Fan-metal fiber gas burner

A metal fiber and blower technology, applied in the direction of burners, burners, household stoves, etc., can solve the problems of low gas volume, weak flame, long time, etc., and achieve the effect of no running noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

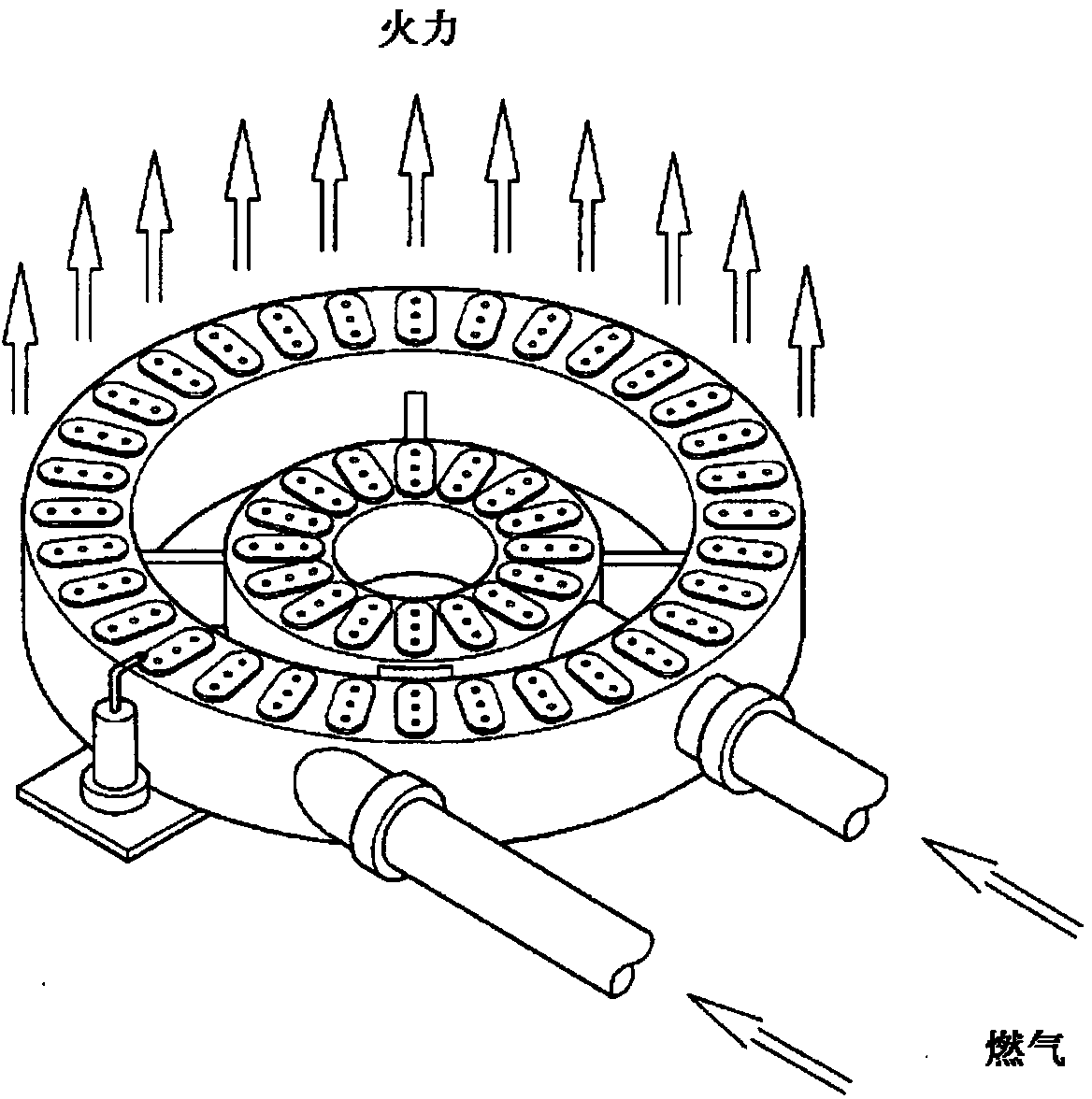

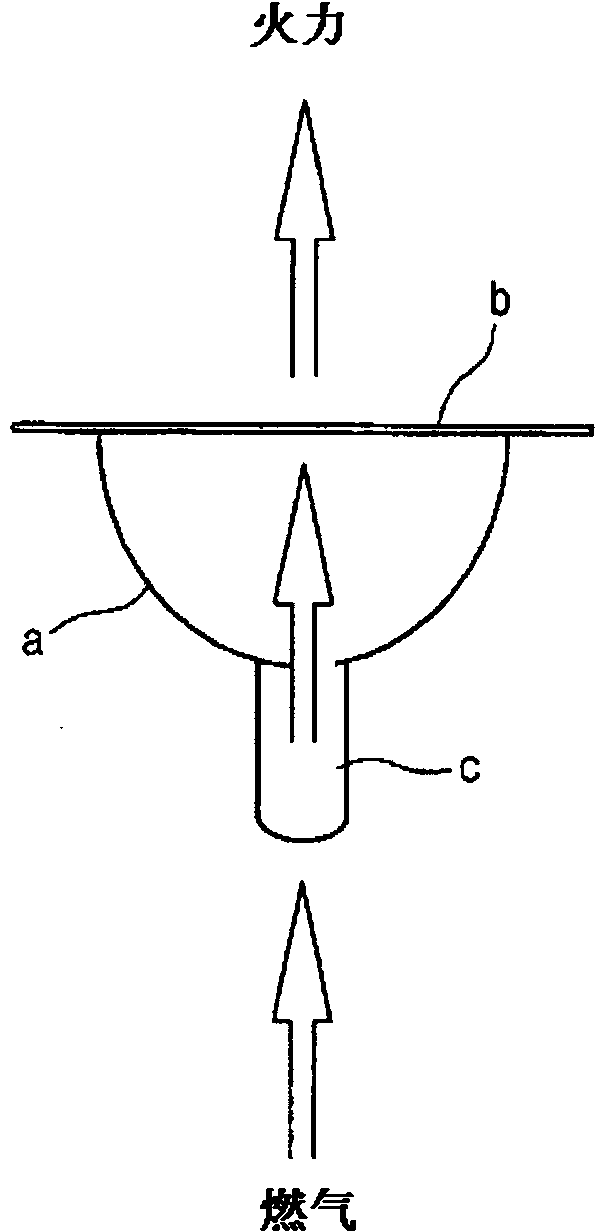

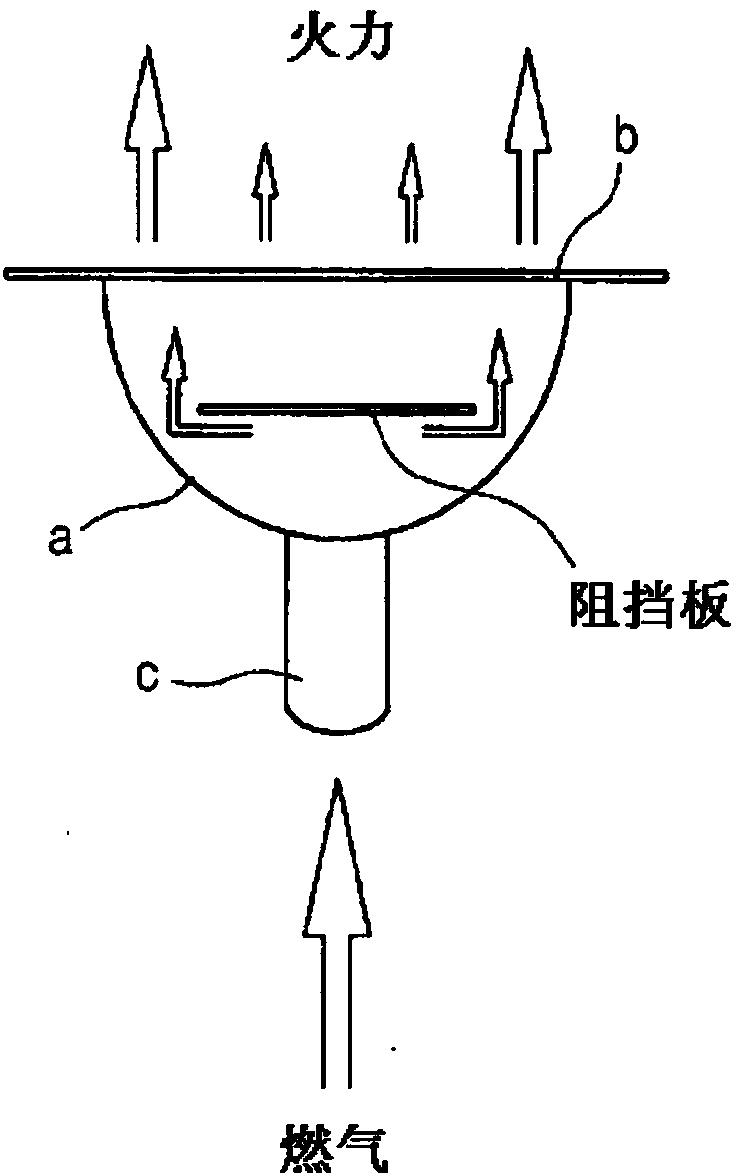

[0031] Such as figure 1 As shown, the basic structure of the blower-metal fiber gas stove of the present invention includes: a burner head 1; a supply pipe 2, which is connected to the center of the bottom of the burner head 1 to communicate with the outside; a gasket 3. The gasket 3 is installed on the combustion part of the burner head 1; and the blower device 4 arranged at the rear end of the supply pipe 2 and the gas supply device arranged on the supply pipe at the front of the blower device 5. Idling dispersing blades 6 are provided inside the burner head 1 .

[0032] The gasket 3 is fixed by laminating the metal mesh 9 and the metal fiber 10 sequentially between the upper fixing frame 7 and the lower fixing frame 8, and the gas is evenly spread and burned throughout the entire surface by utilizing the organizational characteristics of the metal fiber 10. And produce a bright flame.

[0033] The air blast device 4 is a variable air volume type with adjustable air volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com