A burner, specifically a premix burner

A burner, premixing technology, applied in burners, burners, gas fuel burners, etc., can solve problems such as structural complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

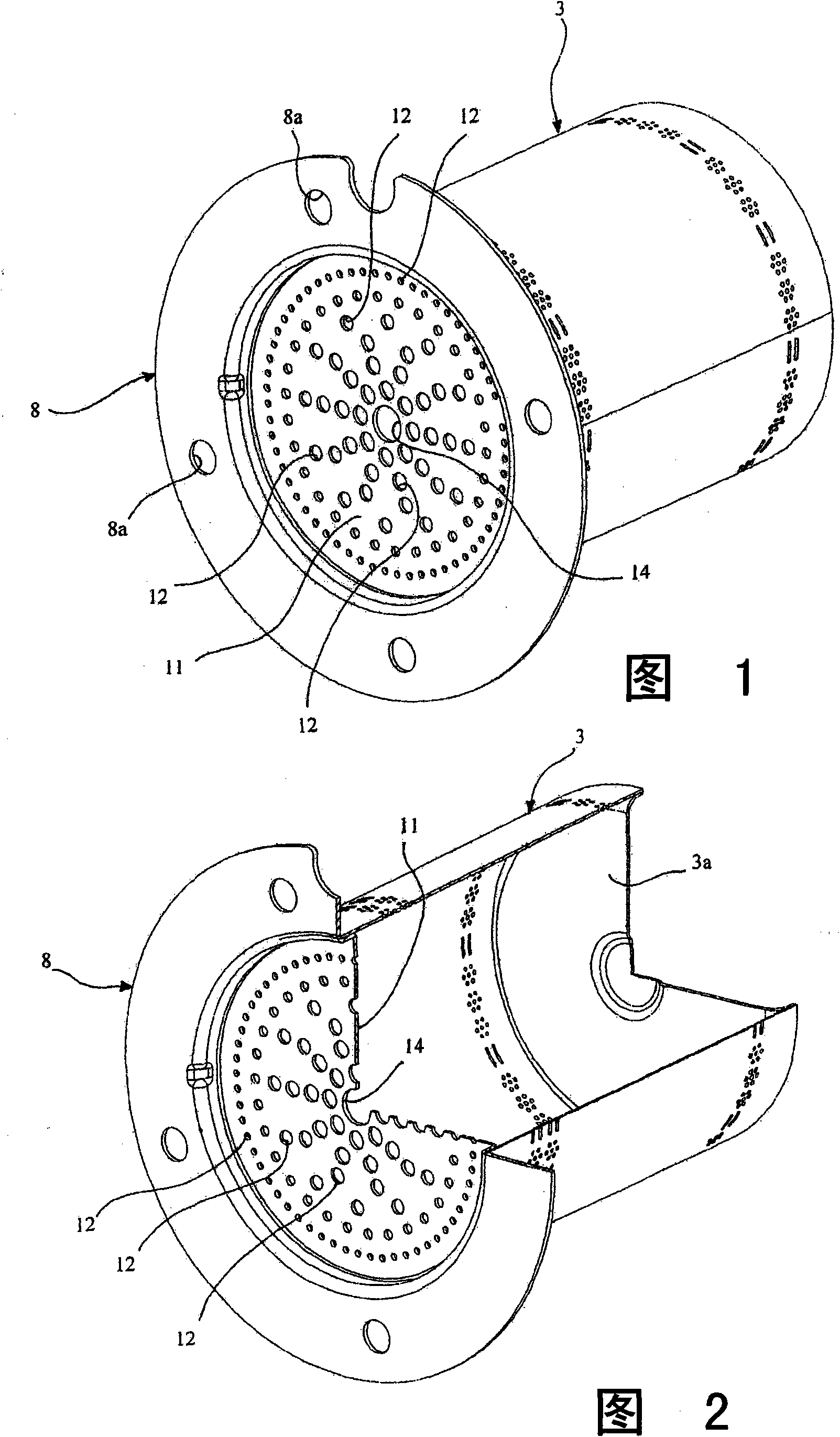

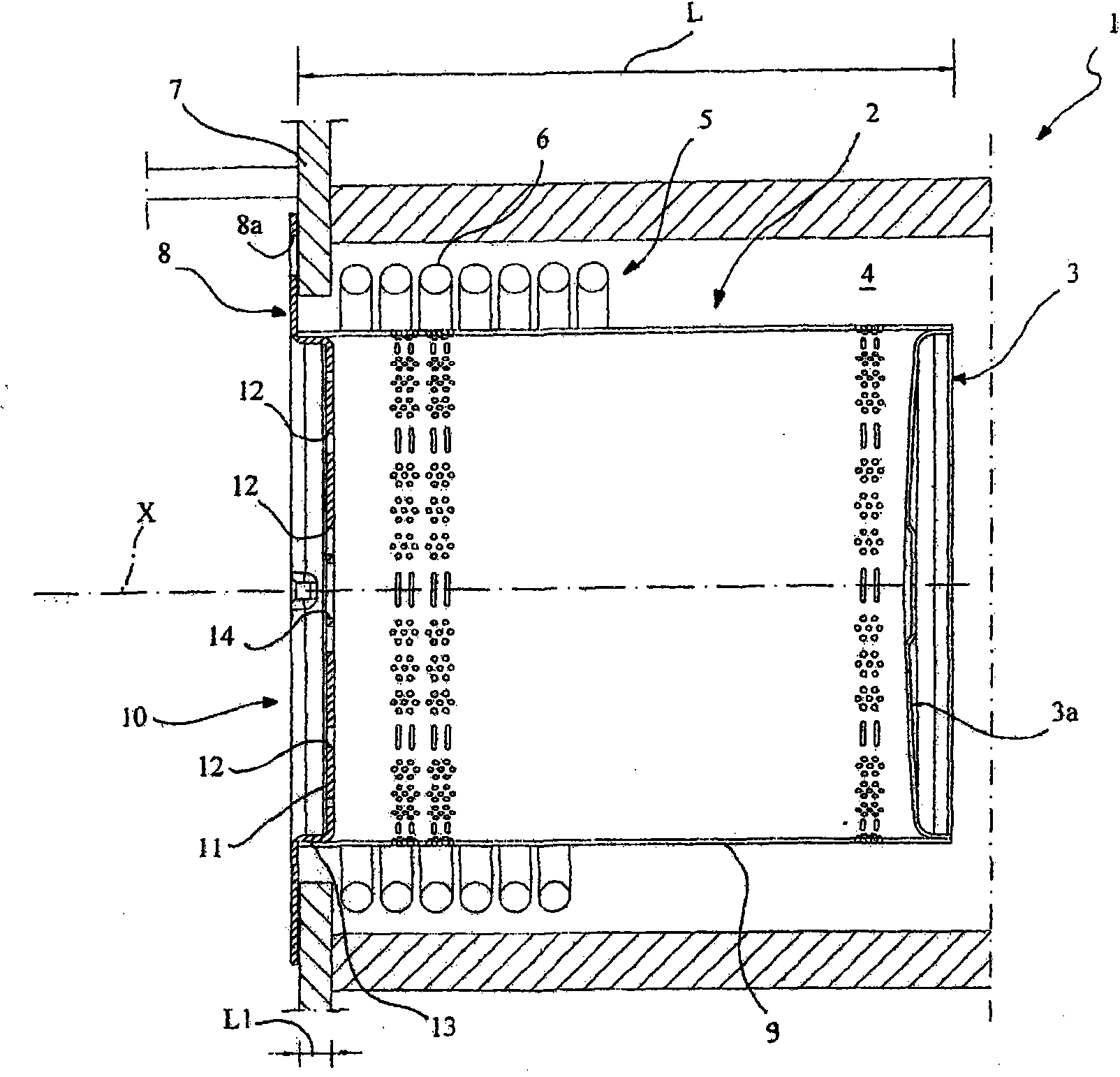

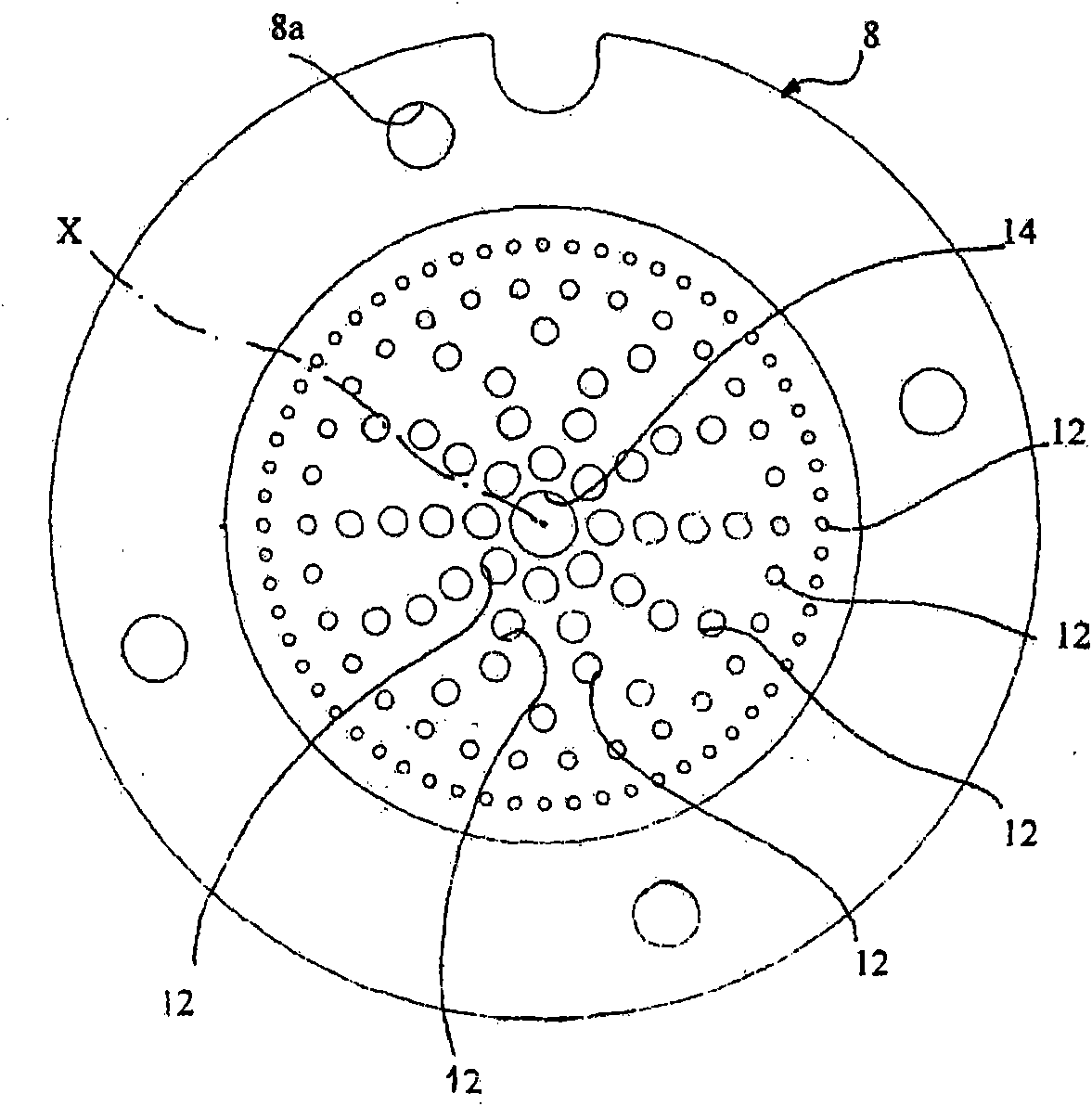

[0017] Referring to the accompanying drawings, reference number 1 designates the burner manufactured according to the present invention as a whole, in particular, a burner for premixed combustible gas.

[0018] The burner comprises a burner body 2 with a burner head 3 in which an air and gas mixture supplied to the burner is combusted, eg by means of fan means (not shown).

[0019] The burner is designed to be accommodated in a combustion chamber 4 of a heating device (not shown), which is shown only schematically, and a heat exchanger 5 is also accommodated in the combustion chamber, which is provided with a tube bundle 6, the working fluid in The tube bundle is circulated and heated by means of burners.

[0020] The burner body 2 is fixed to a shutter element 7 provided to seal the combustion chamber, which is removably connected to the stationary structure of the combustion chamber. Reference numeral 8 designates a connecting flange that fixes the burner body to the gate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com