Liquid removing equipment and liquid removing method

An equipment and liquid technology, which is applied to the liquid removal equipment and liquid removal field of optical film materials, can solve the problem of residual liquid on the surface of optical film materials, and achieve the effect of improving production yield, increasing yield and increasing production speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

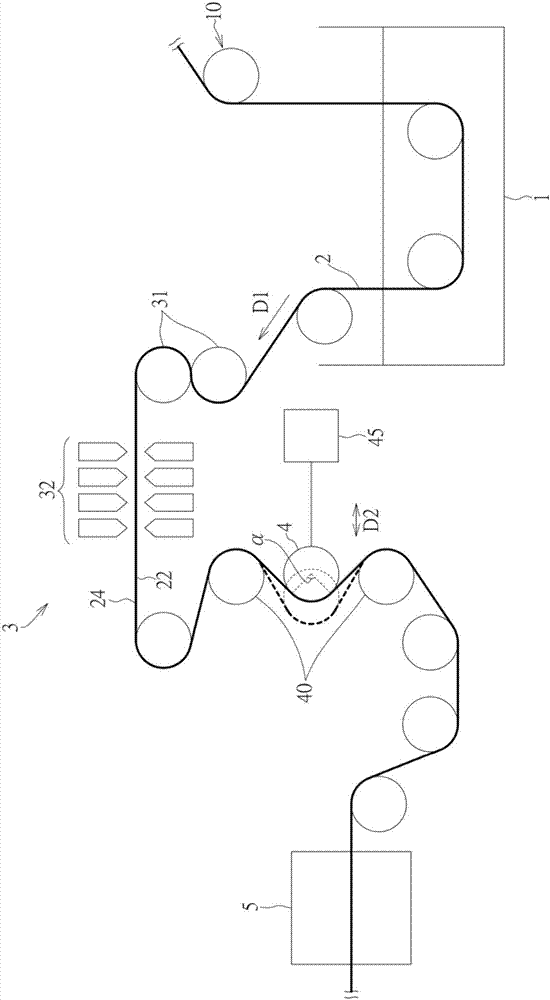

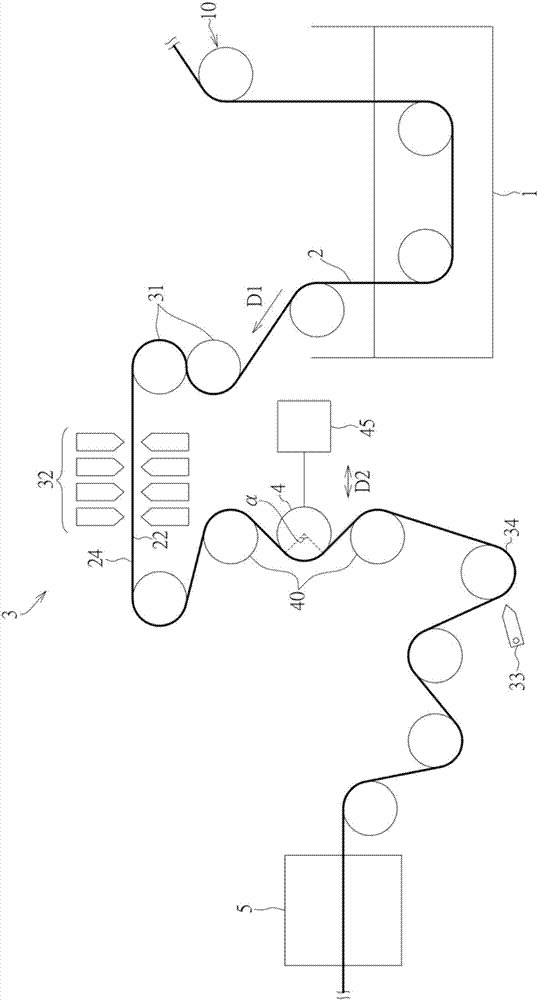

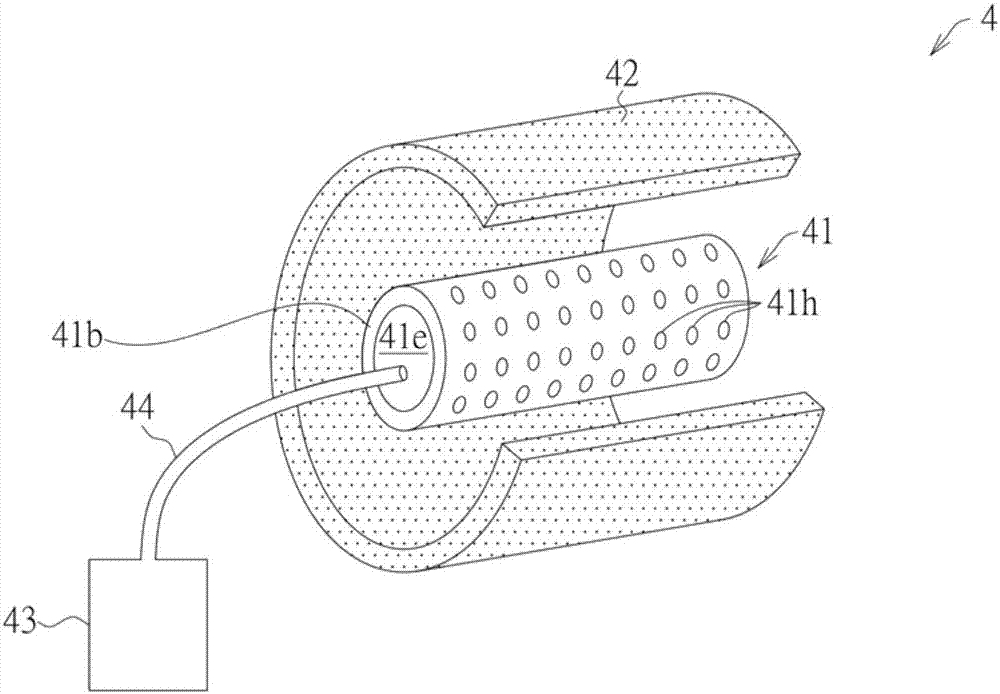

[0056] The invention relates to a liquid removal device and a liquid removal method. In the embodiment of the content of the present invention, the equipment used in the preparation process of the optical film material includes a liquid suction roller, which is used to contact the optical film material and absorb the liquid on the surface of the optical film material, so as to remove the liquid remaining on the surface of the optical film material of liquid.

[0057] It should be noted that the present invention does not show all possible embodiments, and other implementations not presented in the present invention may also be applicable. Furthermore, the size ratios on the drawings are not drawn to the same scale as the actual product. Therefore, the specification and illustrations are only used to describe the embodiments, not to limit the protection scope of the present invention. In addition, the descriptions in the embodiments, such as detailed structures, preparation p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com