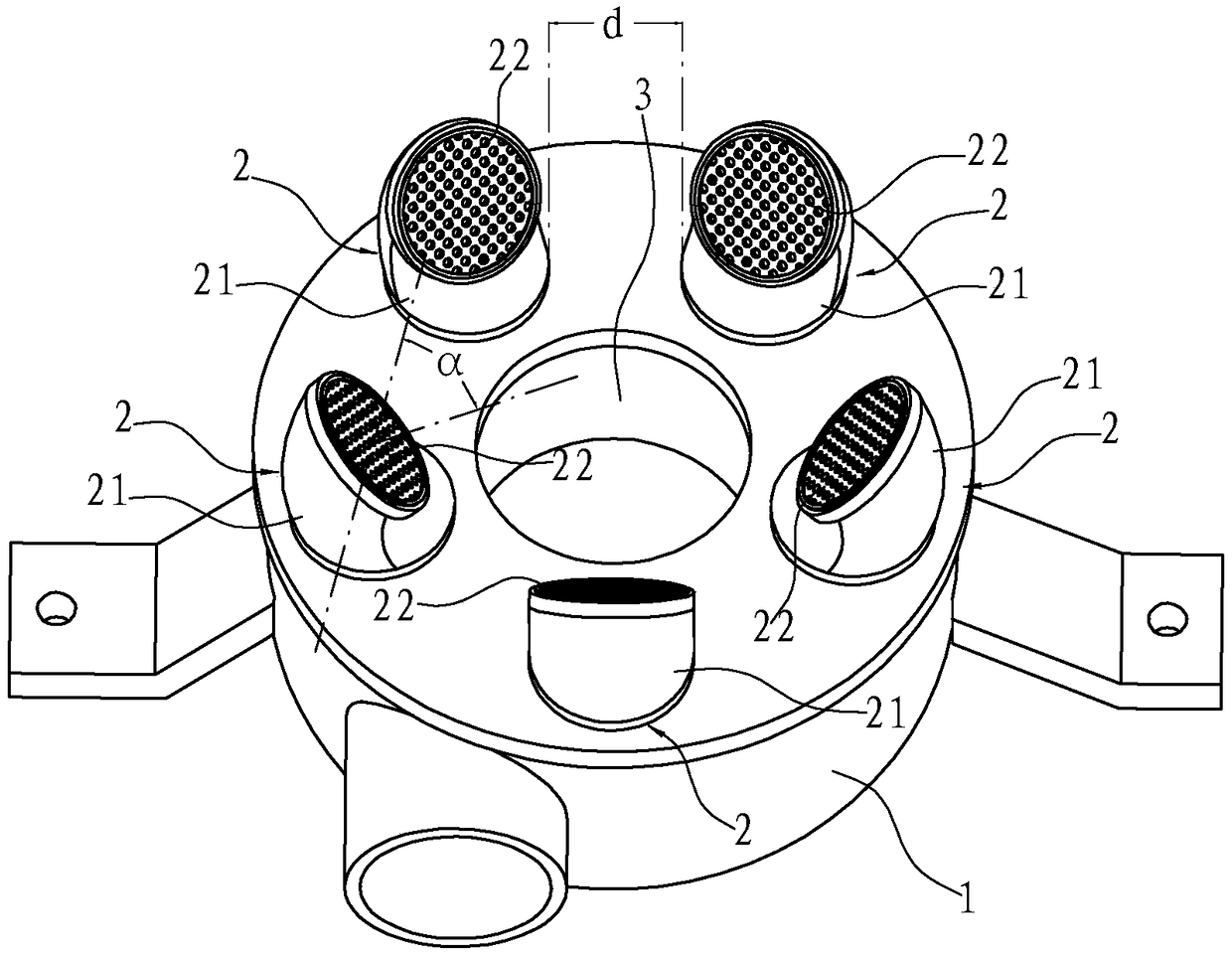

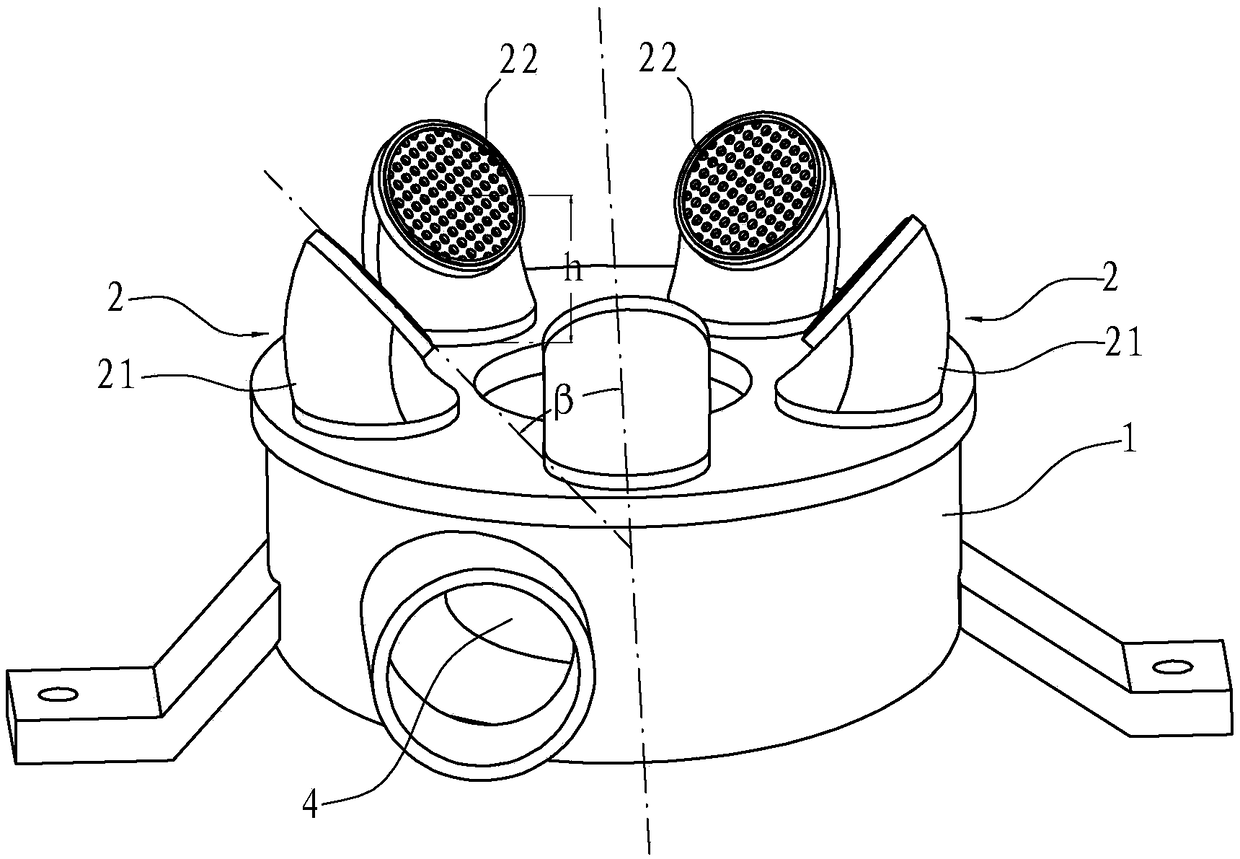

An Independent Combined Rotary Direct Injection Fire Burner

A combined type and burner technology, which is applied in the direction of burner, gas fuel burner, combustion type, etc., can solve the problems of concentrated firepower, affecting combustion efficiency, and air circulation, etc., to achieve uniform firepower, improve combustion efficiency, and complete combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

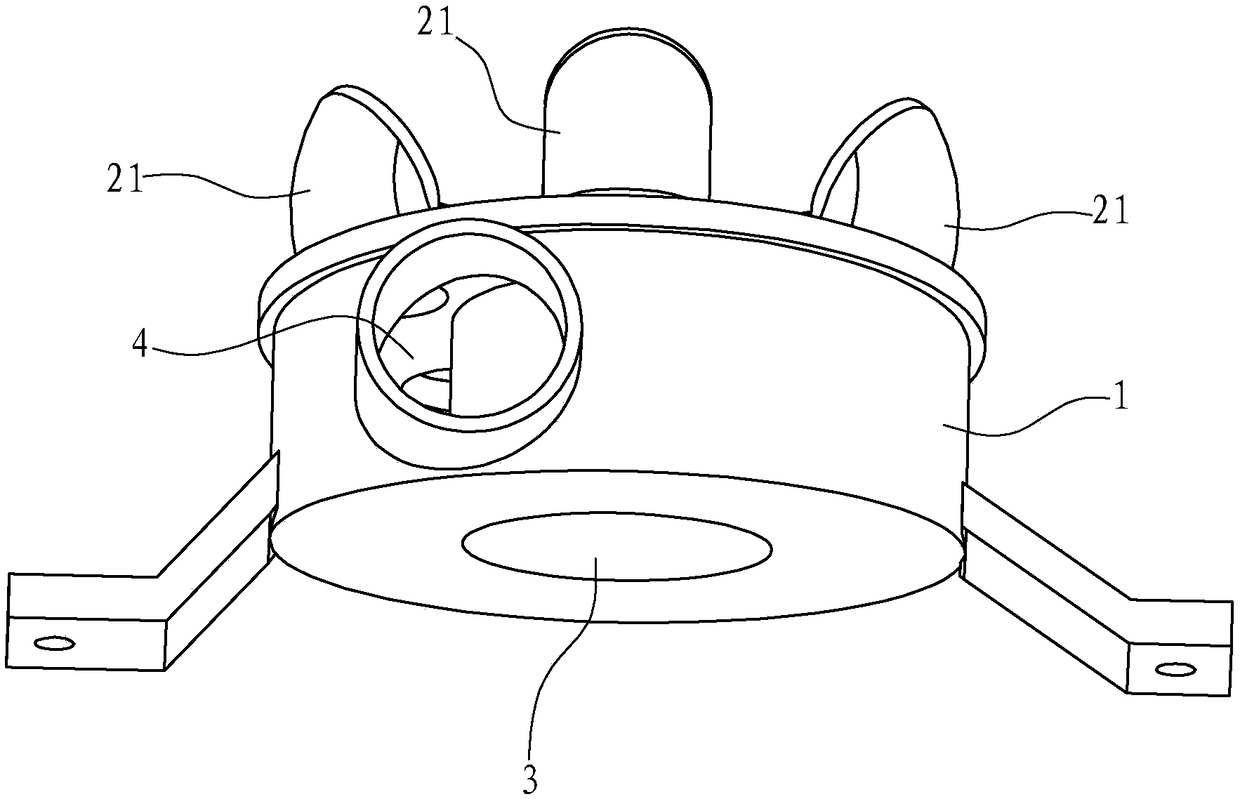

[0022] Such as Figure 4 As shown, different from Embodiment 1, in this embodiment, each connecting pipe 21 and the base 1 are separate structures. Specifically, the top surface of the base 1 is provided with a direct fire mesh body 2 correspond to the mounting holes 11 one by one, the top edge of the hole wall of each mounting hole 11 extends upward along the circumferential direction and protrudes from the top surface to form a mounting boss 111, and the free ends of each connecting pipe 21 are respectively sleeved on the corresponding mounting holes. On the boss 111, the angle of the net sheet 22 can be adjusted as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com