Patents

Literature

117results about "Burner noise abatement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

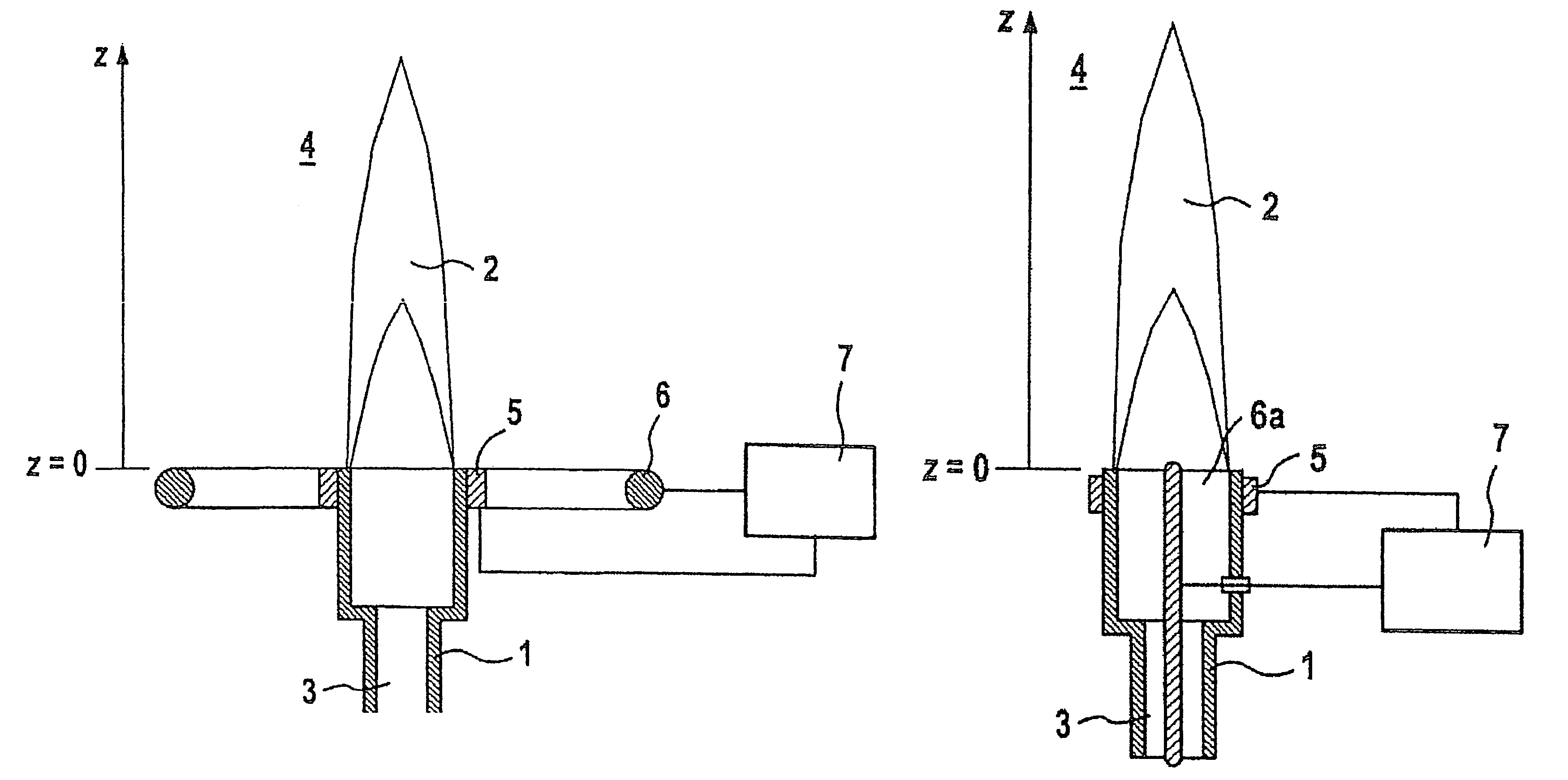

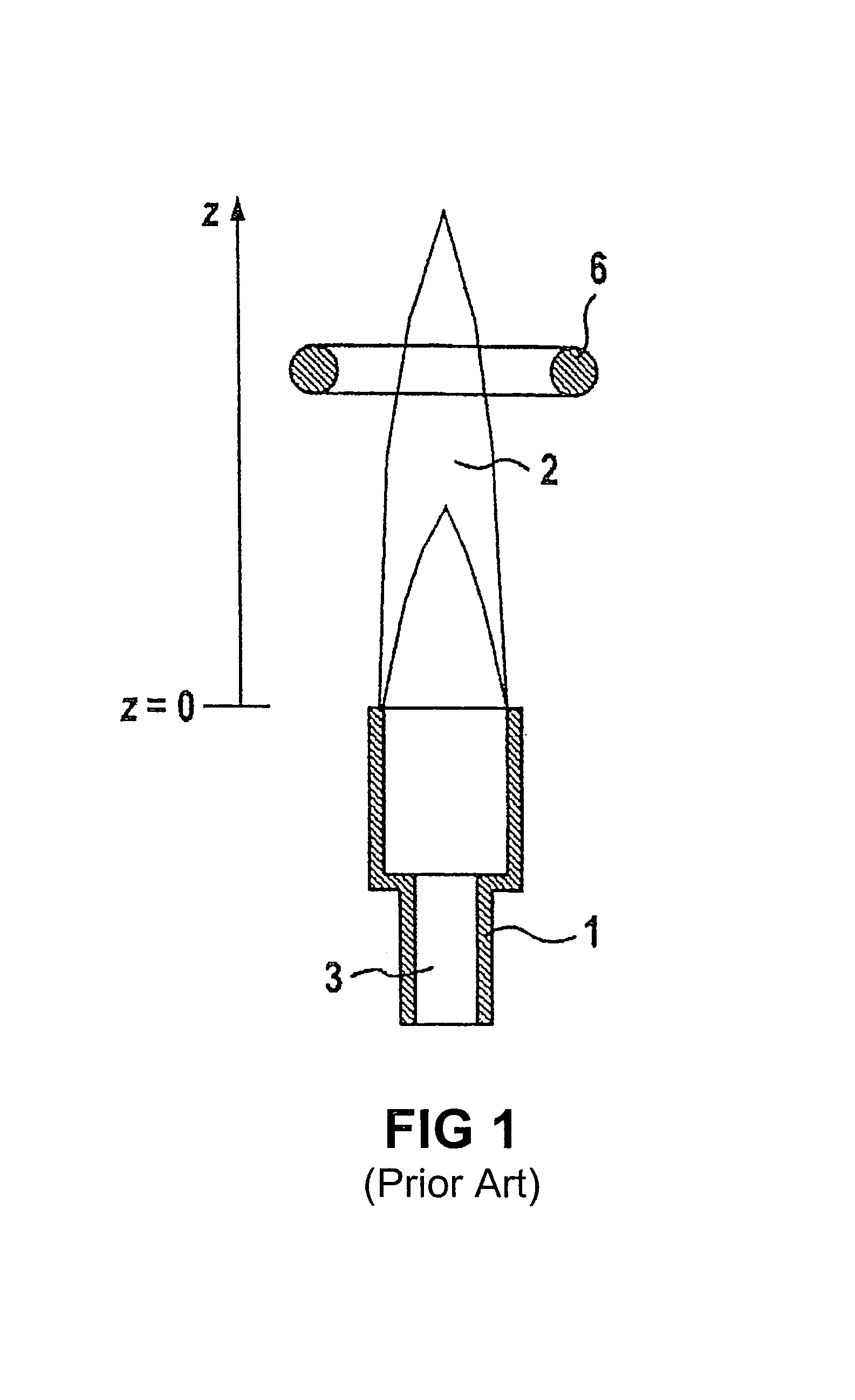

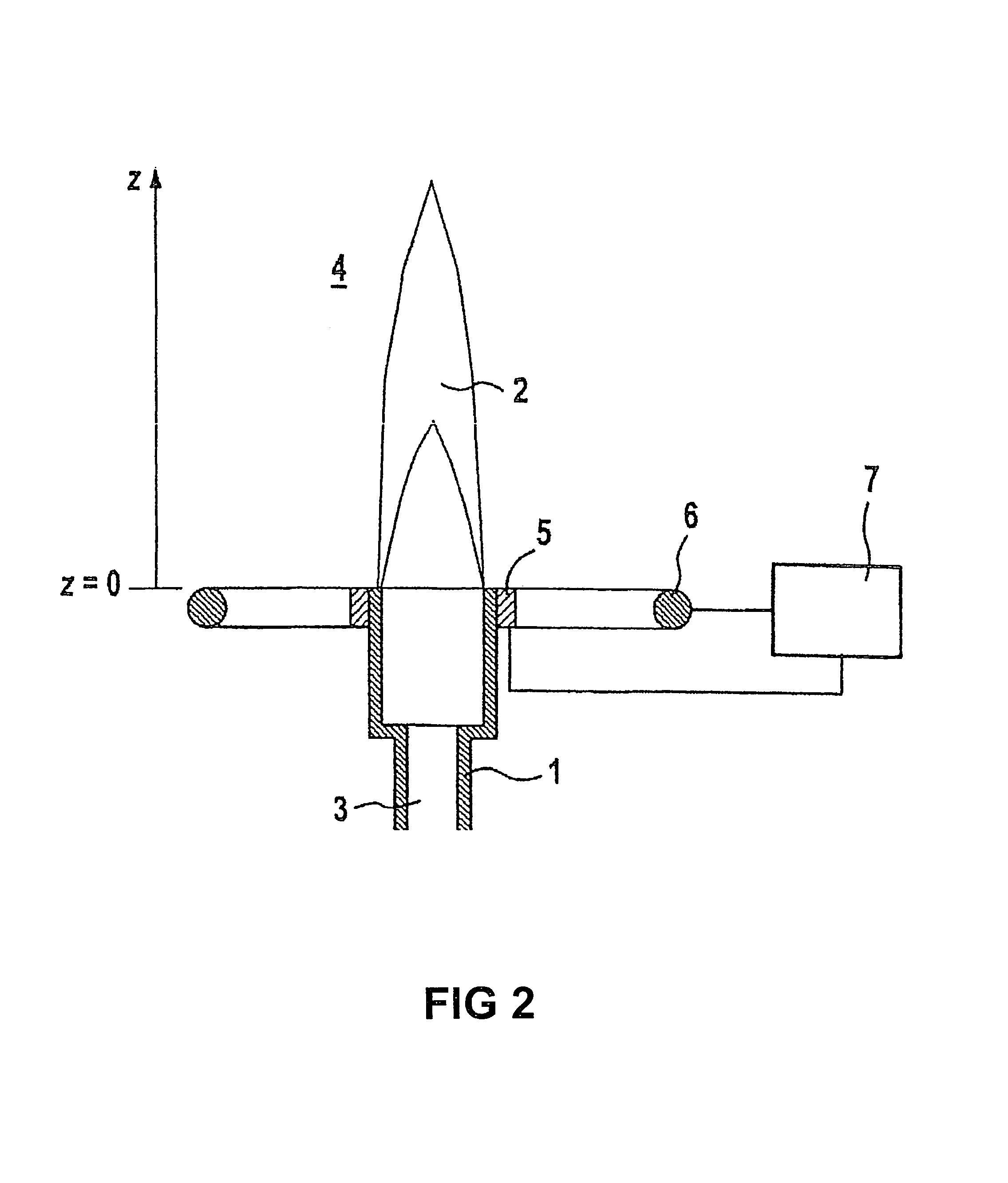

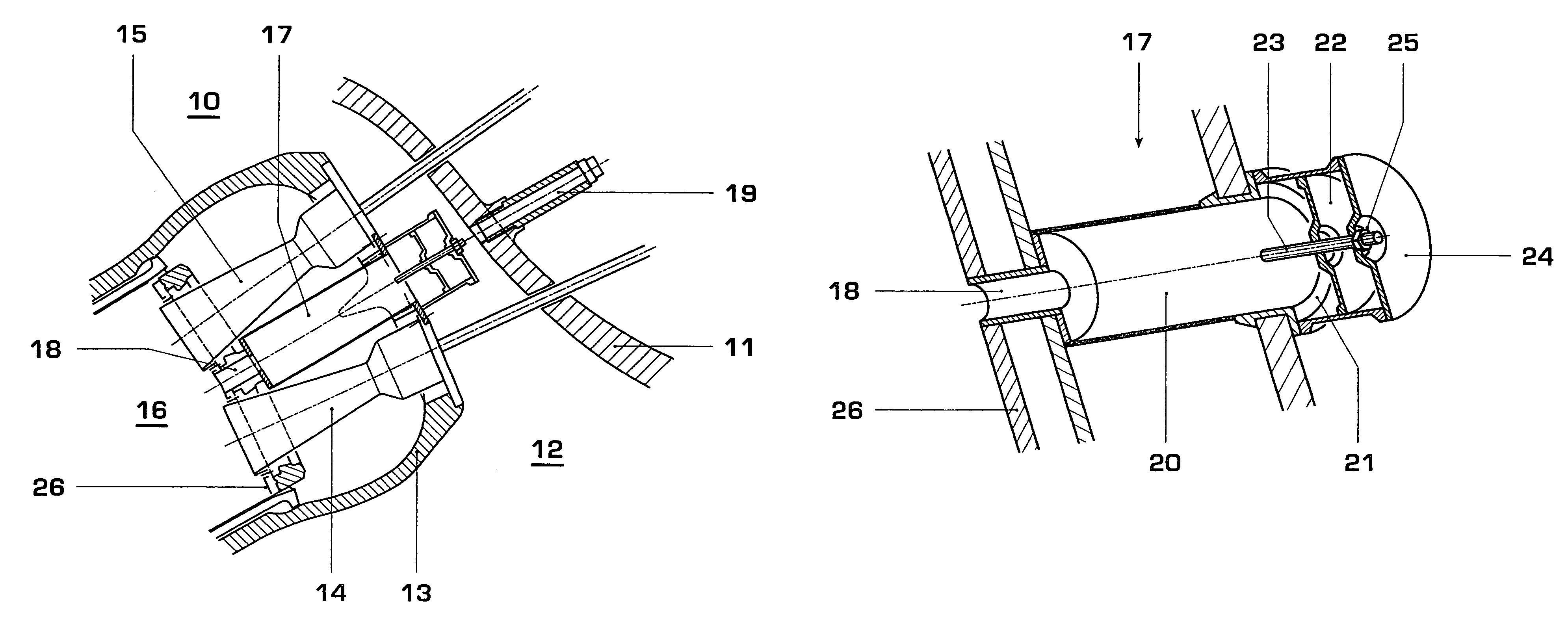

Method and device for influencing combustion processes involving combustibles

InactiveUS7137808B2Increase influenceEconomical and simpleCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHazardous substance

A method and device are for influencing combustion processes, and include an electrical device. The electrical device engages with the flame front so that the electrical field thus produced, only penetrates areas of the flame front in which a stabilizing and harmful-substance-reducing effect is produced. The electrodes of the burner are arranged outside the region of the flame in the associated device.

Owner:SIEMENS AG

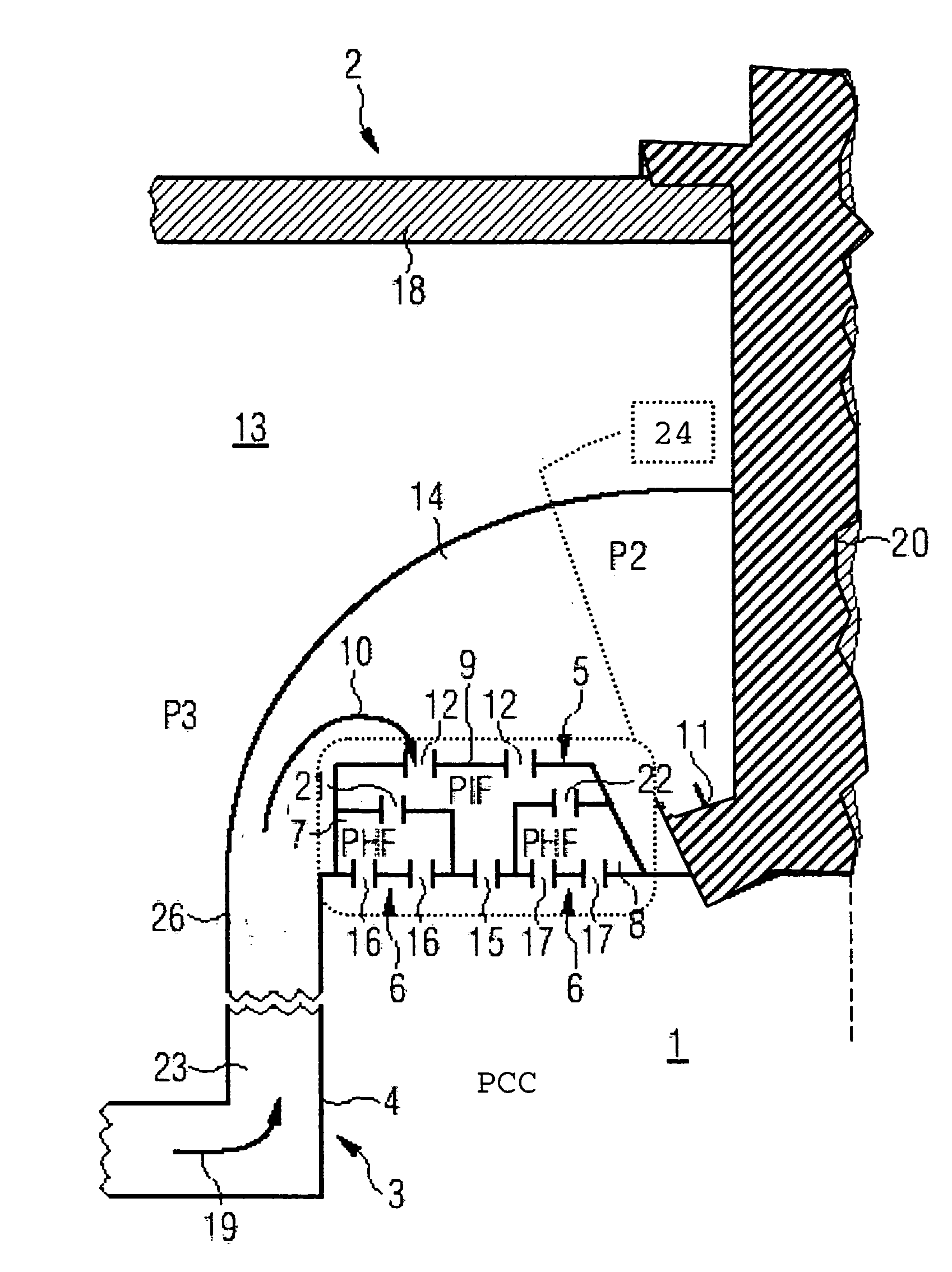

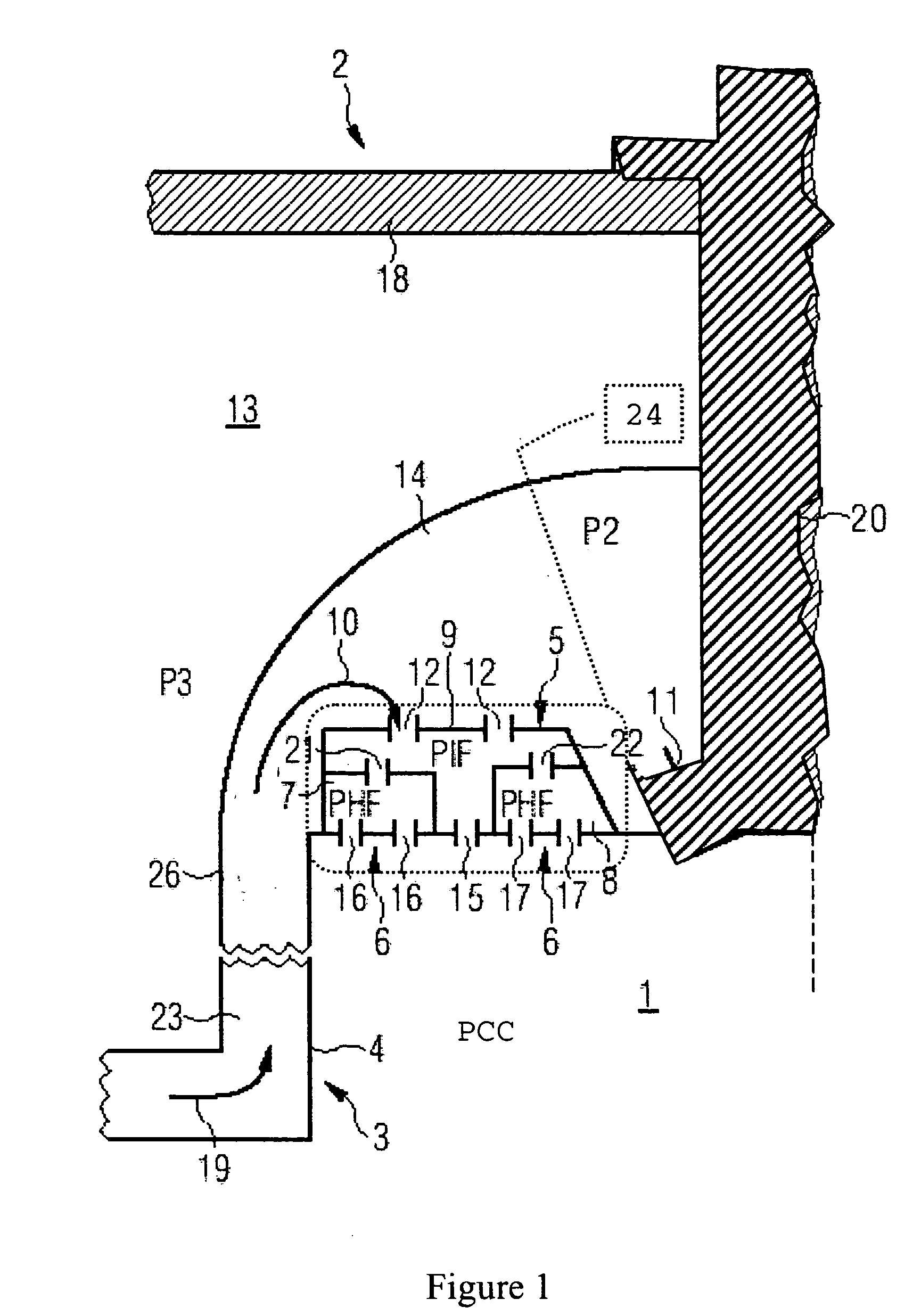

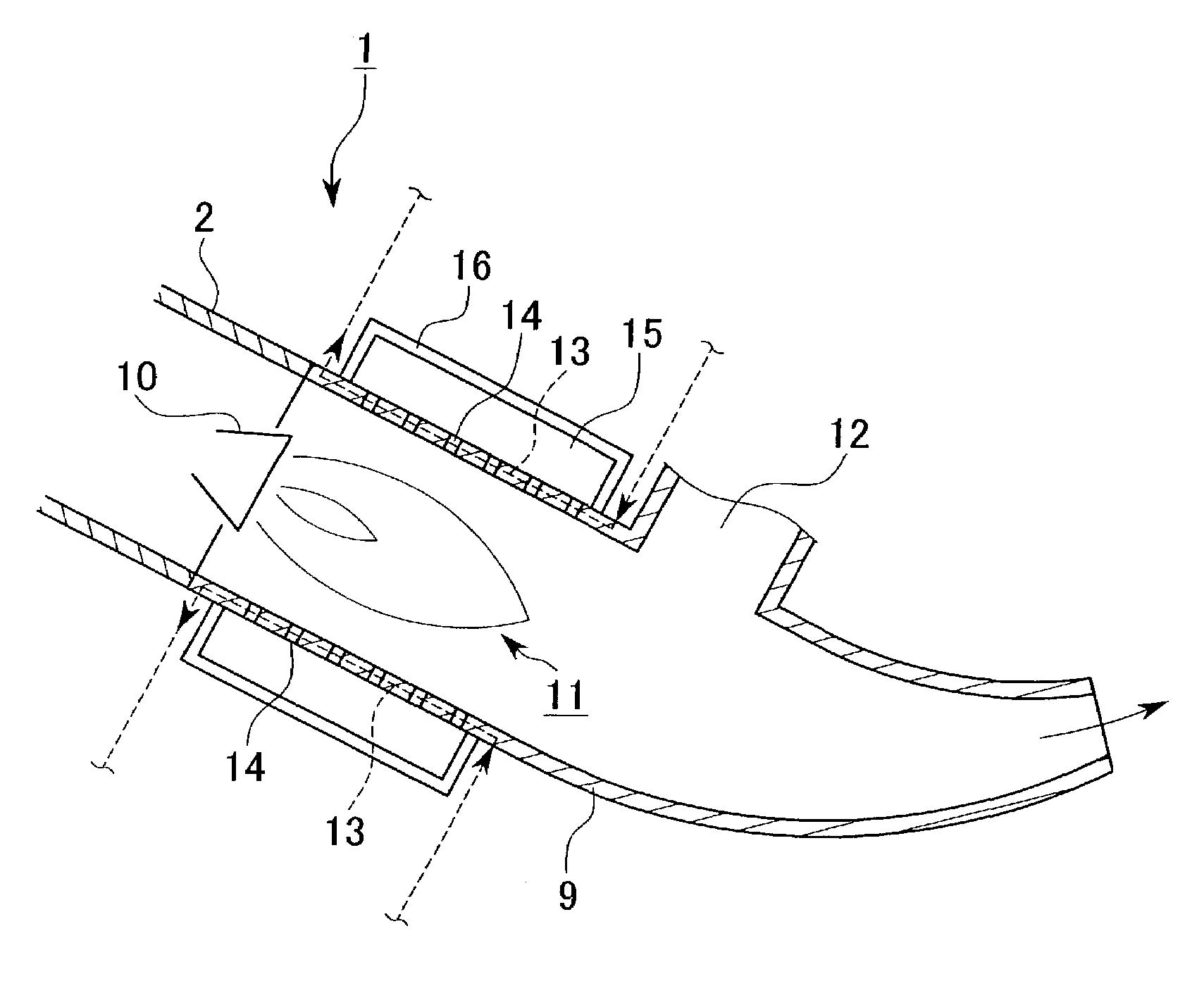

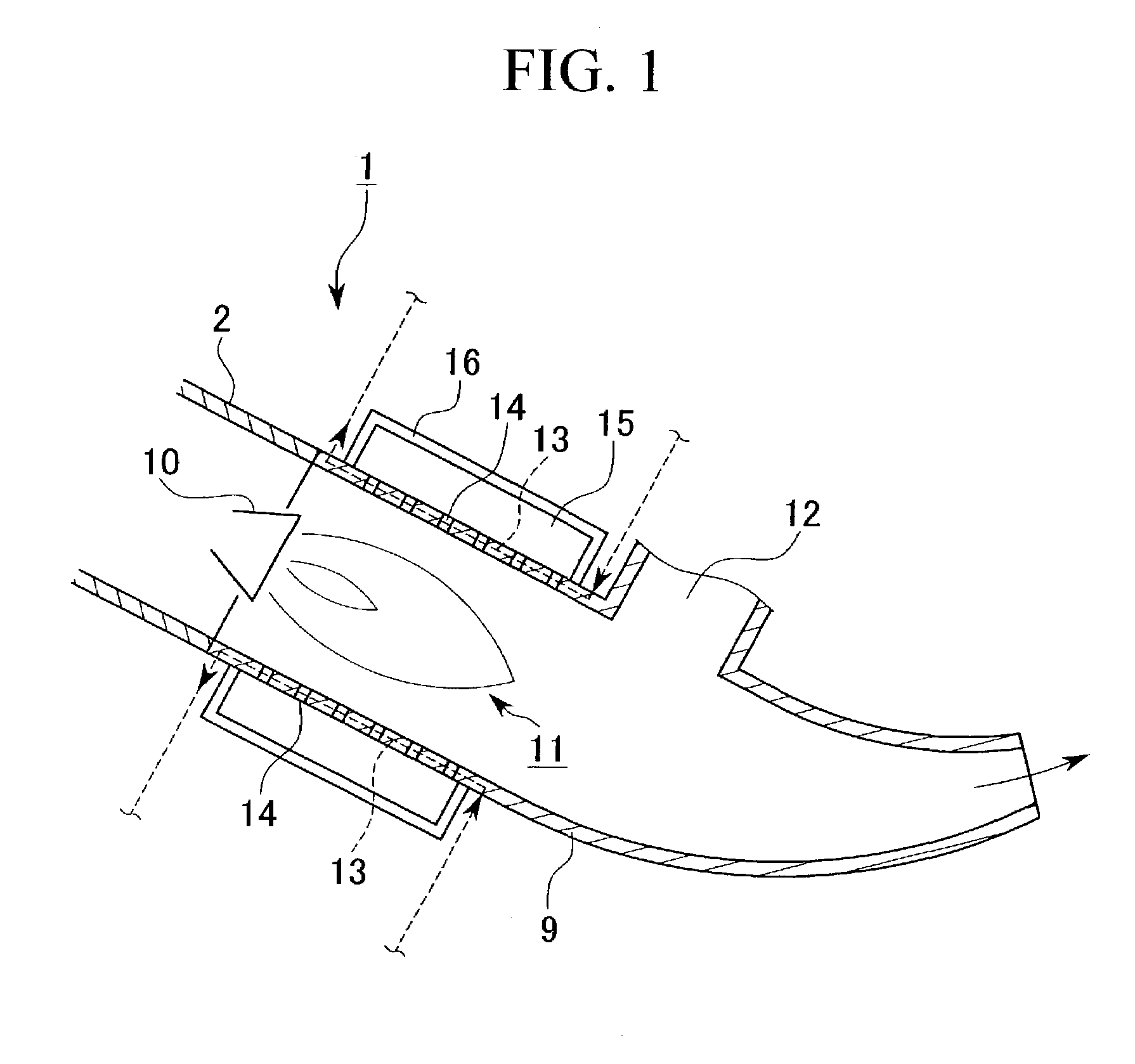

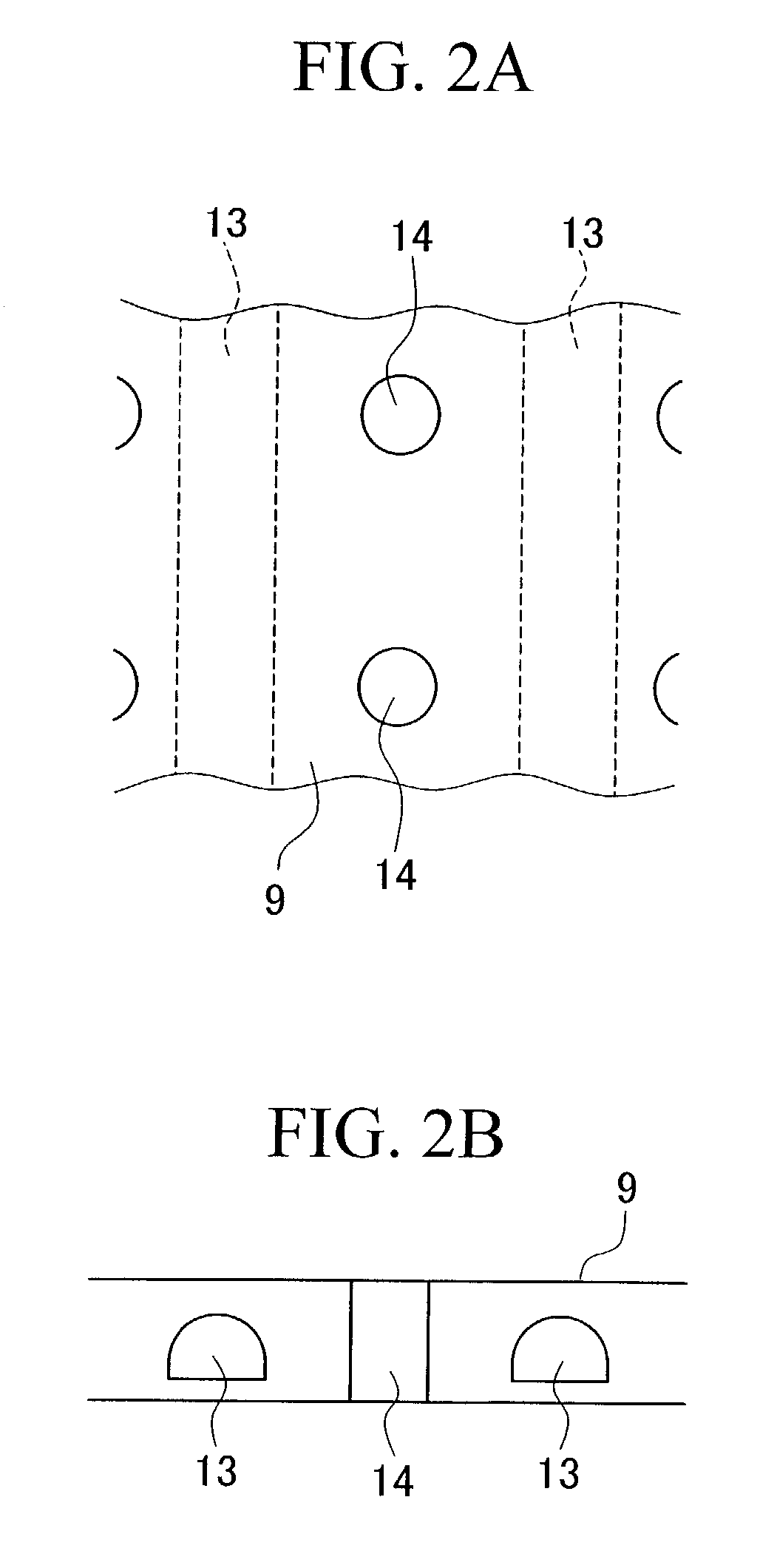

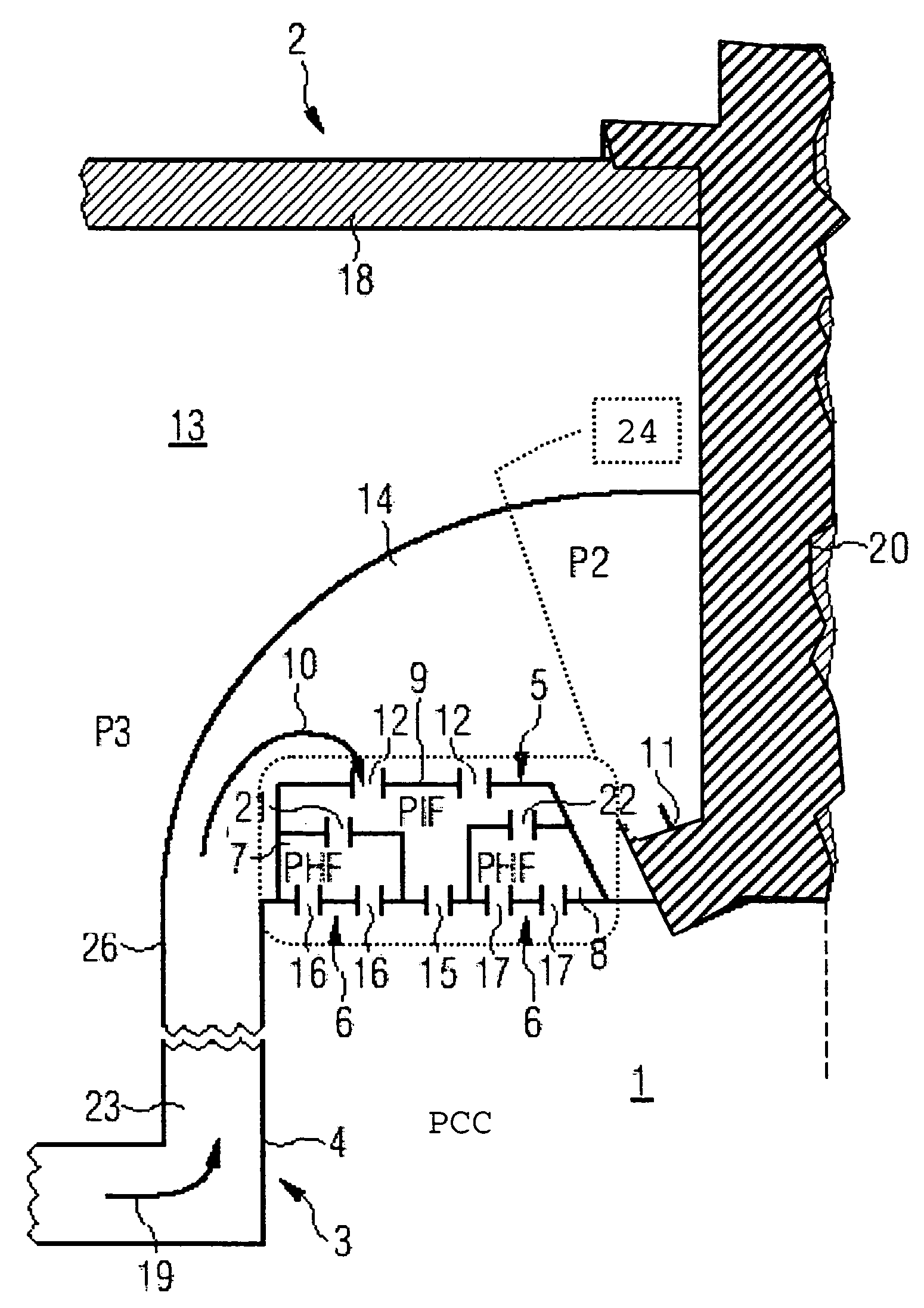

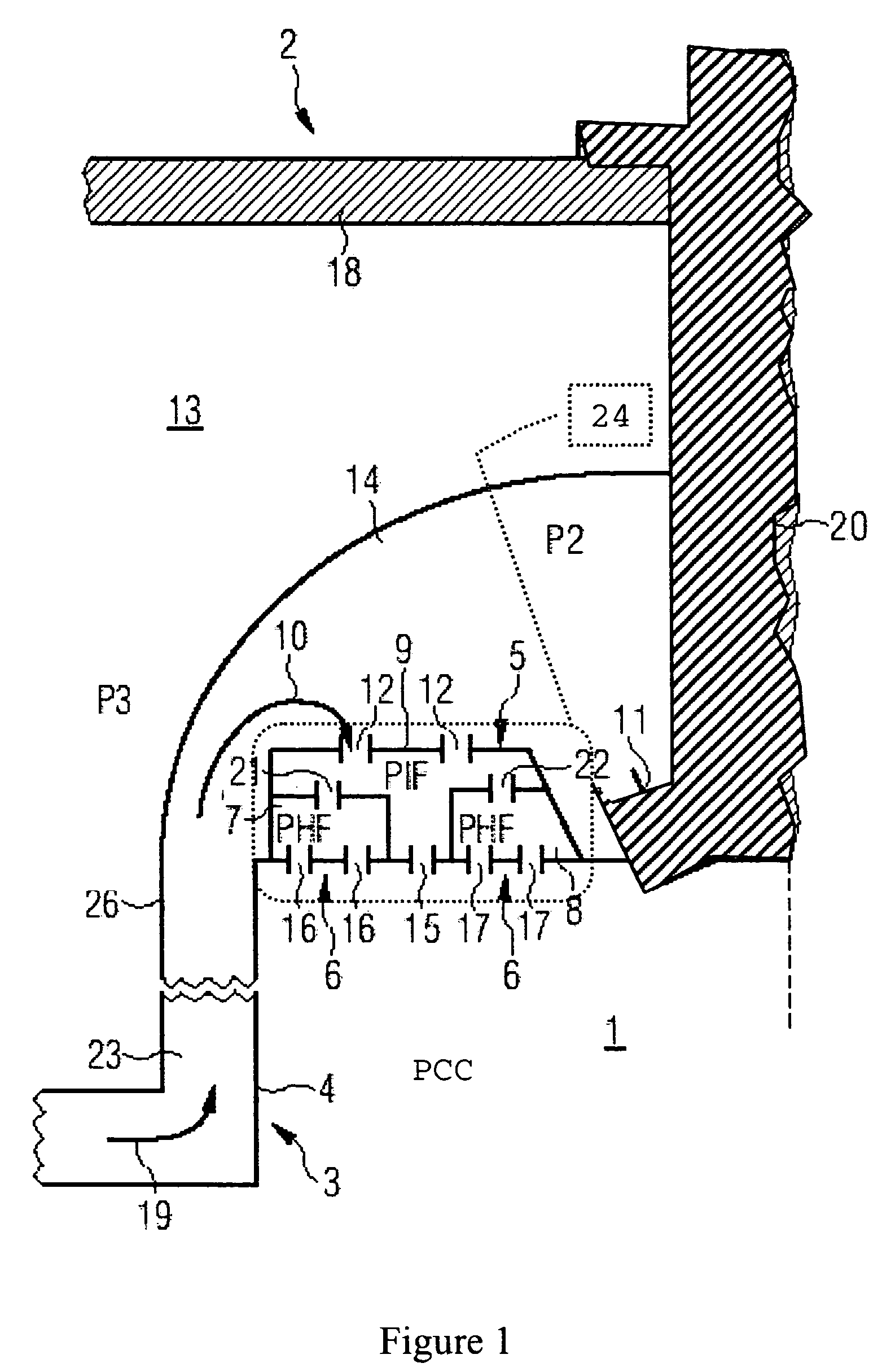

Combustion chamber for a gas turbine with at least two resonator devices

ActiveUS20060059913A1Effective reduction in oscillationReduce impactBurnersContinuous combustion chamberCombustion chamberCooling fluid

A combustion chamber according to the invention, in particular for a gas turbine, includes at least one combustion chamber wall through which cooling fluid flows and at least one resonator device. The combustion chamber according to the invention is distinguished in that the resonator device is integrated into the combustion chamber wall in such a way that it has the cooling fluid flow passing there through.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

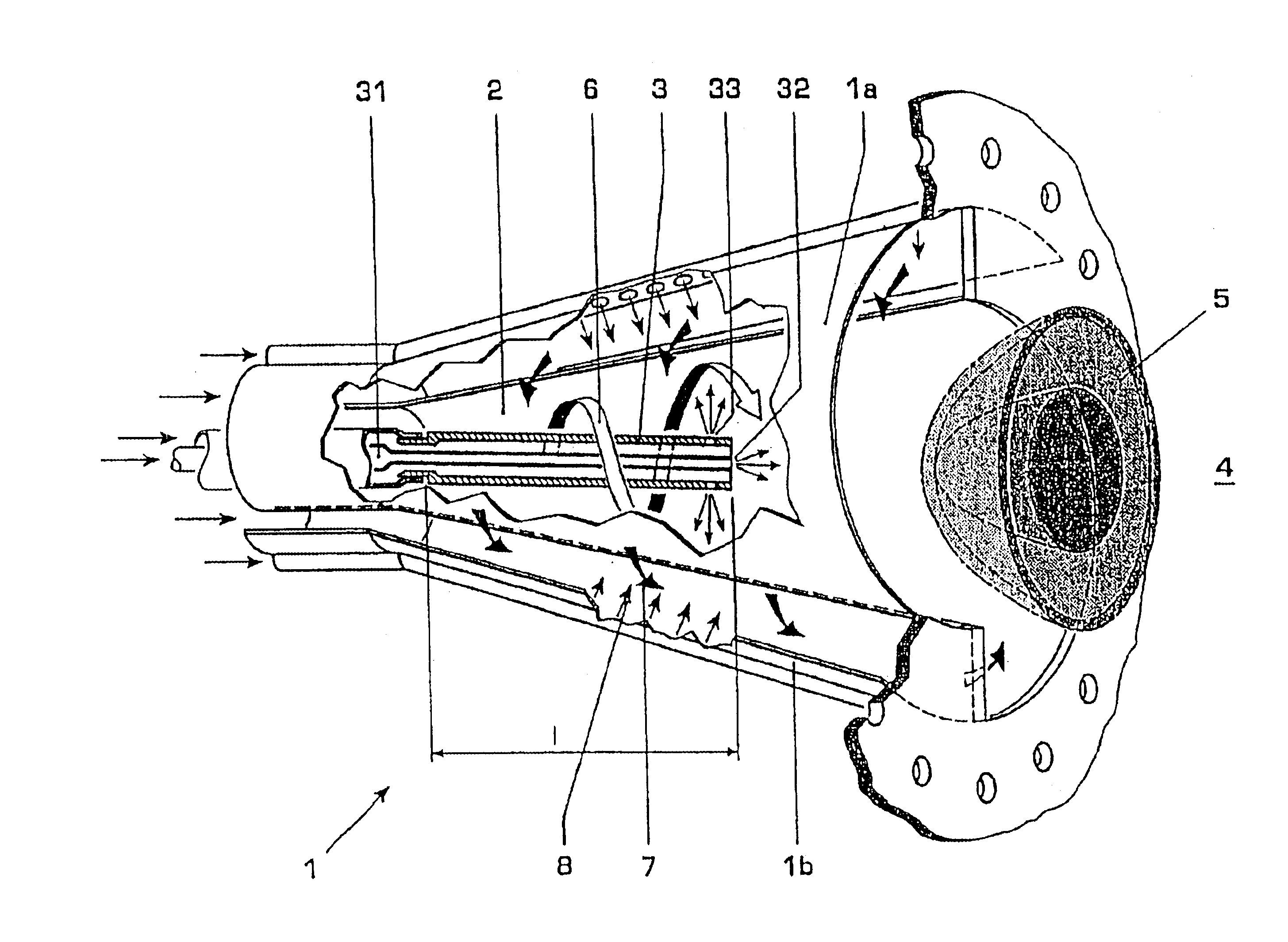

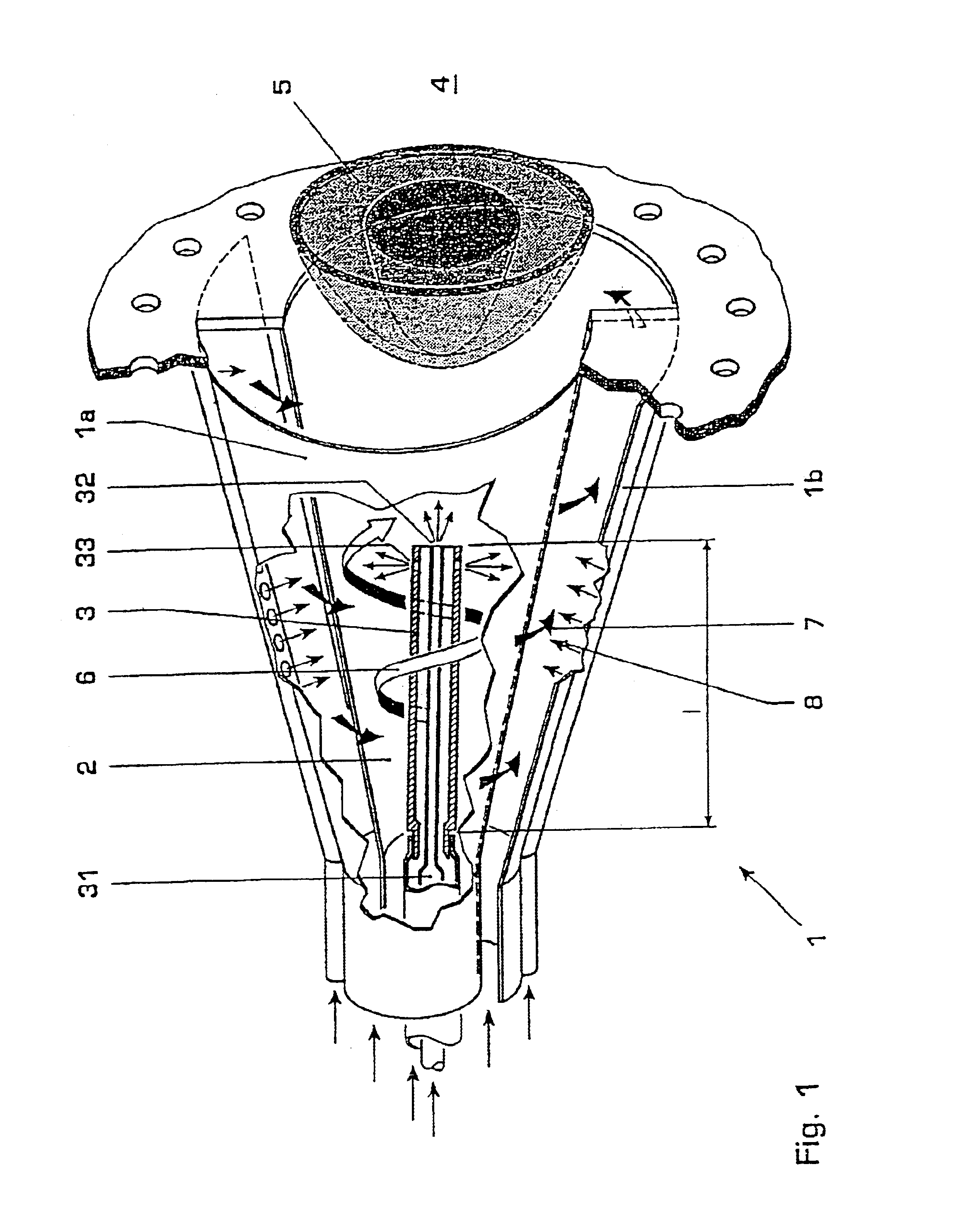

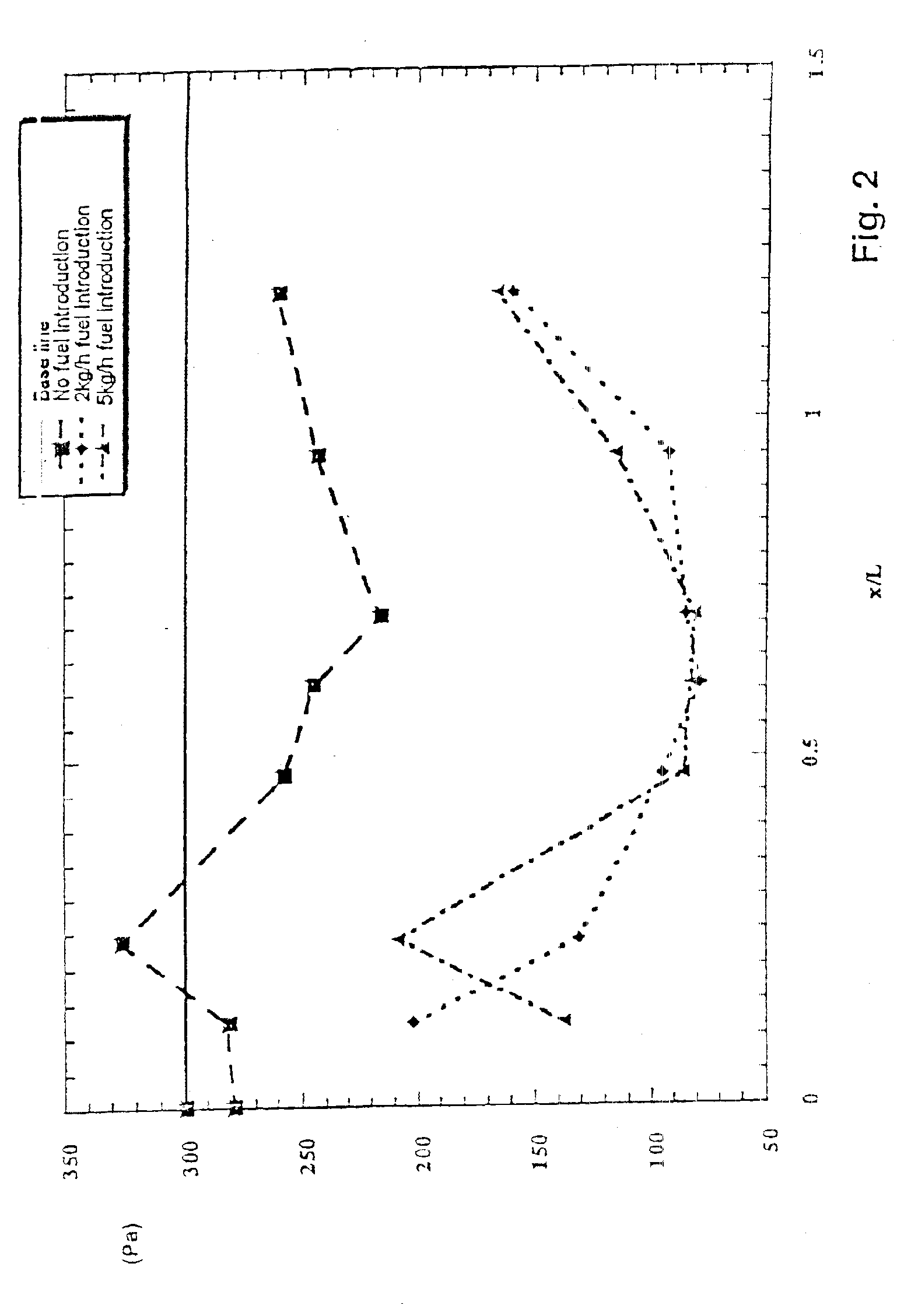

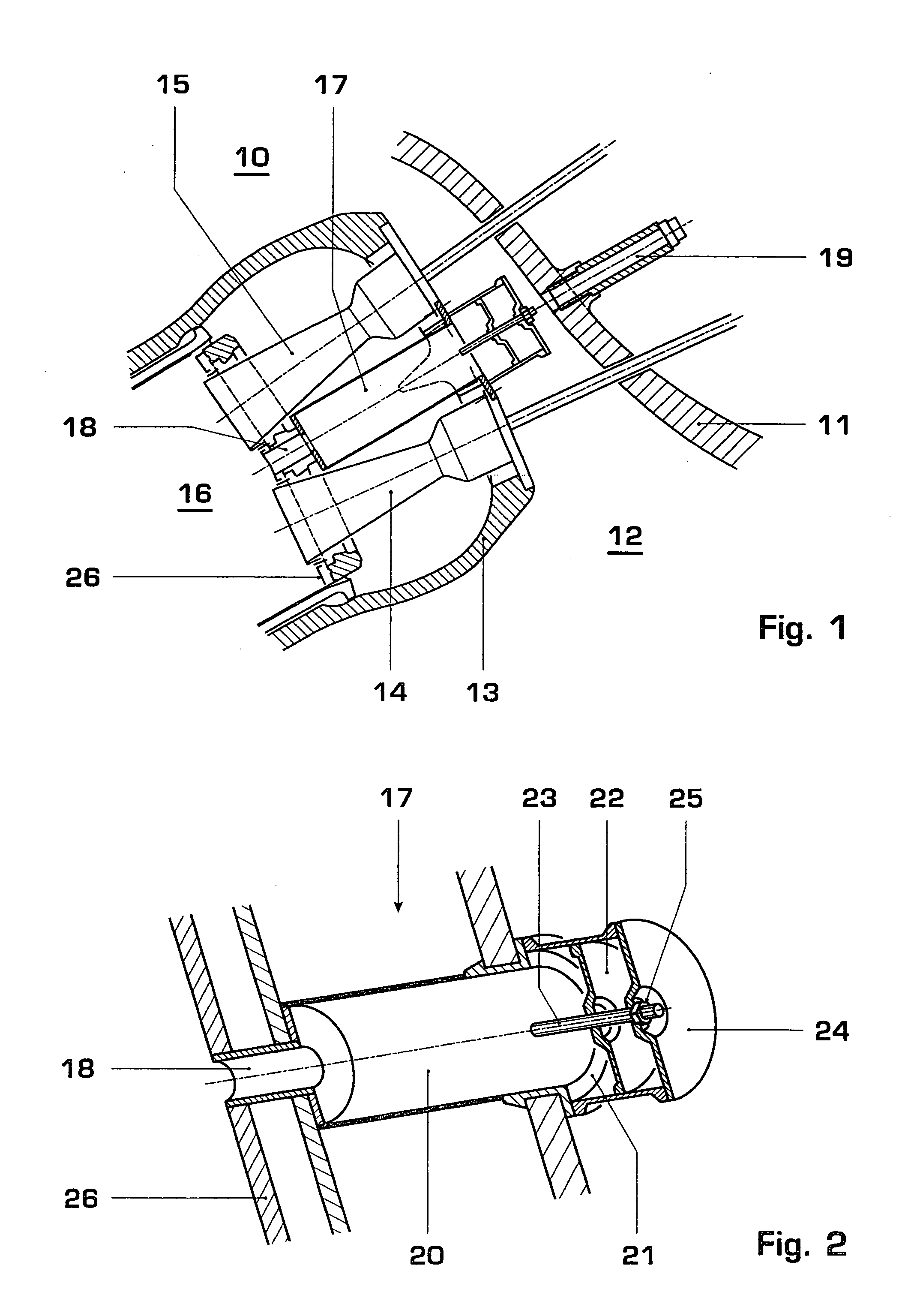

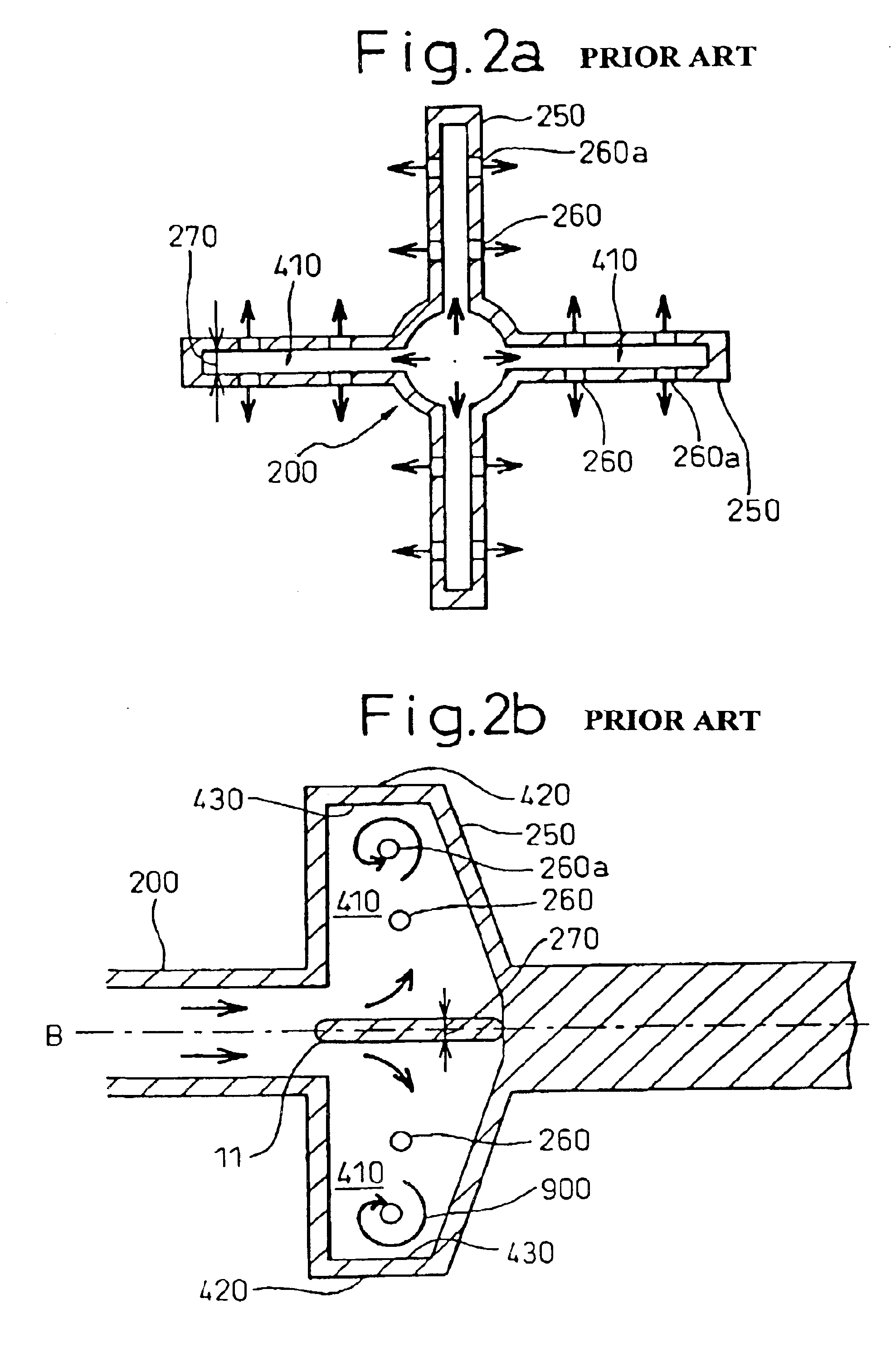

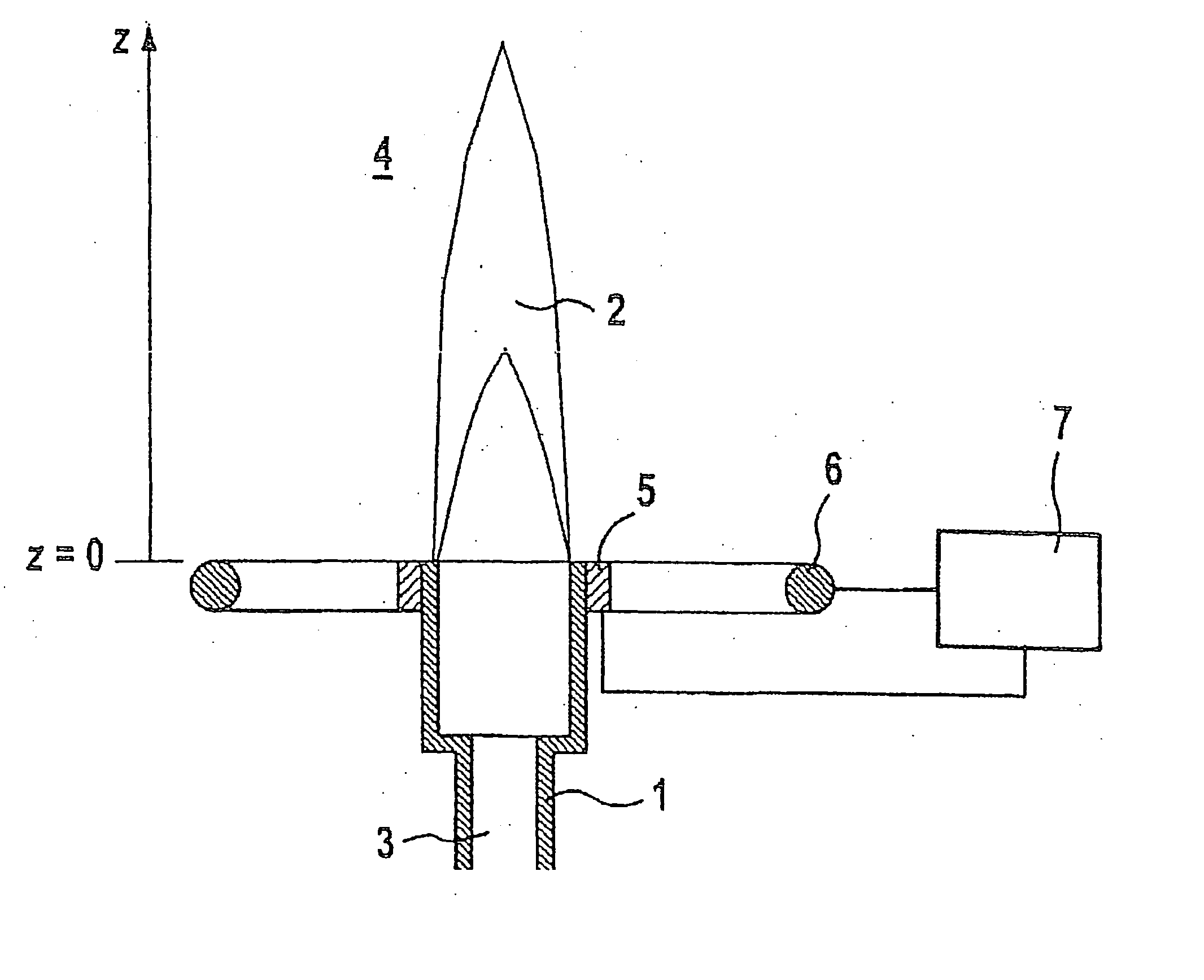

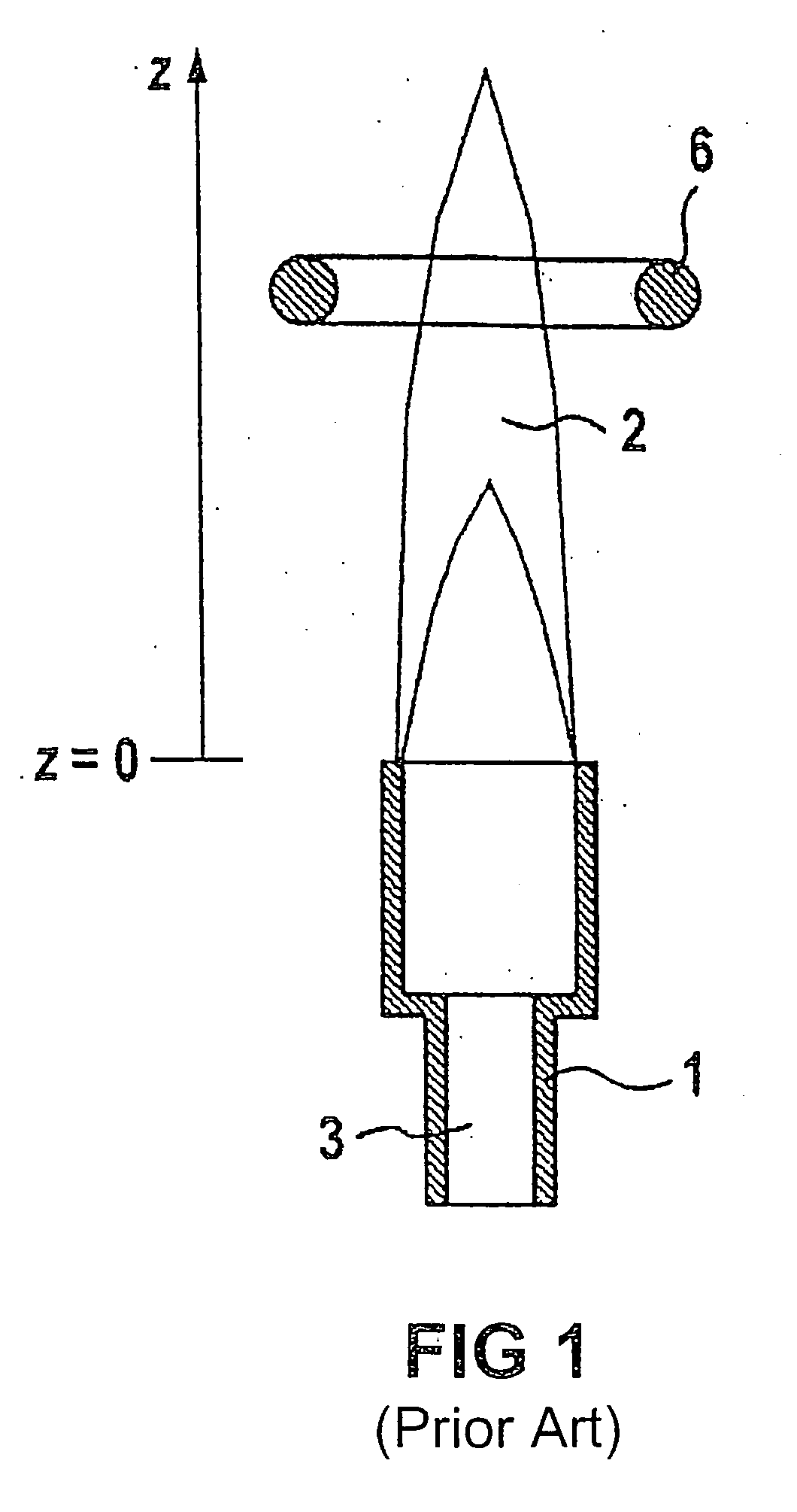

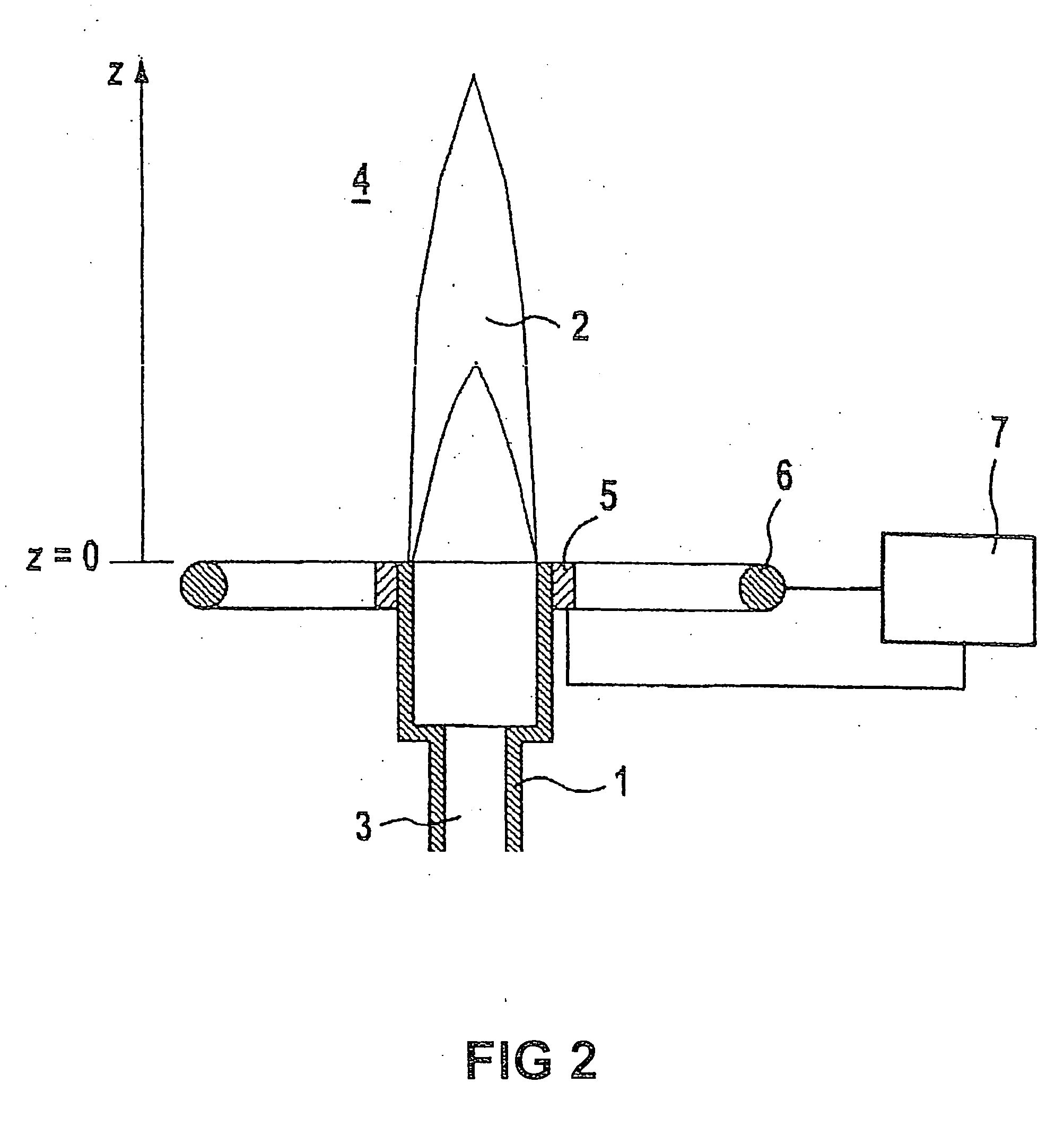

Method for the reduction of combustion-driven oscillations in combustion systems and premixing burner for carrying out the method

InactiveUS6918256B2Reduction of combustion-drivenInhibition formationContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion systemCombustion chamber

A method and a device are described for the controlled damping of combustion-driven oscillations in a turbomachine with a burner system providing at least one burner, into which is introduced, via at least one burner nozzle arranged centrally in the burner, fuel which is intermixed with combustion inflow air flowing into the burner, to form a fuel / air mixture which is ignited in a combustion chamber following the burner system. The invention is distinguished in that the fuel nozzle is designed in the form of a burner lance, at the lance end of which fuel discharge into the burner takes place, and in that the burner lance projects into the burner in the amount of at least one third of the axial burner length.

Owner:ANSALDO ENERGIA IP UK LTD

Apparatus for damping acoustic vibrations in a combustor

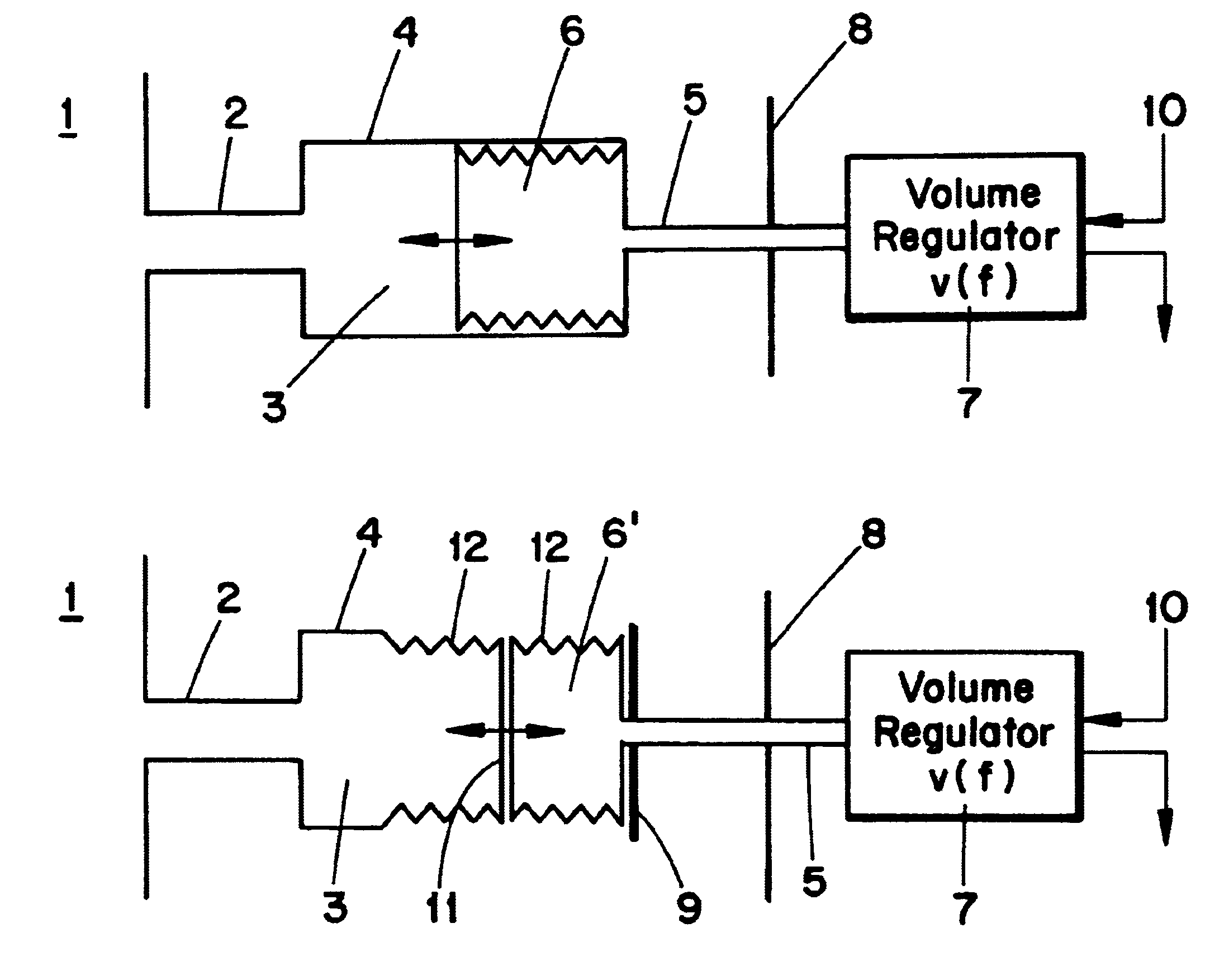

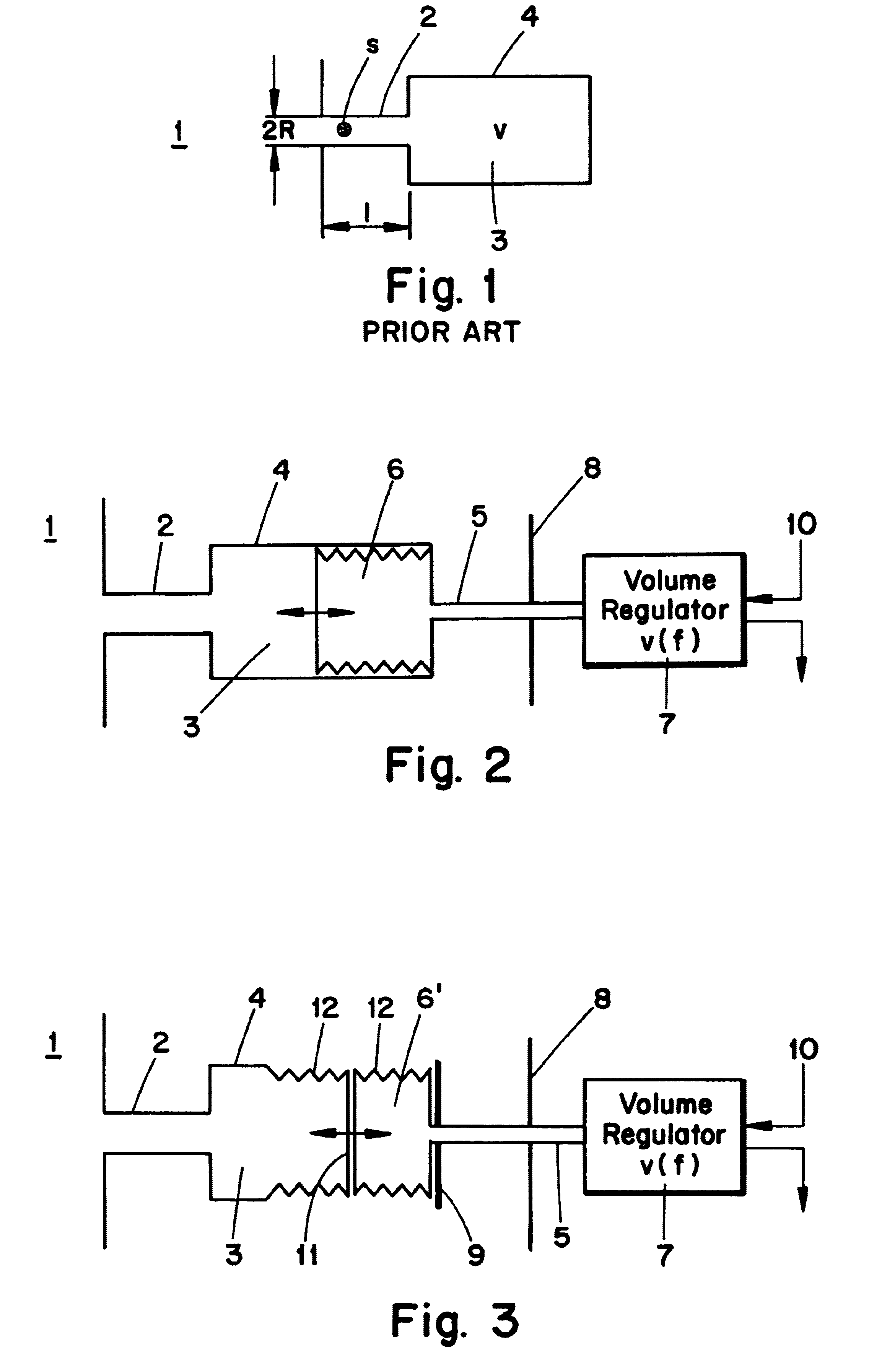

An apparatus for damping acoustic vibrations in a combustor as well as a corresponding combustor arrangement with the apparatus. The apparatus includes a Helmholtz resonator (4) that can be connected via a connecting channel (2) with a combustor (1). The Helmholtz resonator (4) contains a hollow body (6) the volume of which can be changed by adding or draining a fluid via a supply line (5), or is located adjacent to such a hollow body in such a way that the resonance volume (3) of the Helmholtz resonator (4) is changed when the volume of the hollow body (6) is changed. This apparatus makes it possible to adjust the resonance frequency of a Helmholtz resonator arranged inside a pressure container in accordance with the respective current operating point of the combustor to be damped, without having to pass movable components through the pressure container.

Owner:ANSALDO ENERGIA IP UK LTD

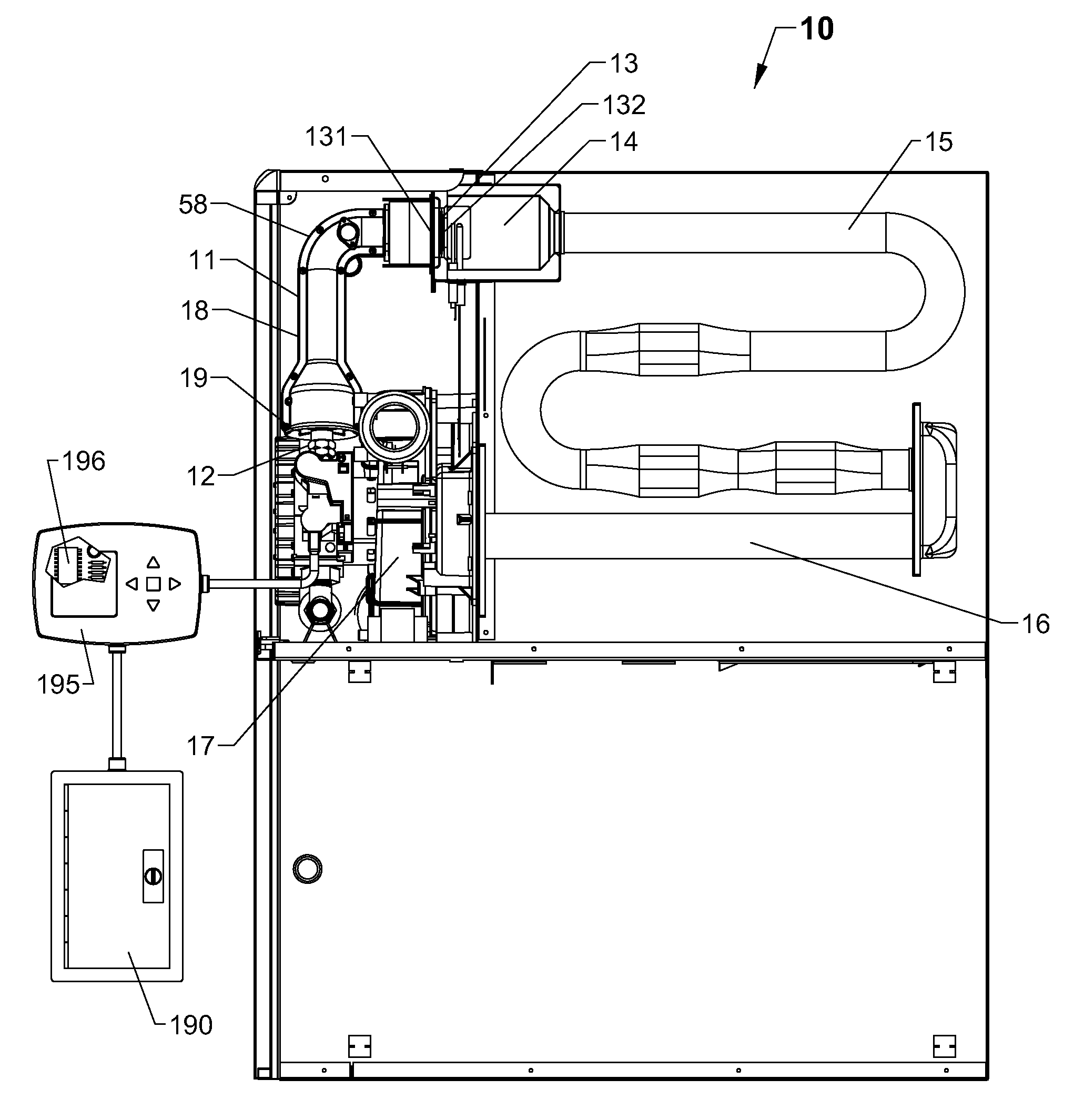

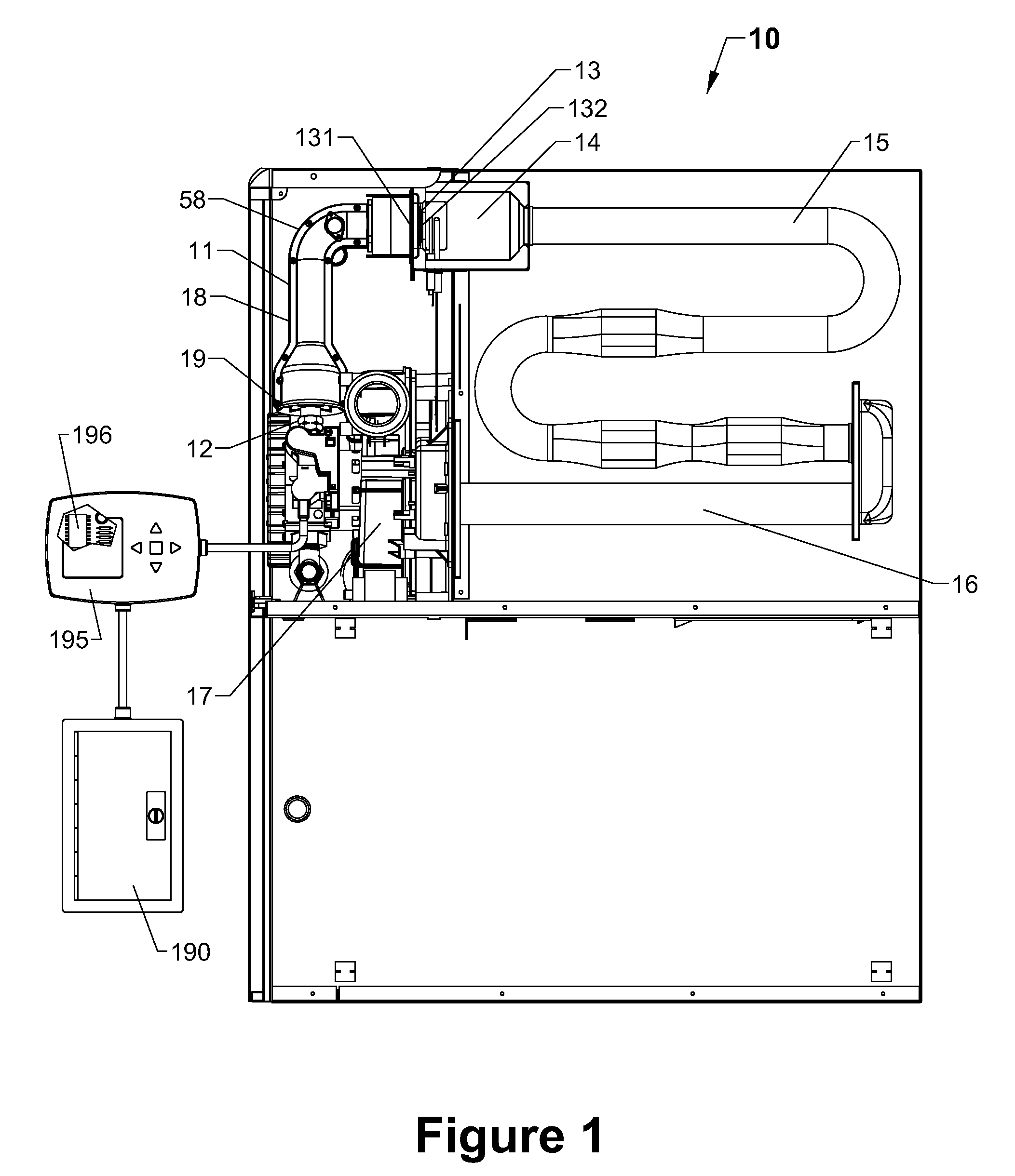

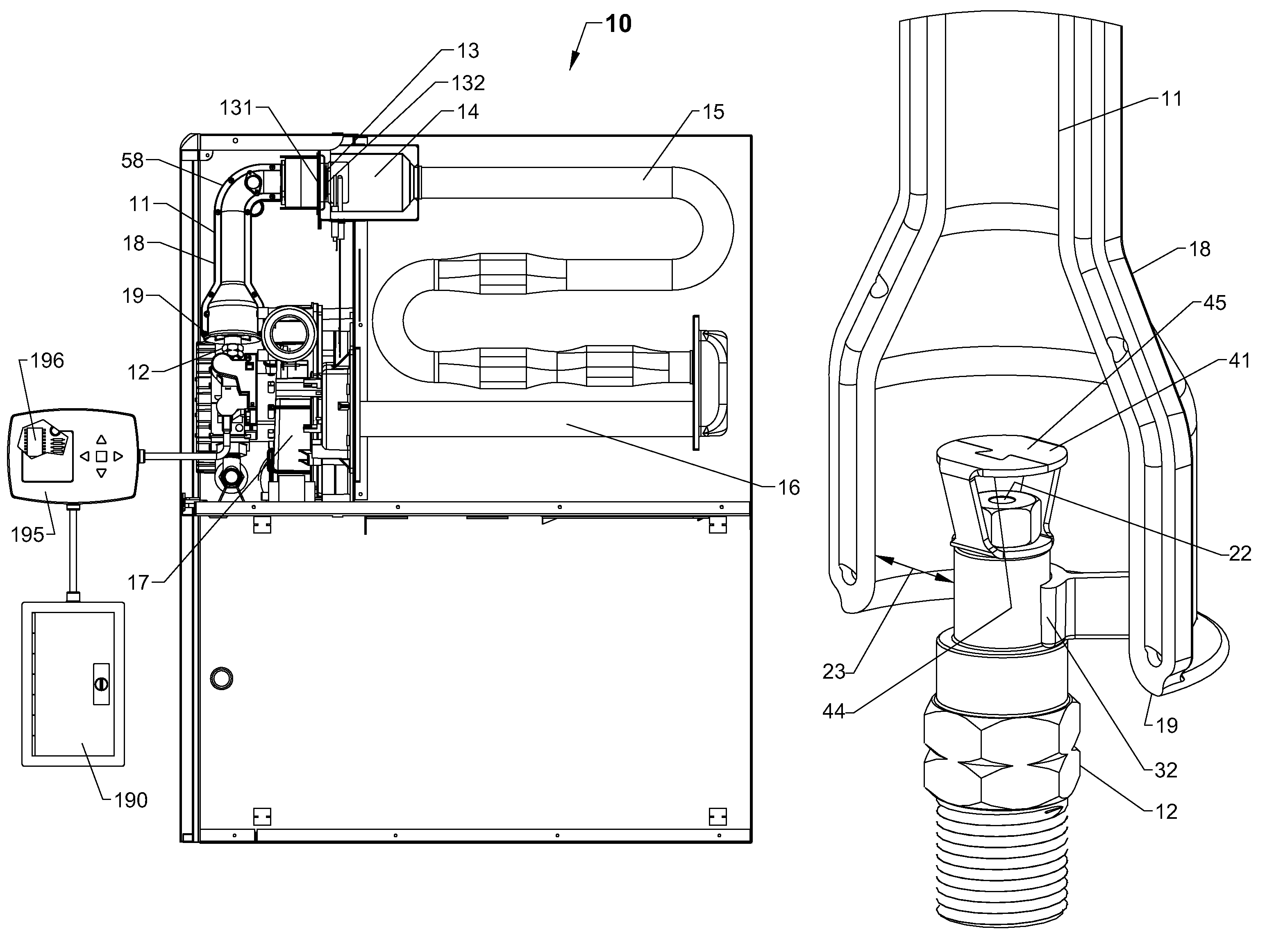

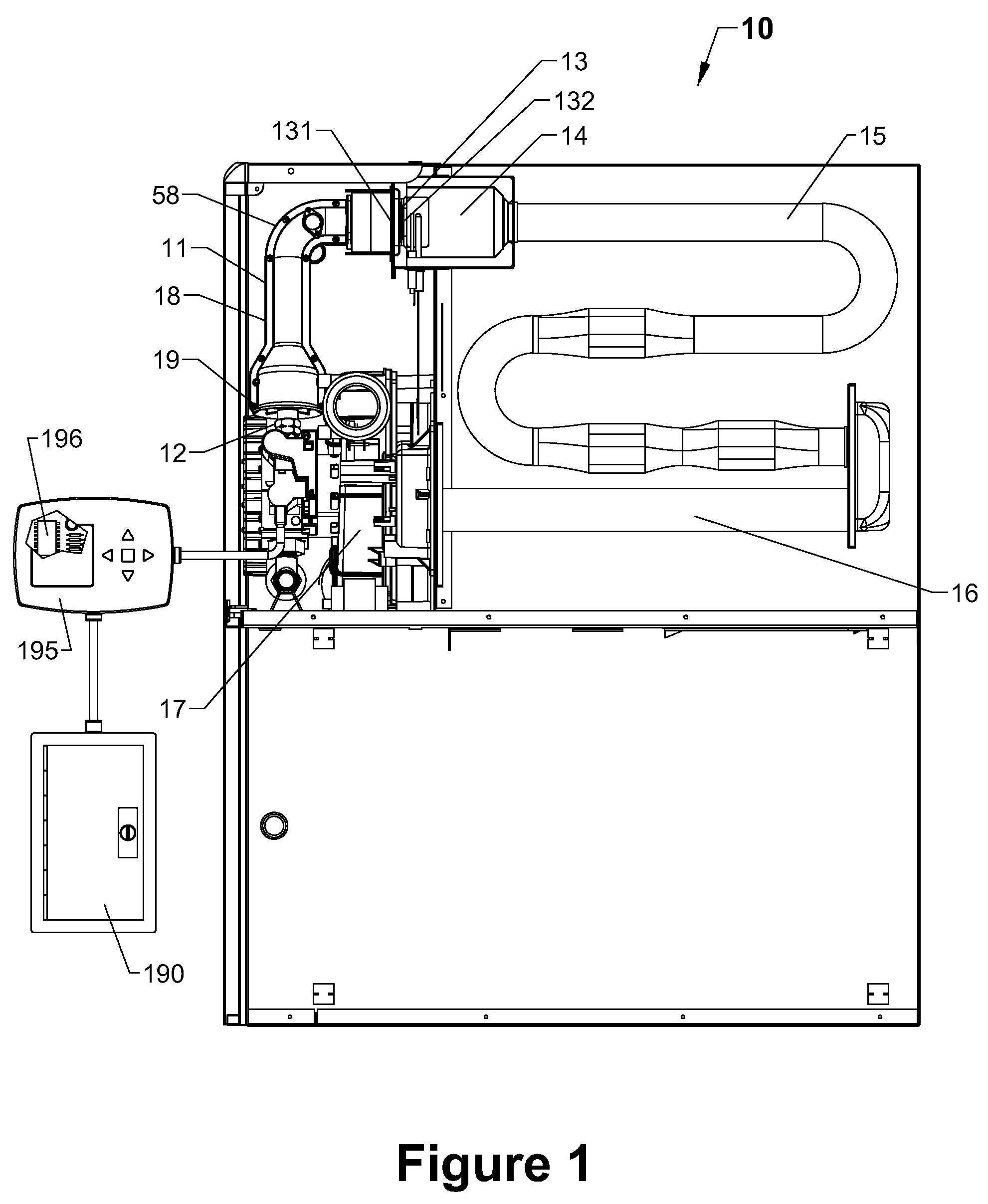

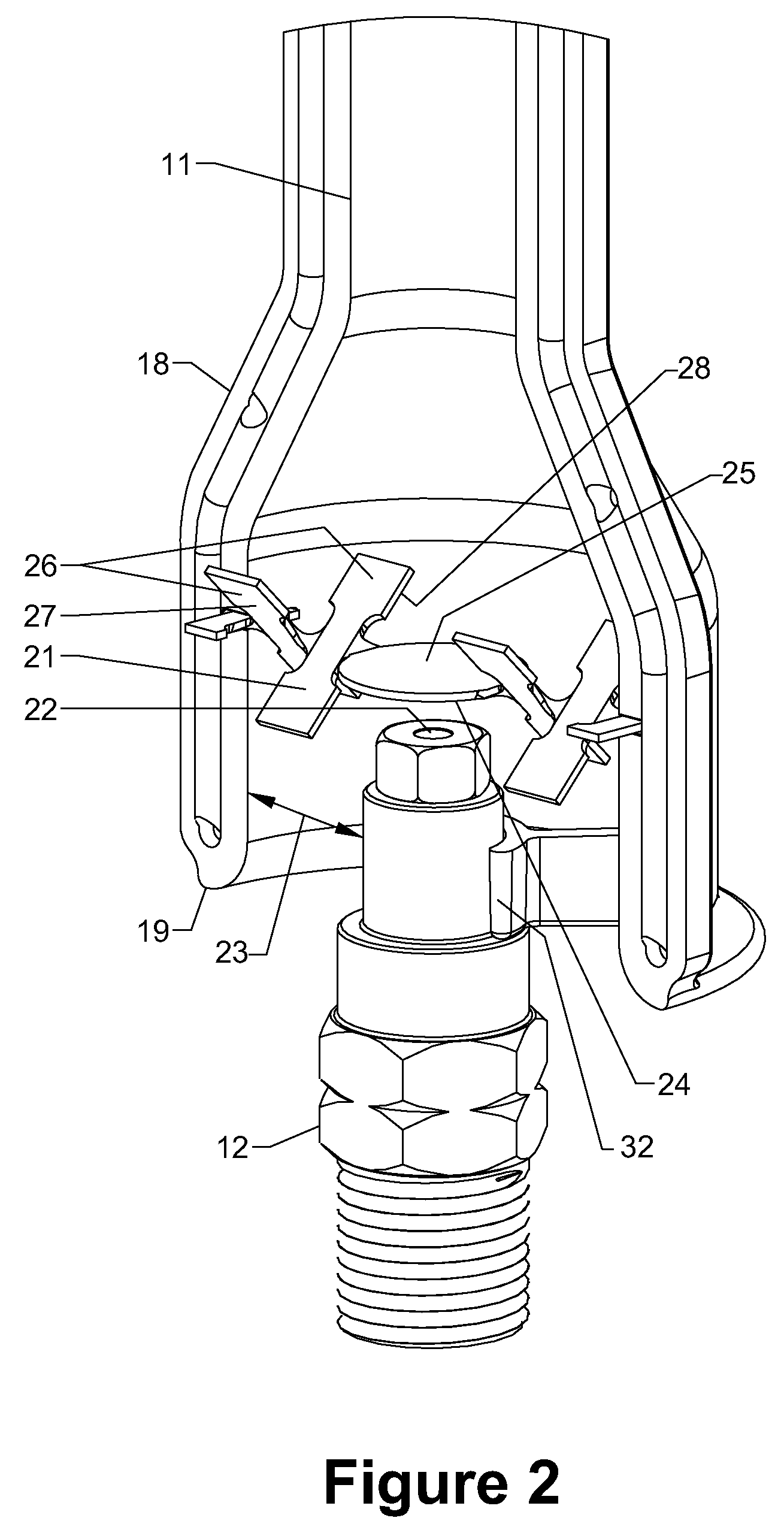

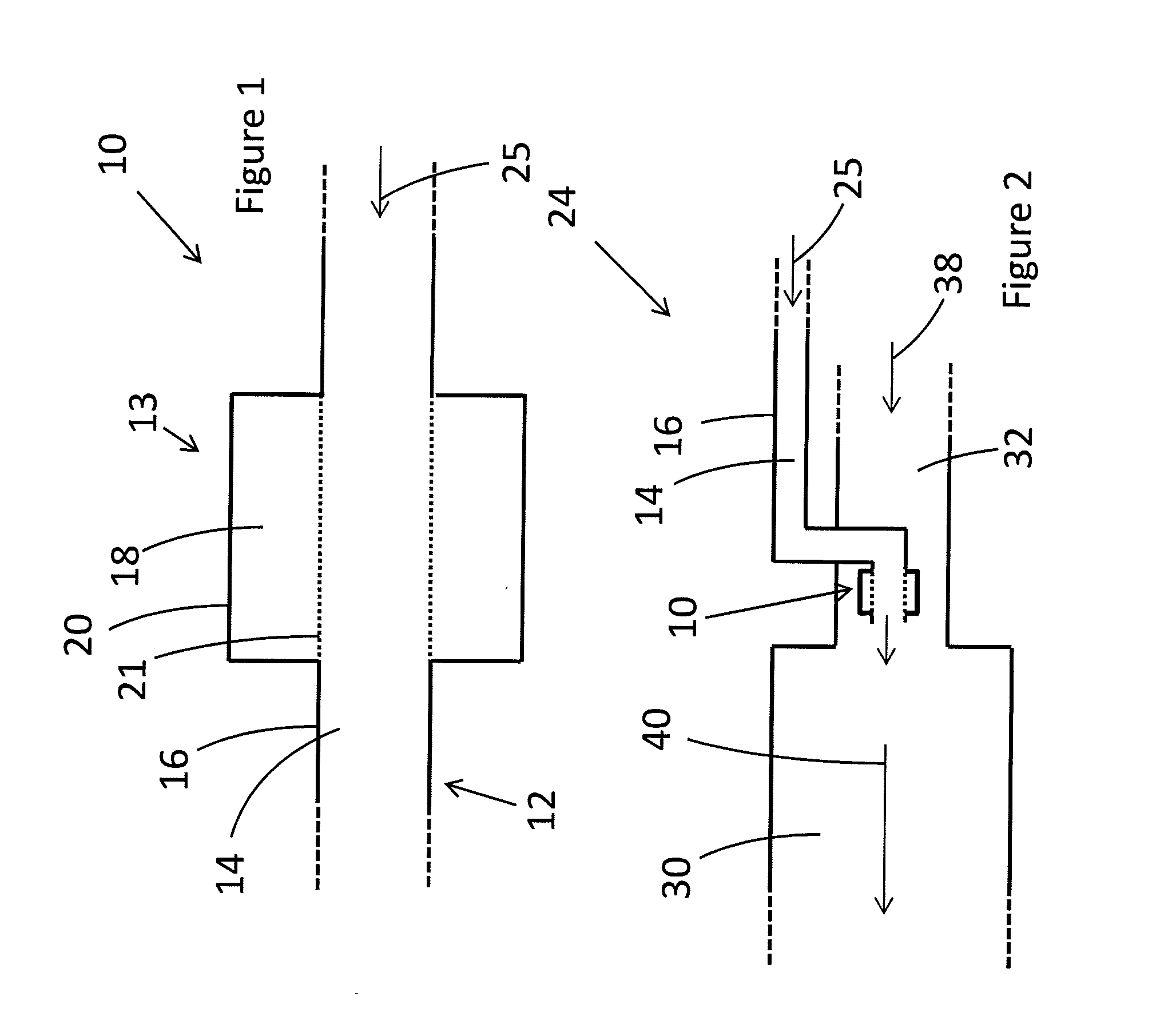

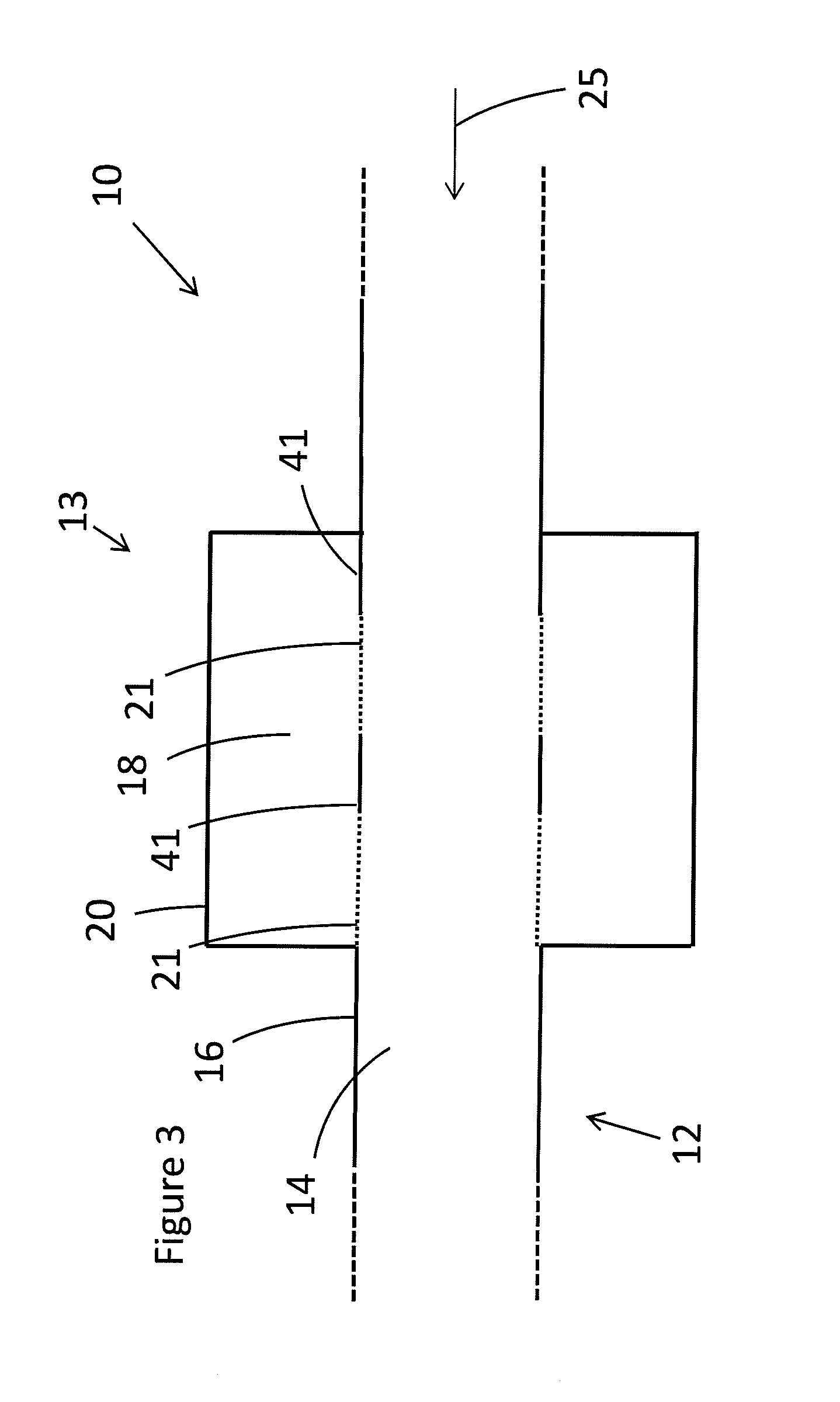

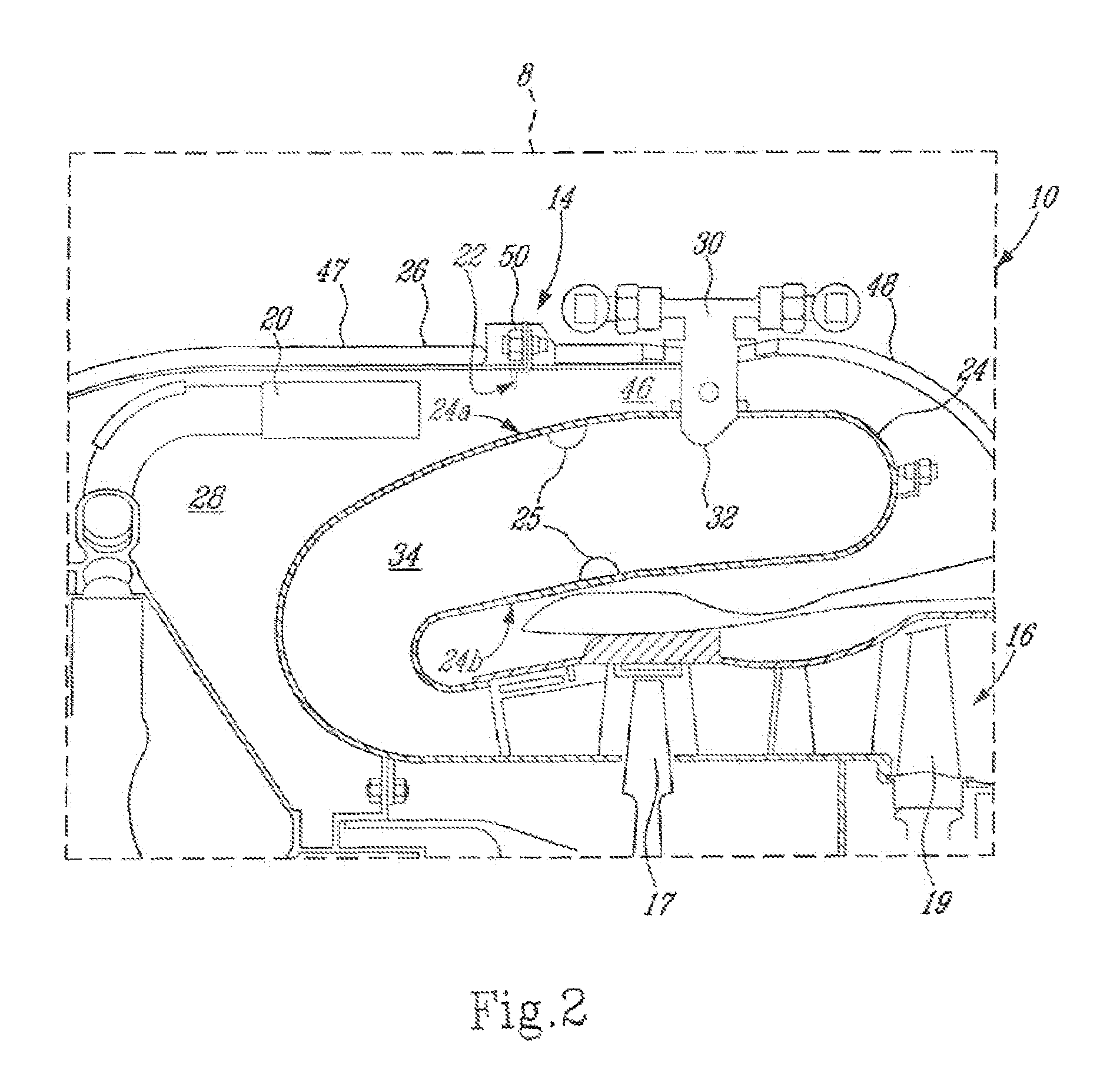

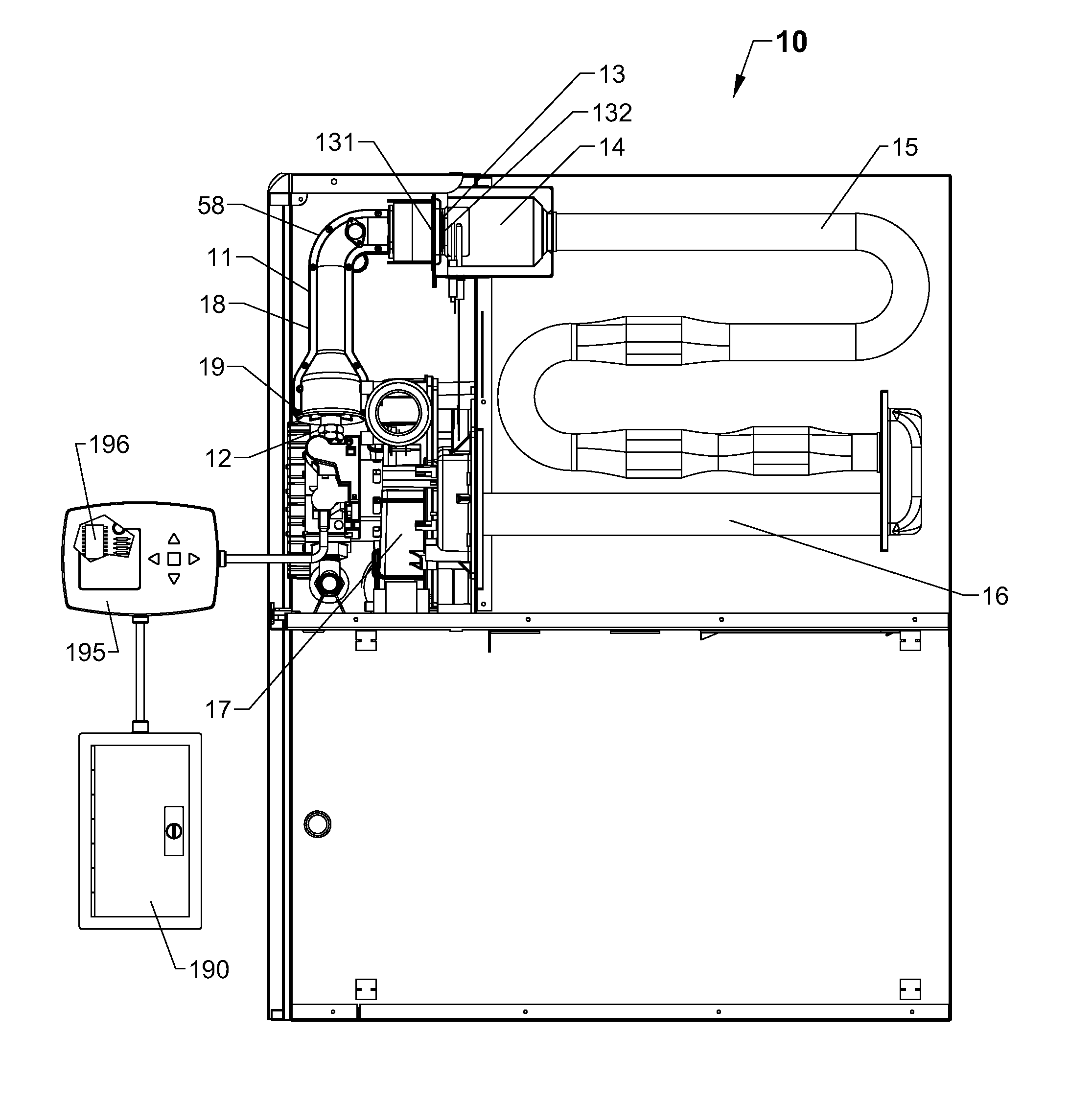

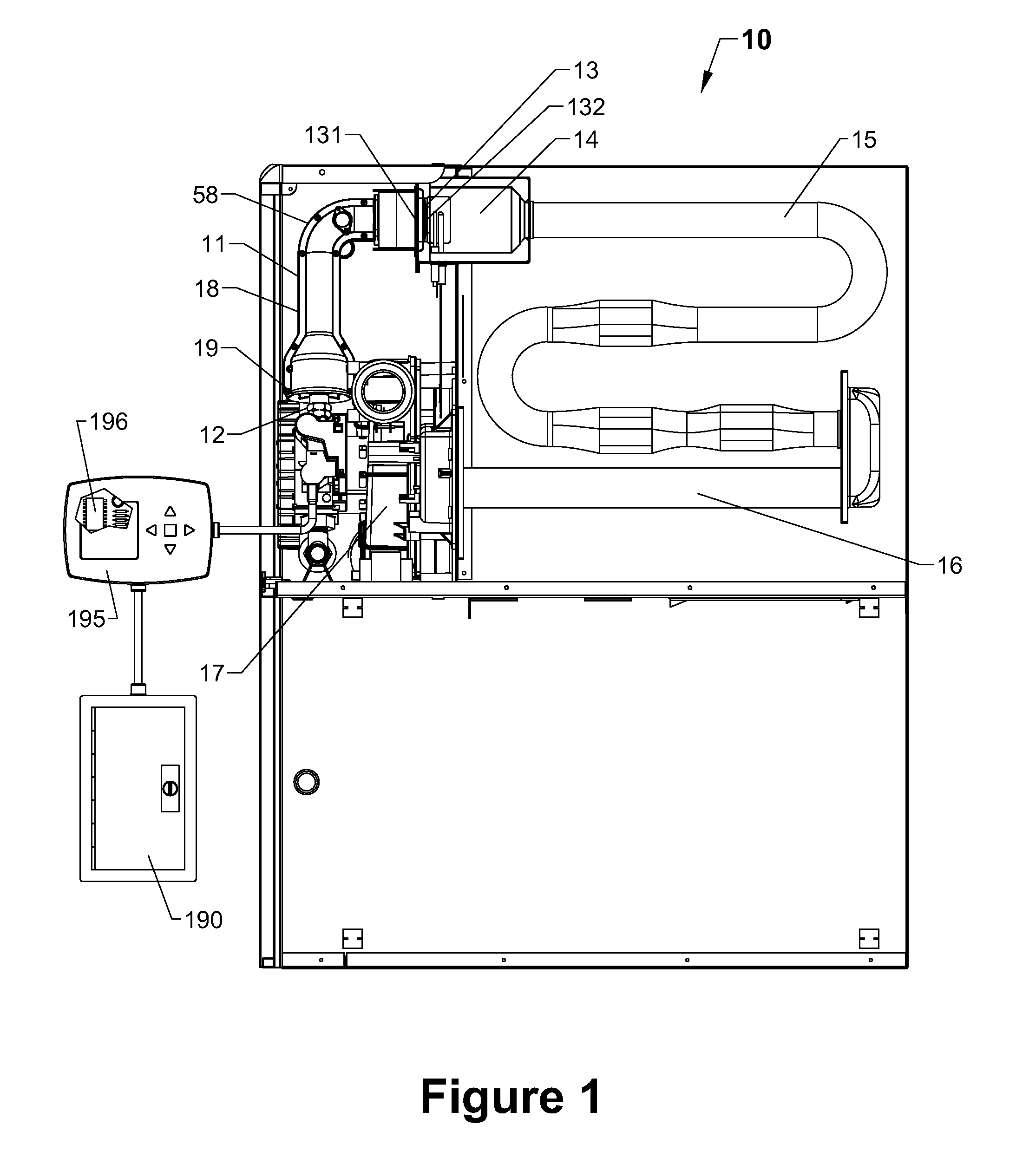

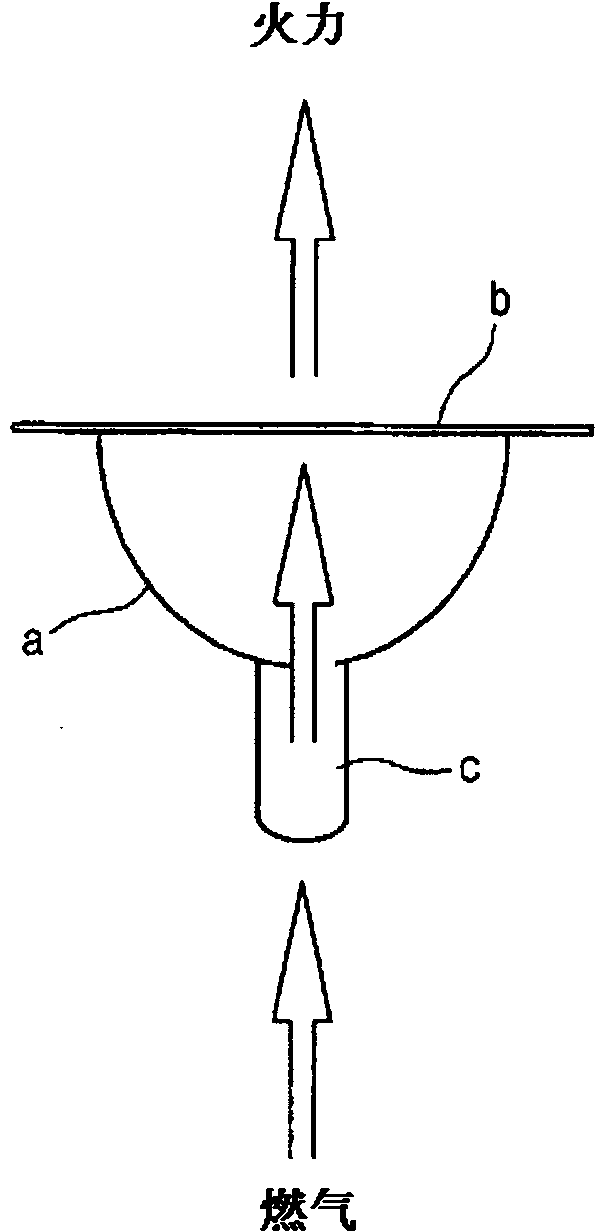

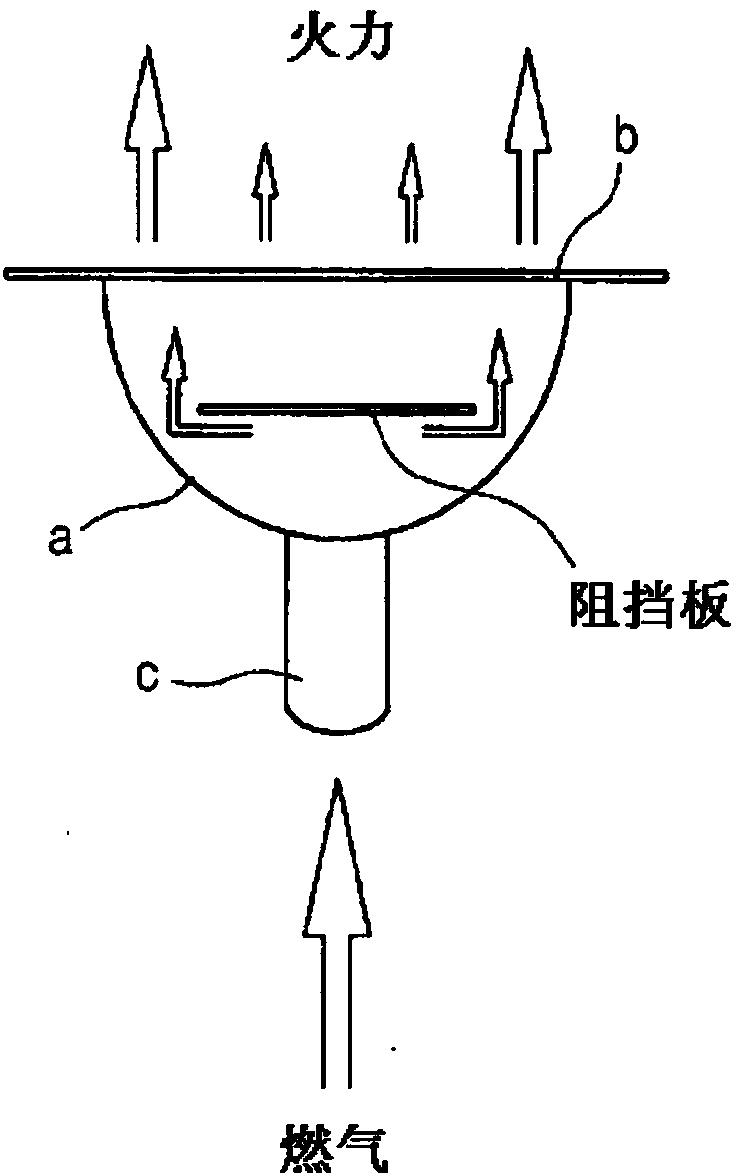

Premix furnace and methods of mixing air and fuel and improving combustion stability

ActiveUS20100310998A1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberCombustor

Premix furnace for heating an occupied space while producing lower NOx emissions and methods of mixing air and fuel delivered to a premix burner and of improving combustion stability. A mixing device may be located within an inlet tube, may have a flat surface that is perpendicular to the direction of fuel flow, or may have two surfaces held at substantially opposite angles to induce swirl. A mixing device may be attached to the fuel injector, may be made from a piece of sheet metal, and may have bends and a hole for attachment to the fuel injector. A fluidic diode in the inlet tube may improve combustion stability and may include a hollow frustum or a frustoconical portion, a cylinder concentric with the inlet tube, or a combination thereof. Some embodiments include refractory insulation lining the combustion chamber or may adjust for elevation or fuel characteristics.

Owner:NORTEK GLOBAL HVAC

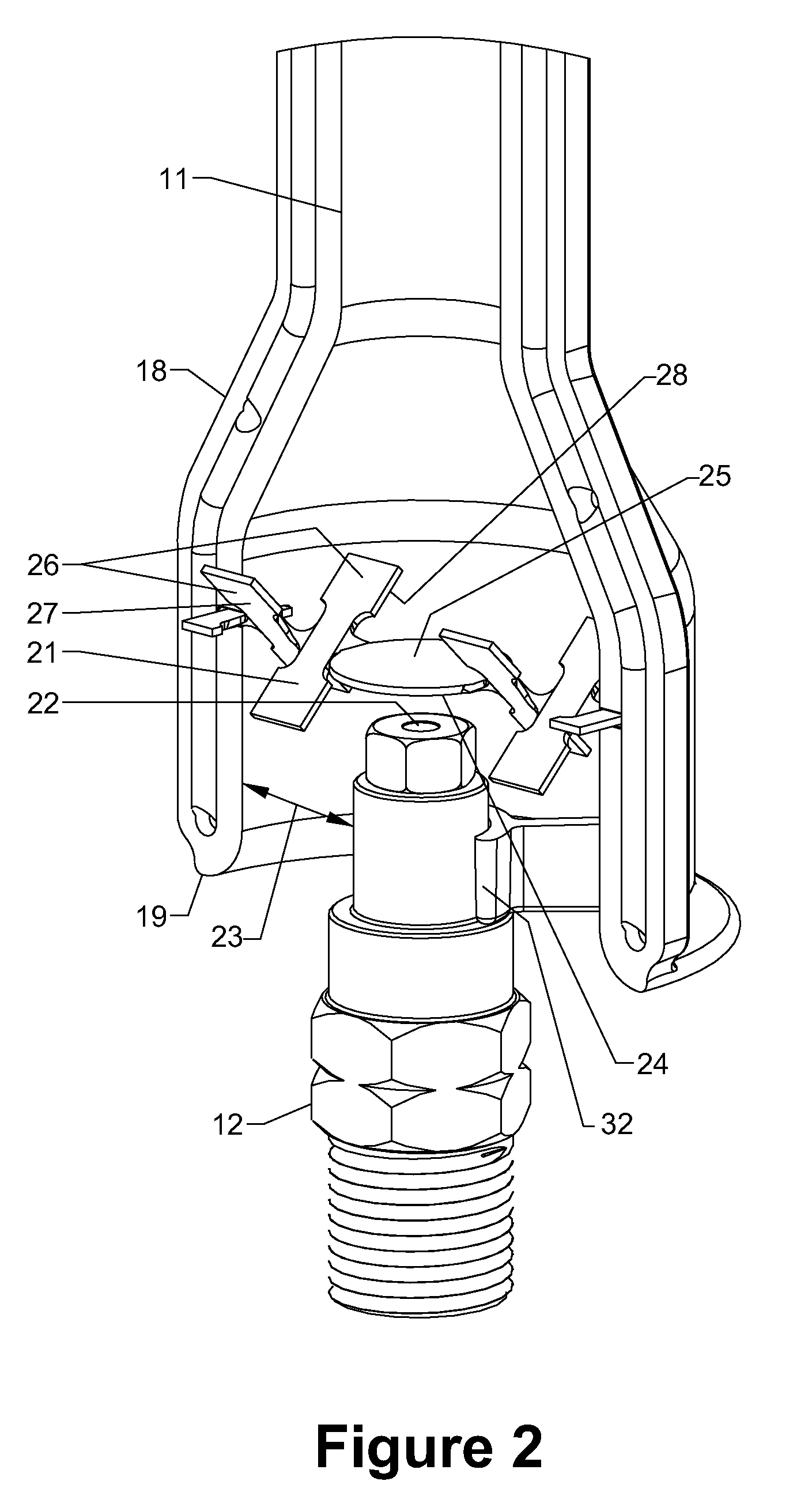

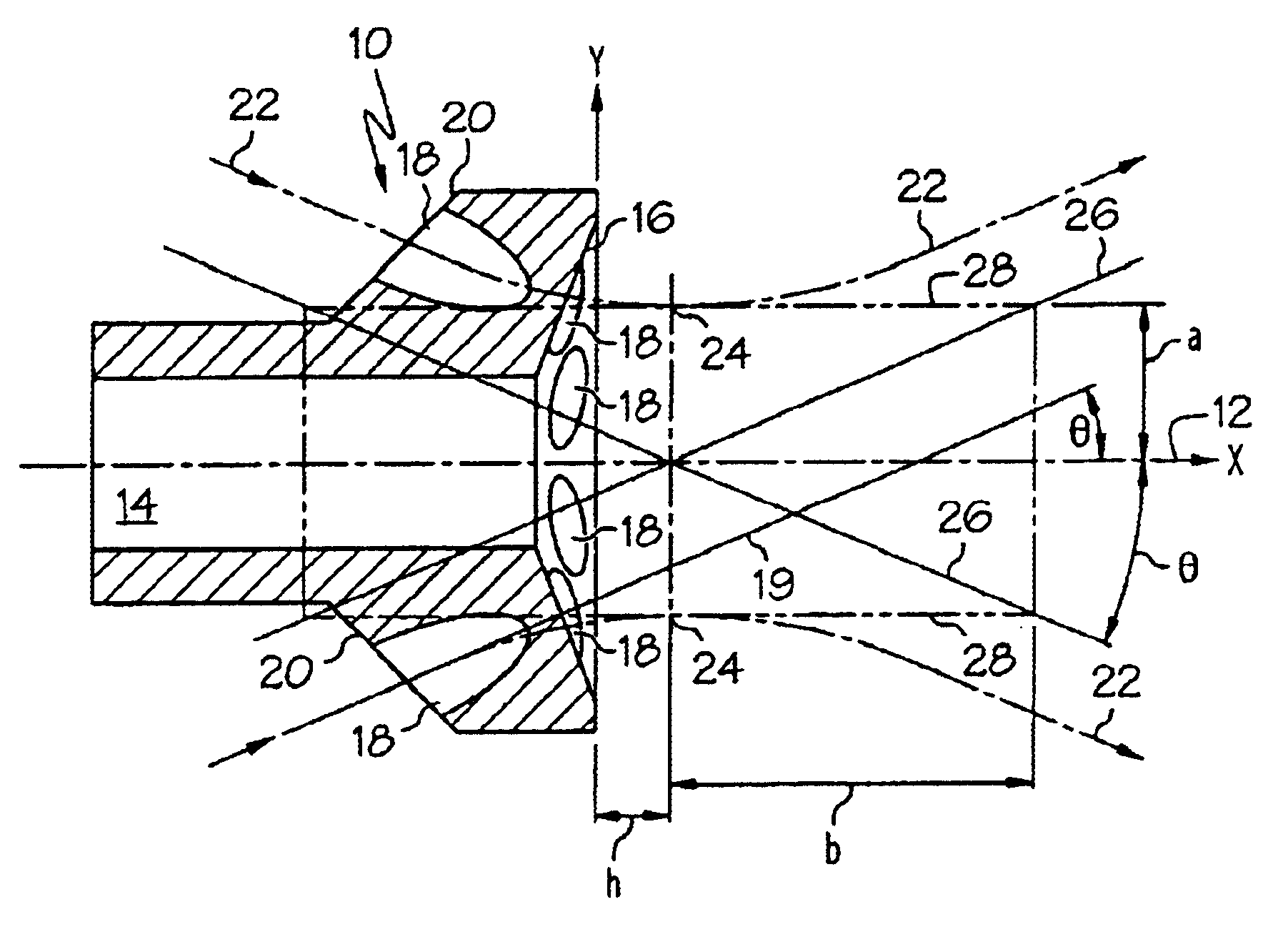

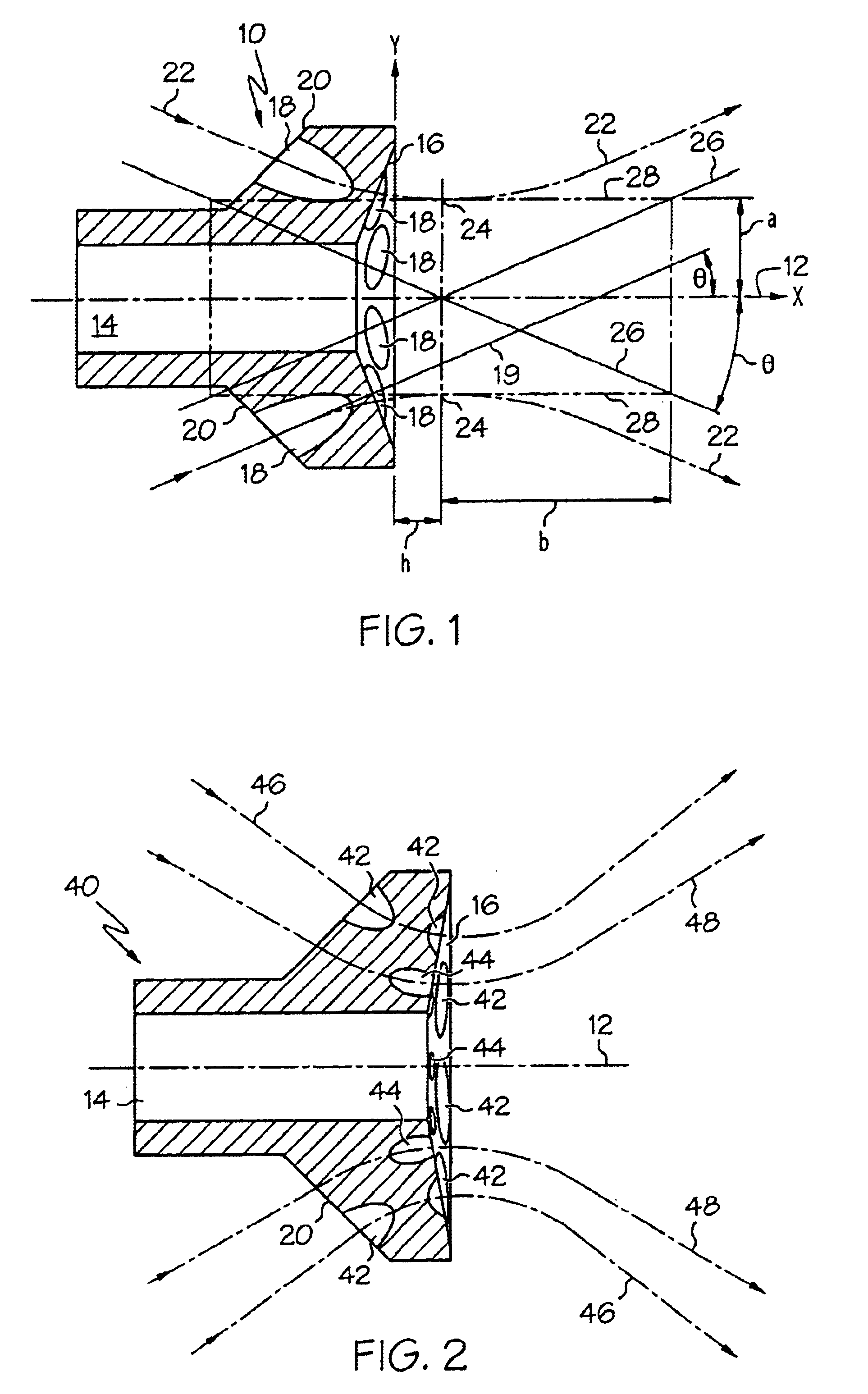

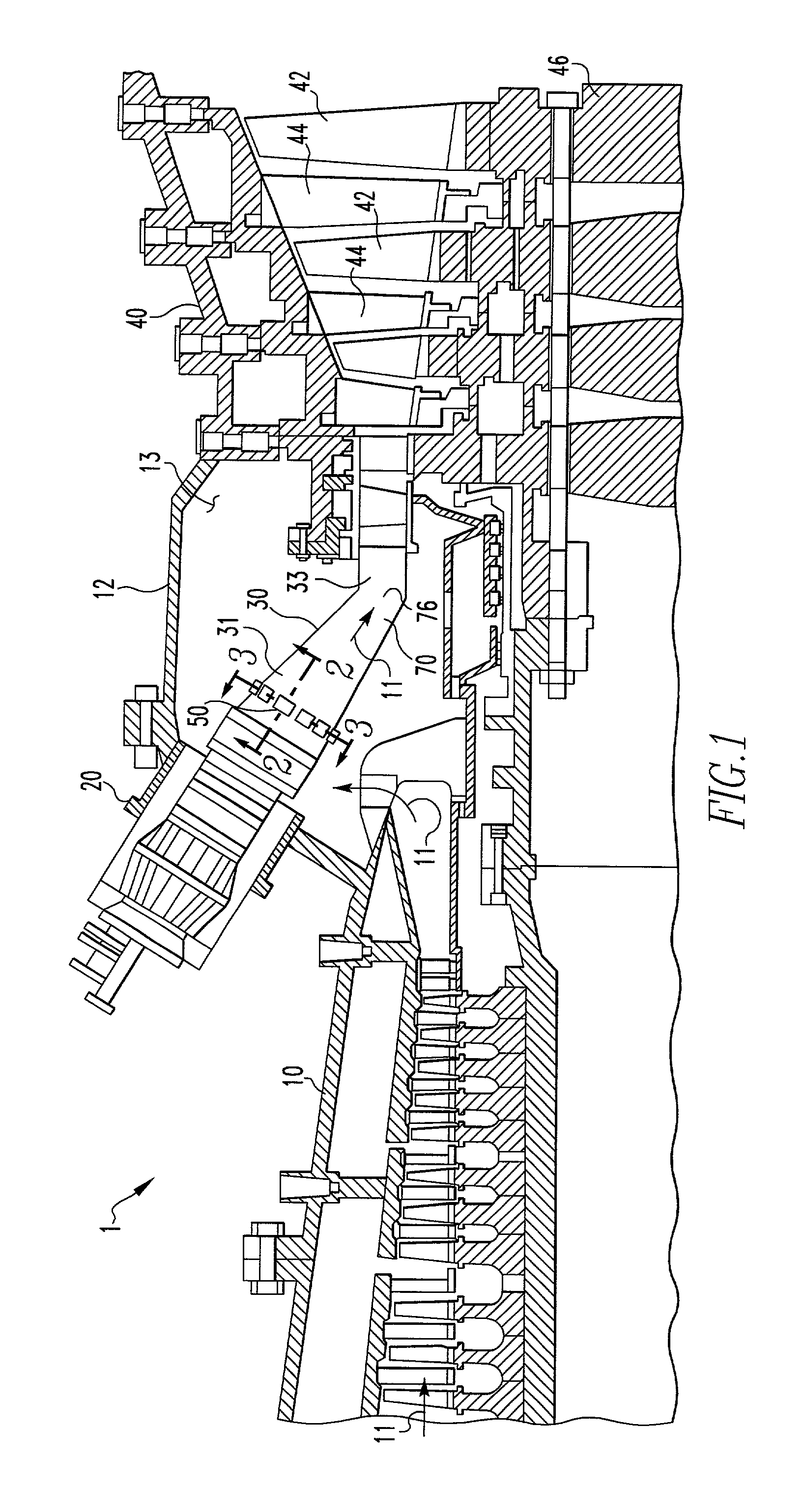

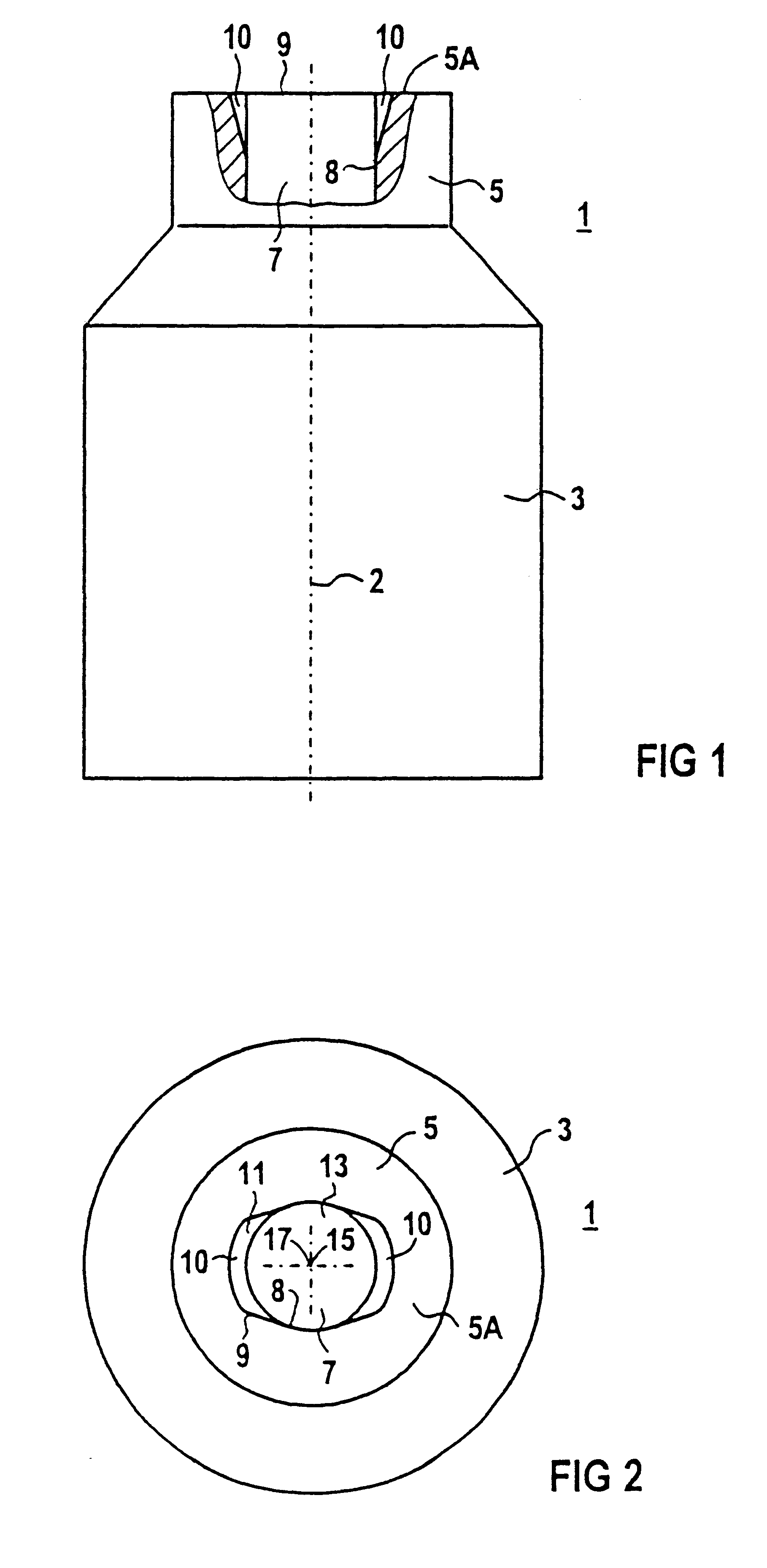

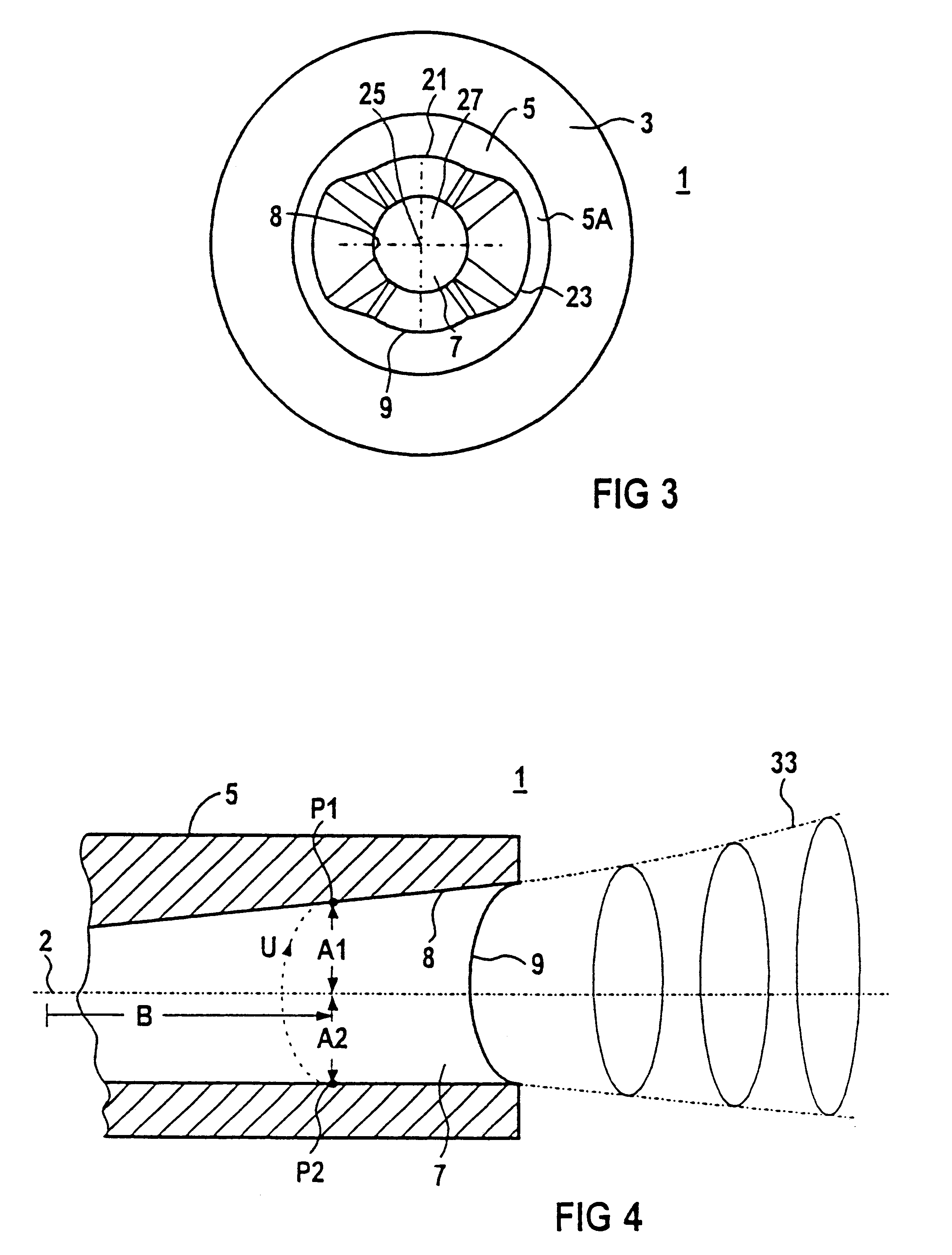

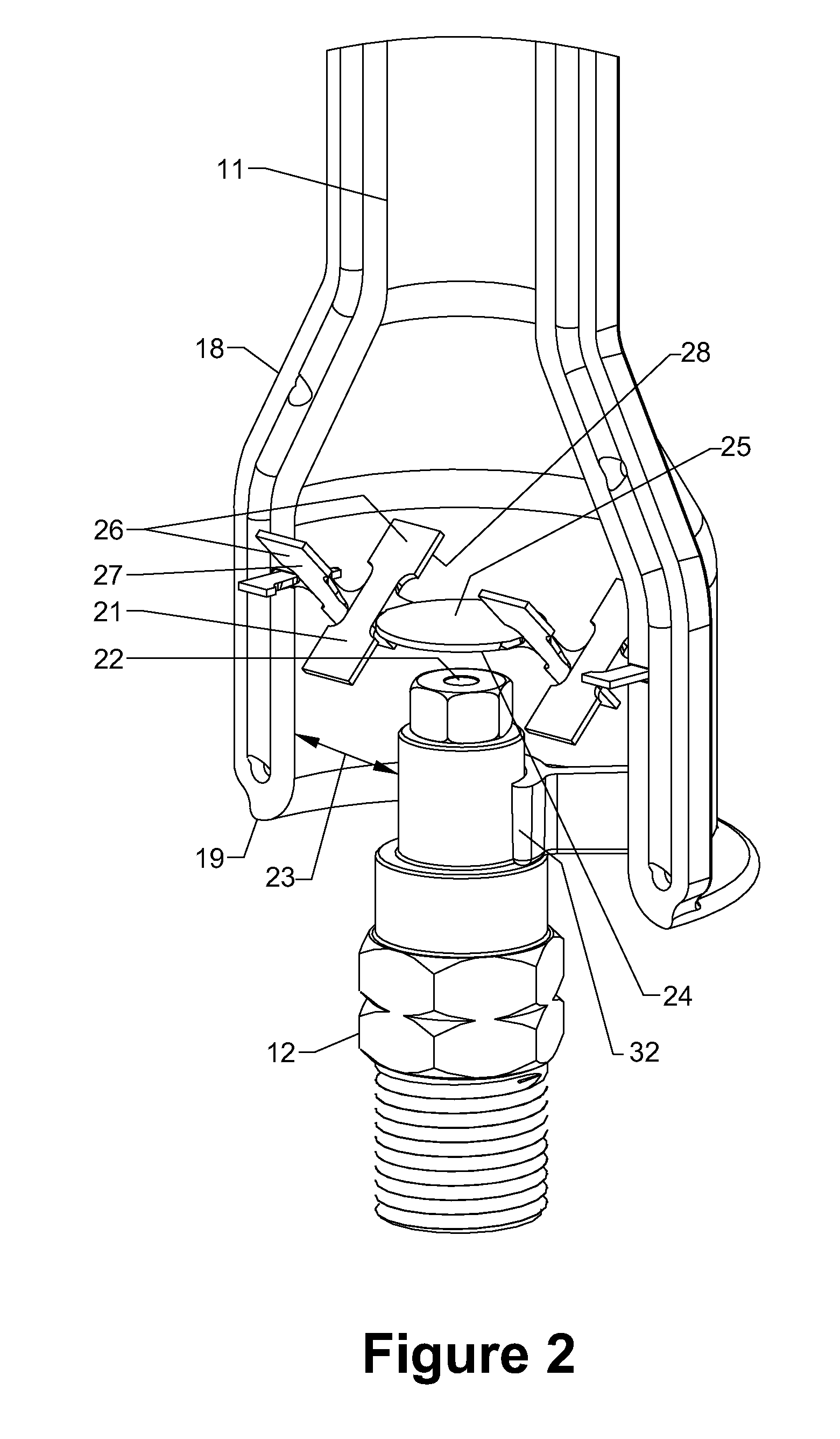

Discrete jet atomizer

InactiveUS6863228B2Reduce noiseImprove combustionContinuous combustion chamberBurner noise abatementEngineeringAirflow

An atomizer including a fuel output portion shaped to provide a fuel output and an air swirler portion shaped to direct streams of air at the fuel. The air swirler portion includes an outer opening and an inner opening located radially inwardly relative to the outer opening. The inner and outer openings are arranged such that an air stream passed through the inner opening does not intersect a conical section defined by an air stream passed through the outer opening unless both of said air streams are moving at least partially radially outwardly.

Owner:DELAVAN

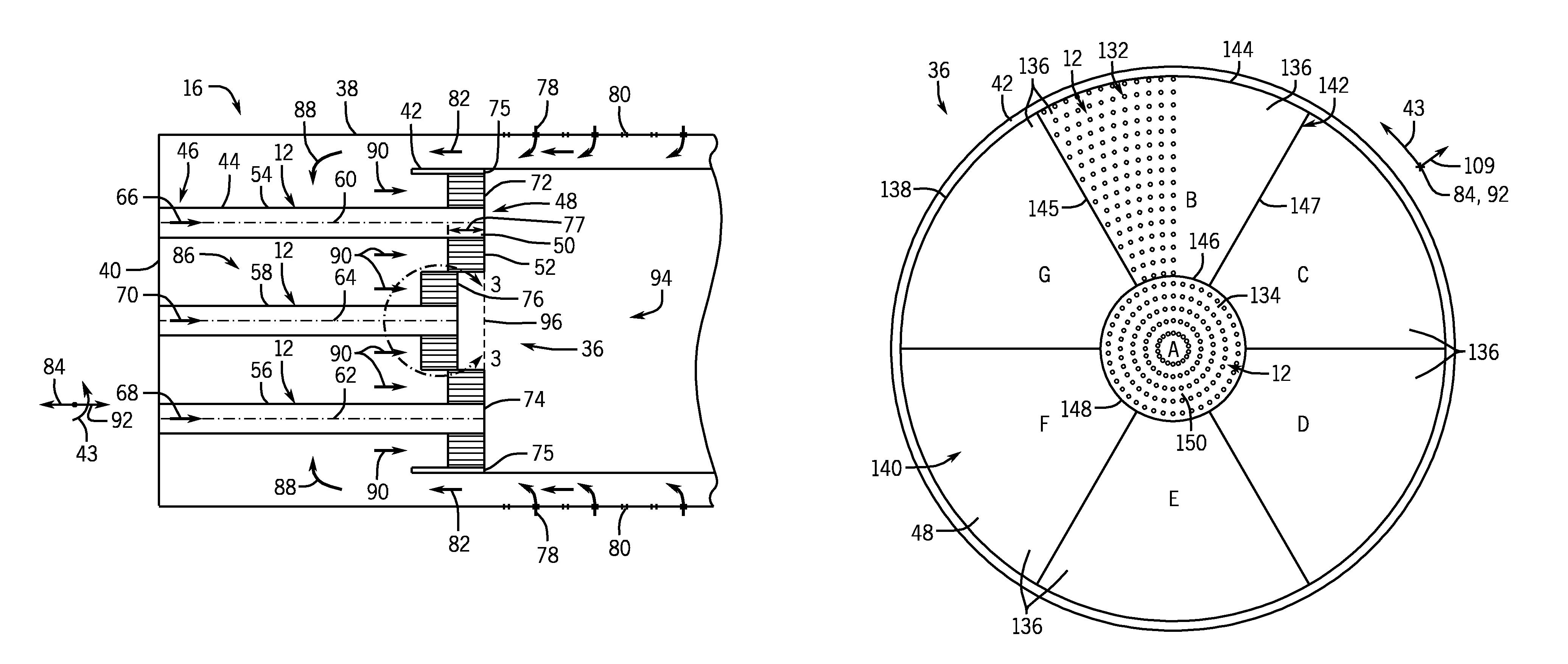

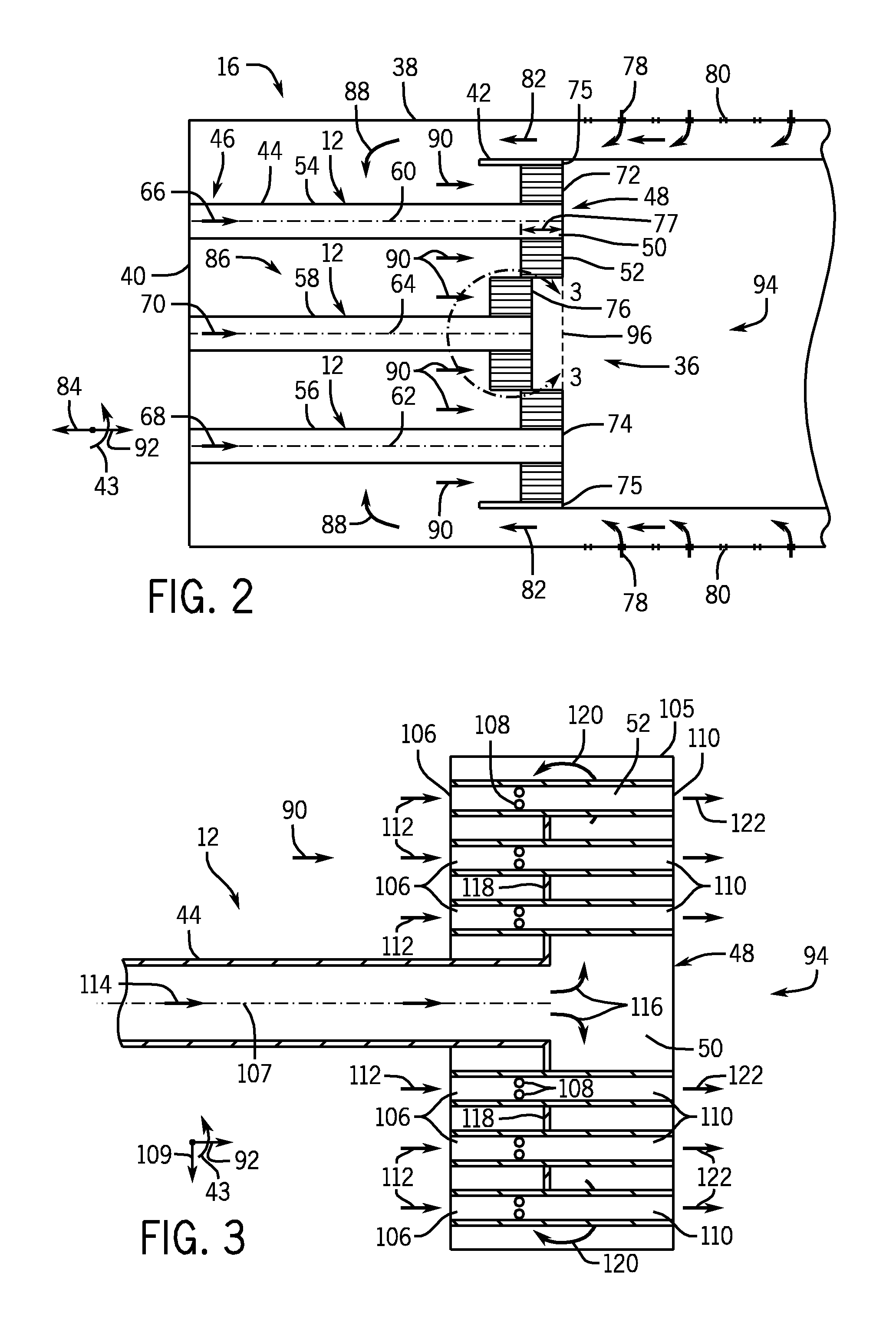

System and method for injecting fuel

According to various embodiments, a system includes a staggered multi-nozzle assembly. The staggered multi-nozzle assembly includes a first fuel nozzle having a first axis and a first flow path extending to a first downstream end portion, wherein the first fuel nozzle has a first non-circular perimeter at the first downstream end portion. The staggered multi-nozzle assembly also includes a second fuel nozzle having a second axis and a second flow path extending to a second downstream end portion, wherein the first and second downstream end portions are axially offset from one another relative to the first and second axes. The staggered multi-nozzle assembly further includes a cap member disposed circumferentially about at least the first and second fuel nozzles to assemble the staggered multi-nozzle assembly.

Owner:GENERAL ELECTRIC CO

Combustion chamber for a gas turbine

InactiveUS20050103018A1Simple adaptationAvoid disadvantagesBurnersContinuous combustion chamberCombustion chamberControl theory

At least one Helmholtz damper is arranged at a combustion chamber for a gas turbine in order to damp thermoacoustic oscillations; the damping volume of this Helmholtz damper is in communication with the combustion chamber via a connecting passage. Optimum damping is achieved in a simple way by virtue of the Helmholtz damper being designed in such a manner that its damping frequency is adjustable.

Owner:ANSALDO ENERGIA IP UK LTD

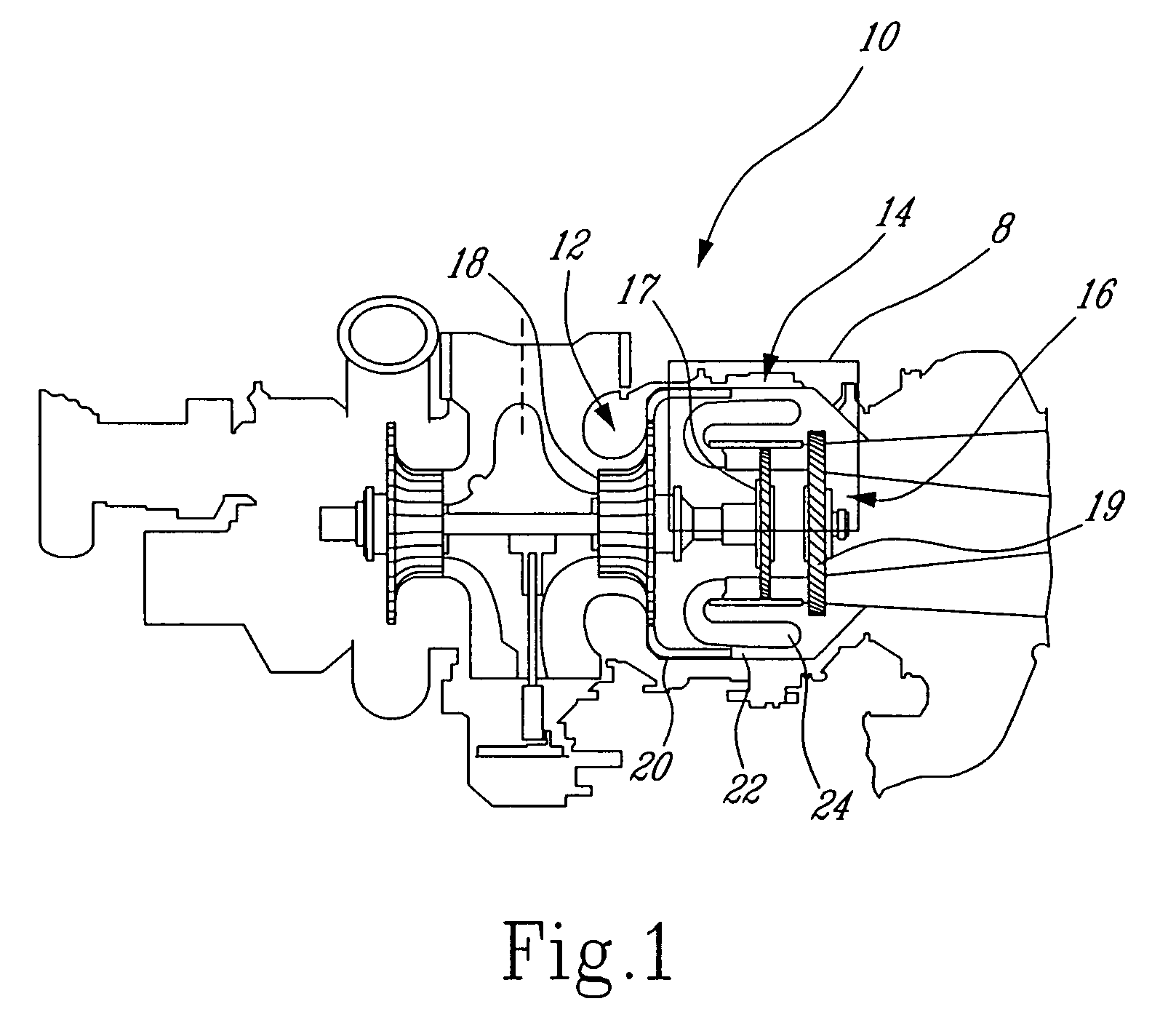

Gas turbine combustor, gas turbine, and jet engine

InactiveUS6973790B2Avoid resonanceReduce oscillationBurnersContinuous combustion chamberJet engineCombustor

For the purpose of reduced NOx gas emission, a gas turbine engine comprises a cylinder having a combustion region inside of the cylinder; a resonator having a cavity and provided around the surface of the cylinder and sound absorption holes formed on the cylinder and having opening ends on the cylinder.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Combustion chamber for a gas turbine

InactiveUS7331182B2Simple adaptationAvoid disadvantagesBurnersContinuous combustion chamberCombustion chamberControl theory

At least one Helmholtz damper is arranged at a combustion chamber for a gas turbine in order to damp thermoacoustic oscillations; the damping volume of this Helmholtz damper is in communication with the combustion chamber via a connecting passage. Optimum damping is achieved in a simple way by virtue of the Helmholtz damper being designed in such a manner that its damping frequency is adjustable.

Owner:ANSALDO ENERGIA IP UK LTD

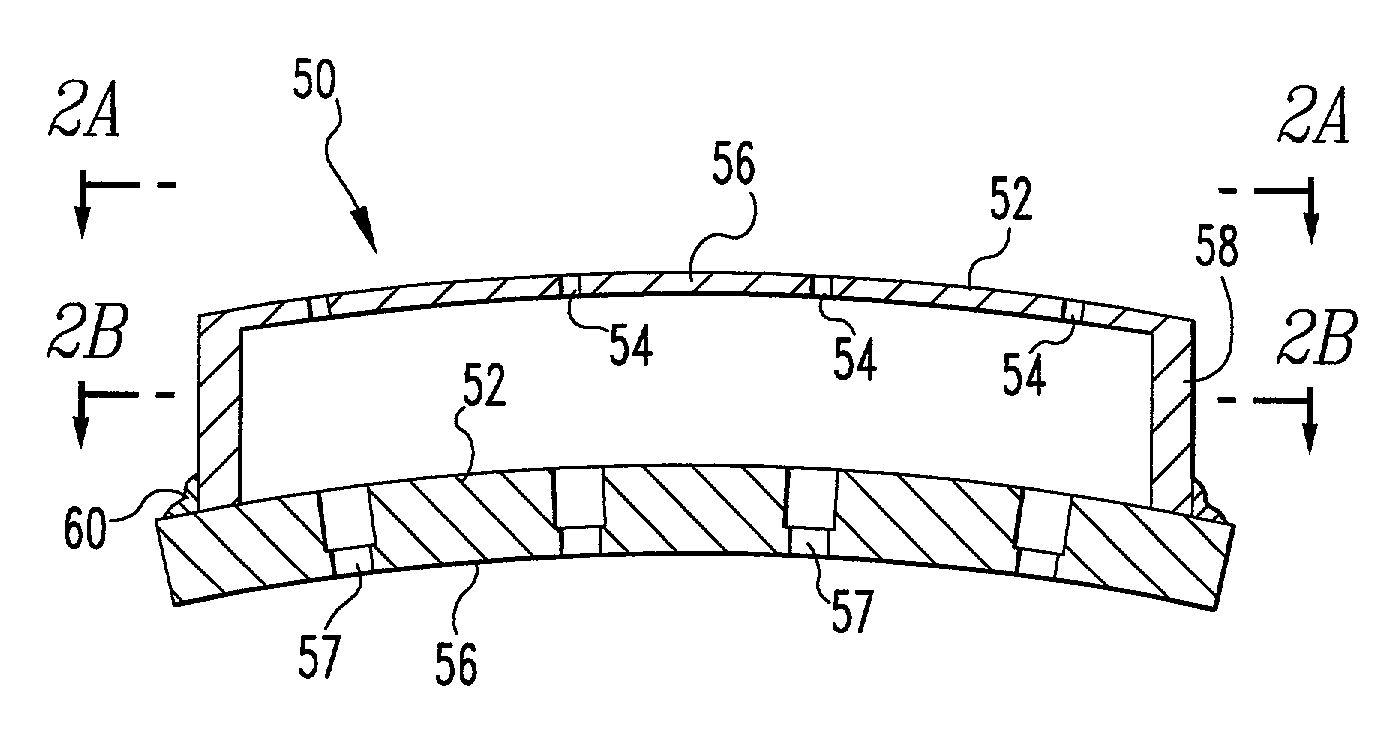

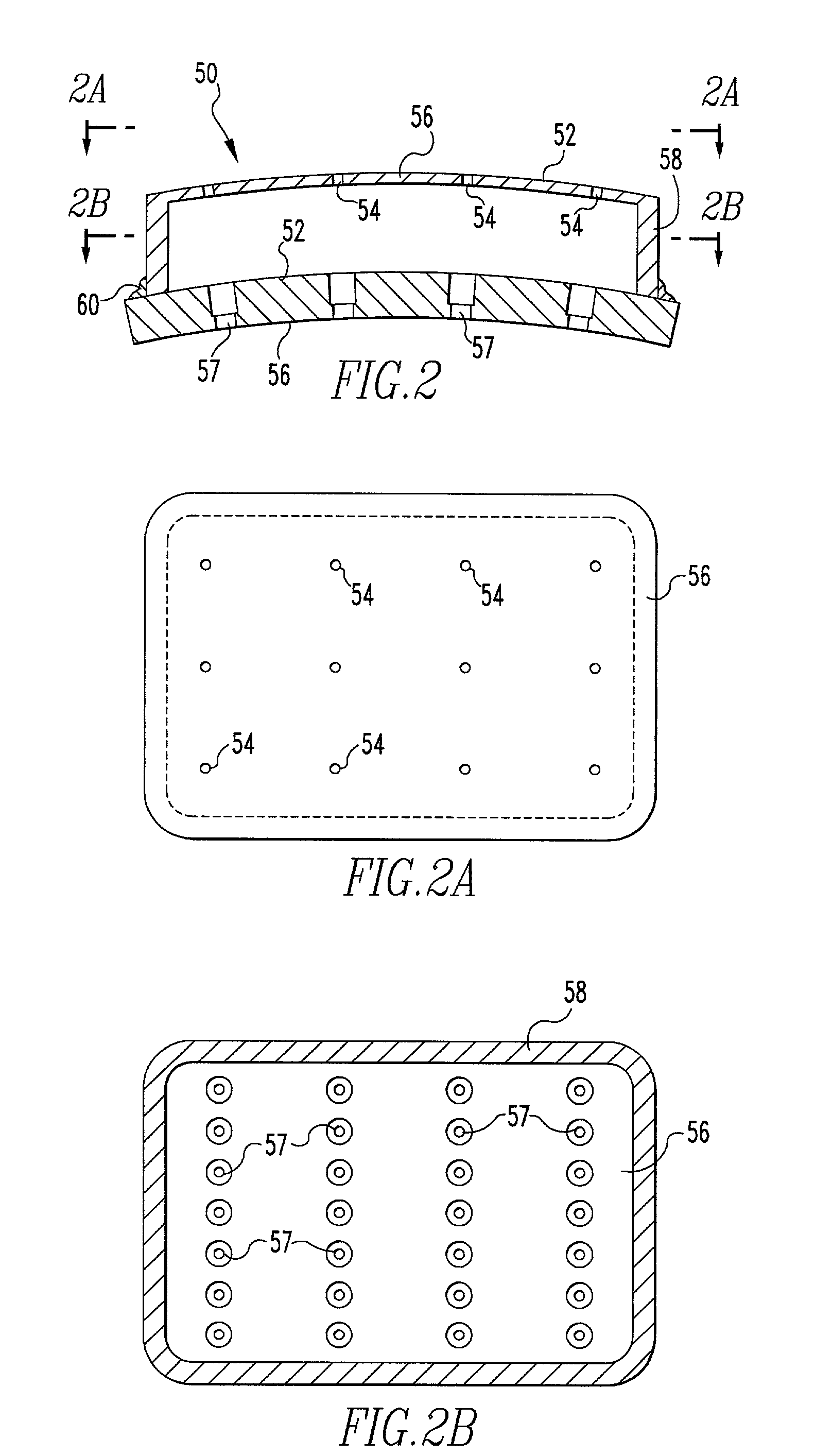

Resonator adopting counter-bored holes and method of suppressing combustion instabilities

InactiveUS7194862B2Add additional massSuppress energyBurnersContinuous combustion chamberCombustion instabilityCombustion

A resonator for damping pressure waves or instabilities in a system supported by acoustic energy wherein the resonator adopts the use of counter-bored openings on the downstream side of the resonator within the flow path of the system. The resonator includes a first member and a second member where the second member includes a plurality of openings therethrough with each hole having a counter-bore on its upstream side. The first member has a size substantially smaller than the diameter of said flow path and a first plurality of openings therethrough. The openings are in fluid communication with the flow path. The second member has a size generally equal to the first member and a second plurality of openings therethrough, which openings are in fluid communication with the flow path.

Owner:SIEMENS ENERGY INC

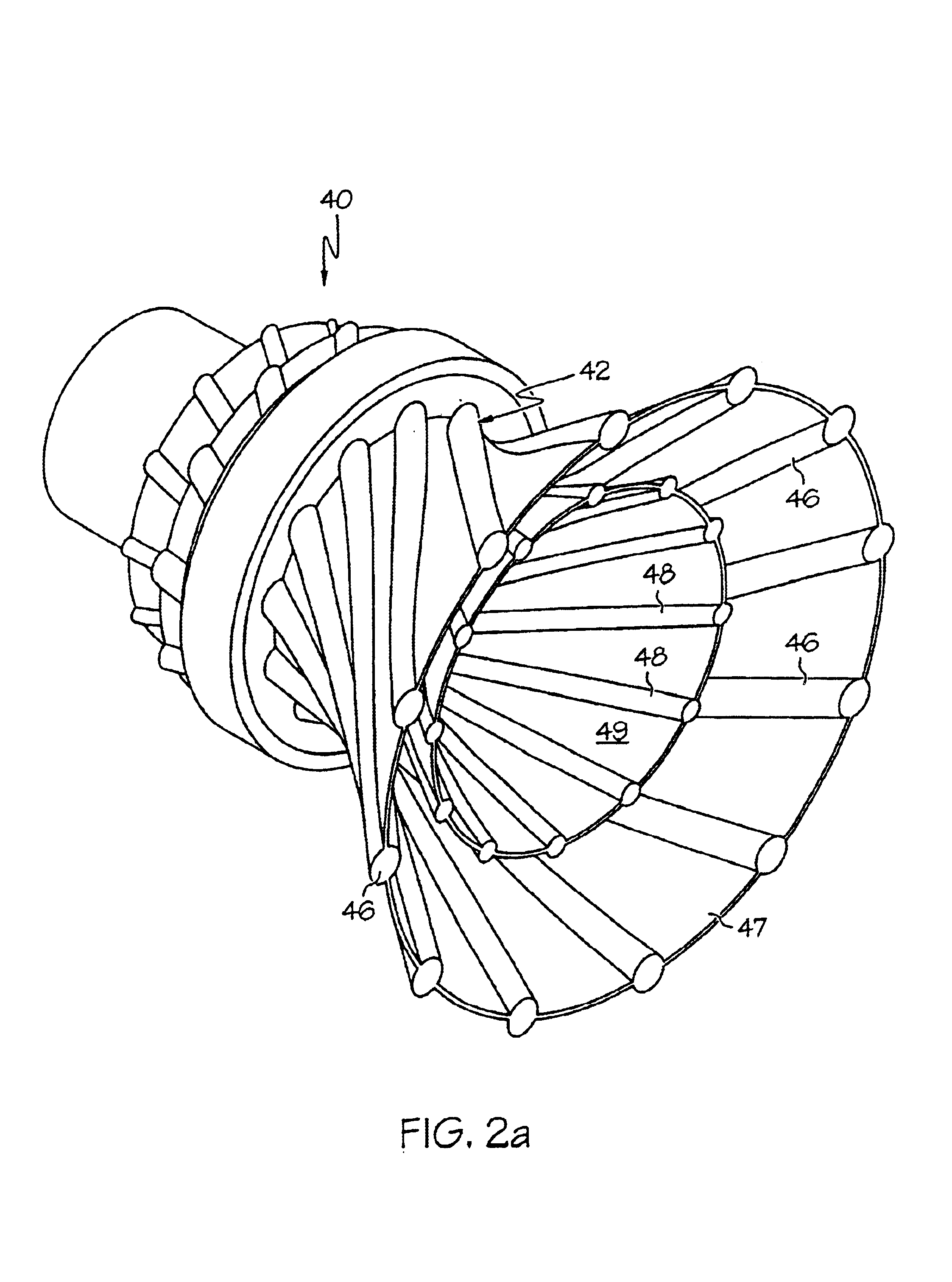

System and method for injecting fuel

ActiveUS20120180495A1Reduce the amplitudeBurnersTurbine/propulsion fuel supply systemsSpray nozzleMechanical engineering

According to various embodiments, a system includes a staggered multi-nozzle assembly. The staggered multi-nozzle assembly includes a first fuel nozzle having a first axis and a first flow path extending to a first downstream end portion, wherein the first fuel nozzle has a first non-circular perimeter at the first downstream end portion. The staggered multi-nozzle assembly also includes a second fuel nozzle having a second axis and a second flow path extending to a second downstream end portion, wherein the first and second downstream end portions are axially offset from one another relative to the first and second axes. The staggered multi-nozzle assembly further includes a cap member disposed circumferentially about at least the first and second fuel nozzles to assemble the staggered multi-nozzle assembly.

Owner:GENERAL ELECTRIC CO

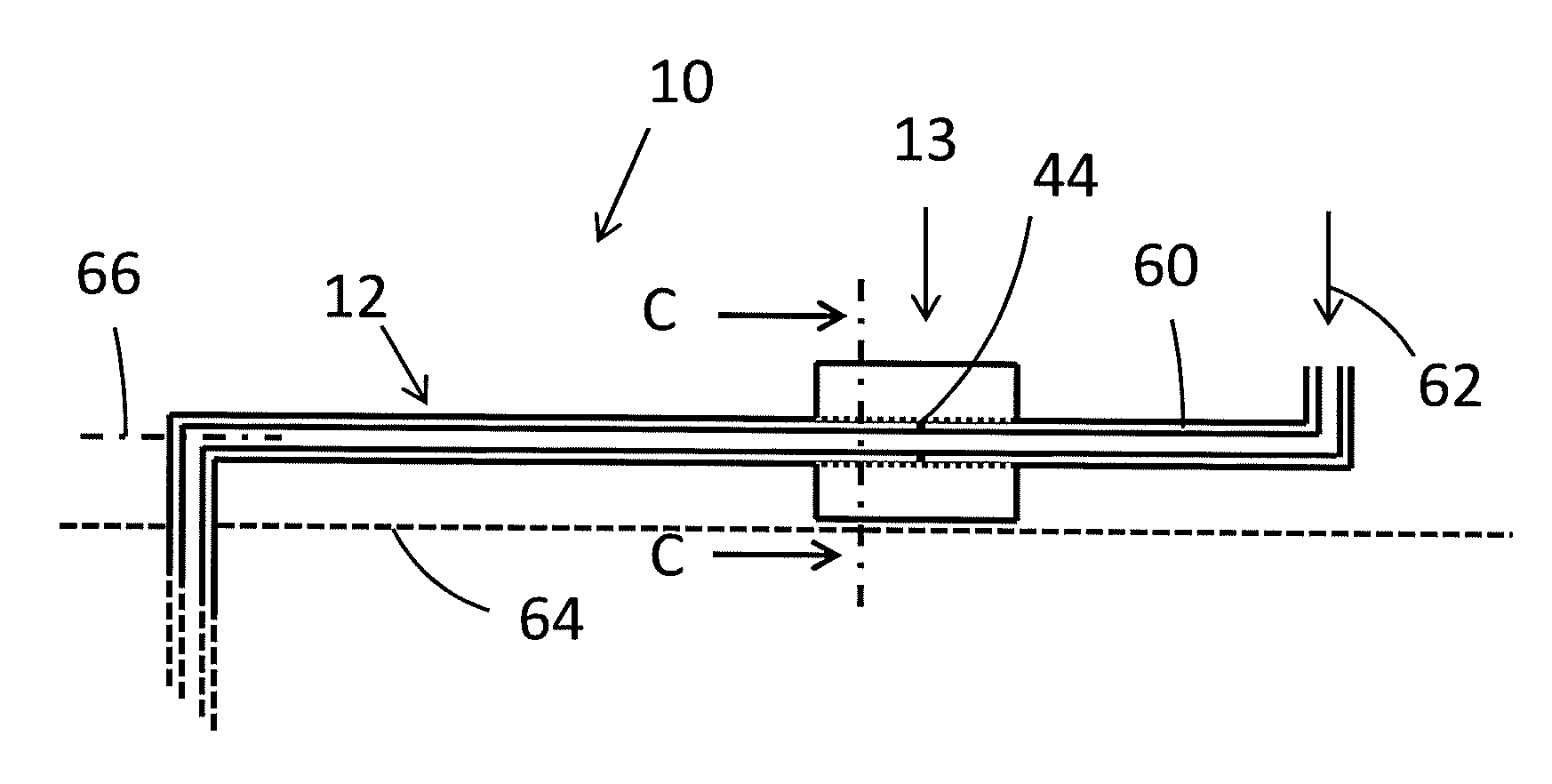

Premix furnace and methods of mixing air and fuel and improving combustion stability

ActiveUS8167610B2Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

Premix furnace for heating an occupied space while producing lower NOx emissions and methods of mixing air and fuel delivered to a premix burner and of improving combustion stability. A mixing device may be located within an inlet tube, may have a flat surface that is perpendicular to the direction of fuel flow, or may have two surfaces held at substantially opposite angles to induce swirl. A mixing device may be attached to the fuel injector, may be made from a piece of sheet metal, and may have bends and a hole for attachment to the fuel injector. A fluidic diode in the inlet tube may improve combustion stability and may include a hollow frustum or a frustoconical portion, a cylinder concentric with the inlet tube, or a combination thereof. Some embodiments include refractory insulation lining the combustion chamber or may adjust for elevation or fuel characteristics.

Owner:NORTEK GLOBAL HVAC

Combustion chamber for a gas turbine with at least two resonator devices

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

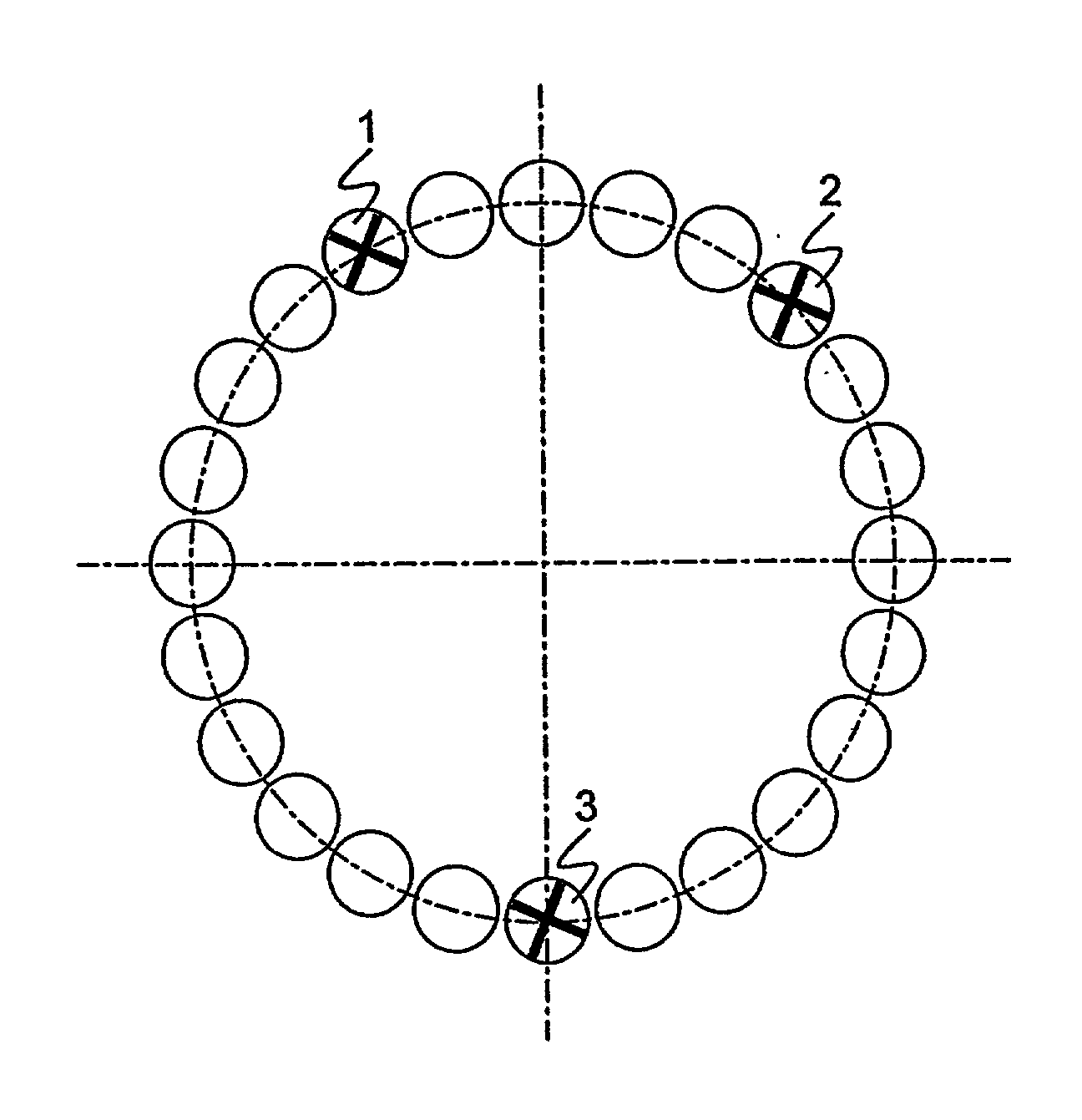

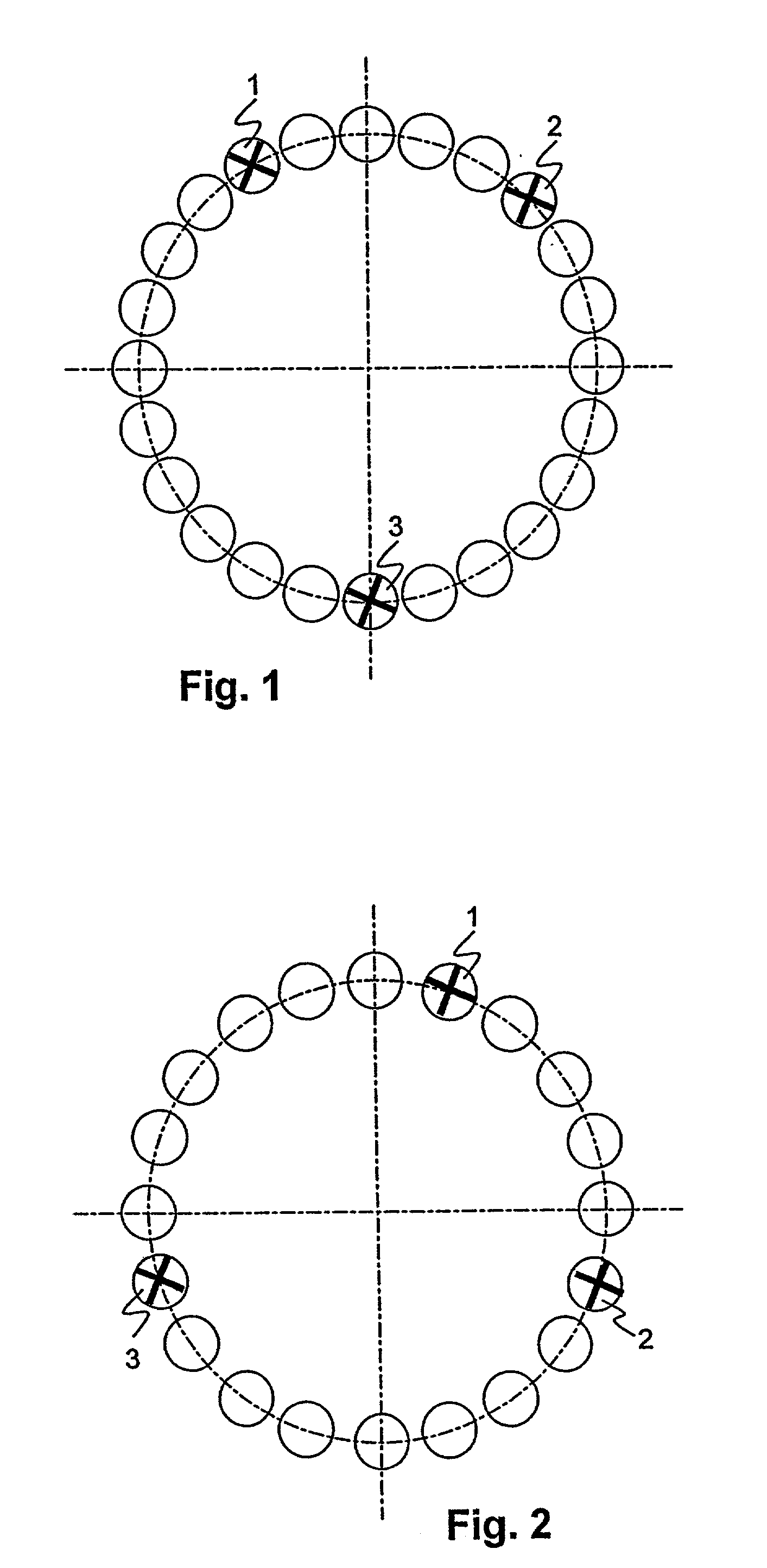

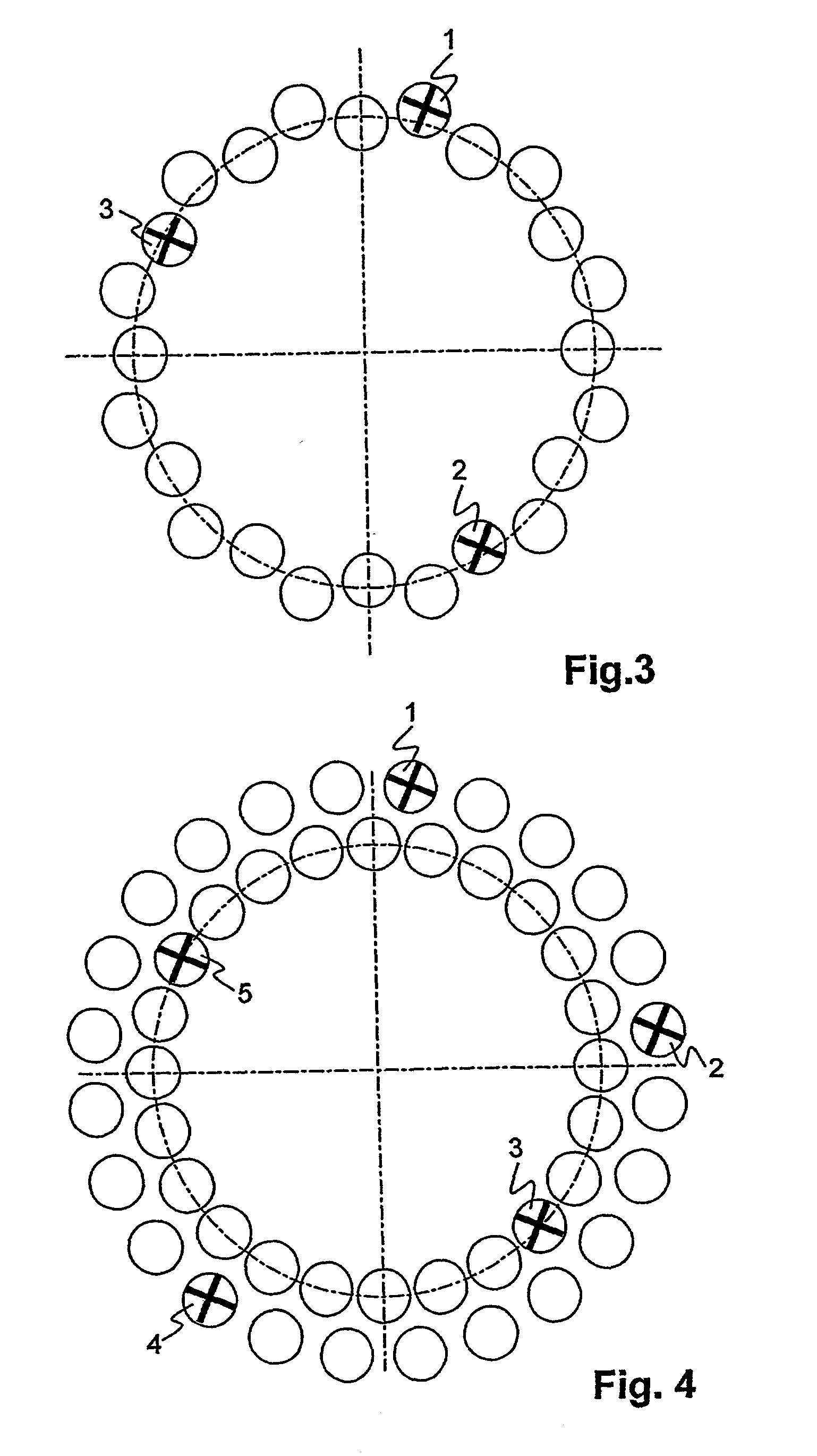

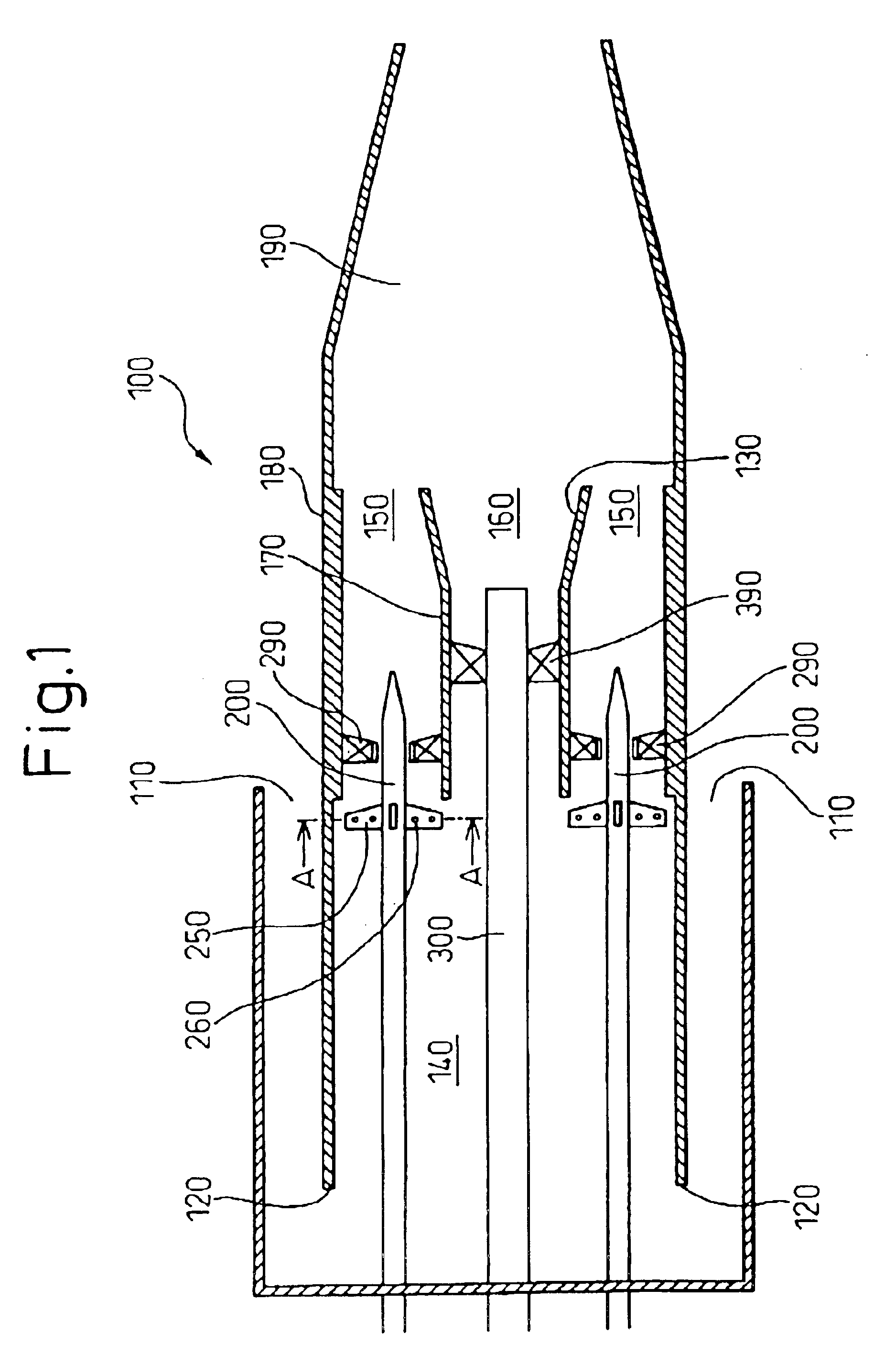

Vibration reduction in a combustion chamber

InactiveUS20020162336A1Large dampingIncrease frequencyBurnersTurbine/propulsion fuel supply systemsCombustion chamberCombustor

A combustion chamber according to the invention has a number b0 of annularly arranged burners, of which a number k of modulatable burners have means for modulating a fuel mass flow, k being k<b0, and the modulatable burners being arranged in such a way that between every pair of adjacent modulatable burners are arranged in each case a1, a2, . . . ak nonmodulatable burners, and that the values a1+1, a2+1, . . . , ak+1 are not integral divisors of b0. In a preferred embodiment of the invention, a highest value of <paragraph lvl="0"><in-line-formula>LCM(b0, a1+1), LCM(b0, a2+1), . . . LCM(b0, ak+1) < / in-line-formula>is maximum, LCM designating the lowest common multiple. It thereby becomes possible to damp a maximum number of azimuthal vibration modes of the combustion chamber by means of a minimum number of modulatable burners. Each pair of modulatable burners gives rise to at least one undesirable vibration or instability which, however, is damped by the other modulatable burner or burners arranged according to the invention.

Owner:ALSTOM TECH LTD

Combustor containing fuel nozzle

InactiveUS6931854B2Occurrence can be relatively easily preventedReduce generationContinuous combustion chamberBurner noise abatementCombustorInjection port

There is provided a combustor comprising a fuel nozzle which is comprised of a rodlike body which has a fuel passage and which is located in an air passage; a plurality of hollow members which are connected to the fuel passage and which extend in radial directions from the rodlike body into the air passage; at least one injection port formed in each hollow member to inject a fuel from the fuel passage into the air passage; and a projection which extends from a farmost inner wall of each hollow member that is most distant from an axis of the rodlike body to the injection port that is most distant from the axis. A hole for leaking fuel that is connected to an air passage may be formed in a farmost inner wall of the hollow member that is more distant from an axis of a rodlike body than the injection port that is most distant from the axis, or may be formed to be adjacent to all the injection ports on an upstream or downstream side in the direction of the airflow. Thus, a vortex does not occur in the hollow column.

Owner:MITSUBISHI HEAVY IND LTD

Helmholtz damper and method for regulating the resonance frequency of a Helmholtz damper

Owner:ANSALDO ENERGIA SWITZERLAND AG

Method and device for influencing combustion processes involving combustibles

InactiveUS20070026354A1Increase influenceEconomical and simpleBurner noise abatementGaseous fuel burnerCombustorHazardous substance

Owner:BRANSTON DAVID WALTER +2

Helmholtz damper and method for regulating the resonance frequency of a helmholtz damper

Owner:ANSALDO ENERGIA SWITZERLAND AG

Gas turbine fuel pipe comprising a damper

ActiveUS20160177836A1Minimize build-upMinimises fuel feed pressure requirementContinuous combustion chamberTurbine/propulsion fuel flow conduitsLine tubingFuel line

The invention concerns a gas turbine fuel pipe, having a fuel line, the fuel line having a fuel line volume, a fuel line outer wall and an opening in the fuel line outer wall, a damper having a damper volume and a damper outer wall and attached in fluid communication with the fuel line, wherein the damper covers the opening in the fuel line outer wall, and a perforated lining extending across at least part of the opening in the fuel line outer wall. Various embodiments are also described, along with a method of use of the apparatus.

Owner:ANSALDO ENERGIA SWITZERLAND AG

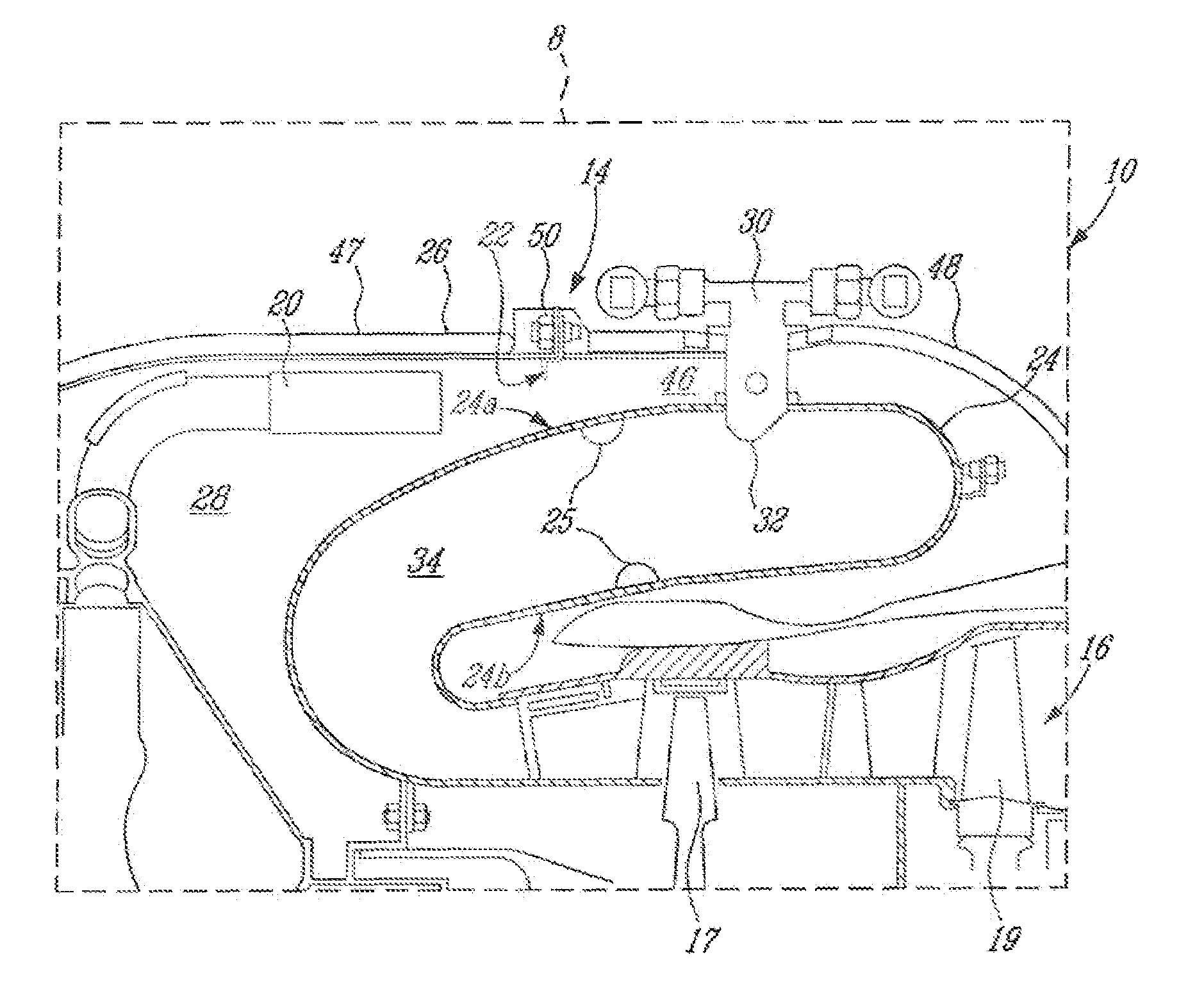

Aerodynamic trip for a combustion system

ActiveUS7302802B2Reduce combustion noiseUniform temperature distributionBurnersContinuous combustion chamberCombustion systemCombustion noise

A apparatus and method for improving combustion by improving at least one of temperature distribution in the combustor, pressure distribution around the combustor and combustion noise level in the combustor, by redistributing air around the combustor to modify the structure of the air flow prior to entry into the combustor.

Owner:PRATT & WHITNEY CANADA CORP

Mixing device for mixing fuel and air and furnace with a mixing device

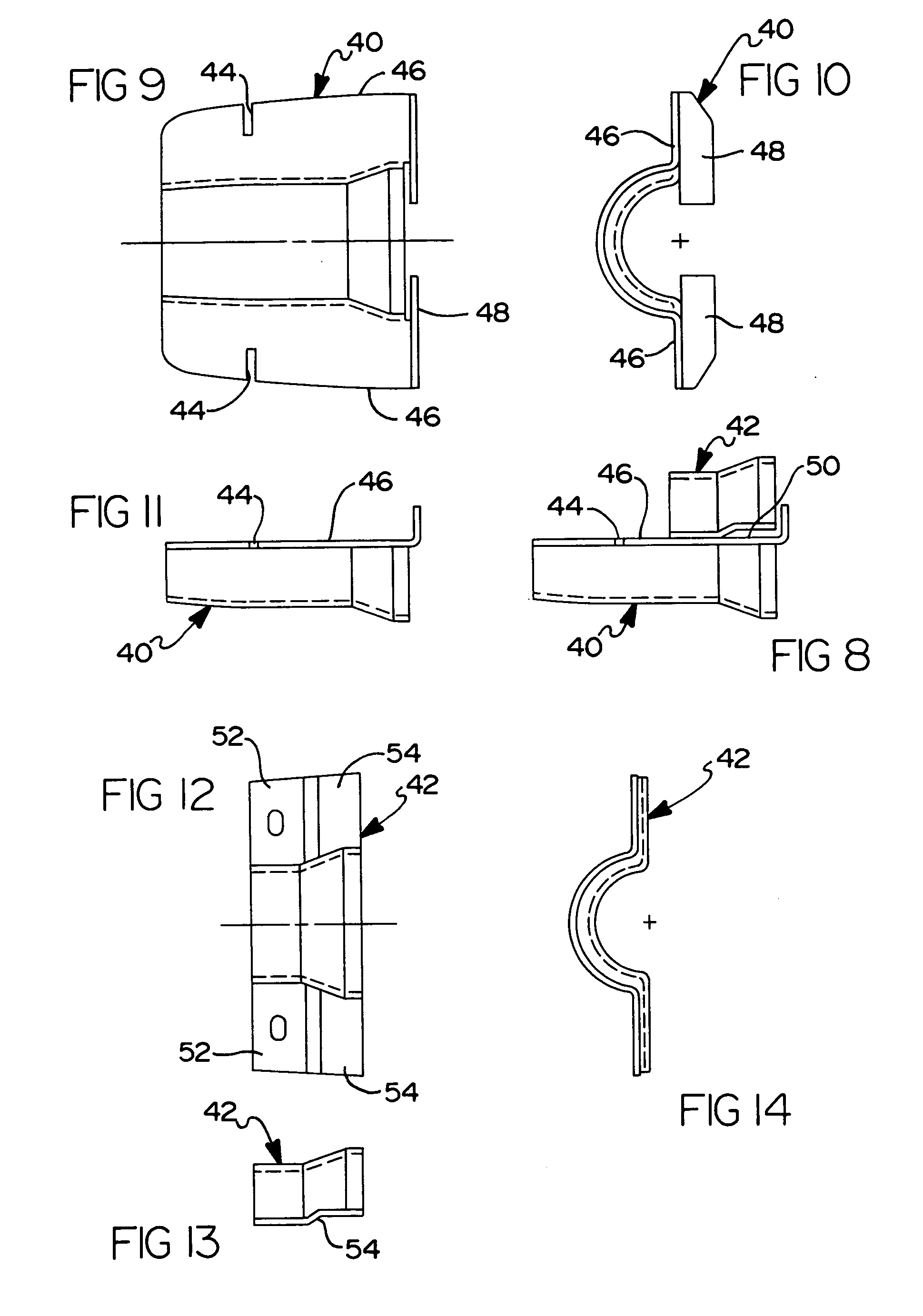

InactiveUS20120180774A1Burner noise abatementAir-treatment apparatus arrangementsCombustorMelting furnace

Mixing devices for mixing fuel and air for a premix burner or furnace and furnaces (e.g., premix) with mixing devices. Furnaces may be for heating an occupied space, and may produce lower NOx emissions. A mixing device may be located within an inlet tube, may have a surface that is perpendicular to the direction of fuel flow or that forms a circle, or may have two surfaces held at substantially opposite angles to induce swirl. A portion of the mixing device may extend over an orifice of the fuel injector. A mixing device may be attached to the fuel injector, may be made from a piece of sheet metal, and may have a hole for attachment to the fuel injector. Mixing devices may have a center, two arms, and two ends, which may be separated by bends. A burner plate may be sandwiched between surfaces to allow for expansion.

Owner:NORDYNE

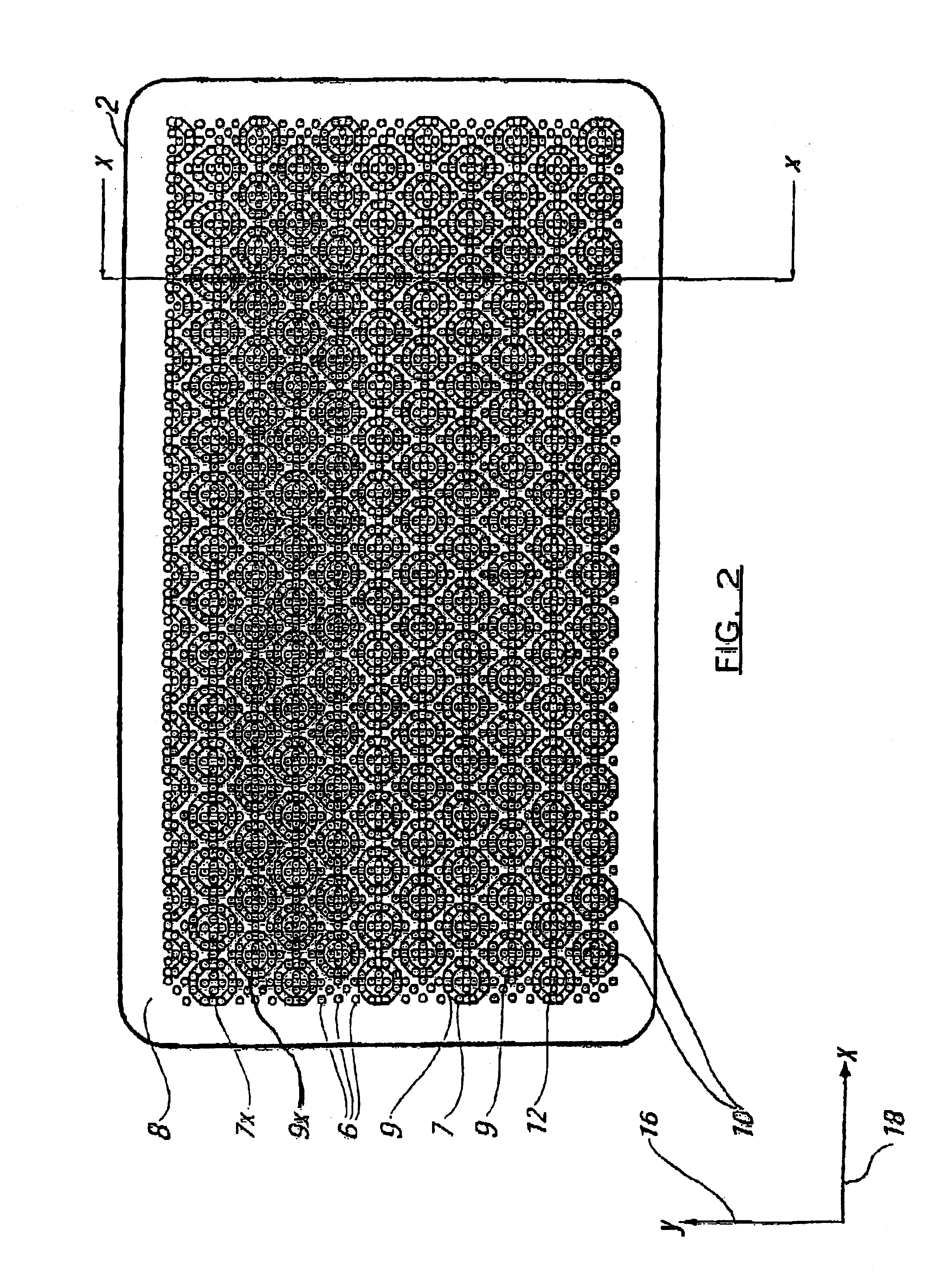

Burner plaque with continuous channels

A ceramic burner plaque is described being of a predetermined thickness defined between first and second planar surfaces and through which a plurality of burner ports (6) pass from one surface to the other. The ports are arranged in offset rows and a plurality of polygonal channels (10) are cut into the second surface (8) of the plaque, said channels also being arranged in offset fashion rows and being of a depth less than the thickness of the plaque. The channels are ideally octogonal in shape and of a width which widens progressively from the narrow base of the channel within the thickness of the plaque towards the second surface. The width of the channels at their base is ideally similar or marginally greater to the dimensions of the burner ports and the shape and position of the channels is such that a plurality of burner ports are coincidental with the base thereof.

Owner:SIT BRAY

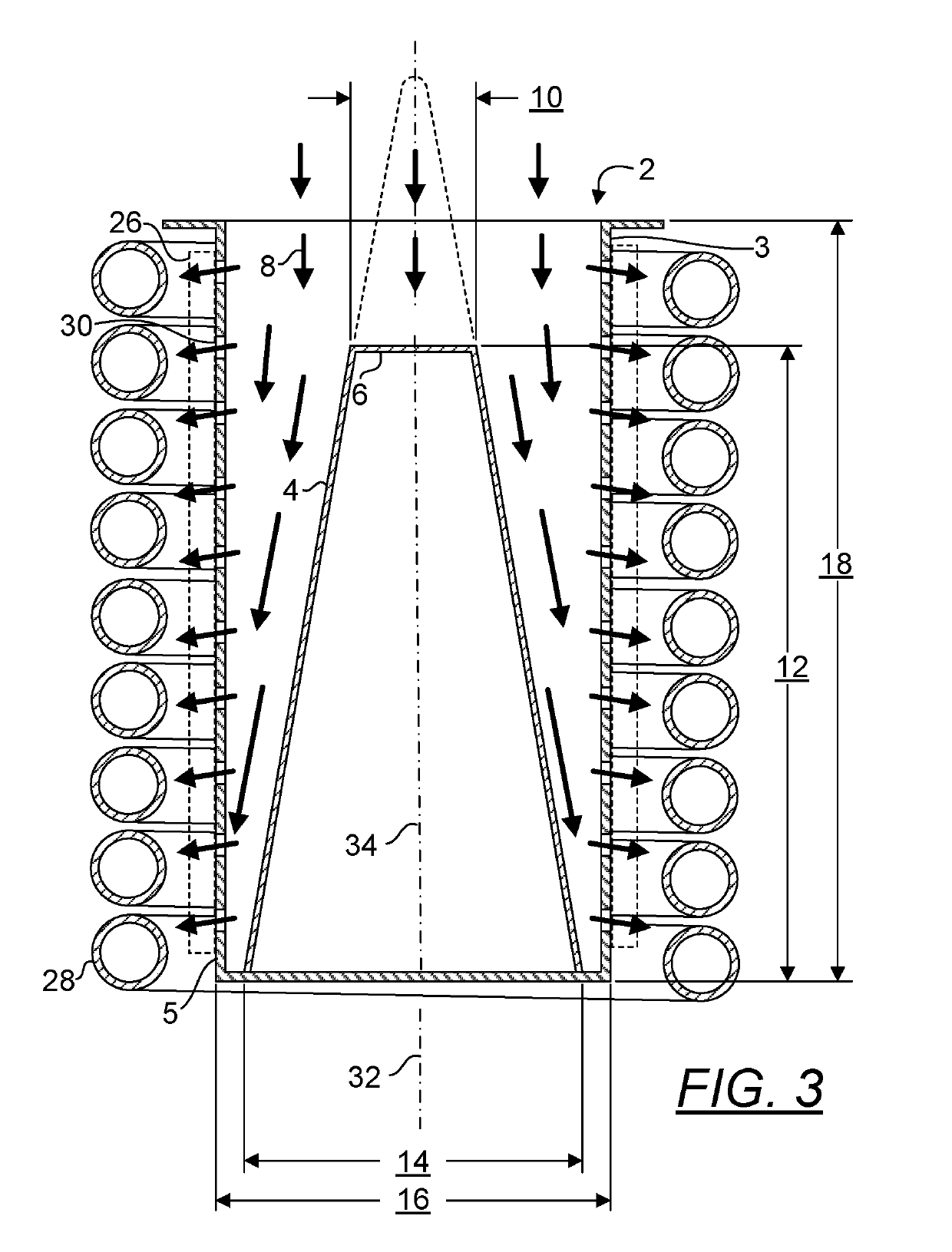

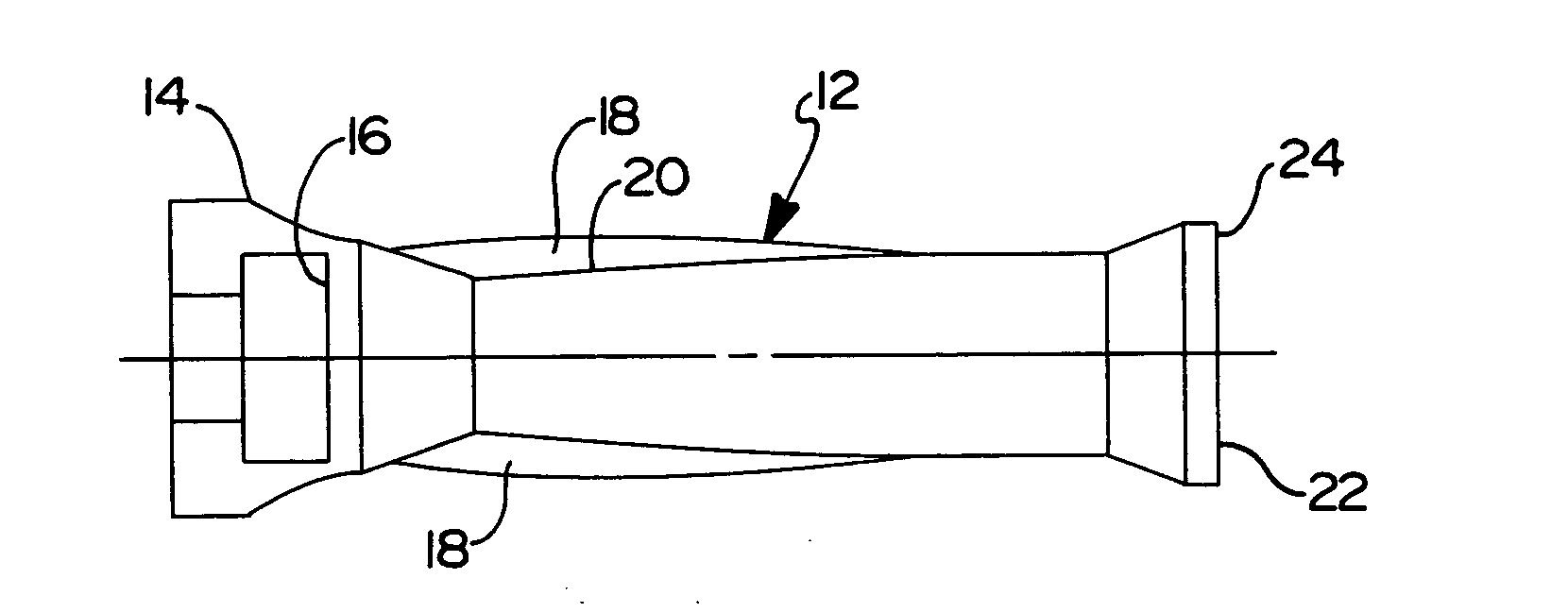

Burner resonance canceling apparatus

A burner resonance canceling apparatus adapted to cancel a resonance caused in a burner tube having a side wall, apertures disposed on the side wall, a first end configured for receiving a fuel mixture flow, a closed second end, a central axis extending through the first end and the second end, the apparatus includes a member having an enlarged end, a reduced end and a central axis extending through the enlarged end and the reduced end, wherein the enlarged end is configured to be positioned at the second end, the central axes are substantially coaxially disposed and the reduced end is configured to face the fuel mixture flow brought through the first end into the burner tube and the burner tube and the member cooperate to define a chamber the fuel mixture flow is configured to traverse from the reduced end to the enlarged end.

Owner:INTELLIHOT

Inshot burner

InactiveUS20050026100A1Improve combustion efficiencyReduce manufacturing costBurner noise abatementLiquid fuel evaporation burnersEngineeringMechanical engineering

An inshot burner is provided including a burner body and a nozzle assembly provided in an outlet opening of the burner body. The nozzle assembly includes a disc-like member having a central hole therein and a plurality of radially spaced holes spaced around a perimeter of the central hole. A tube member is disposed in the central hole of the disc-like member.

Owner:MUELLER IND INC

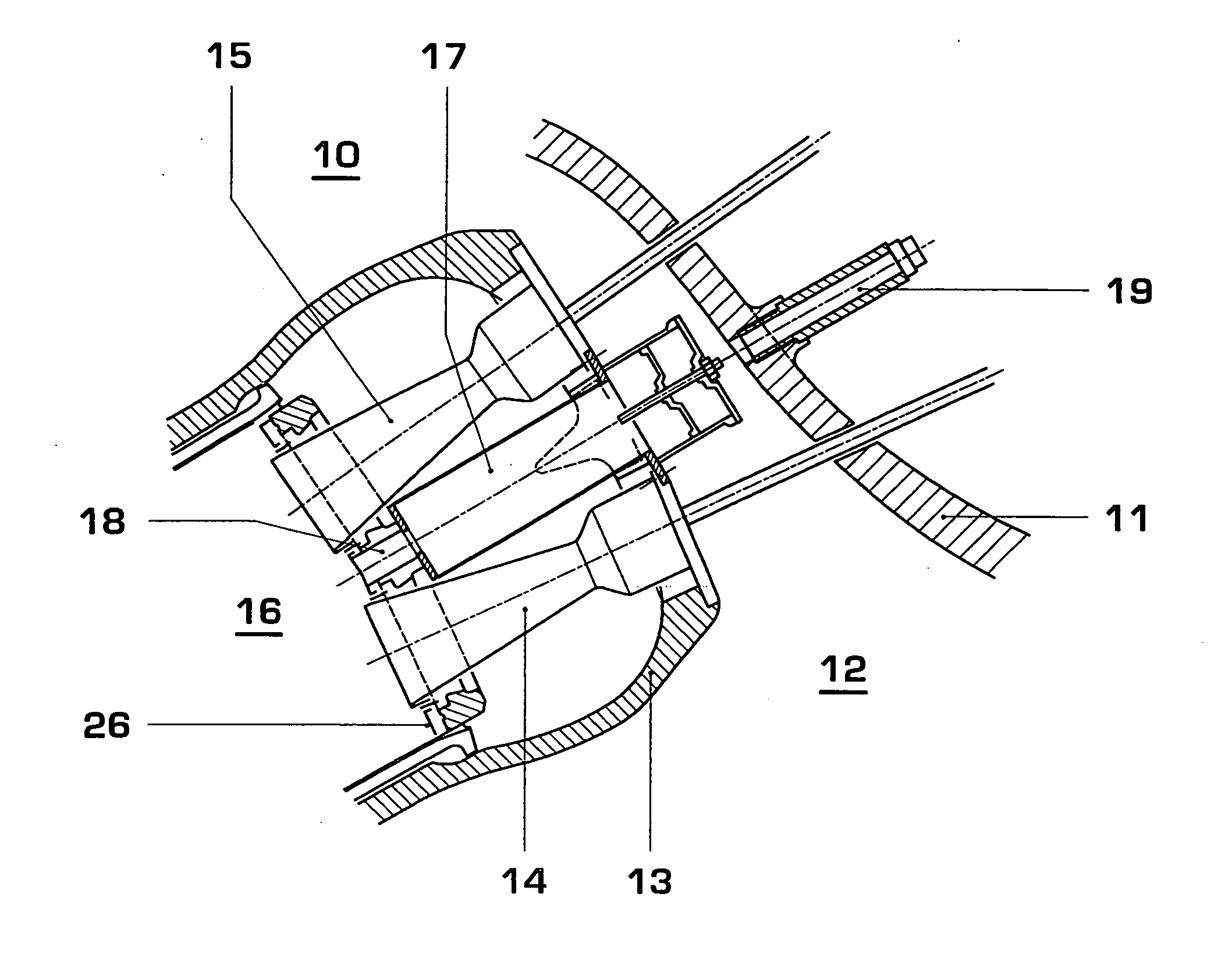

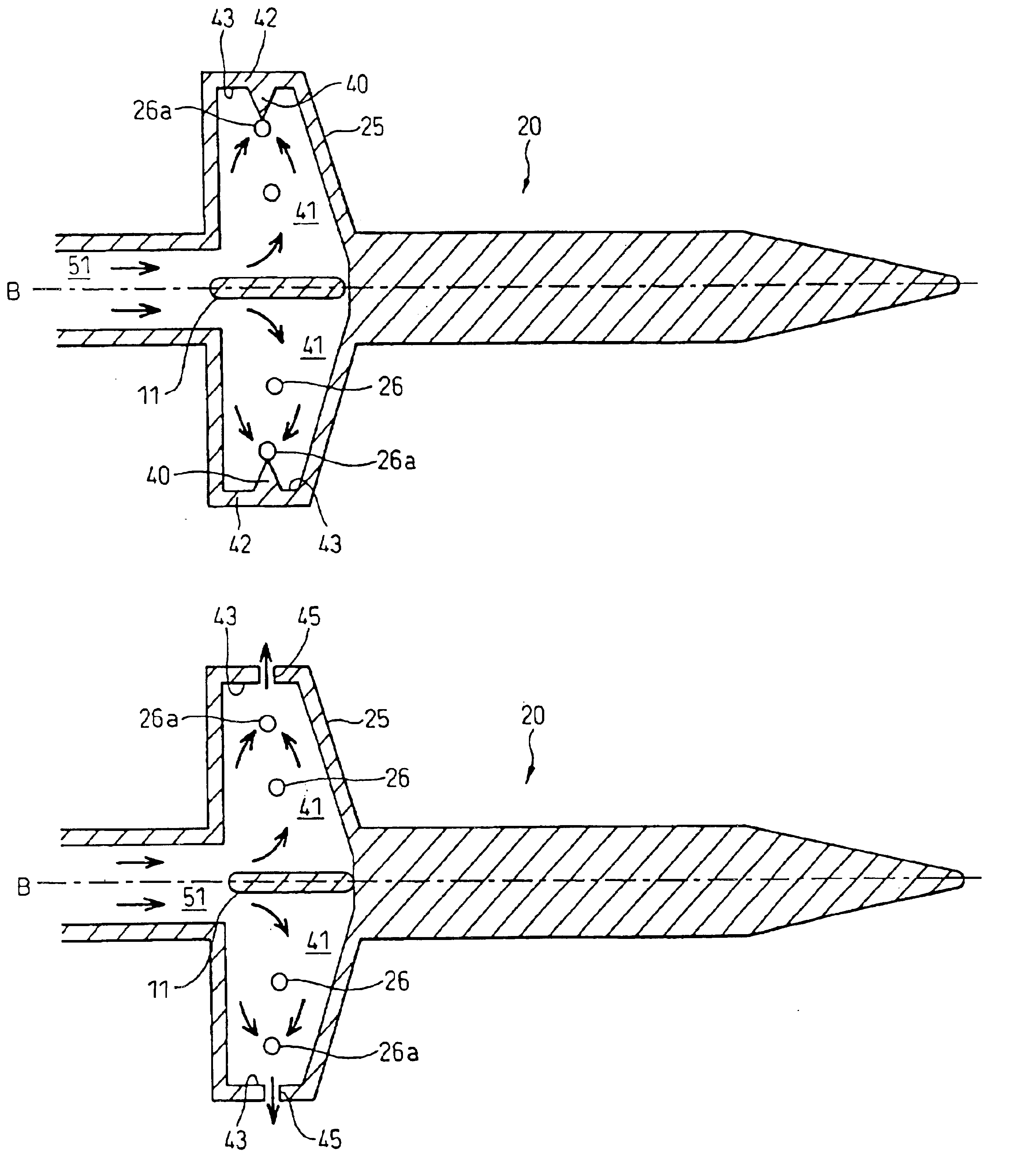

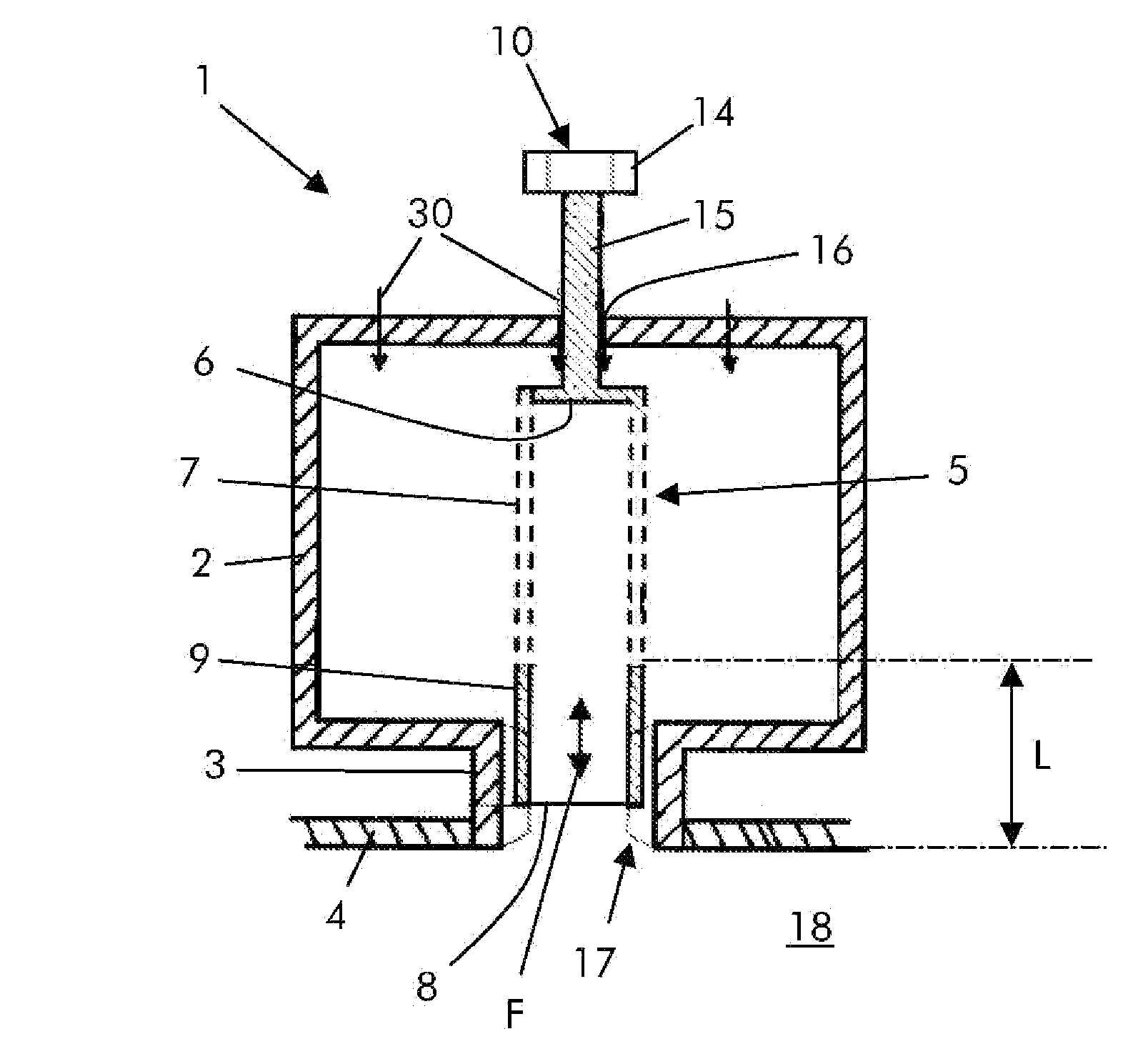

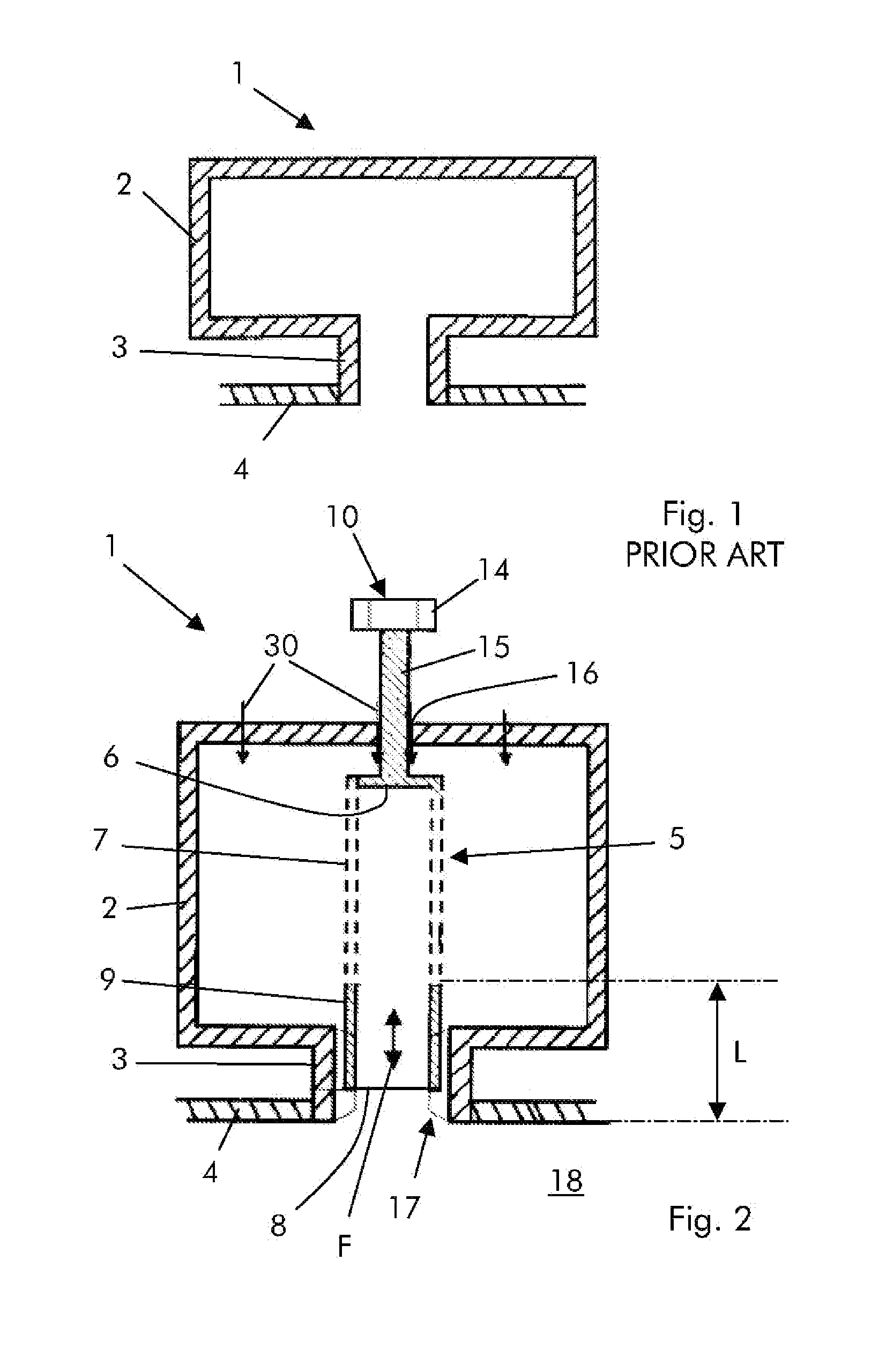

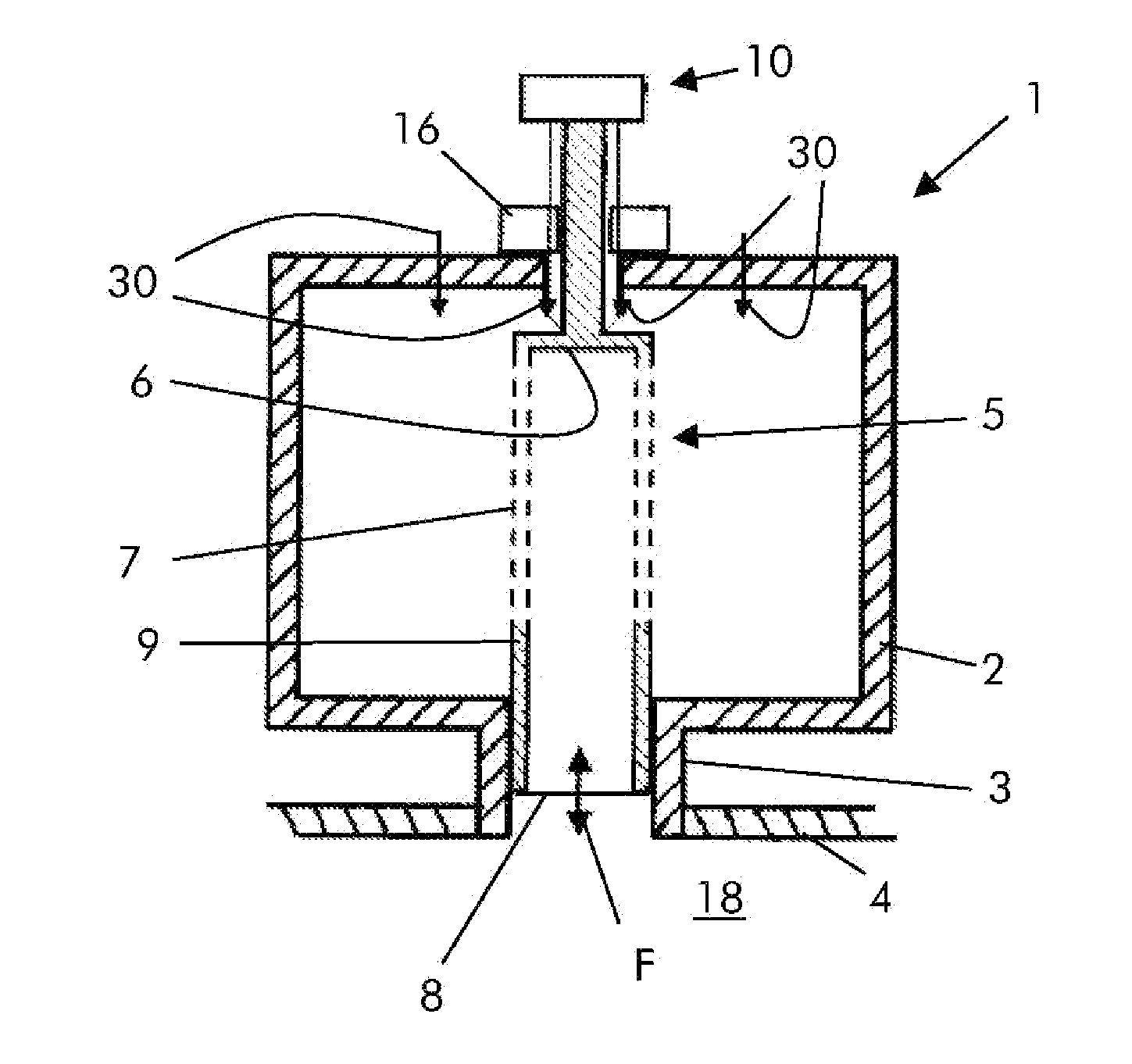

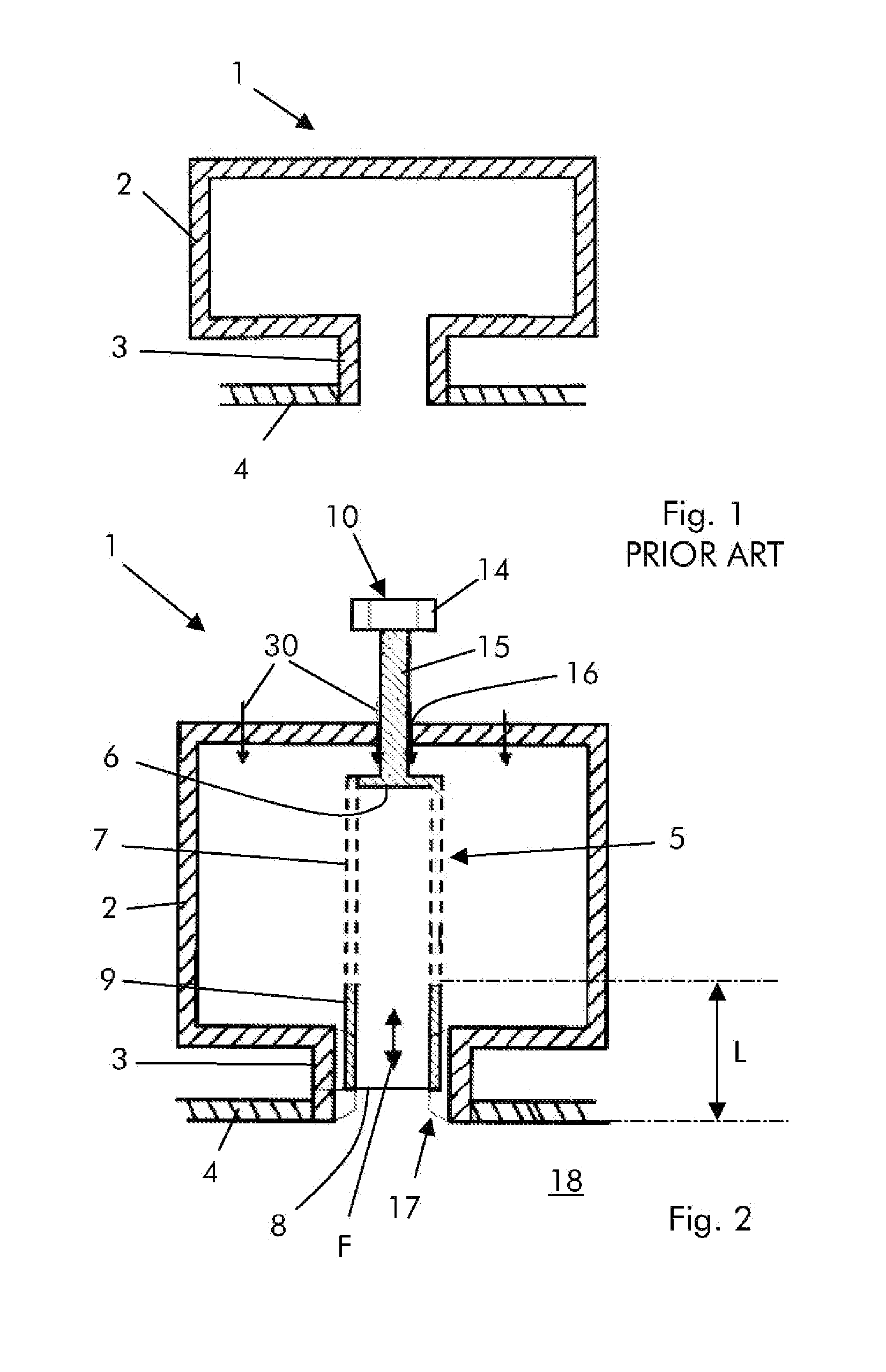

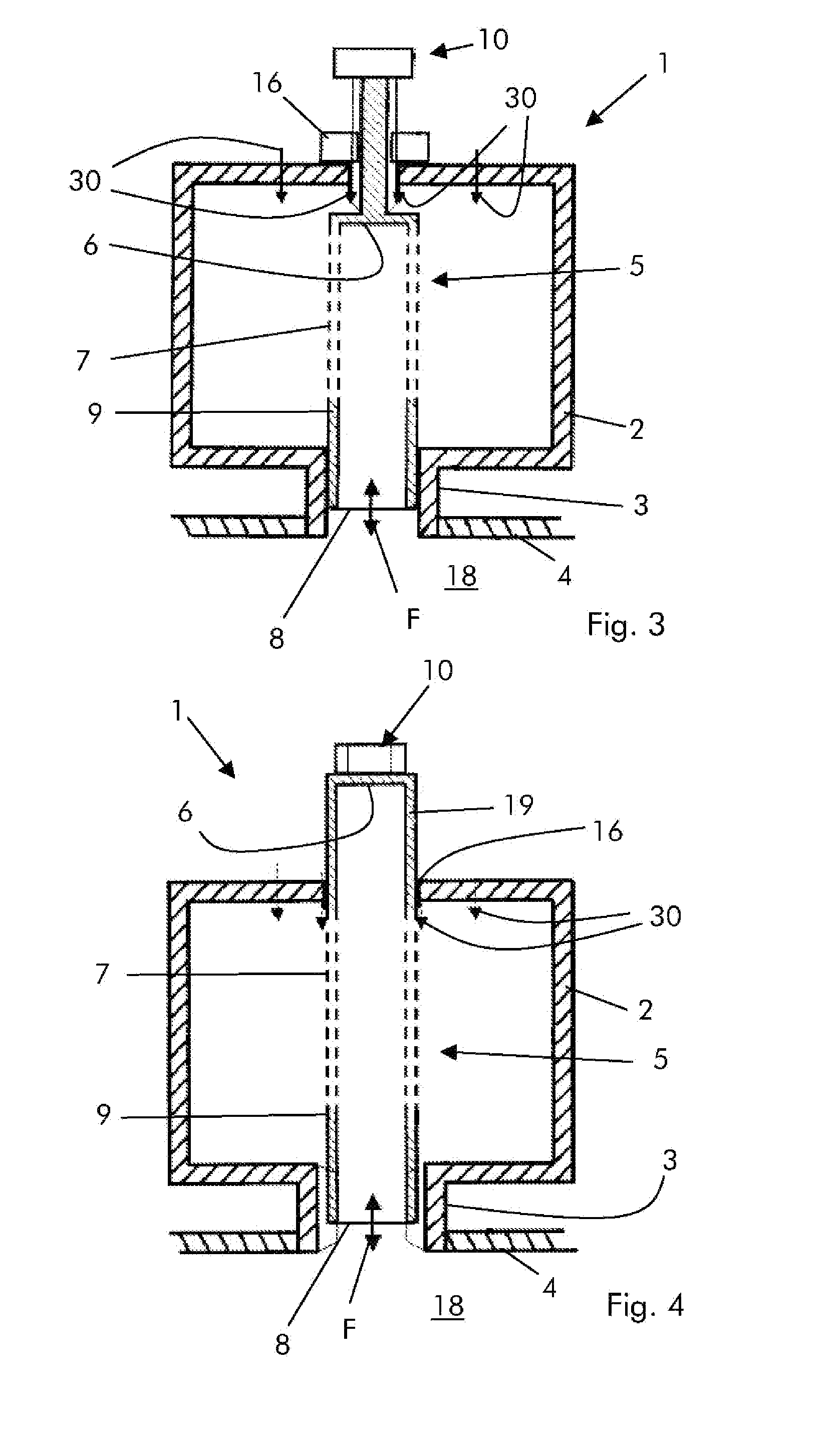

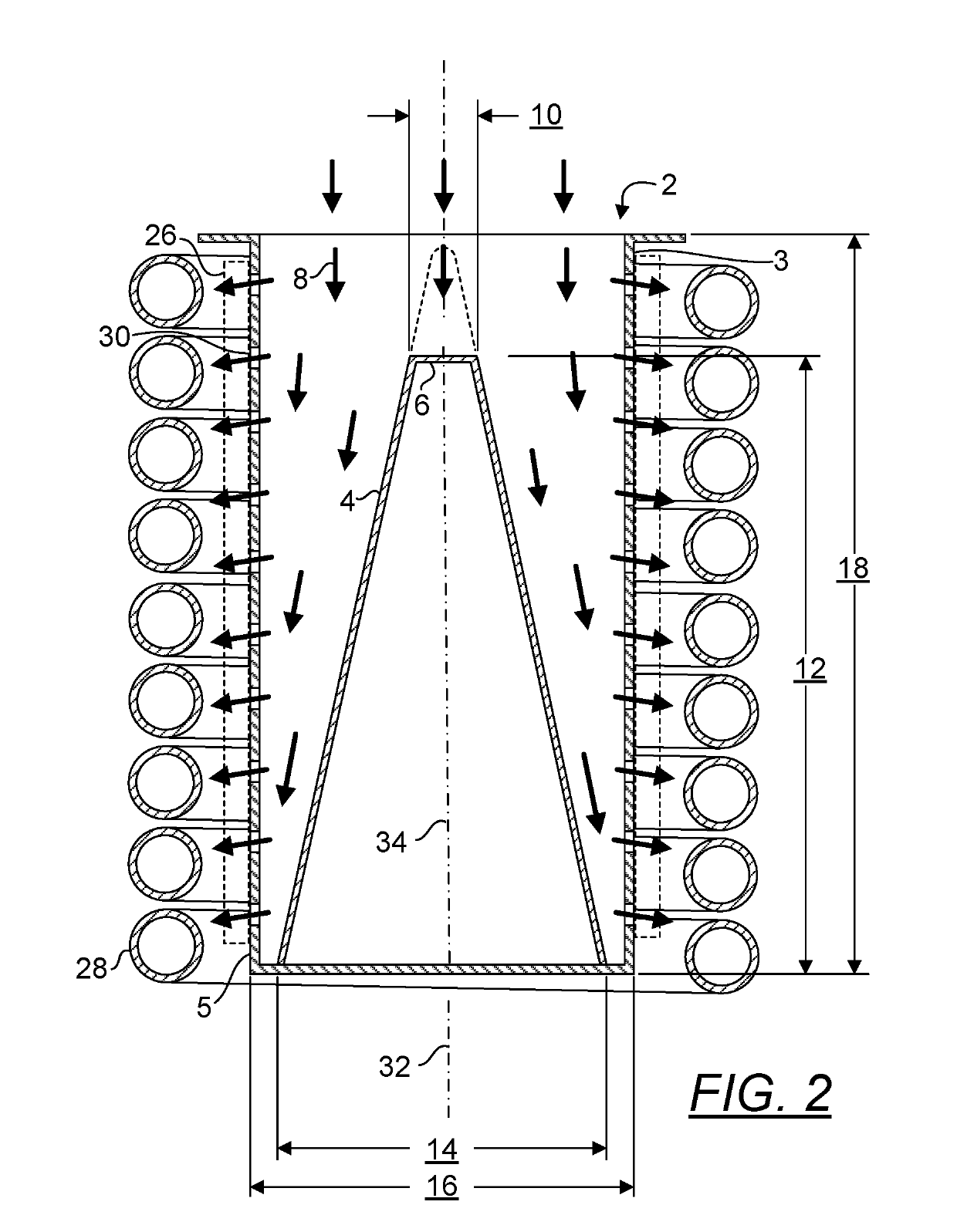

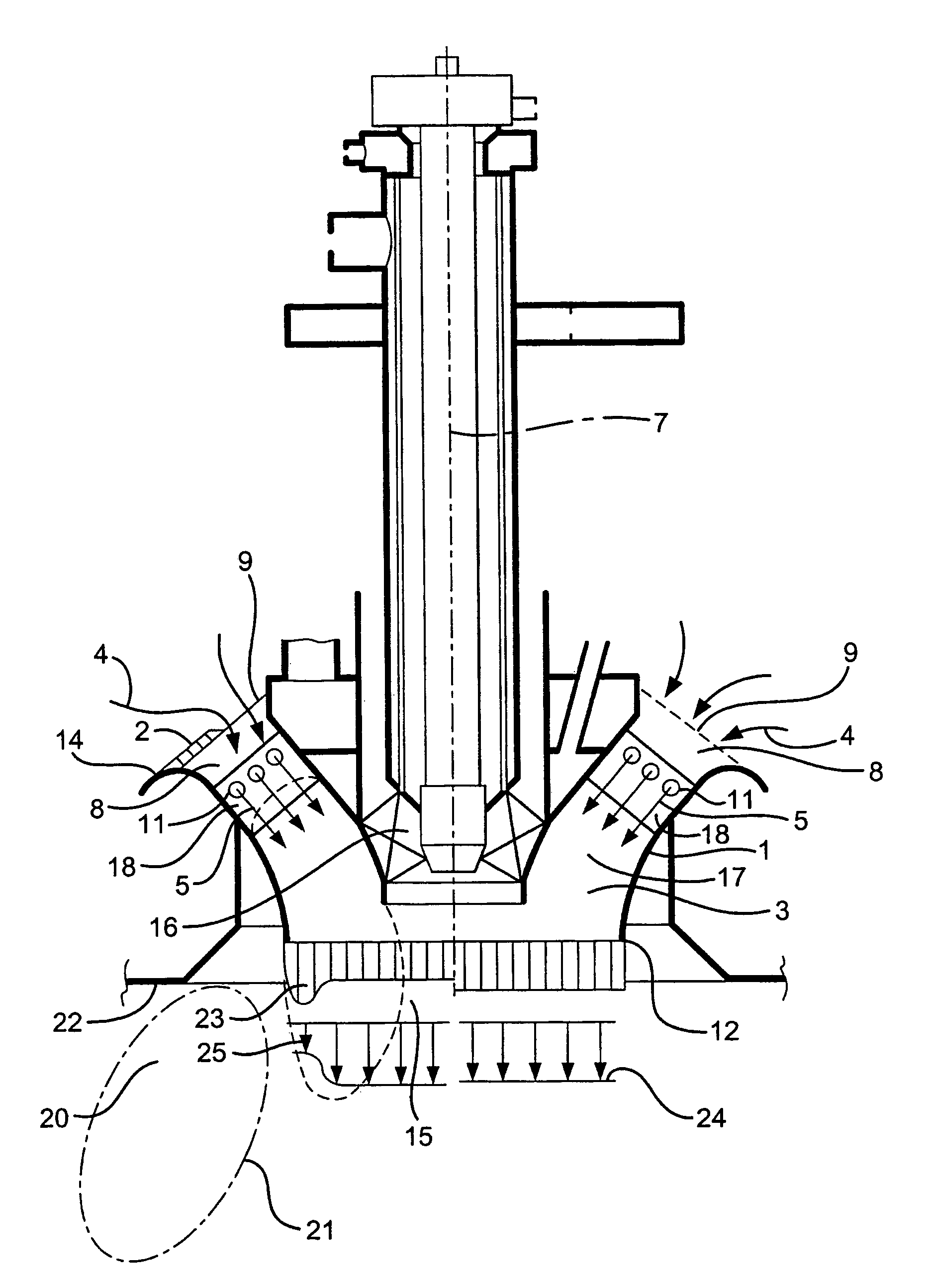

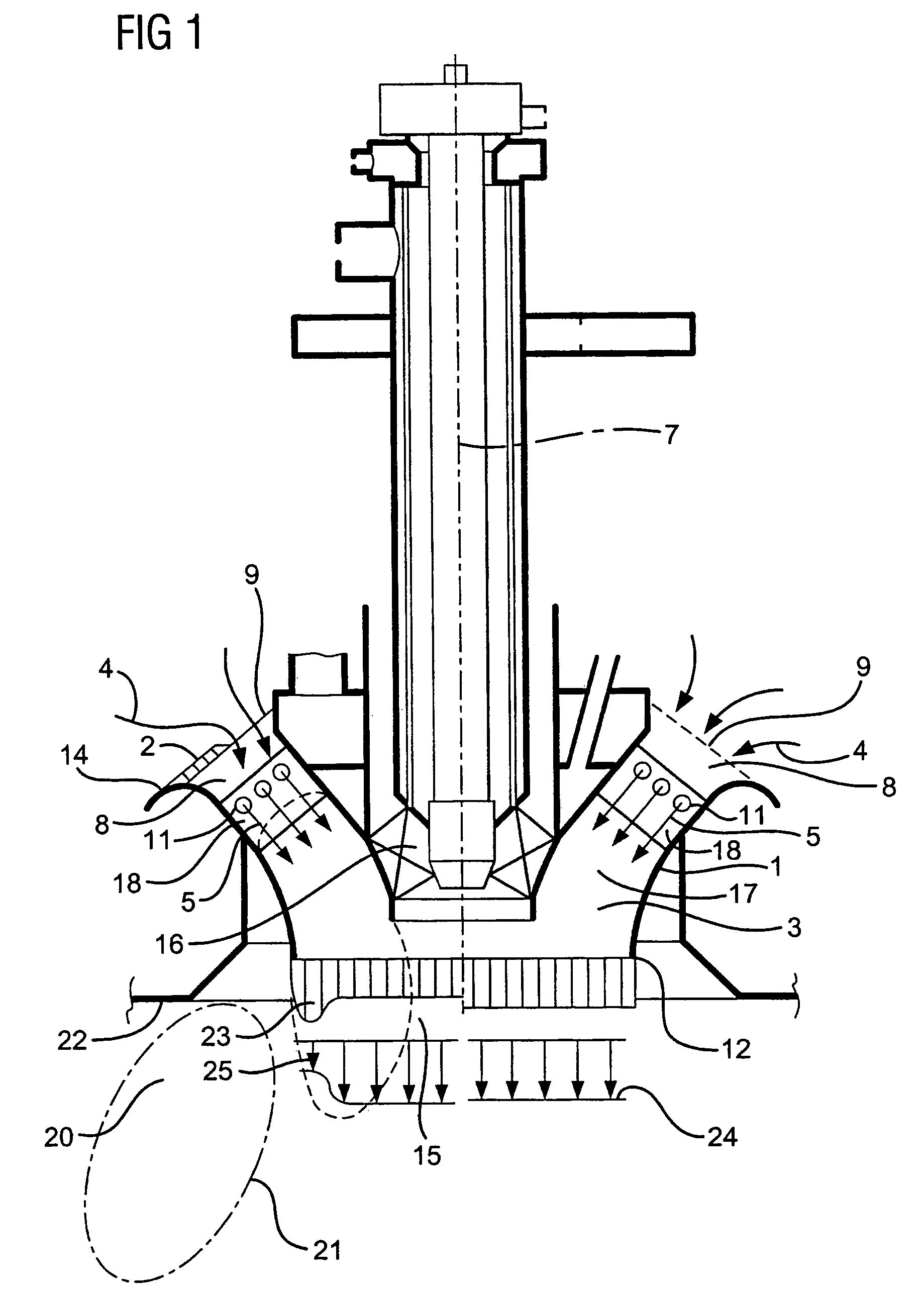

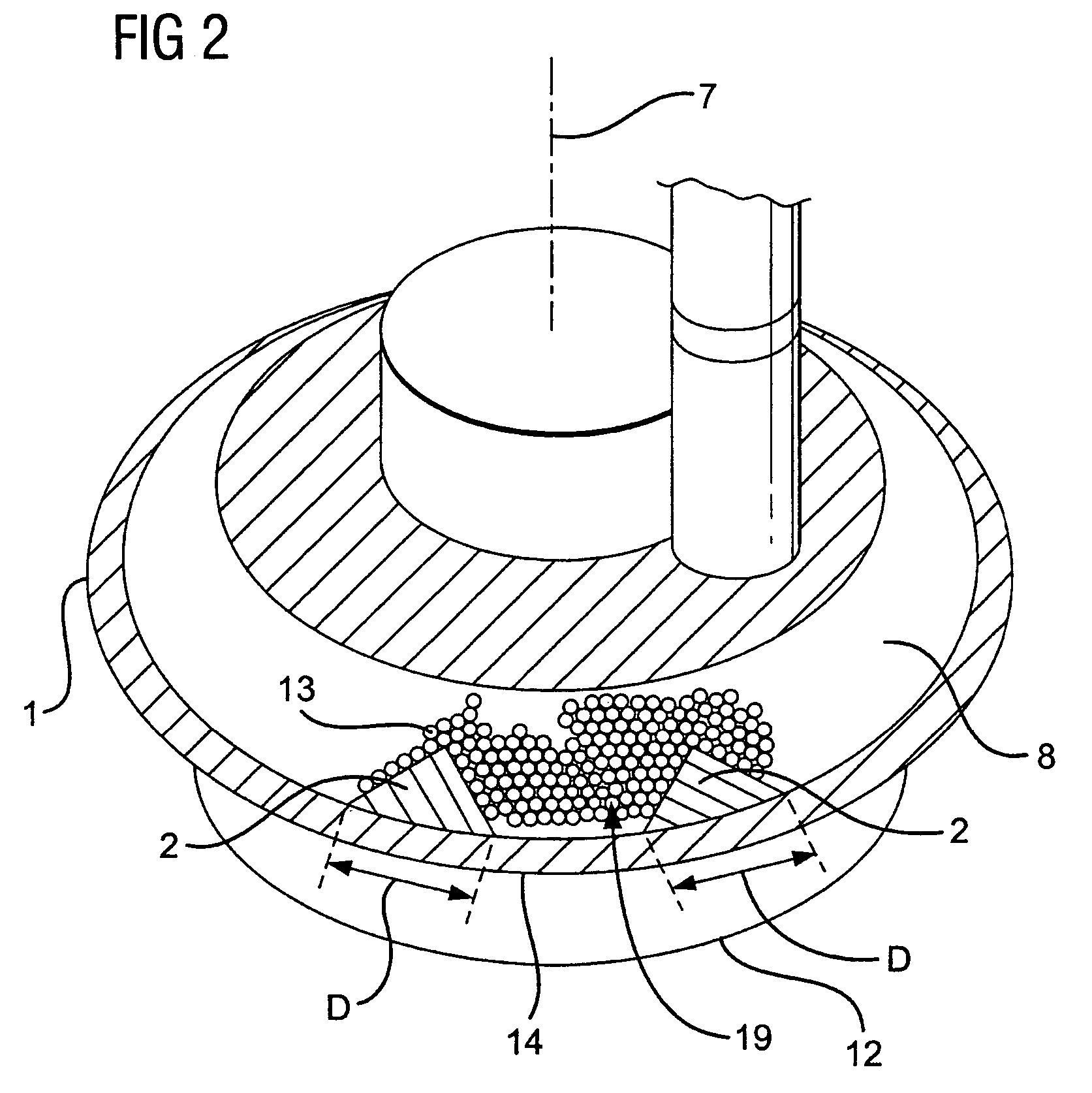

Burner apparatus for burning fuel and air

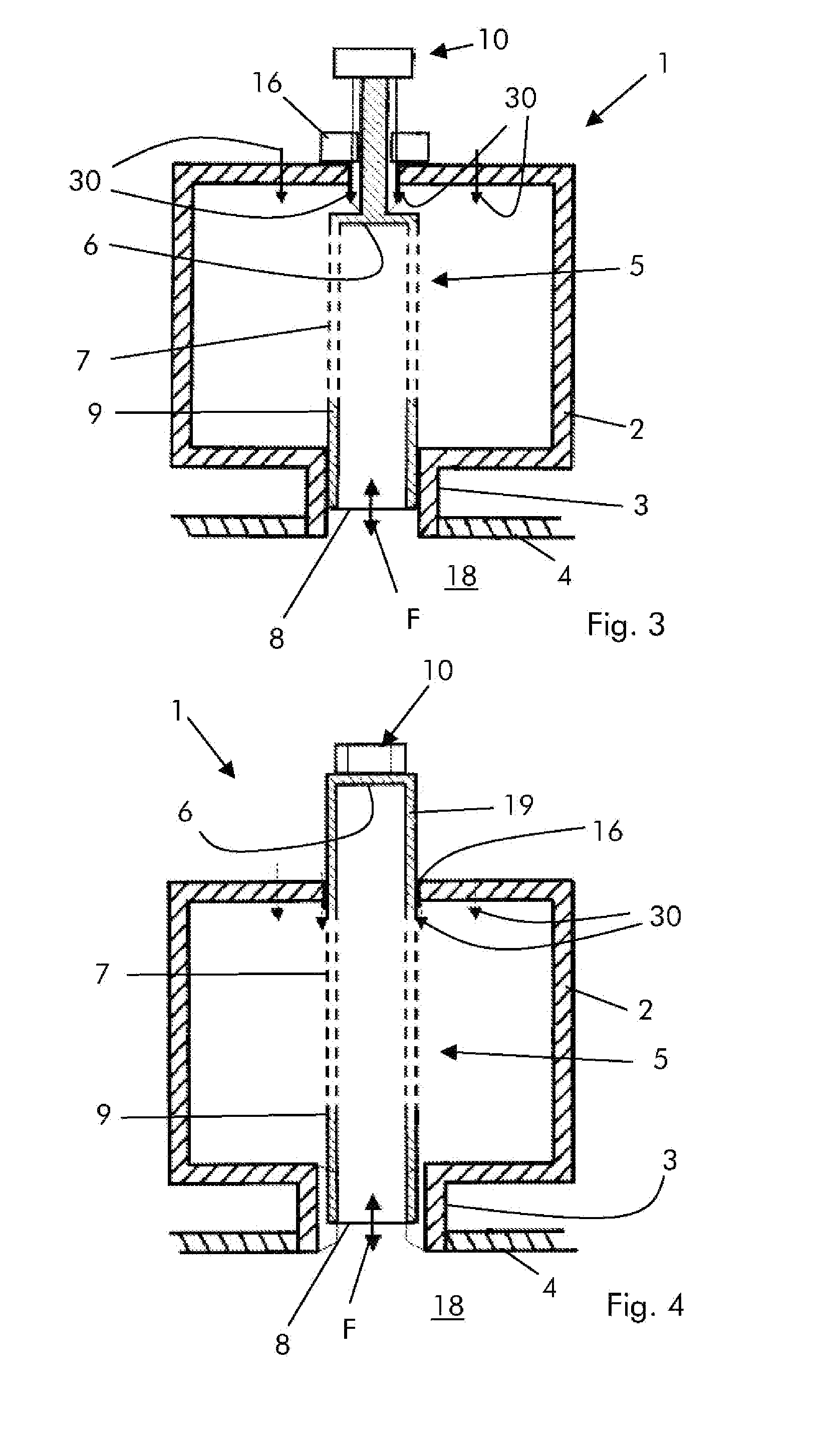

InactiveUS7051530B2Reduce airflowReduces maximum pressure amplitudeBurner safety arrangementsContinuous combustion chamberCombustorNuclear engineering

The invention relates to a burner apparatus (1) for burning fuel (5) with air (4) to combustion gas, in particular within a combustion turbine, comprising a premixing chamber (3) for premixing fuel (5) and air (4) with. The premixing chamber (3) having an air inlet (8) for air (4) to enter said premixing chamber (3), a fuel inlet (11) for a gaseous or liquid fuel (5) to enter said premixing chamber (3), and an outlet (12) for a mixture of air (4) an fuel (5) wherein, the fuel inlet (11) being located between said air inlet (8) and said outlet (12). The burner apparatus (1) Further comprises at least one air blocking member (2) situated at the air inlet (8) for stabilising a burner premixing flame by locally blocking the flow of air (4) entering said premixing chamber (3) so that downstream said outlet (12) a locally inhomogeneous fuel concentration (23) results generating a locally hot stream of combustion gas being hotter than the average flame temperature.

Owner:SIEMENS AG

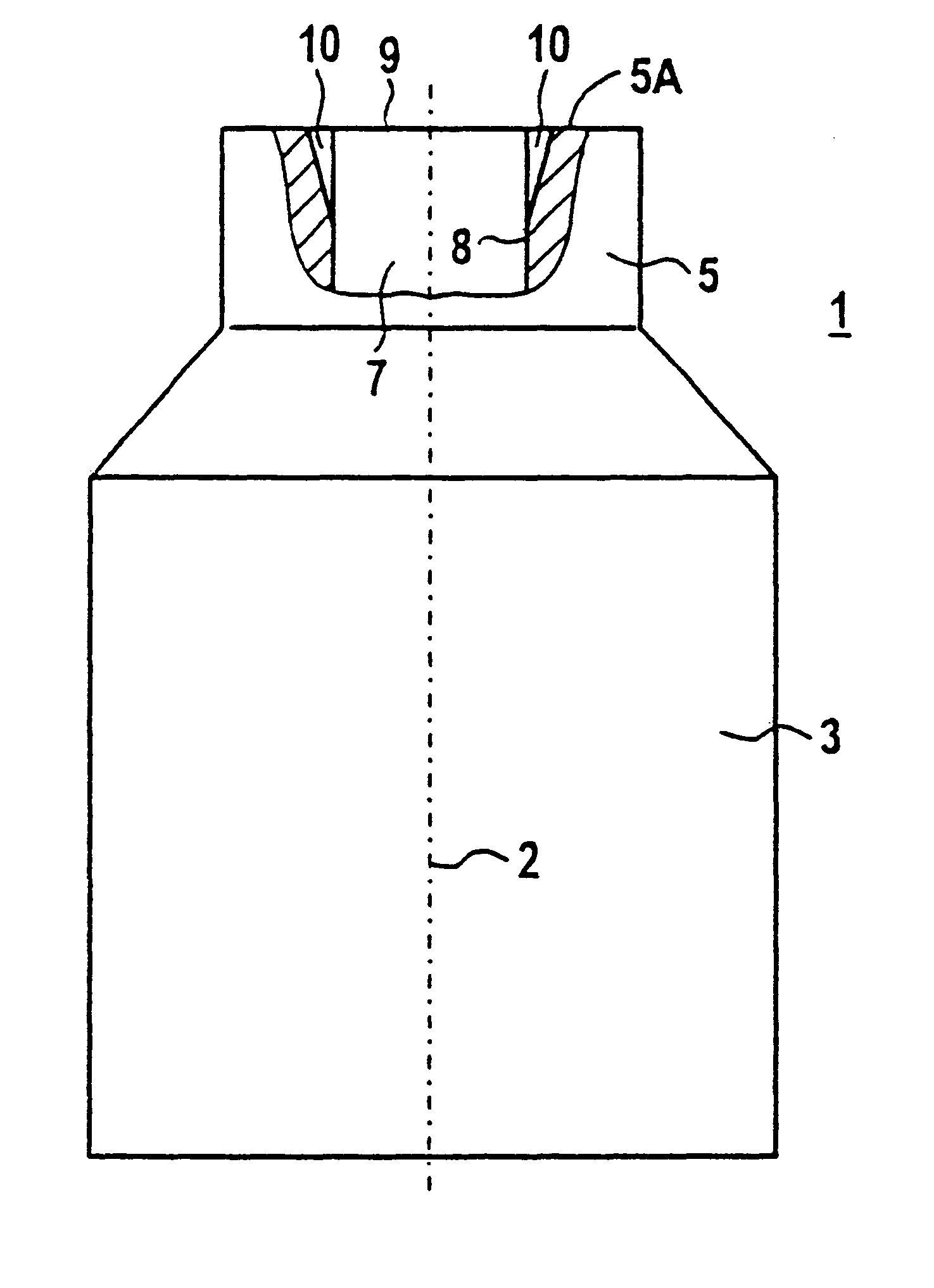

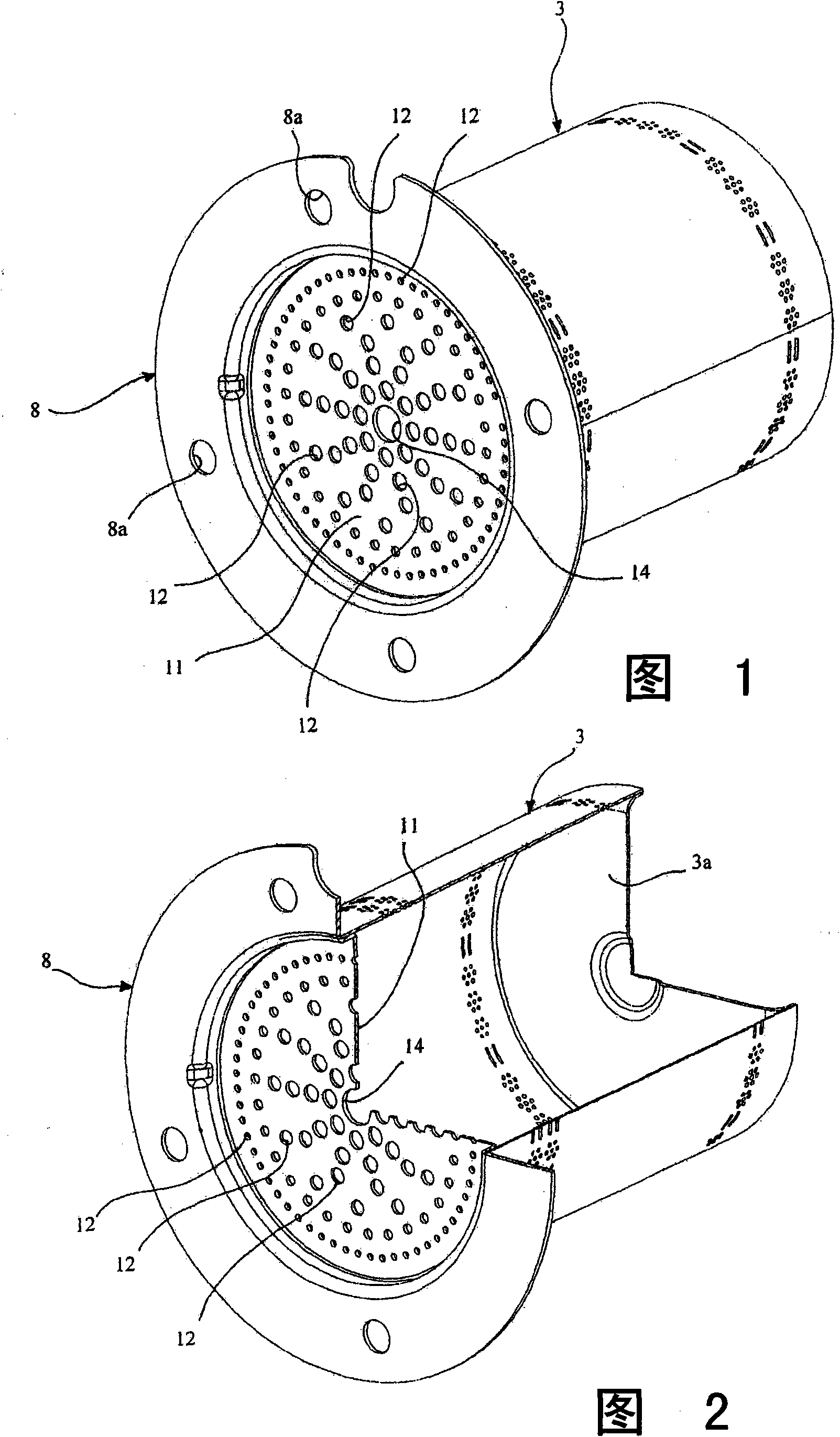

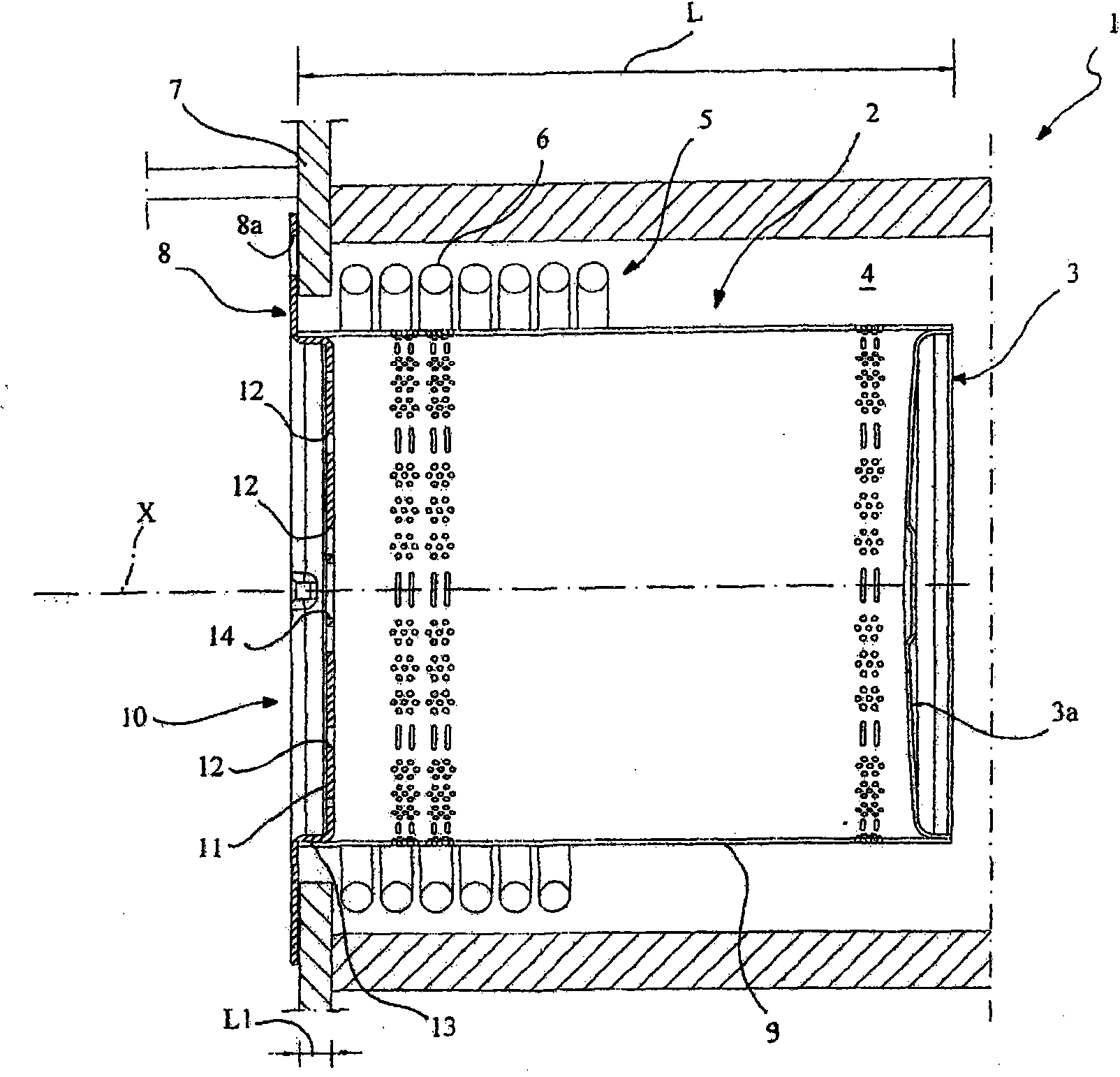

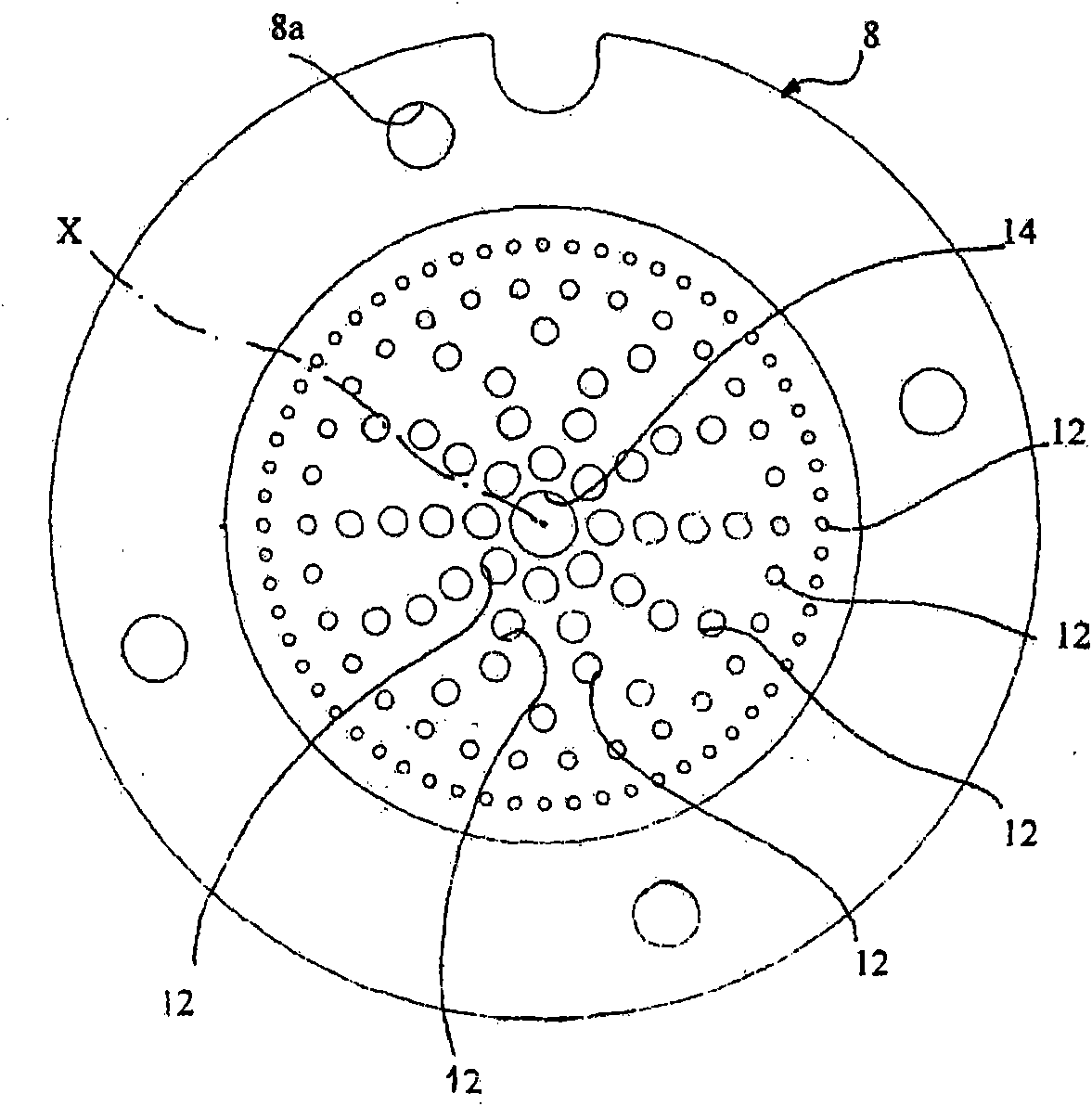

A burner, specifically a premix burner

InactiveCN101861496ASave assembly timeReduce manufacturing and assembly costsBurner noise abatementGaseous fuel burnerCombustorCombustion chamber

A burner, particularly for combustible gas with premixing, comprises a cylindrical burner head (3) designed to be housed in a combustion chamber (4) of a heating apparatus, on which an air and gas mixture supplied to the combustion chamber (4) is burnt, the head (3) including a cylindrical shell (9) with through apertures, fixed at a first axial end by a connecting flange (8) to a shutter element (7) intended to seal the combustion chamber (4), while its opposite axial end has a solid end wall (3a) which seals the head (3), an element (10) for distributing the air and gas mixture, positioned inside the burner head (3) and intended to distribute the flow of combustible mixture reaching the burner on to the burner head (3). The distributor element comprises a platelike portion (11) extending as a continuation of said connecting flange (8) and extending substantially in an orthogonal direction to the axial direction of extension of the cylindrical head, the platelike portion (11) having through apertures (12) for distributing the mixture to the burner head (3).

Owner:意大利精密机械技术股份公司

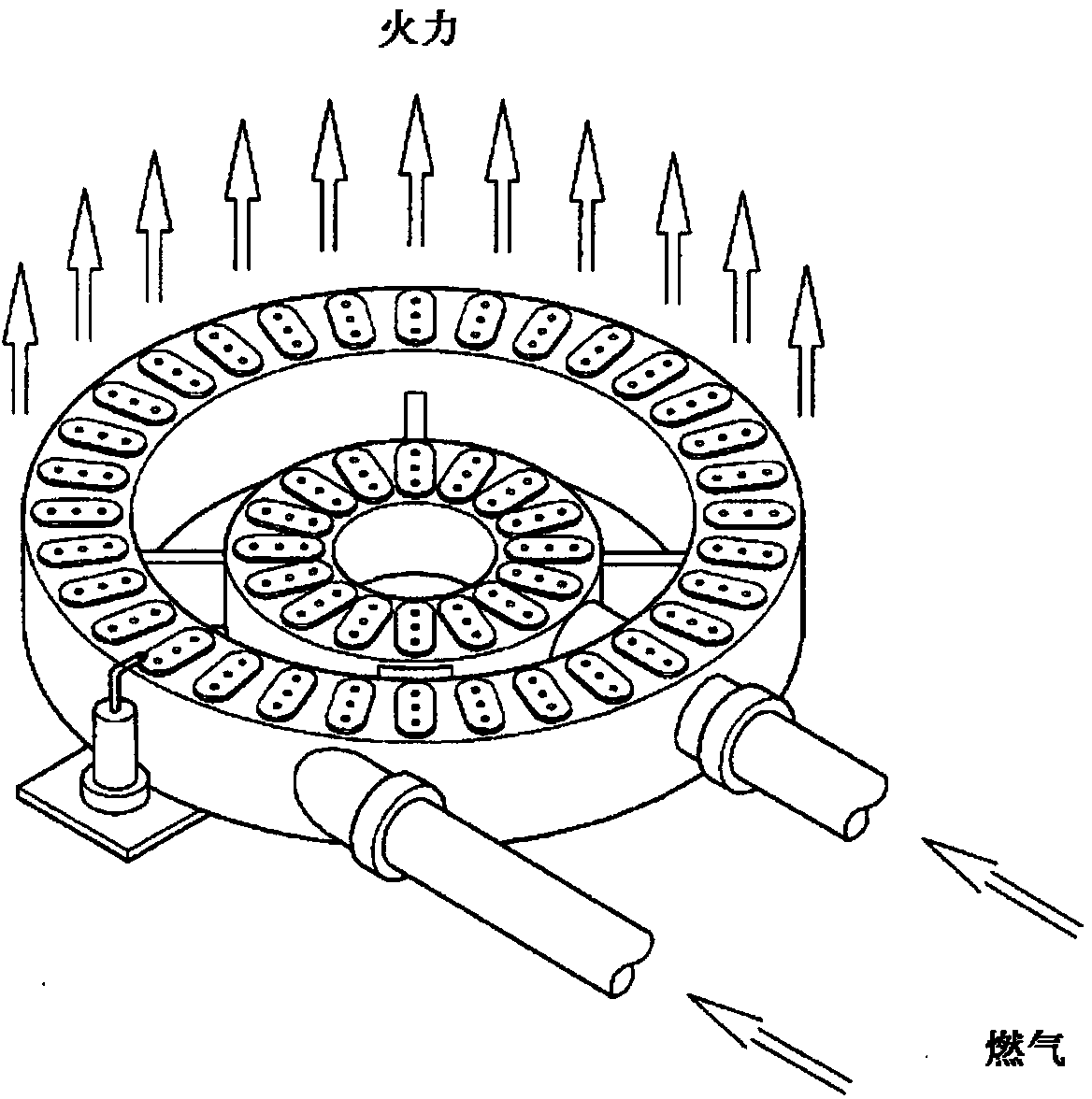

Fan-metal fiber gas burner

InactiveCN104145162AUniform firepowerNo running noiseDomestic stoves or rangesBurner noise abatementCombustion noiseMetal fibers

The purpose of the present invention is to provide a fan-metal fiber gas burner which is a metal fiber pad type gas burner for supplying gas with blow pressure and burning the supplied gas, forms a uniform flame regardless of any areas by diffusing the gas over the whole pad, and solves a gas combustion noise problem, the gas burner comprising: a detachable metal fiber pad provided at a combustion part of a burner head; a supply tube connected to the center of the bottom of the burner head; and an air blower for supplying the oxygen necessary for gas combustion to the supply tube, wherein a no-load rotation type dispersion blade having a curved induction plate is provided to rotate in the same place in response to the supply pressure of the gas below the pad at the burner head so as to uniformly disperse the gas in all directions.

Owner:宋金锡

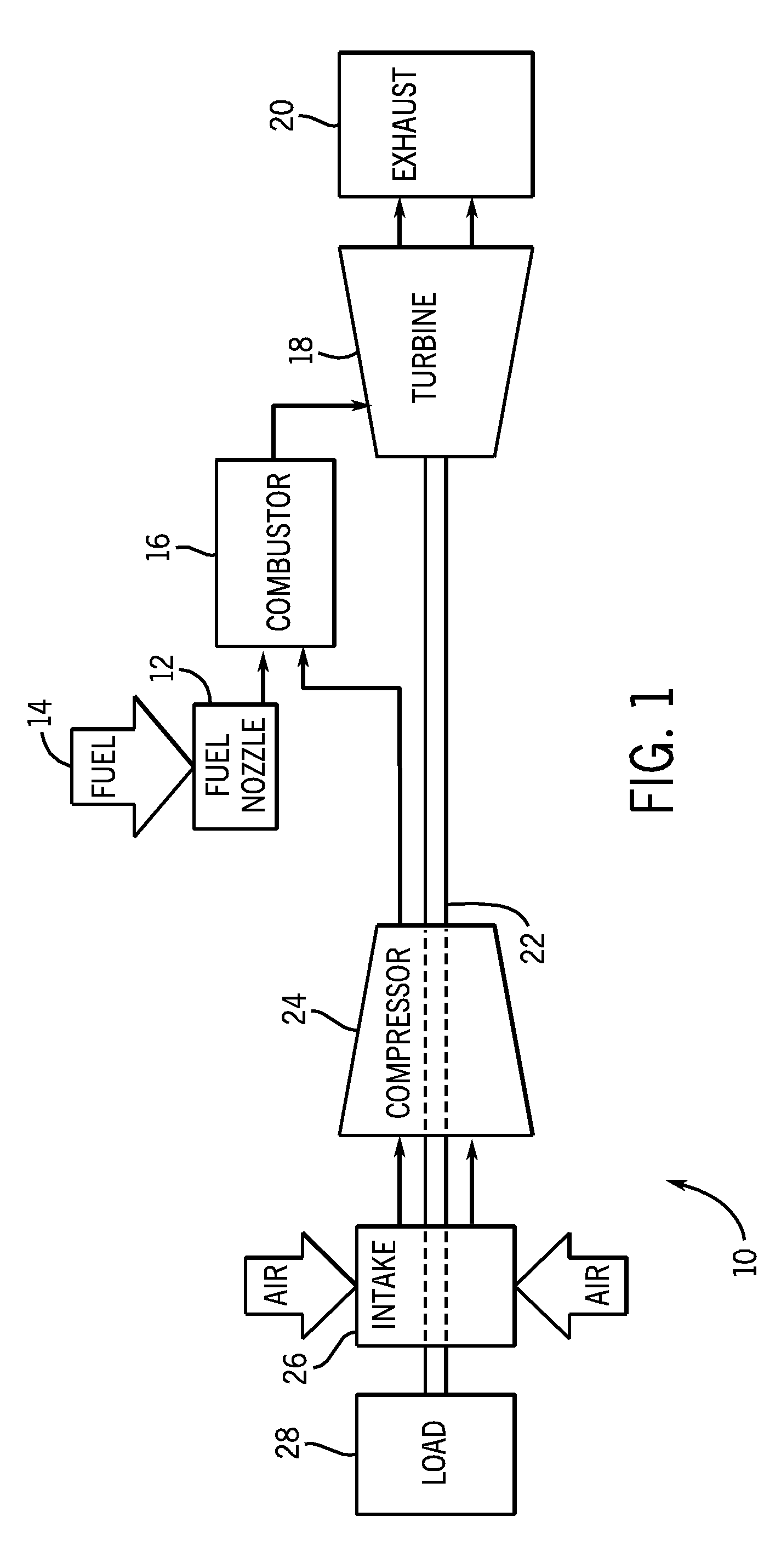

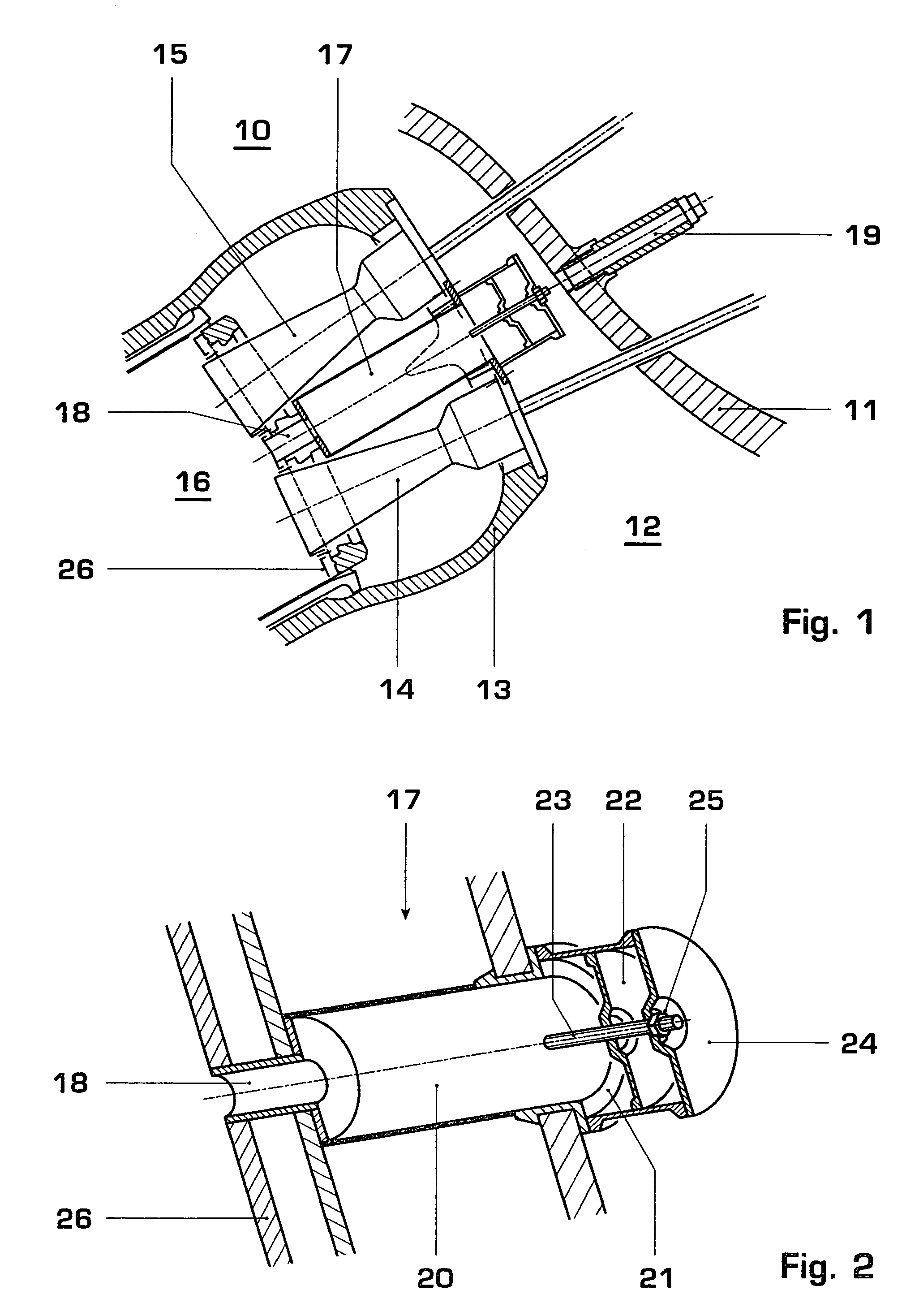

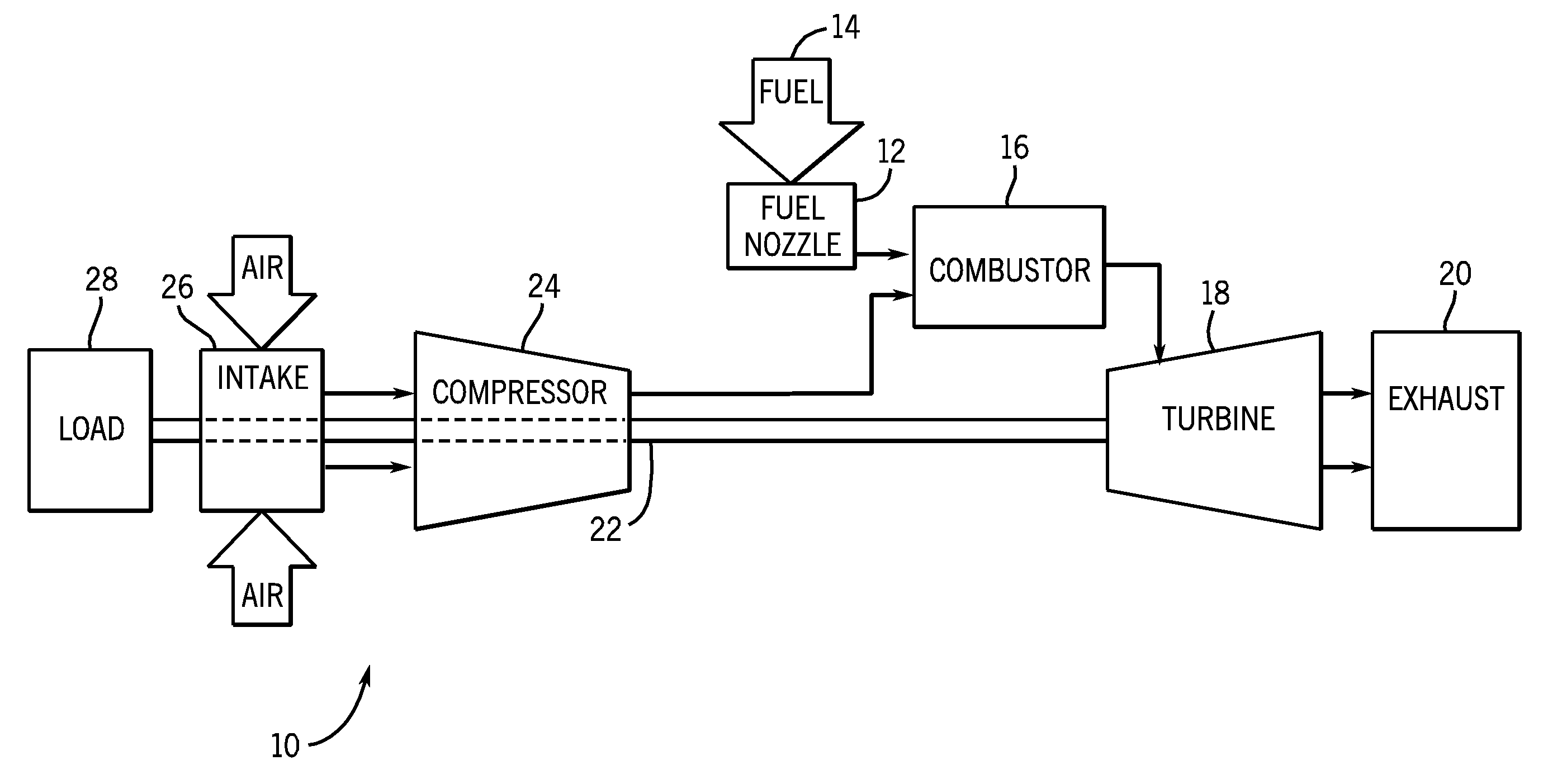

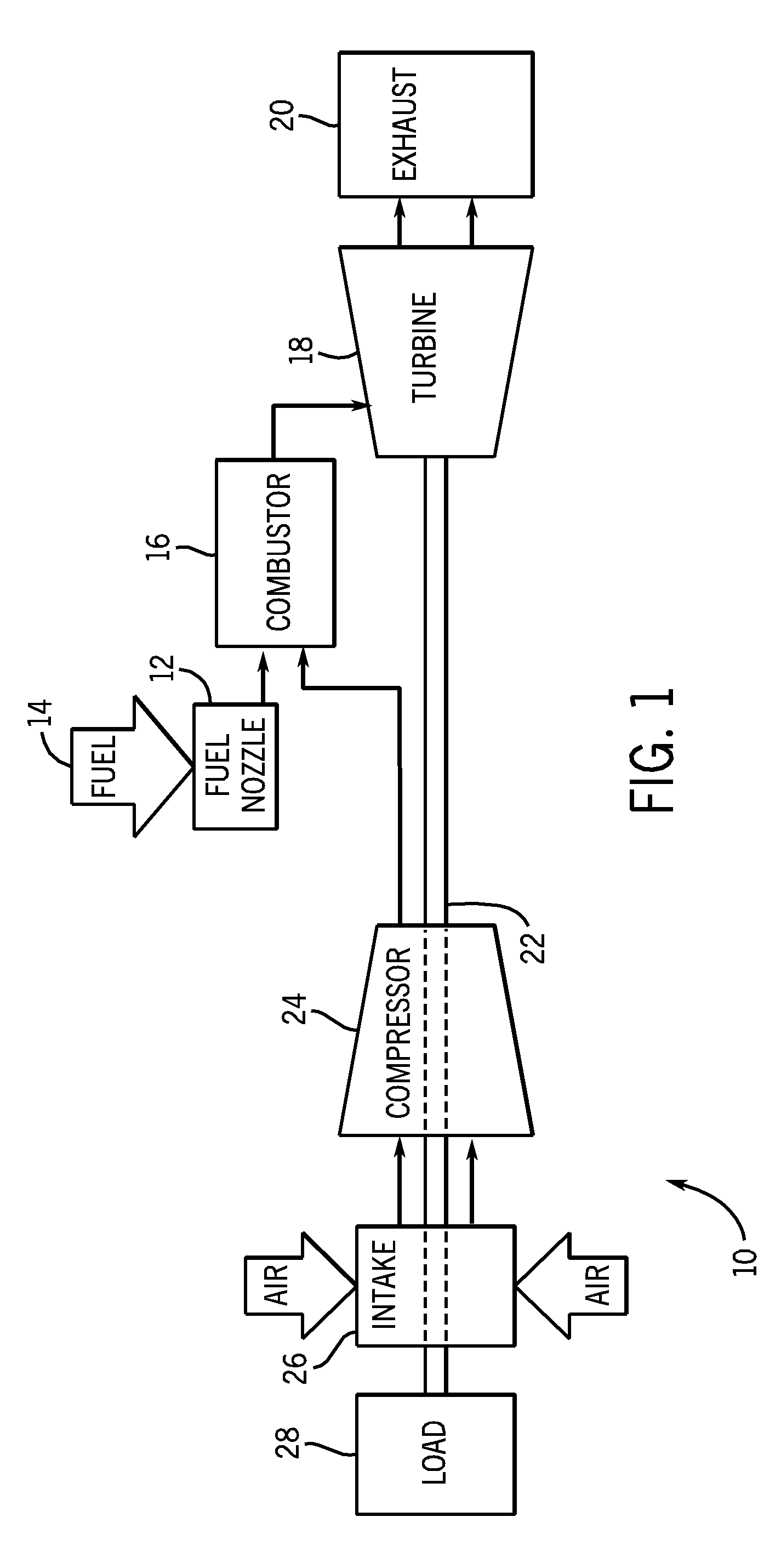

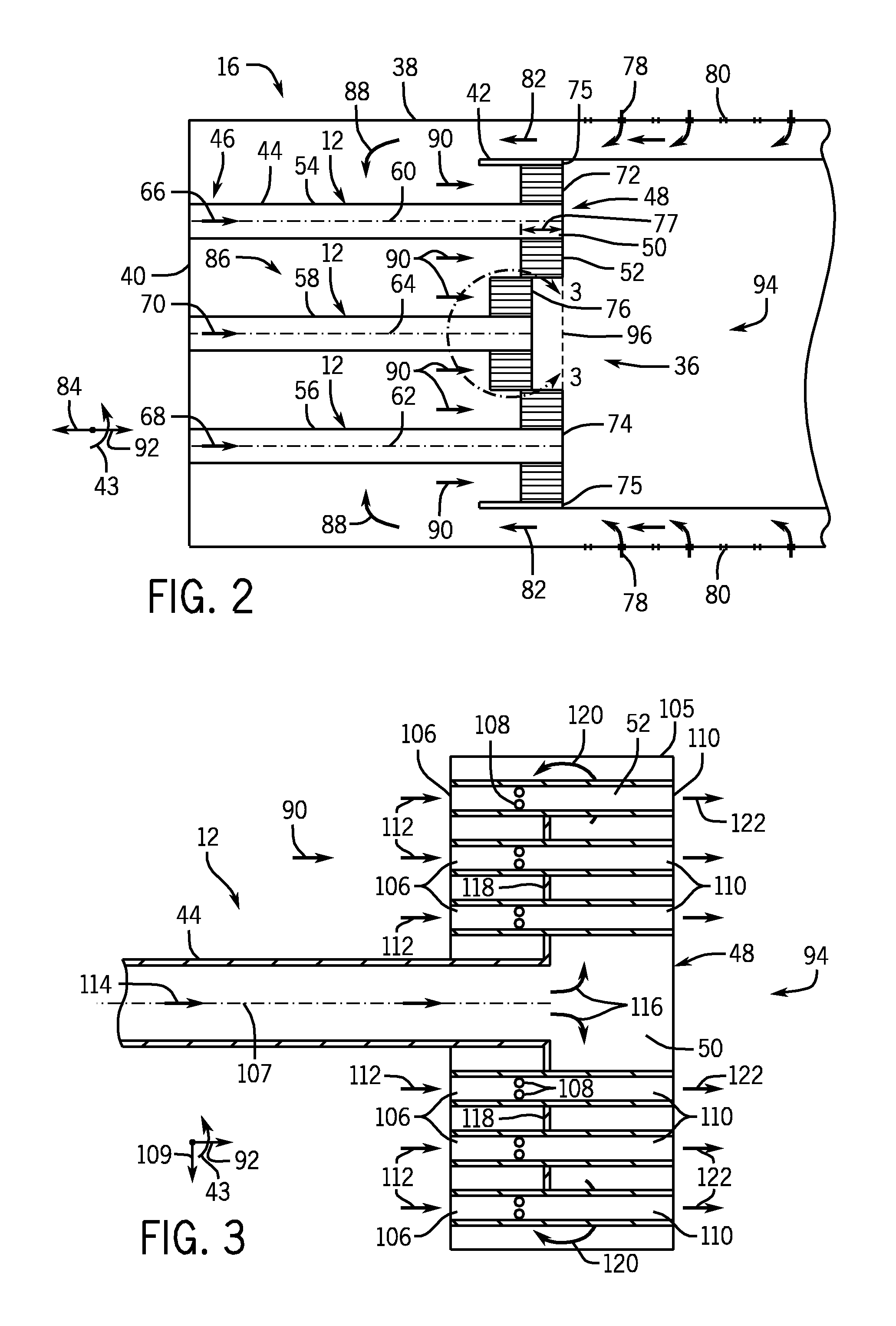

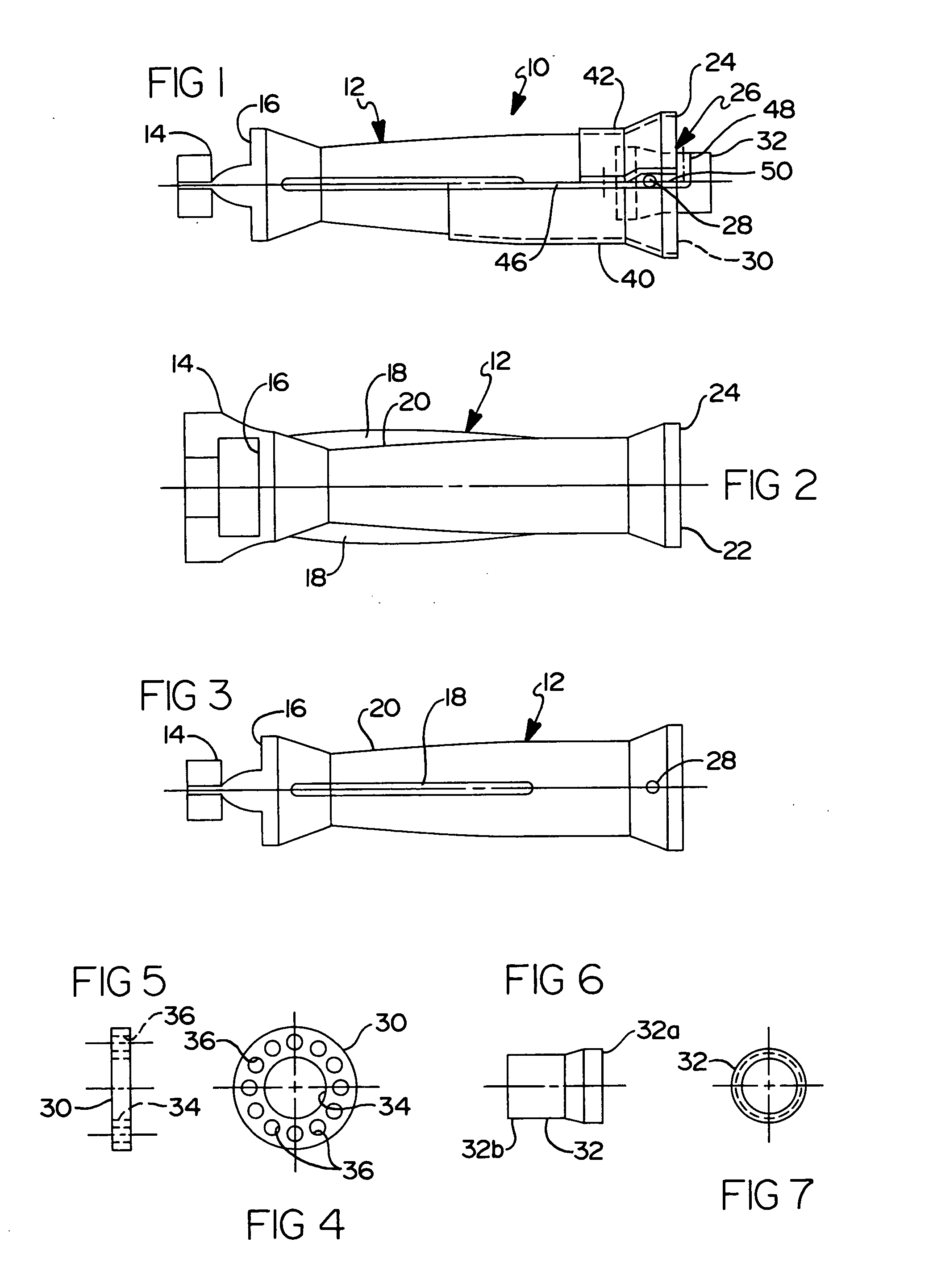

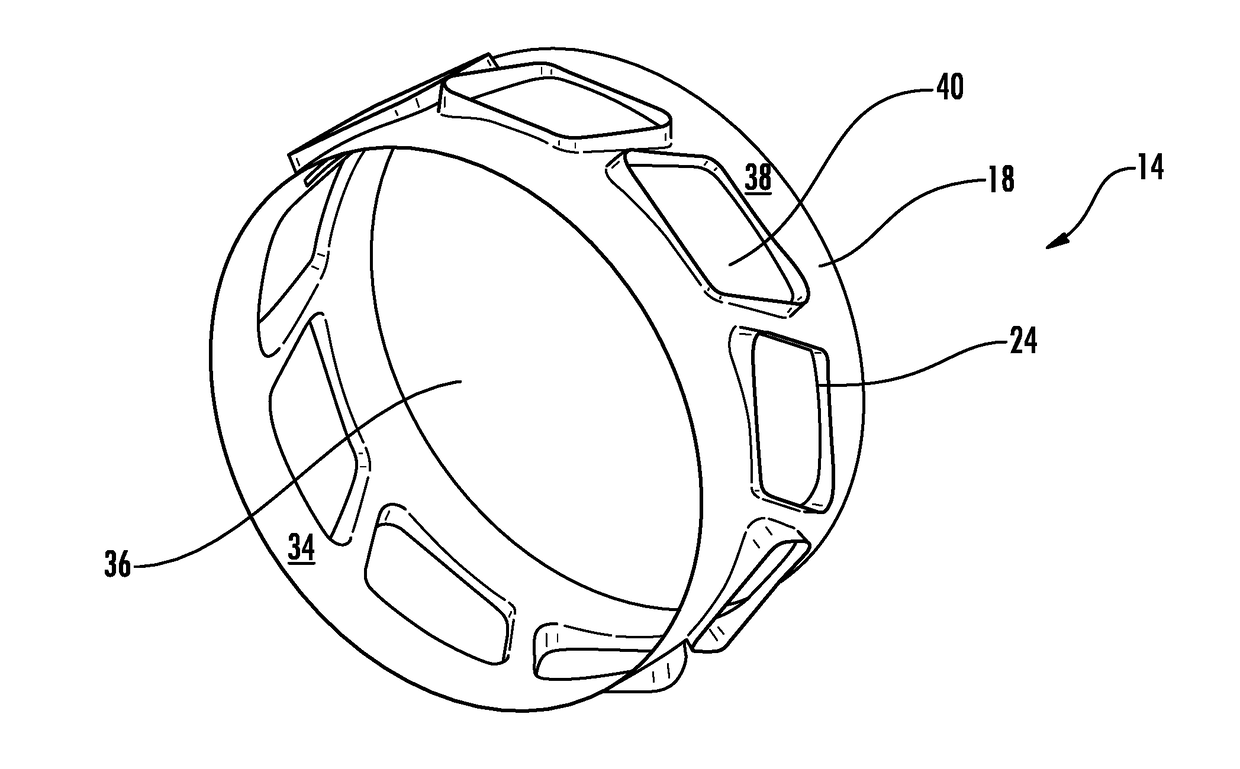

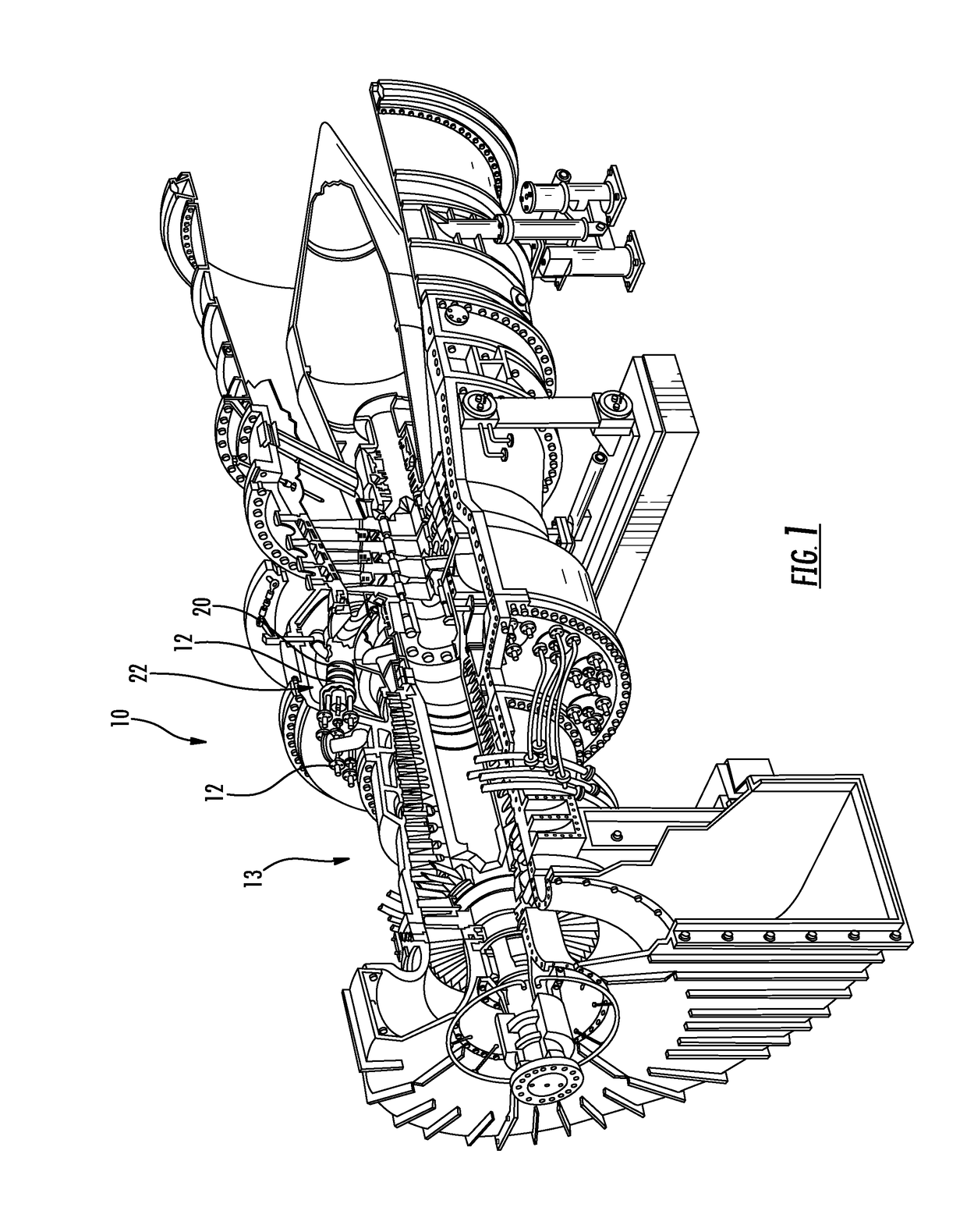

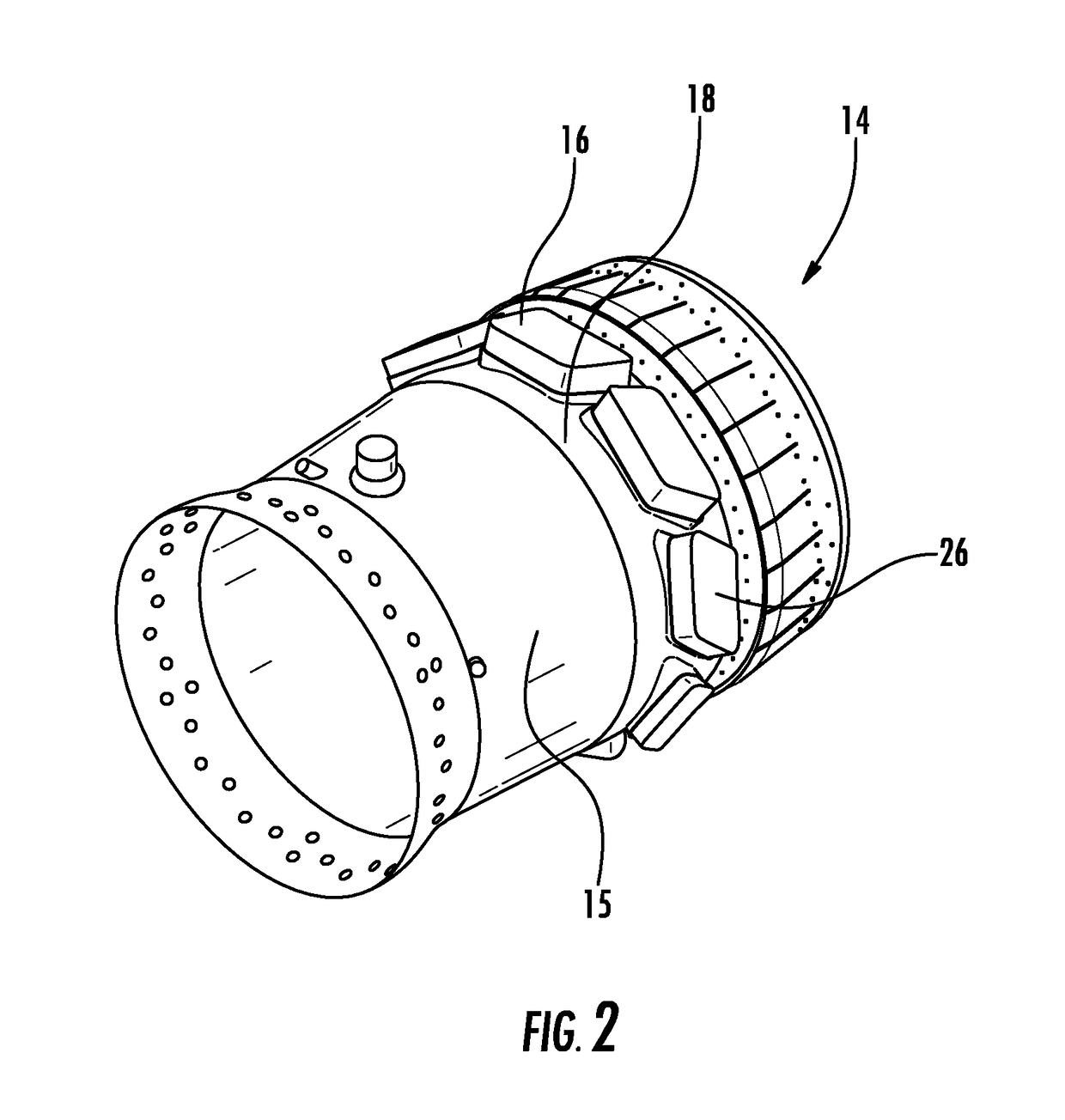

Acoustic damping system for a combustor of a gas turbine engine

ActiveUS20170276350A1Mixing profileEasy to operateBurnersContinuous combustion chamberCombustion chamberCombustor

An acoustically dampened gas turbine engine (10) having a gas turbine engine combustor (12) with an acoustic damping resonator system (14) is disclosed. The acoustic damping resonator system (14) may be formed from one or more resonators (16) formed from a resonator housing (18) positioned within the gas turbine engine combustor (12) at an outer housing (20) forming a combustor basket (22) and extending circumferentially within the combustor (12). In at least one embodiment, the resonator housing (18) may include resonator chambers (26) that may be welded in place within resonator chamber (26) receivers (24) but easily replaceable without exposing the resonator housing (18) to damage. In another embodiment, an inner surface (32) of the resonator chamber (26) may be offset radially outward from an inner surface (34) of the resonator housing (18), thereby creating a flow-path discontinuity and reducing heating of the resonator chamber (26). The acoustic damping resonator system (14) may mitigate dynamics thereby increasing an engine operating envelope and decreasing emissions.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com