Oil leakage prevention noise reduction energy-saving furnace core used for compression type combustion furnace

A combustion furnace, oil leakage prevention technology, applied in the burner noise control, burner, burner and other directions, can solve the problems of low fuel utilization rate, high noise, etc., to improve the utilization rate of energy, reduce noise, and improve utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

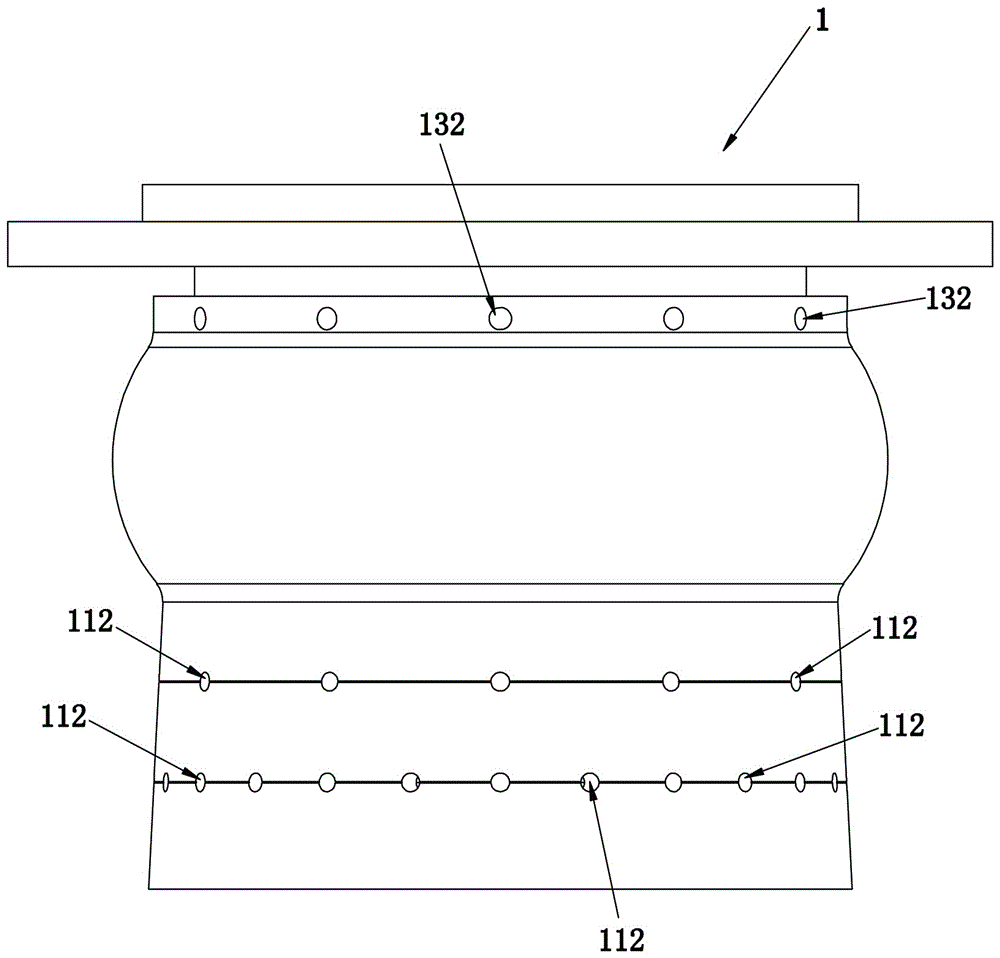

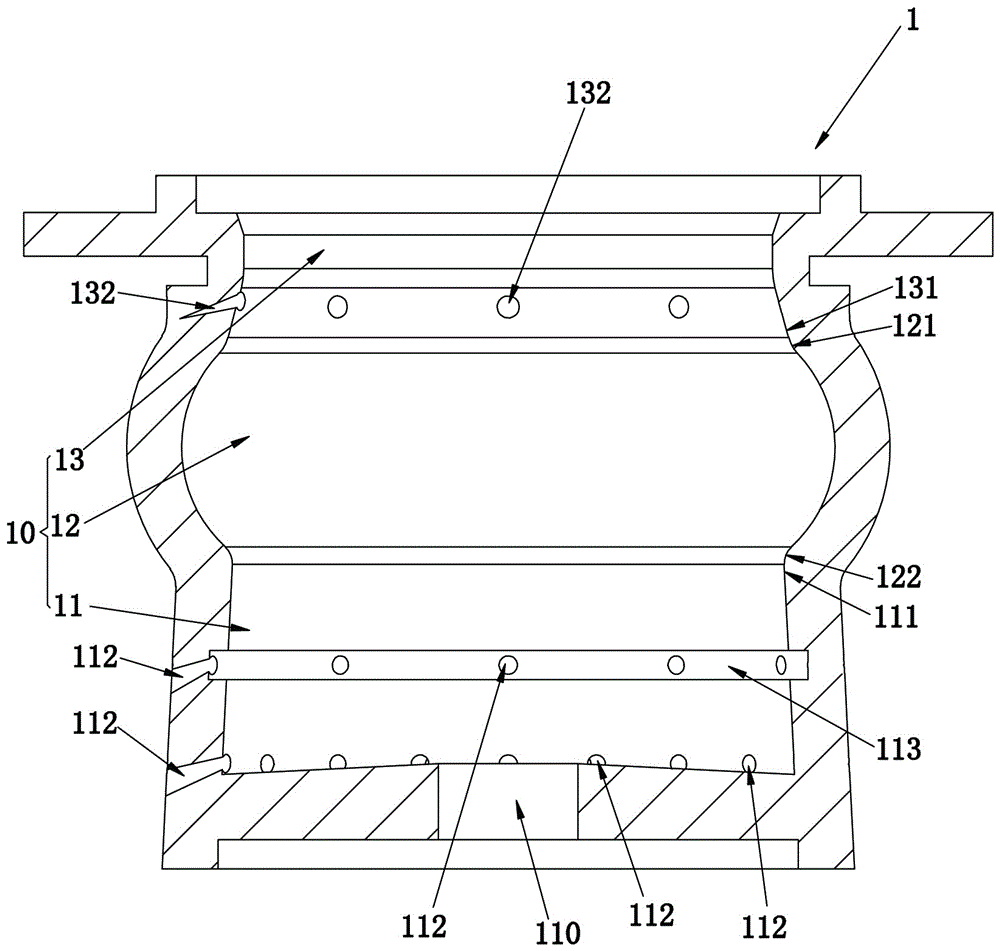

[0020] refer to figure 1 , figure 2 , an oil-leakage-proof, noise-reducing, energy-saving furnace core for compression combustion furnaces, comprising a furnace core body 1, the hollow area of the furnace core body 1 being a combustion zone 10; the combustion zone 10 consists of combustion pools 11 arranged sequentially from bottom to top , an annular depression 12 and a necking area 13; the annular depression 12 is arranged around the inner wall of the furnace core body 1 . Fuel burns in the combustion pool 11 to generate flames, and the flames are ejected from the fire end of the top of the furnace core body 1 after passing through the annular depression 12 and the necking area 13 from the combustion pool 11. The concave surface of the annular depression 12 is an arc surface, the top edge 121 of the annular depression 12 is connected with the arc surface of the bottom edge 131 of the above-mentioned necking area 13, and the bottom edge 122 of the annular depression 12 is...

Embodiment approach 2

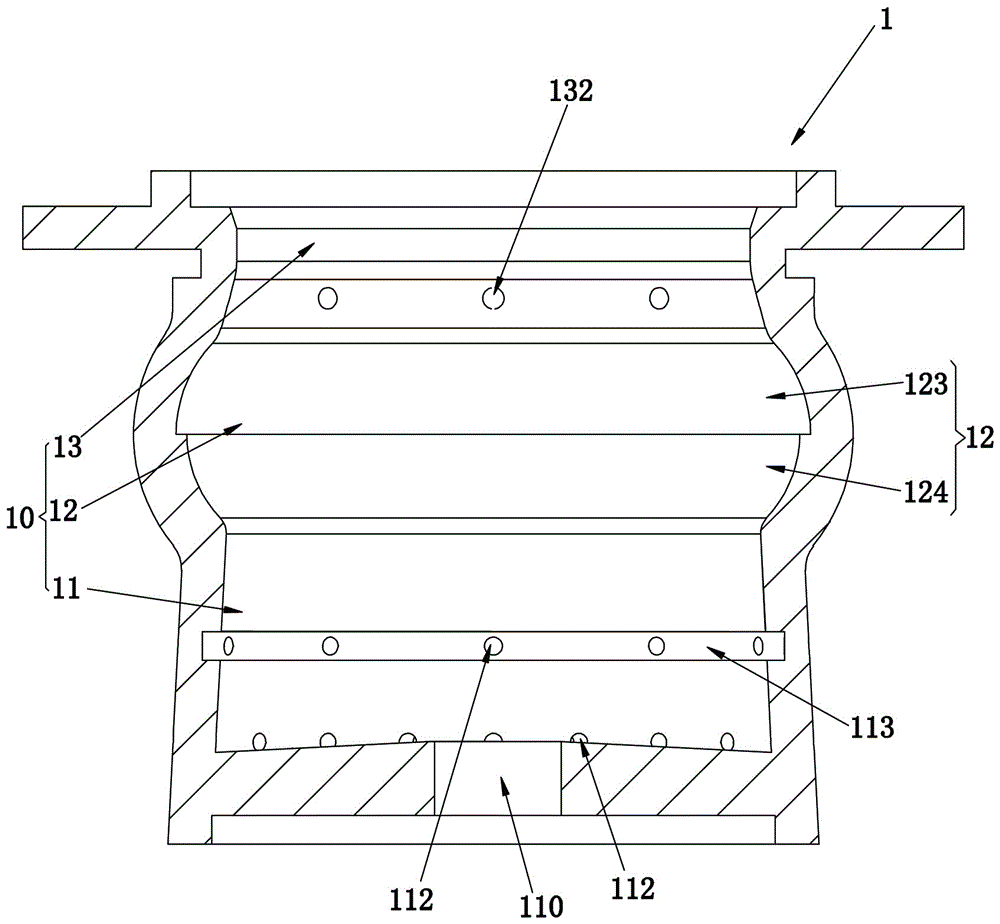

[0024] The difference between this embodiment and the first embodiment lies in the structure of the annular recess 12 . refer to image 3 , the annular depression 12 of the present embodiment is formed by an upper annular concave surface 123 and a lower annular concave surface 124, the upper annular concave surface 123 and the lower annular concave surface 124 are arc-shaped structures, and the diameter of the upper annular concave surface 123 is greater than the diameter of the lower annular concave surface 124; The top edge 121 of the upper annular concave surface 123 is transitionally connected with the bottom edge 131 of the constriction area 13 , and the bottom edge 122 of the lower annular concave surface 124 is transitionally connected with the top edge 111 of the combustion pool 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com