Preparation method and application of HHK-CC@-MXenes composite flexible electrode material

A HHK-CC, flexible electrode technology, applied in the field of preparation of HHK-CC@MXenes composite flexible electrode materials, can solve the problems of mechanical strength, cost synthesis process limitations, large-scale production obstacles, etc., to achieve low cost, structure Stable and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 3g MAX precursor to 20ml 6mol L -1 Solution of HCl and 2.0g LiF, etch at 30°C for 60h, remove phase A to obtain multilayer Ti 3 C 2 T X . Take 1g multilayer Ti 3 C 2 T X Firstly, the intercalation was carried out in 8ml DMSO solution for 10min, then the excess DMSO was washed away with deionized water, and the obtained material was ultrasonically exfoliated for 4h. The resulting suspension was then centrifuged at 8000 rpm to remove unstripped Ti 3 C 2 T X , centrifuged to obtain the supernatant, that is, to obtain a single layer or few layers of Ti with a solid content of 12mg / ml 3 C 2 T X nanosheet solution, the Ti3 C 2 T X The nanosheet solution was diluted to a solid content of 2 mg / ml for use.

[0033] Immerse 0.5g CC in a solution containing 2g potassium permanganate, 15ml concentrated sulfuric acid and 15ml concentrated nitric acid and activate at 30°C for 8h to obtain HHK-CC; 3 C 2 T X The nanosheets are uniformly drop-coated on the oxidized ...

Embodiment 2

[0036] Add 3g MAX precursor to 30ml 6mol L -1 A solution of HCl and 2.0g LiF was etched at 40°C for 50h to remove phase A to obtain multilayer Ti 3 C 2 T X . Take 1g multilayer Ti 3 C 2 T X Firstly, the intercalation was carried out in 10ml DMSO solution for 20min, then the excess DMSO was washed away with deionized water and the obtained material was ultrasonically exfoliated for 5h. The resulting suspension was centrifuged at 10,000 rpm to remove unstripped Ti 3 C 2 T X , centrifuged to obtain the supernatant, that is, to obtain a single layer or few layers of Ti with a solid content of 12mg / ml 3 C 2 T X nanosheet solution, the Ti 3 C 2 T X The nanosheet solution was diluted to a solid content of 2 mg / ml for use.

[0037] Immerse 0.5g CC in a solution containing 2g potassium permanganate, 20ml concentrated sulfuric acid and 10ml concentrated nitric acid and activate at 40°C for 7h to obtain HHK-CC; 3 C 2 T X The nanosheets are uniformly drop-coated on the o...

Embodiment 3

[0040] Add 3g MAX precursor to 30ml 6mol L -1 Solution of HCl and 3.0g LiF, etch at 50°C for 40h, remove phase A to obtain multilayer Ti 3 C 2 T X . Take 1g multilayer Ti 3 C 2 T X Firstly, the intercalation was carried out in 12ml DMSO solution for 20min, then the excess DMSO was washed away with deionized water and the obtained material was ultrasonically exfoliated for 5h. The resulting suspension was centrifuged at 10,000 rpm to remove unstripped Ti 3 C 2 T X , centrifuged to obtain the supernatant, that is, to obtain a single layer or few layers of Ti with a solid content of 12mg / ml 3 C 2 T X nanosheet solution, the Ti 3 C 2 T X The nanosheet solution was diluted to a solid content of 2 mg / ml for use.

[0041] Immerse 0.5g CC in a solution containing 3g potassium permanganate, 10ml concentrated sulfuric acid and 20ml concentrated nitric acid and activate at 50°C for 6h to obtain HHK-CC; 3 C 2 T X The nanosheets are uniformly drop-coated on the oxidized c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

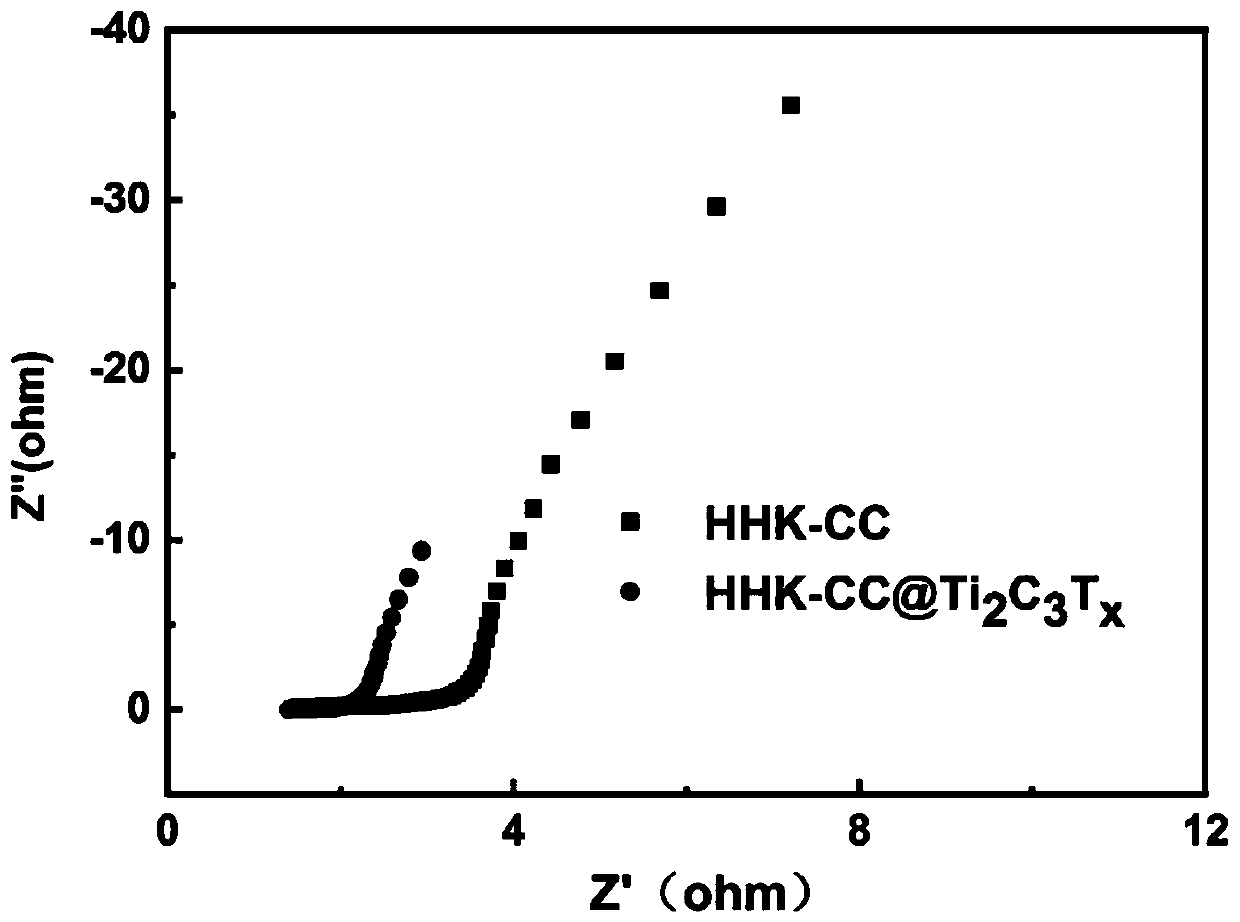

| Charge transfer resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com