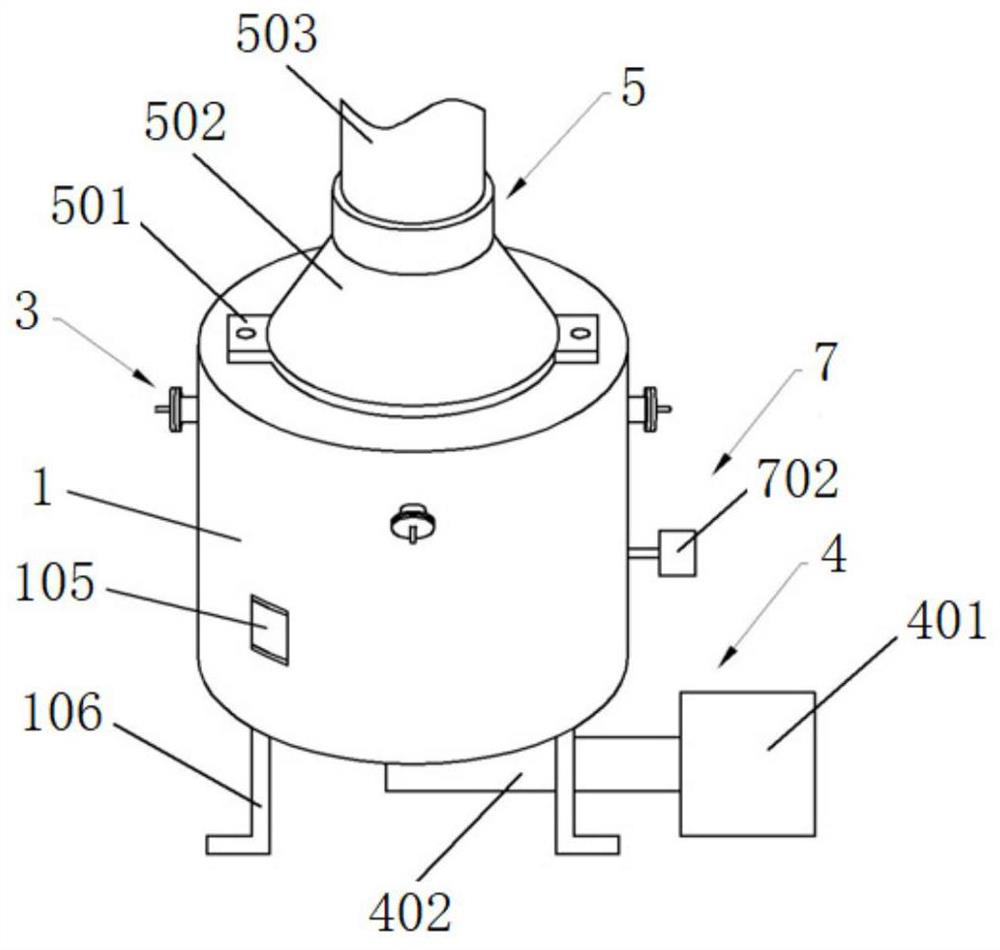

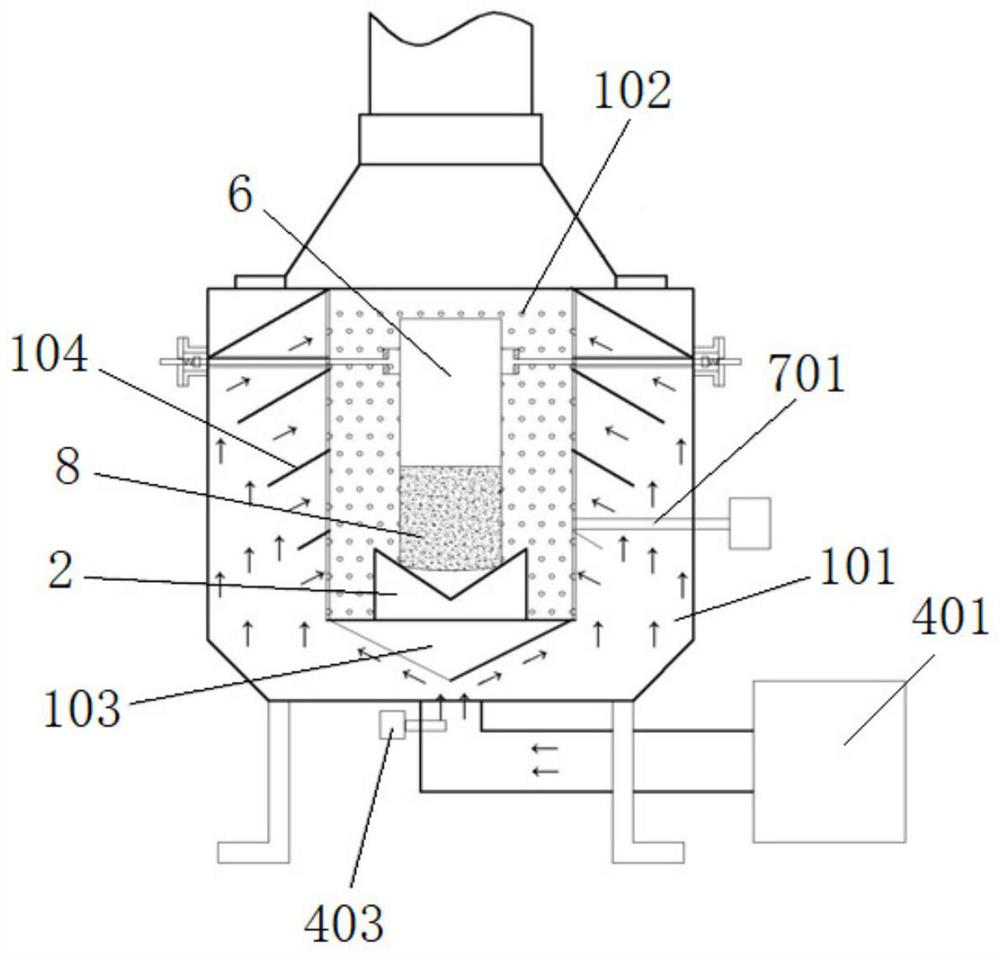

Chalcogenide glass air cooling device and air cooling control method of chalcogenide glass

An air-cooling device and chalcogenide glass technology, applied in household refrigeration devices, cooling fluid circulation devices, lighting and heating equipment, etc., can solve the problems of uncontrollable melt cooling speed and uniform air cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] 1. Setting parameters

[0079] Set the target temperature T and target time t for each step of the program in the plc control panel, as follows:

[0080] initial Step1 Step2 Step3 Step4 Step5 Target temperature T T 0

T 1

T 2

T 3

T 4

T 5

target time t t 1

t 2

t 3

t 4

t 5

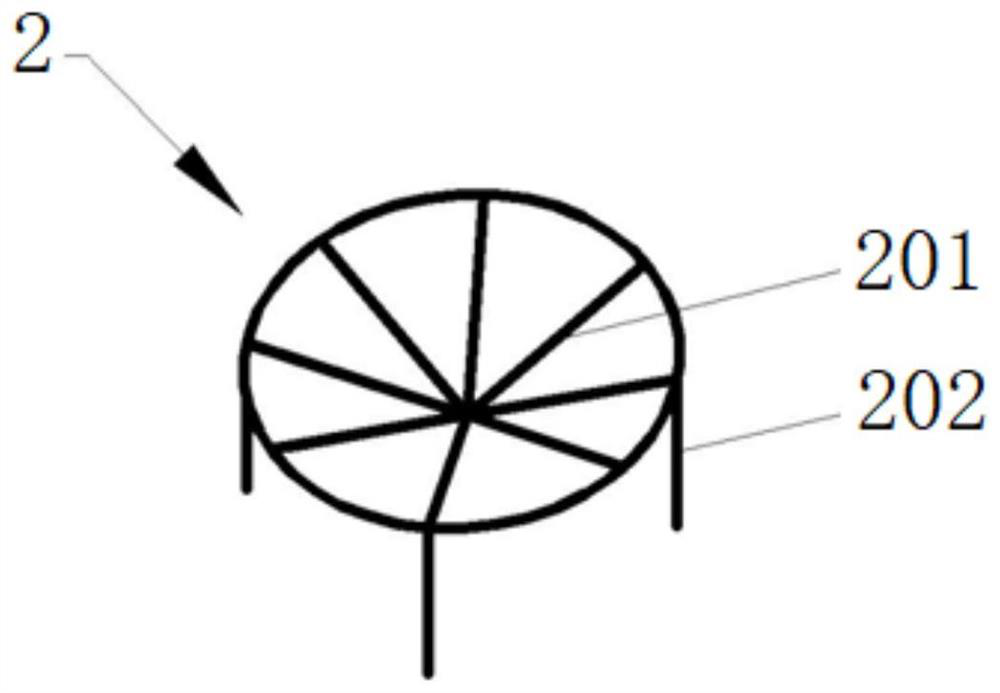

[0081] 2. Placement of synthetic container

[0082] Place the synthesis vessel containing the chalcogenide glass melt on the centering device.

[0083] 3. Turn on the air cooling program, as follows:

[0084] Generally, the actual temperature of the synthesis vessel is slightly higher than the initial value T 0 , first turn on the air-cooling program switch, and use the infrared sensor to measure the temperature of the surface of the synthesis container in real time;

[0085]When the surface temperature of the synthesis vessel reaches T 0 , the air cooling starts automatically, and the target temperature T1 and targe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com