Uniform-heating screen with cooling structure for thermally-stimulated furnace

A technology of cooling structure and thermal simulation, applied in the direction of furnace cooling, furnace, furnace type, etc., can solve the problems of uneven heating of workpieces, inability to accurately control cooling speed, etc., achieve good cooling/insulation effect, accurately control cooling speed, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

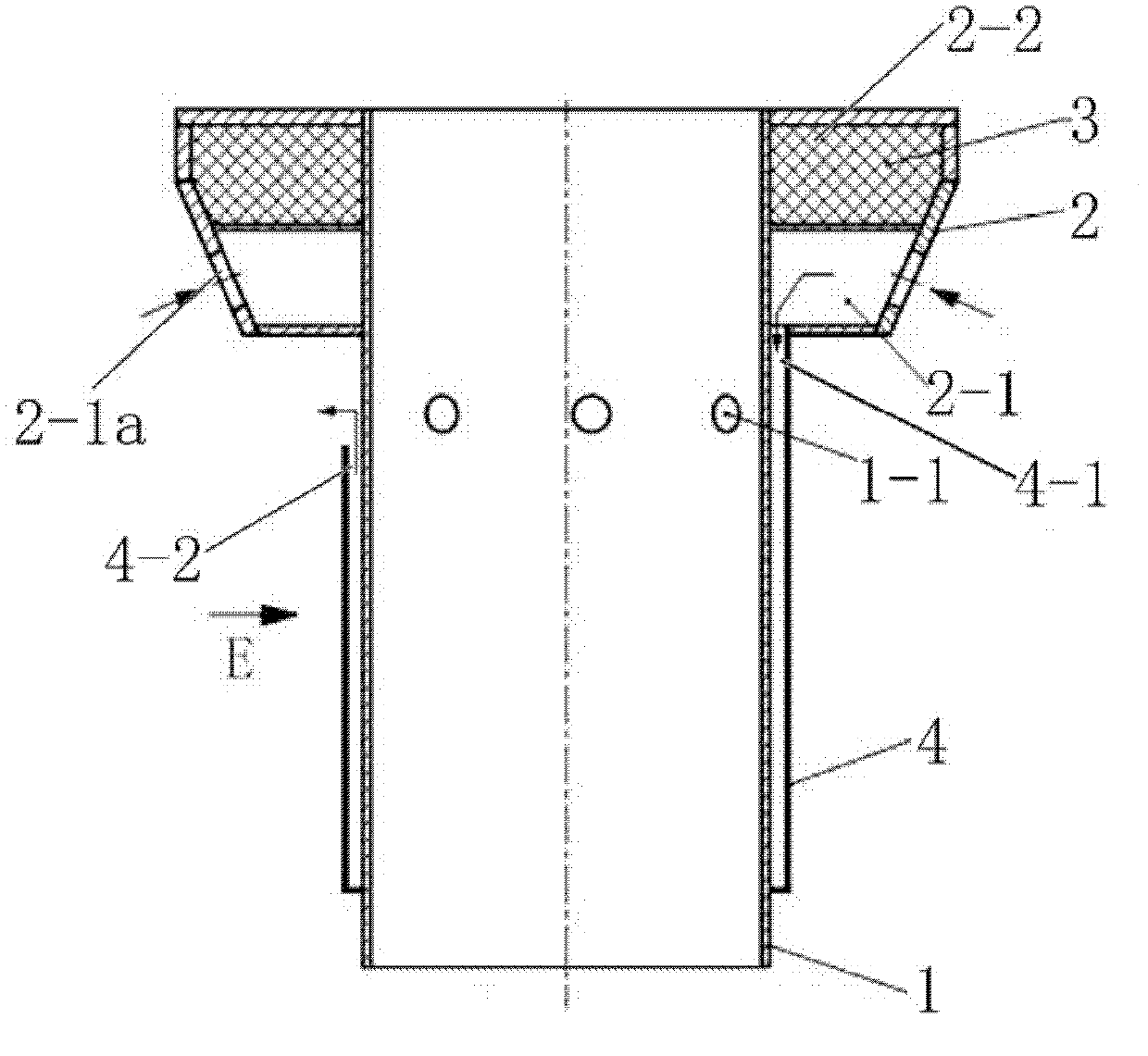

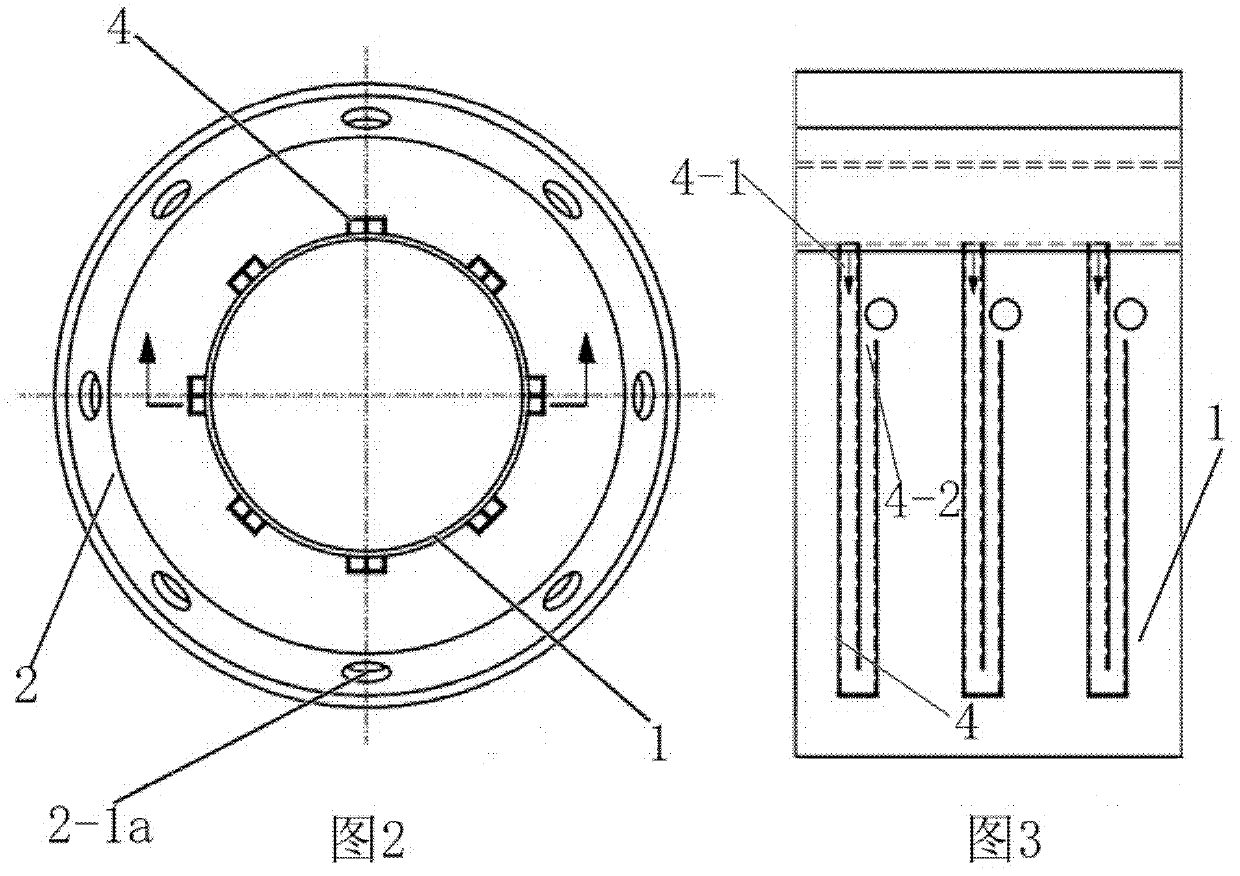

[0021] refer to figure 1 , figure 2 and image 3 , this embodiment includes a housing 1 and a hollow flange 2 connected to the top of the housing 1; the inner cavity of the hollow flange 2 is divided into an air inlet chamber 2-1 and a heat insulation chamber 2-2; in the air inlet chamber 2- The side wall of 1 is provided with several evenly distributed air intake holes 2-1a, and thermal insulation cotton 3 is provided in the heat insulation cavity 2-2; several uniformly distributed cooling air ducts 4 are provided on the outer wall of the housing 1 , the air inlet 4-1 of the cooling air passage 4 communicates with the air inlet cavity 2-1, and the air outlet 4-2 thereof is open.

[0022] In this example:

[0023] The outer shape of the hollow flange 2 is that the lower part is in the shape of a truncated inverted cone, and the upper part is in the shape of a cylinder. Since the lower part of the hollow flange 2 is in the shape of a truncated inverted cone, it can be conn...

specific Embodiment 2

[0028] The characteristics of this embodiment: the outer shape of the hollow flange 2 is truncated and inverted conical. The number of the air intake holes 2-1a is two, three, four, five, six, seven, nine, ten or twelve. Others are the same as in Example 1.

specific Embodiment 3

[0029] The characteristics of this embodiment: the number of the cooling air ducts 4 is two, three, four, five, six, seven, nine, ten or twelve. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com