Inshot burner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description of the preferred embodiment(s) is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

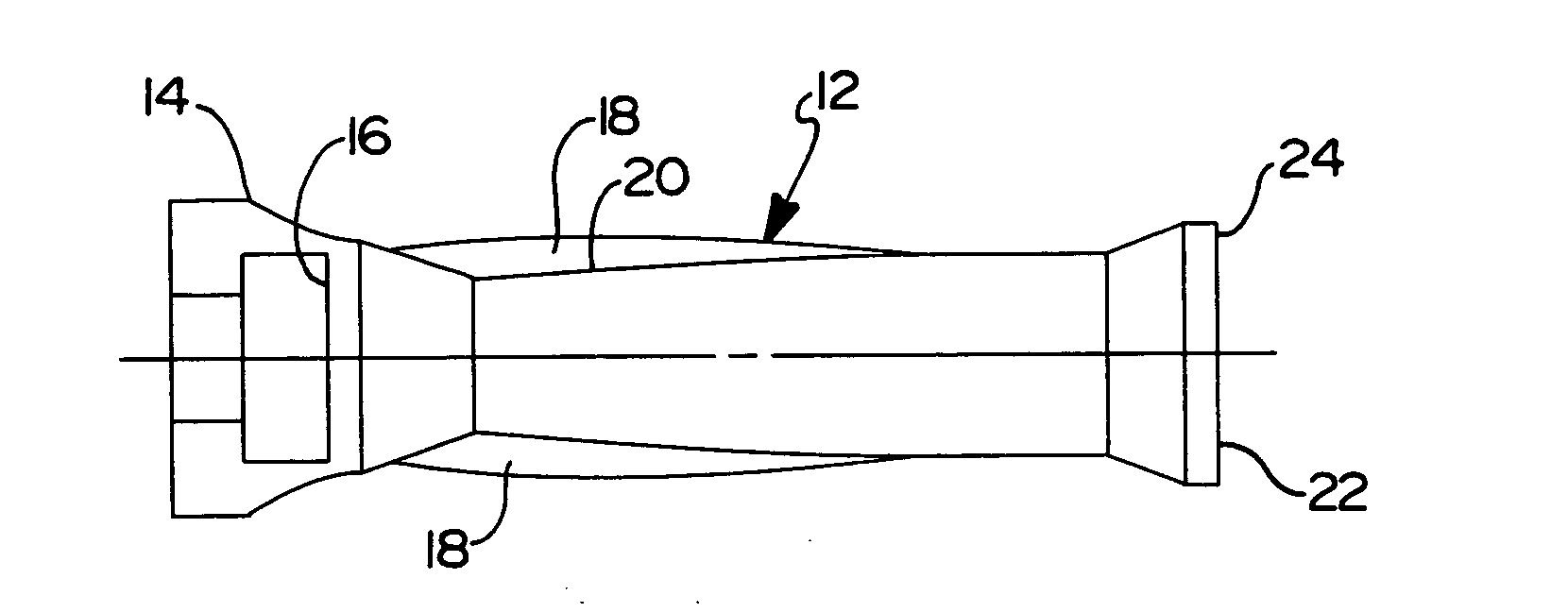

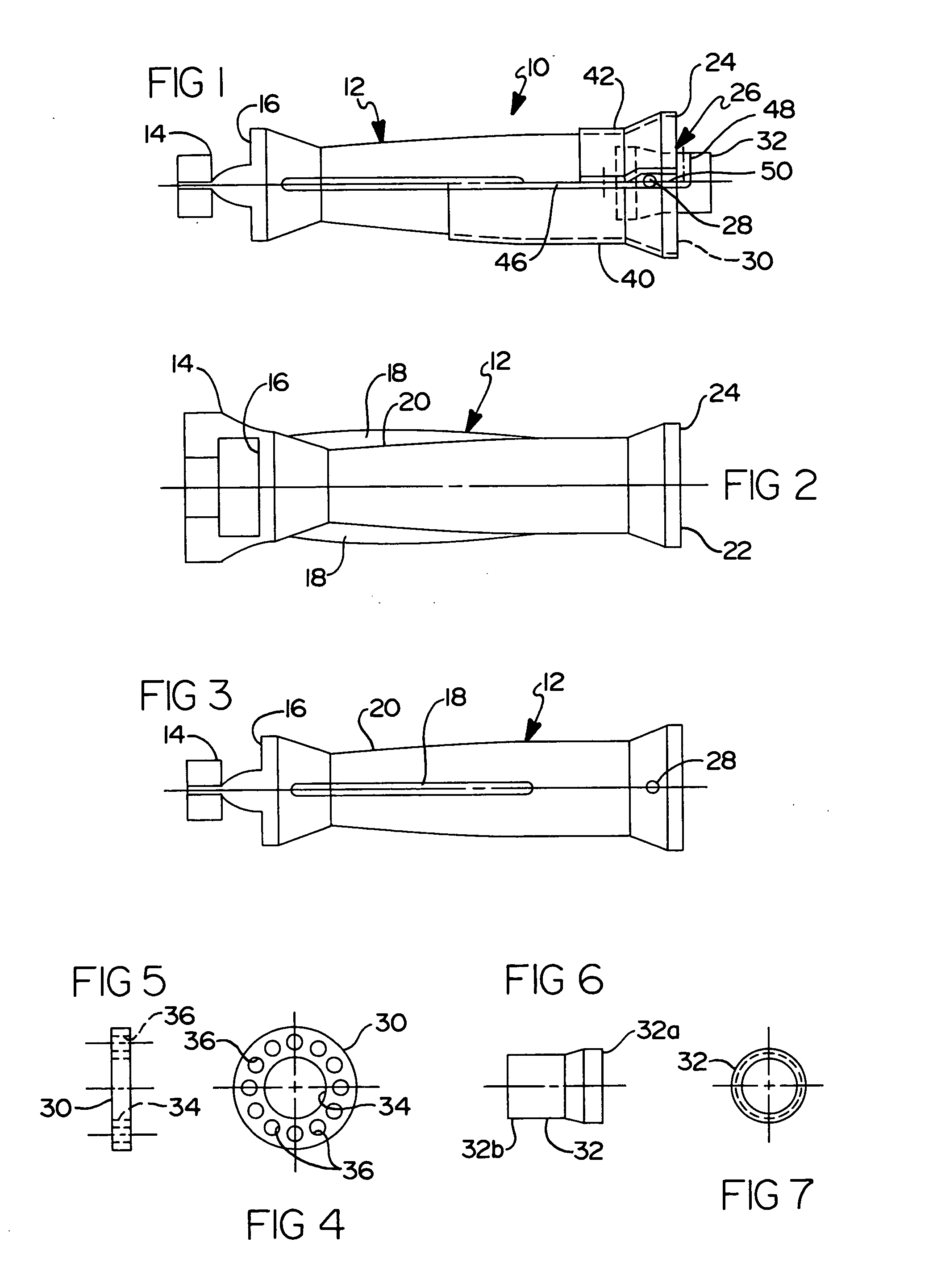

[0023] With reference to FIG. 1, an inshot burner 10, according to the principles of the present invention, is shown. The burner 10 has five component parts that make up the complete assembly. A burner body 12, as best illustrated in FIGS. 2 and 3 is fabricated from a one inch illuminized tube having a 0.065 inch thickness wall. An inch and a half from the back of the tube 12, a reduced diameter portion 14 is provided to create a special shape for the air intake 16. A bead 18 is formed on opposite sides of the burner body in the area of a reduced diameter portion 20. The beads 18 are used to locate the burner body 12, as will be described in greater detail herein. The back of the tube 14 is formed to locate the back of the burner 10 over an orifice that feeds gas to the burner and also forms a window for the primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com