Thermal simulation furnace with heating/cooling controllable structure and capable of sampling halfway

A thermal simulation, cooling channel technology, applied in lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of large sample size, large cooling speed adjustment range, simulation data can not meet the requirements of process test, etc. Accurate and controllable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

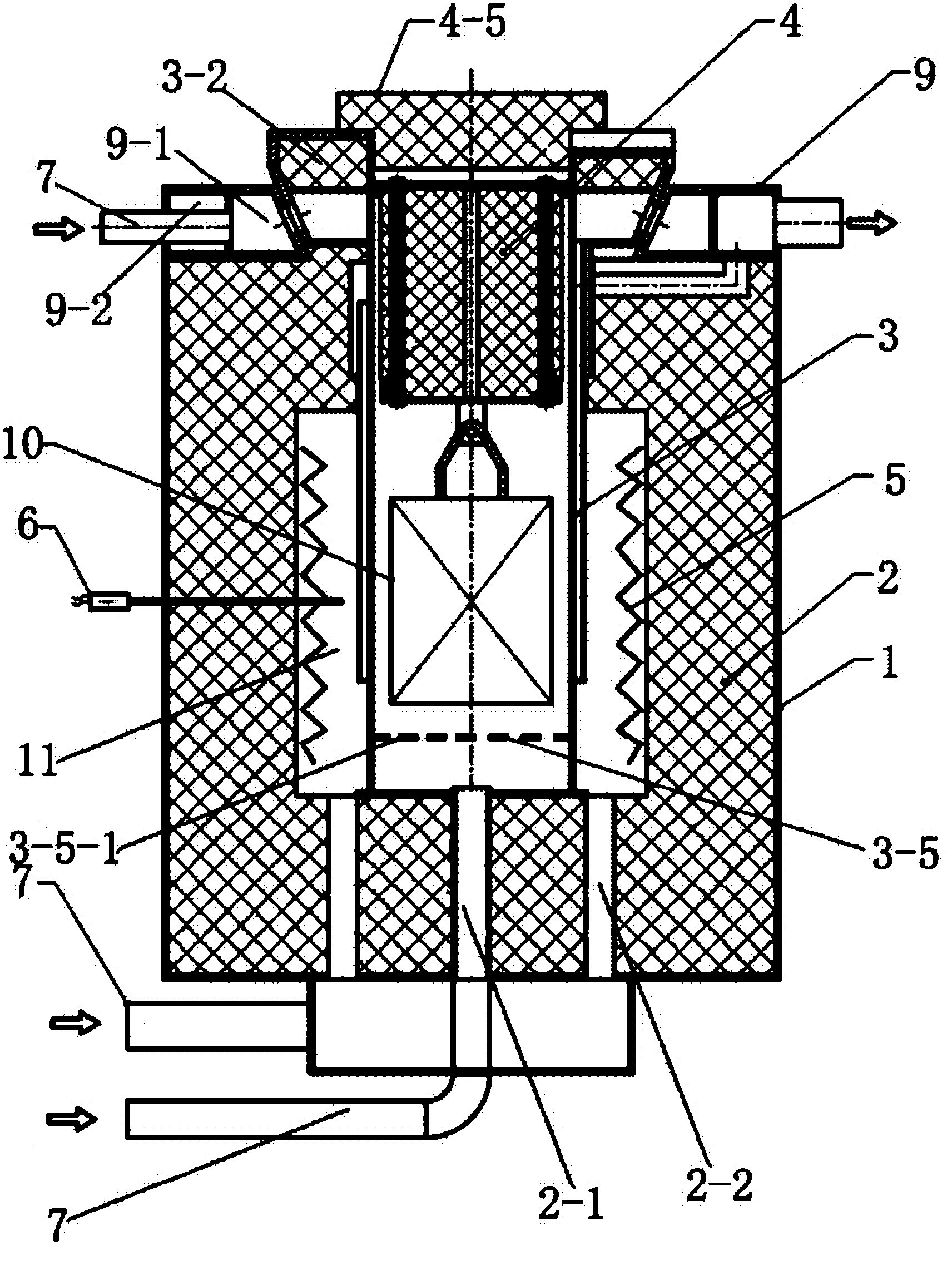

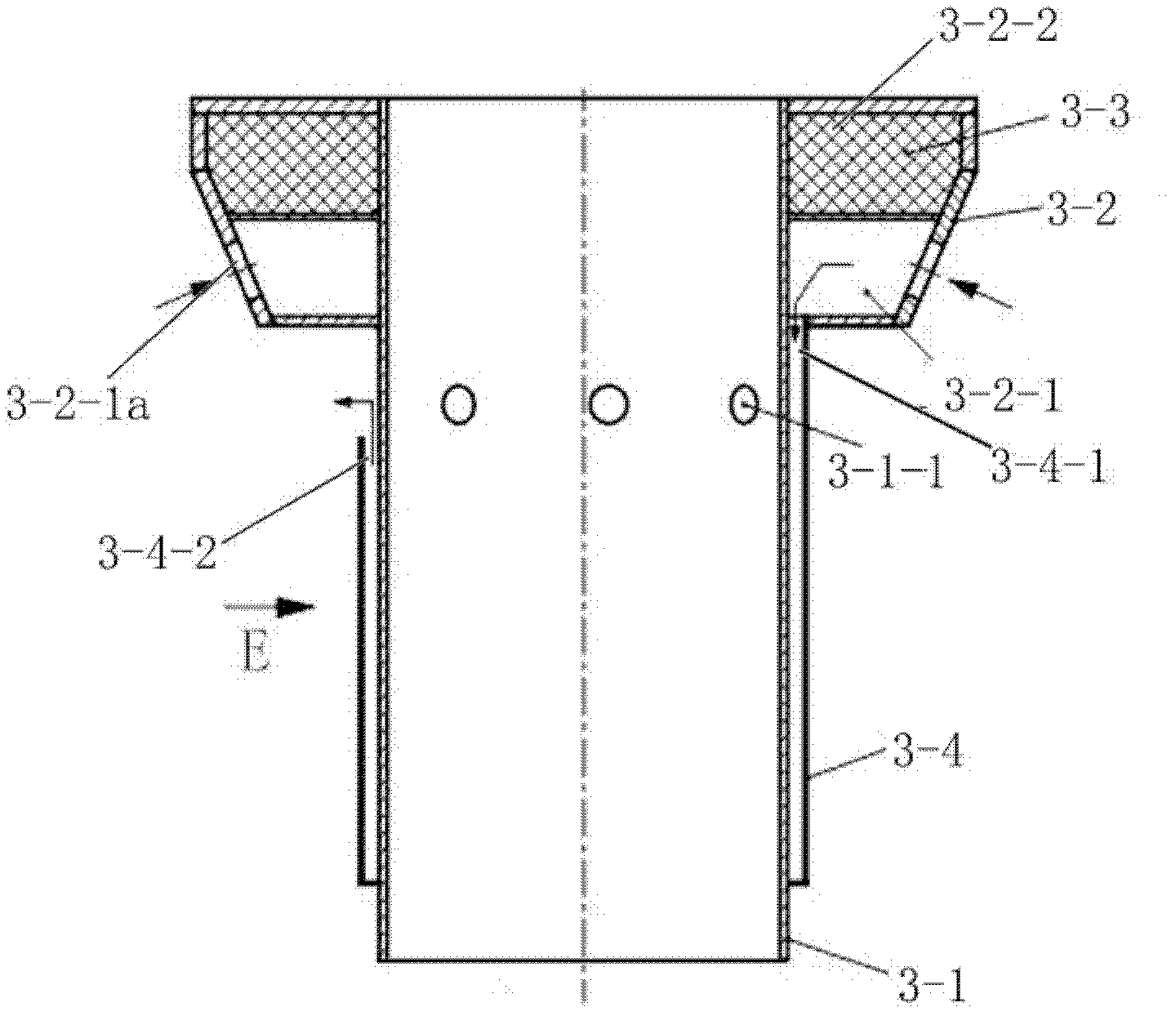

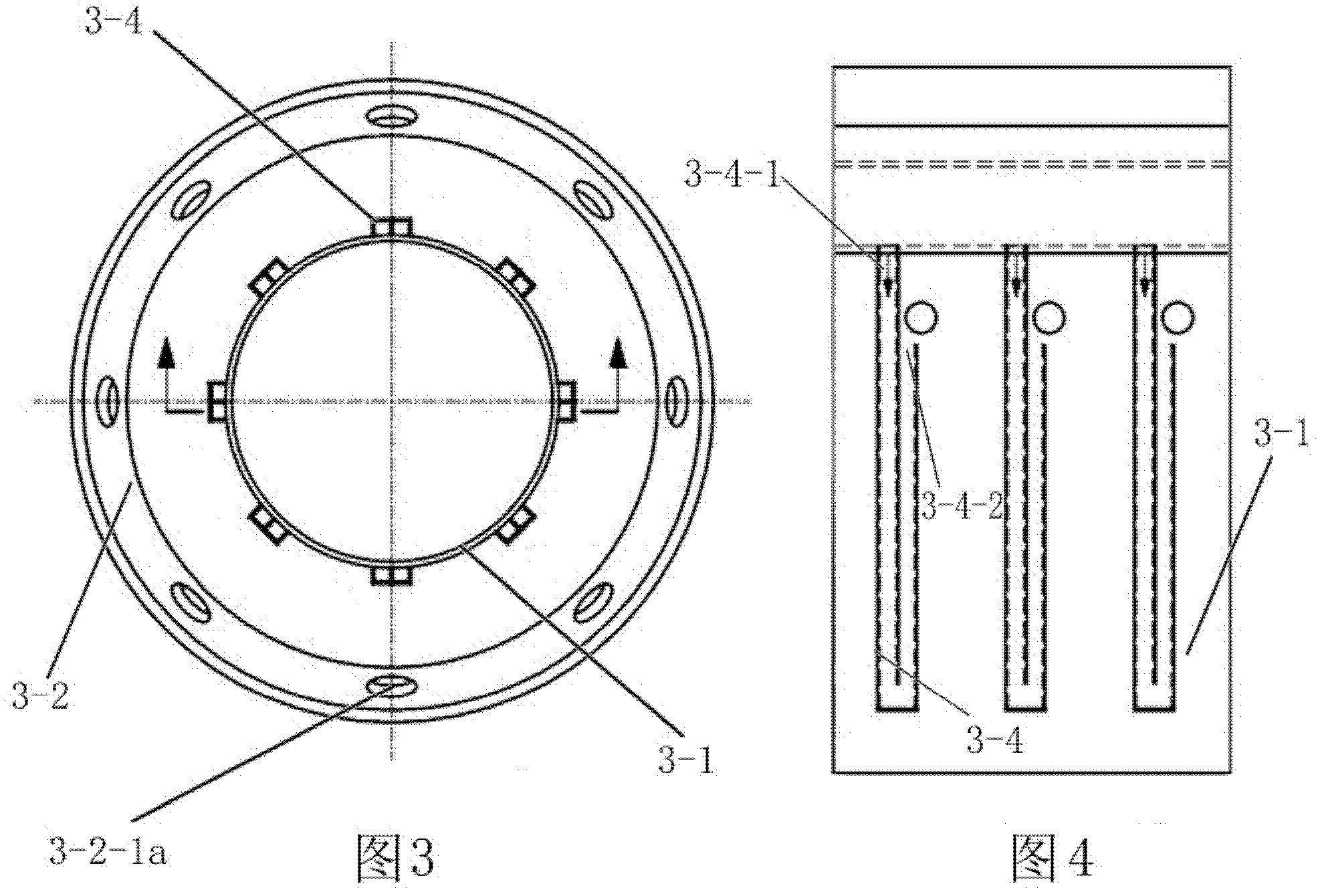

[0041] refer to Figure 1 to Figure 7 , the present embodiment includes a furnace shell 1, a furnace lining 2 arranged in the furnace shell 1, a soaker 3 arranged in the inner cavity of the furnace village 2, a radiation type sampling device 4 arranged at the top opening of the soaker 3, and a heating Component 5, thermoelectric cell 6, cooling pipeline 7 and control device; the outer wall of the vapor chamber 3 is provided with a number of uniformly distributed vapor chamber cooling air ducts 3-4 to form a vapor chamber with a cooling structure; between the furnace lining 2 and A heating chamber 11 is formed between the vapor chambers 3; on the bottom wall of the furnace lining 2, there are a furnace village and a heating element cooling channel 2-1, and a workpiece cooling channel 2-2, and the furnace village and the heating element cooling channel 2-1 are connected for heating Chamber 11, the workpiece cooling passage 2-2 is connected to the inner cavity of the vapor chambe...

specific Embodiment 2

[0068] The characteristics of this embodiment: the number of the vapor chamber cooling air ducts 3-4 is two, three, four, five, six, seven, nine, ten or twelve. Others are the same as in Example 1.

specific Embodiment 3

[0069] The characteristics of this embodiment: the number of the furnace village and the heating element cooling channels 2-1 is two, three, four, five, six, seven, nine, ten or twelve. Others are the same as in Example 1.

[0070] Other examples:

[0071] The quantity of the air inlet 32-1a of the air inlet cavity 3-2-1 of the first hollow flange 3-2 is two, three, four, five, six, seven, nine, ten or twelve. The number of the steel pipes 4-3 is three, five, six, seven or eight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com