully dried to remove other impurities attached to the surface. Due to the easy oxidation of Mn element itself, before weighing the Mn raw material, wash it twice with 10vol.% nitric acid alcohol solution, then wash it once with absolute ethanol in an ultrasonic cleaner, dry it, and then weigh it with a precision balance. And put it into the smelting equipment for smelting as soon as possible.

[0032] Put the pretreated alloy raw materials into the magnesia crucible of the smelting furnace one by one, and put the Mn at the bottom of the crucible to minimize the evaporation. Preferably...

Embodiment 2

[0035] The molecular formula of the high-entropy alloy prepared in this example is MnFeNiCu. Preferably, the purity of the constituent elements is above 99.9%, so as to reduce the introduction of impurities as much as possible.

[0036] The Fe, Ni, and Cu materials used are weighed with a precision balance, and the weighed raw materials are put into absolute ethanol for ultrasonic cleaning and fully dried to remove other impurities attached to the surface. Due to the easy oxidation of Mn element itself, before weighing the Mn raw material, wash it twice with 10vol.% nitric acid alcohol solution, then wash it once with absolute ethanol in an ultrasonic cleaner, dry it, and then weigh it with a precision balance. And put it into the smelting equipment for smelting as soon as possible.

[0037] Put the pretreated alloy raw materials into the magnesia crucible of the smelting furnace one by one, and put the Mn at the bottom of the crucible to minimize the evaporation. Preferably...

PUM

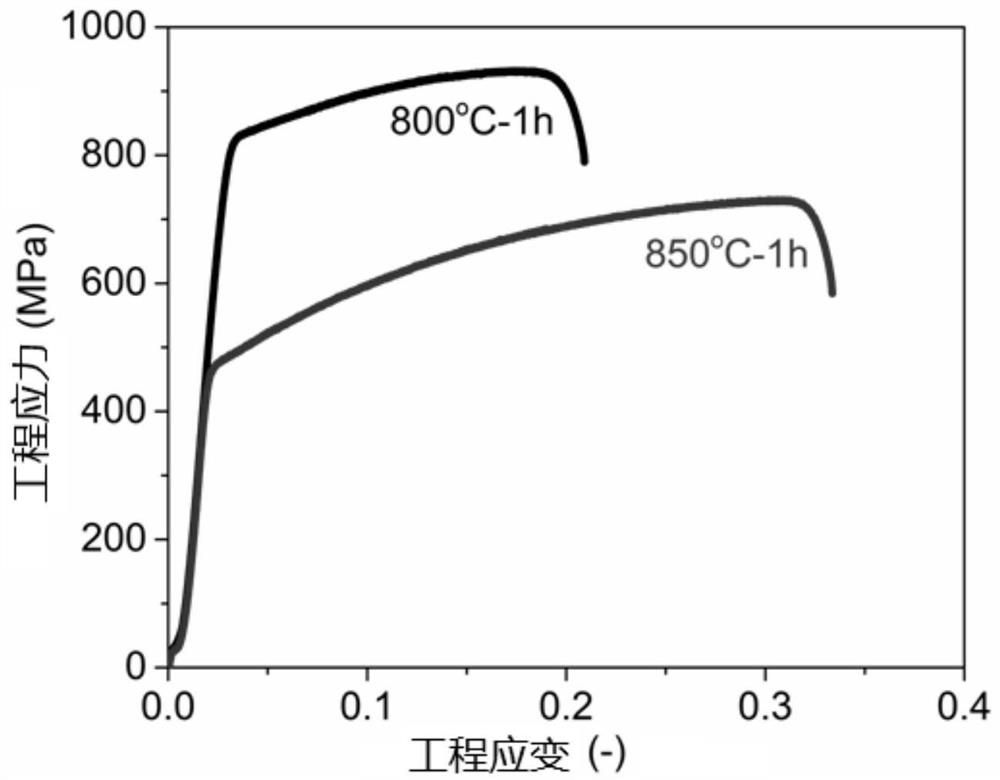

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com