Self-supported titanium nitride/graphene combined electrode and preparation method thereof

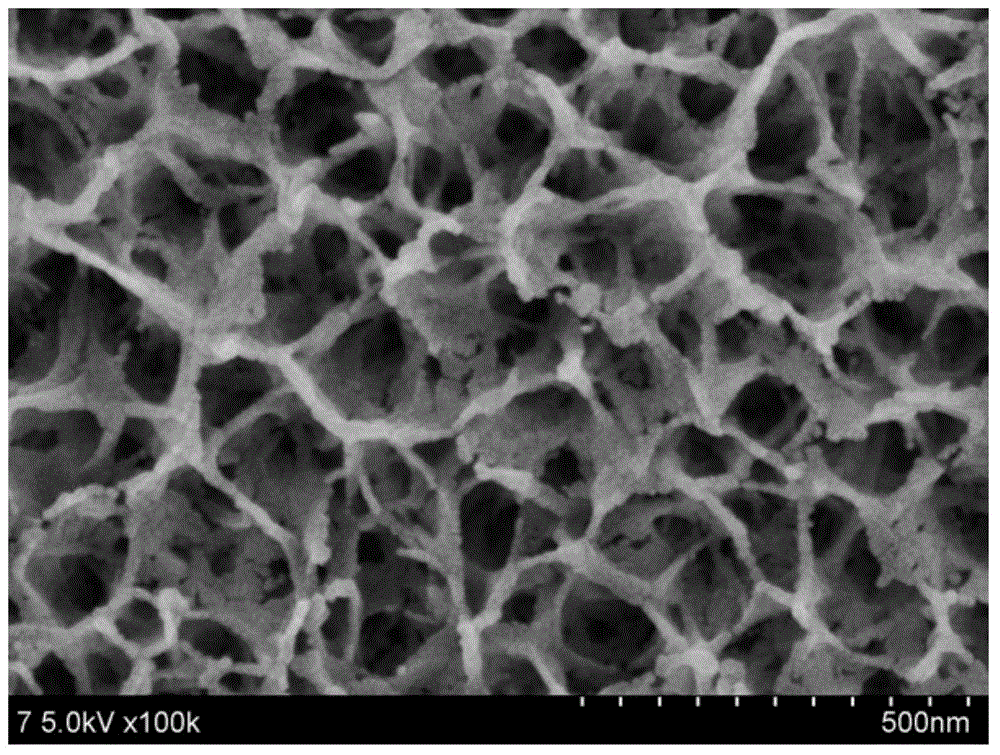

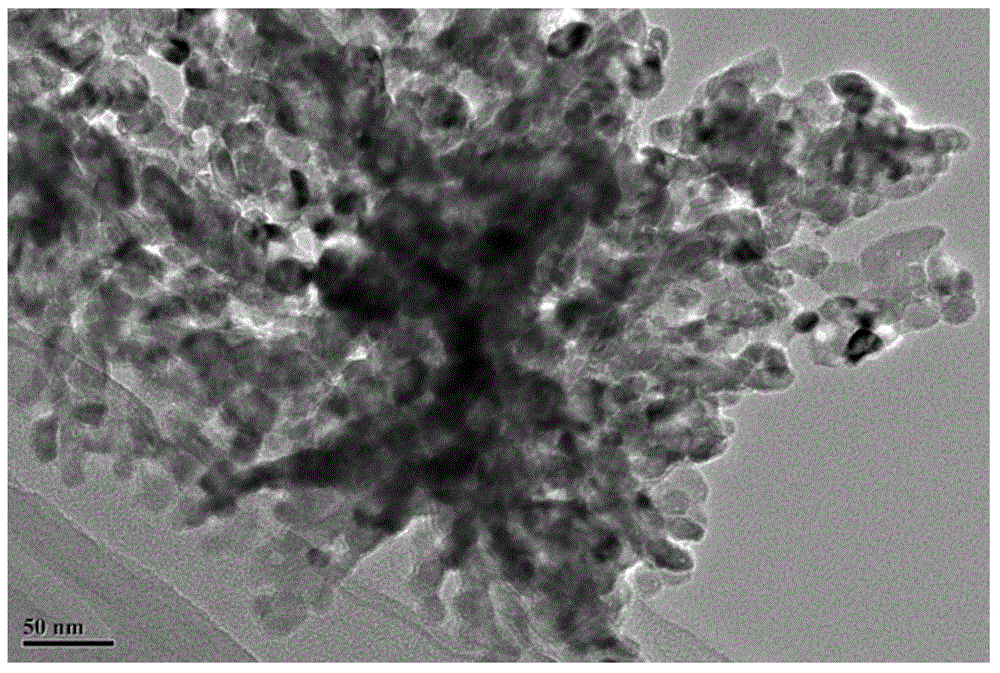

A graphene composite, titanium nitride technology, applied in circuits, capacitors, electrical components and other directions, can solve the problems of close-packed particles unfavorable for full contact between electrolyte and electrode materials, easy agglomeration of nitride particles, and poor electron transmission capacity. Achieve the effect of favorable electron transport, simple process route and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of self-supporting titanium nitride / graphene composite electrode comprises the following steps:

[0033] (1) Take a titanium foil with a thickness of 200 microns and a purity of 95%, and ultrasonically clean it with detergent, deionized water and ethanol for 15 minutes in turn, soak the cleaned titanium foil in acid solution for 3 minutes, and the acid solution The volume ratio of medium-concentrated hydrofluoric acid, concentrated nitric acid and water is 1:19:100; take out the titanium foil and rinse it with deionized water, and transfer the titanium foil to a beaker filled with a 30% hydrogen peroxide solution at normal pressure. Heat the solution from room temperature to 90°C by heating in a water bath, and keep it warm for 35 minutes. After the reaction, take out the titanium foil and dry it;

[0034] (2) Place the titanium foil obtained in step (1) in a tube-type atmosphere furnace, feed ammonia gas to nitride the titanium foil, the flow rat...

Embodiment 2

[0038] The preparation method of self-supporting titanium nitride / graphene composite electrode comprises the following steps:

[0039] (1) Take a titanium foil with a thickness of 100 microns and a purity of 99%, and ultrasonically clean it with detergent, deionized water and ethanol for 5 minutes in sequence, soak the cleaned titanium foil in acid solution for 2 minutes, and the acid solution The volume ratio of medium-concentrated hydrofluoric acid, concentrated nitric acid and water is 1:10:100; the titanium foil is taken out and rinsed with deionized water, and the titanium foil is transferred to a beaker filled with a 30% hydrogen peroxide solution at normal pressure. Next, heat the solution from room temperature to 90°C with an oil bath, and keep it warm for 50 minutes. After the reaction, take out the titanium foil and dry it;

[0040] (2) The titanium foil obtained in step (1) is placed in a tubular atmosphere furnace, and ammonia gas is fed into the titanium foil for ...

Embodiment 3

[0044] The preparation method of self-supporting titanium nitride / graphene composite electrode comprises the following steps:

[0045] (1) Take a titanium foil with a thickness of 10 microns and a purity of 99.9%, and ultrasonically clean it with detergent, deionized water and ethanol for 5 minutes in turn, soak the cleaned titanium foil in acid solution for 2 minutes, and the acid solution The volume ratio of medium-concentrated hydrofluoric acid, concentrated nitric acid and water is 1:10:100; the titanium foil is taken out and rinsed with deionized water, and the titanium foil is transferred to a beaker filled with a 35% hydrogen peroxide solution at normal pressure. Heat the solution from room temperature to 95°C by microwave, and keep it warm for 10 minutes. After the reaction, take out the titanium foil and dry it;

[0046] (2) The titanium foil obtained in step (1) is placed in a tubular atmosphere furnace, and ammonia gas is fed into the titanium foil for nitriding tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

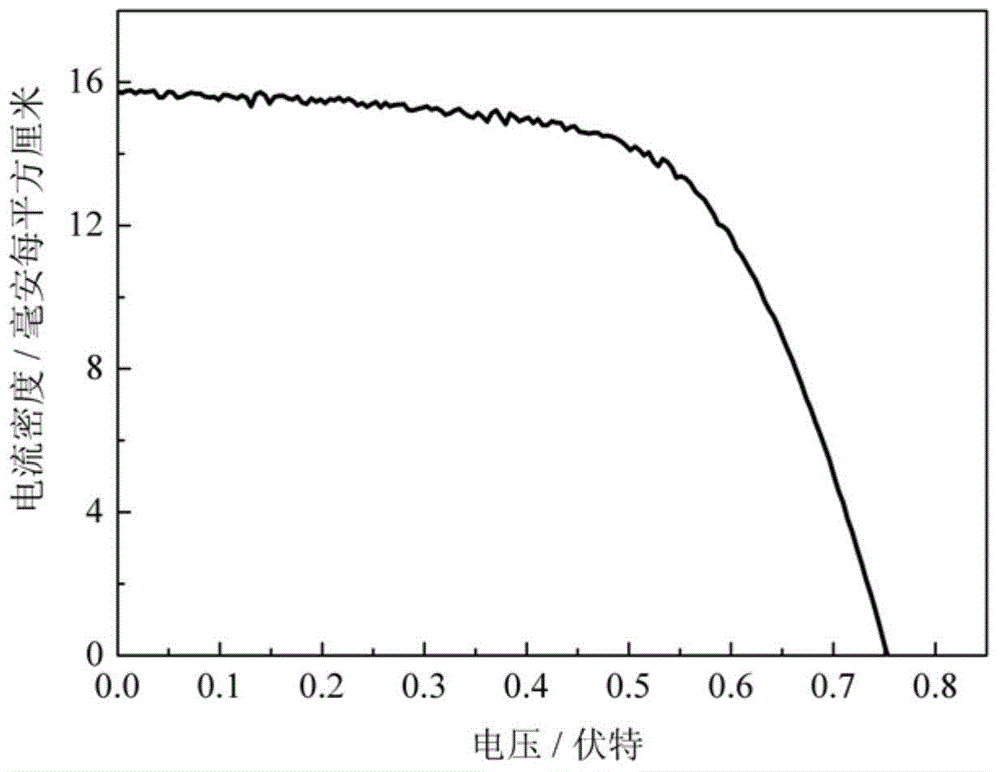

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com