Long linear super capacitor with high power and preparation method thereof

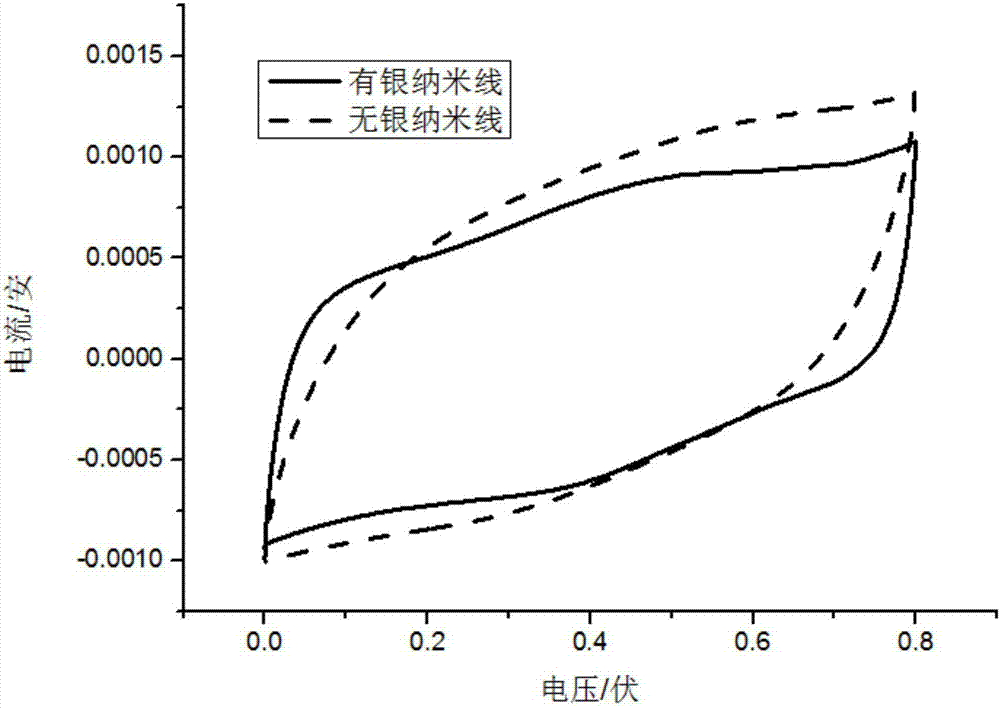

A supercapacitor, high-power technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of poor power characteristics of long-term supercapacitors, to improve power performance and specific capacity, The method is simple and the effect of accelerating the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

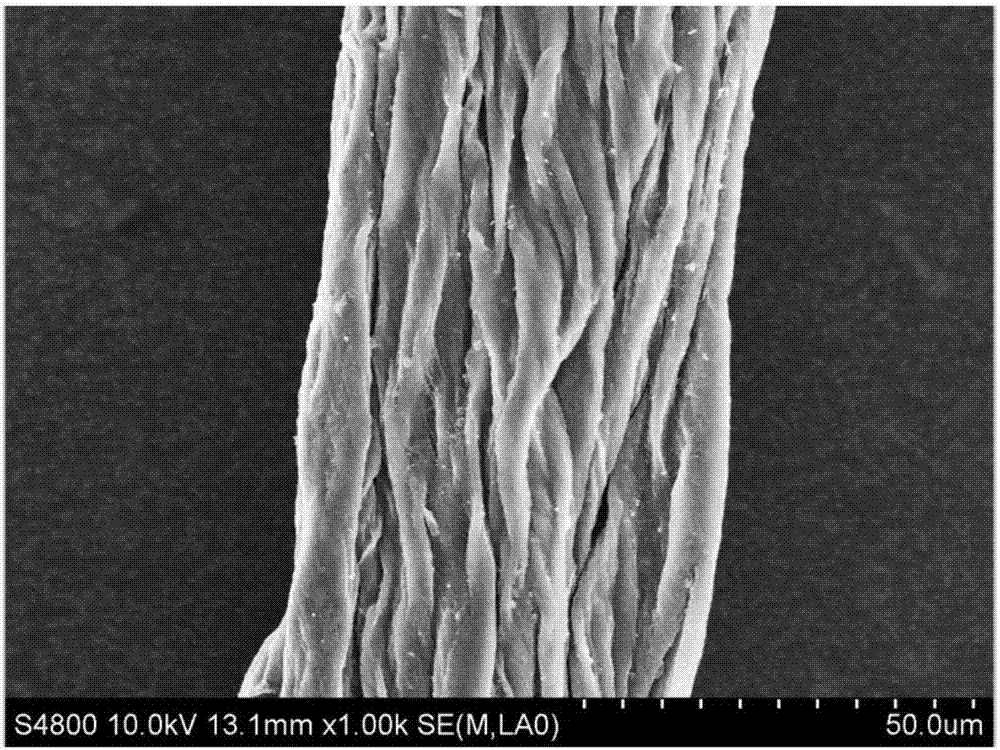

[0036] Step 1: Material preparation: put glass slices into deionized water and ethanol for ultrasonic cleaning for 20 minutes, and blow dry with nitrogen; carbon nanotube powder treatment: put 0.5g of carbon nanotube powder into concentrated nitric acid and water with a volume ratio of 1 : In 60ml acid solution of 2, stir and soak for more than 6 hours, then pour the turbid solution into a centrifuge tube and centrifuge until neutral, take it out and bake it in a vacuum oven at 80°C for 12 hours to remove some of the carbon nanotube powder Impurity ions.

[0037] Step 2: Configuration of the active substance dispersion: Add 0.08gGO and 0.08gMCNTs to 40mL DMF solution respectively, sonicate in an ice bath in a 600W ultrasonicator for 3 hours, and prepare 2mg / ml solutions respectively, and then measure 20mlGO solution Mix with 10ml MCNTs solution and sonicate for 1 hour.

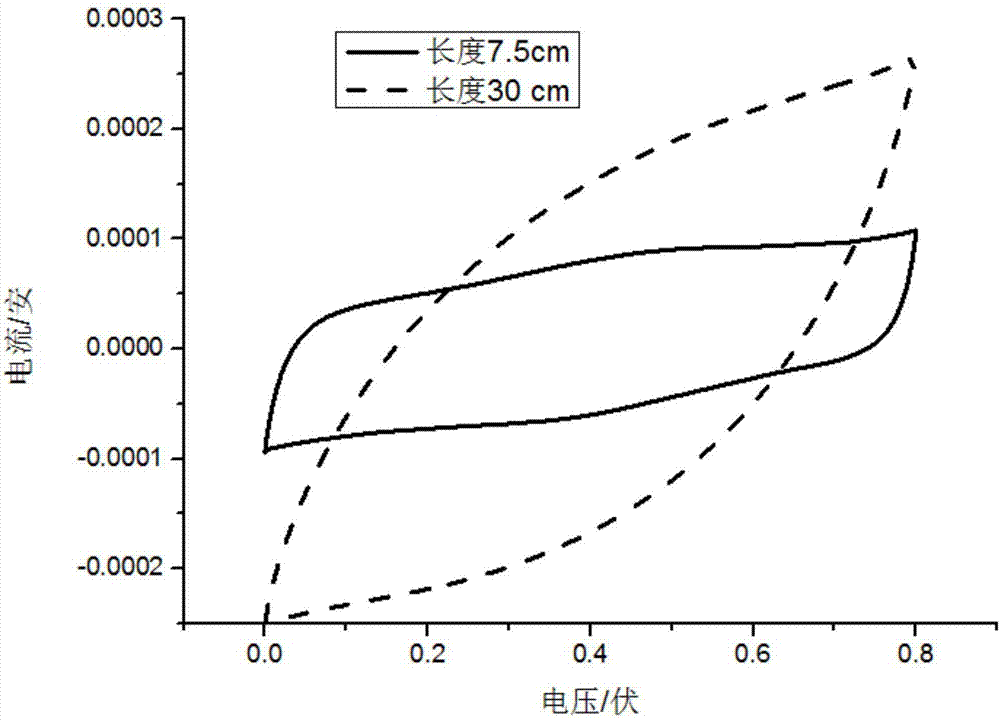

[0038] Step 3: Preparation of supercapacitor single electrode: use a blade to scrape out a film with a width...

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is: in step 3, the length of the glass sheet is changed to 30 cm, the amount of dispensing is changed to 480 μl, the number of twisting revolutions is changed to 2400, and the rest of the steps are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com