Throttling liquid feeding refrigerating system with jet pump

A technology of refrigeration system and jet pump, which is used in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., to achieve the effect of simple structure, avoiding waste and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

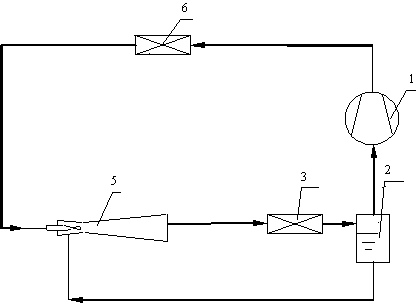

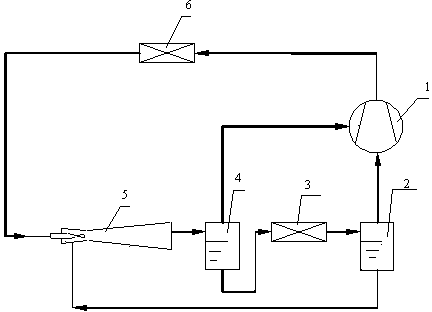

[0023] Please refer to the attached figure 2 , with figure 2 It is a schematic diagram of the jet pump throttling liquid supply refrigeration system of the present invention, and the jet pump throttling liquid supply refrigeration system includes a compressor 1, a condenser 6, a jet pump 5, a vapor-liquid separation liquid supply barrel 4, and an evaporator 3 and the vapor-liquid separation circulation barrel 2, the outlet of the compressor 1 is connected to the inlet of the condenser 6, the outlet of the condenser 6 is connected to the nozzle inlet of the jet pump 5, and the suction port of the jet pump 5 is connected to the steam The liquid outlet of the liquid separation circulation barrel 2 is connected, the discharge port of the jet pump 5 is connected with the inlet of the vapor-liquid separation liquid supply barrel 4, and the gas outlet of the vapor-liquid separation liquid supply barrel 4 is connected with the intermediate suction of the compressor 1 port connectio...

Embodiment 2

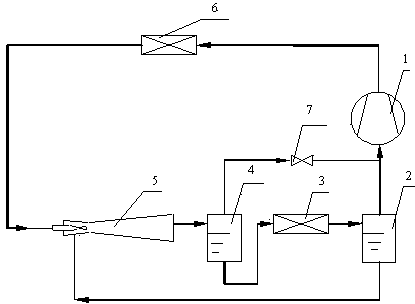

[0028] Please refer to the attached image 3 And attached Figure 5 , with image 3 It is a schematic diagram of the jet pump throttling liquid supply refrigeration system of the present invention (the compressor has no intermediate steam suction port), and the attached Figure 5 It is the pressure-enthalpy diagram of the refrigeration cycle of the jet pump throttling liquid supply refrigeration system (the compressor has no intermediate suction port) of the present invention. Similar to Embodiment 1, the jet pump throttling liquid supply refrigeration system includes a compressor 1, a condenser 6, a jet pump 5, a vapor-liquid separation liquid supply barrel 4, an evaporator 3 and a vapor-liquid separation circulation barrel 2, and The difference in Embodiment 1 is that the compressor 1 does not have an intermediate suction port, the refrigerant vapor (k) from the vapor-liquid separation liquid supply barrel 4 is depressurized (b) through the valve 7, and is separated from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com