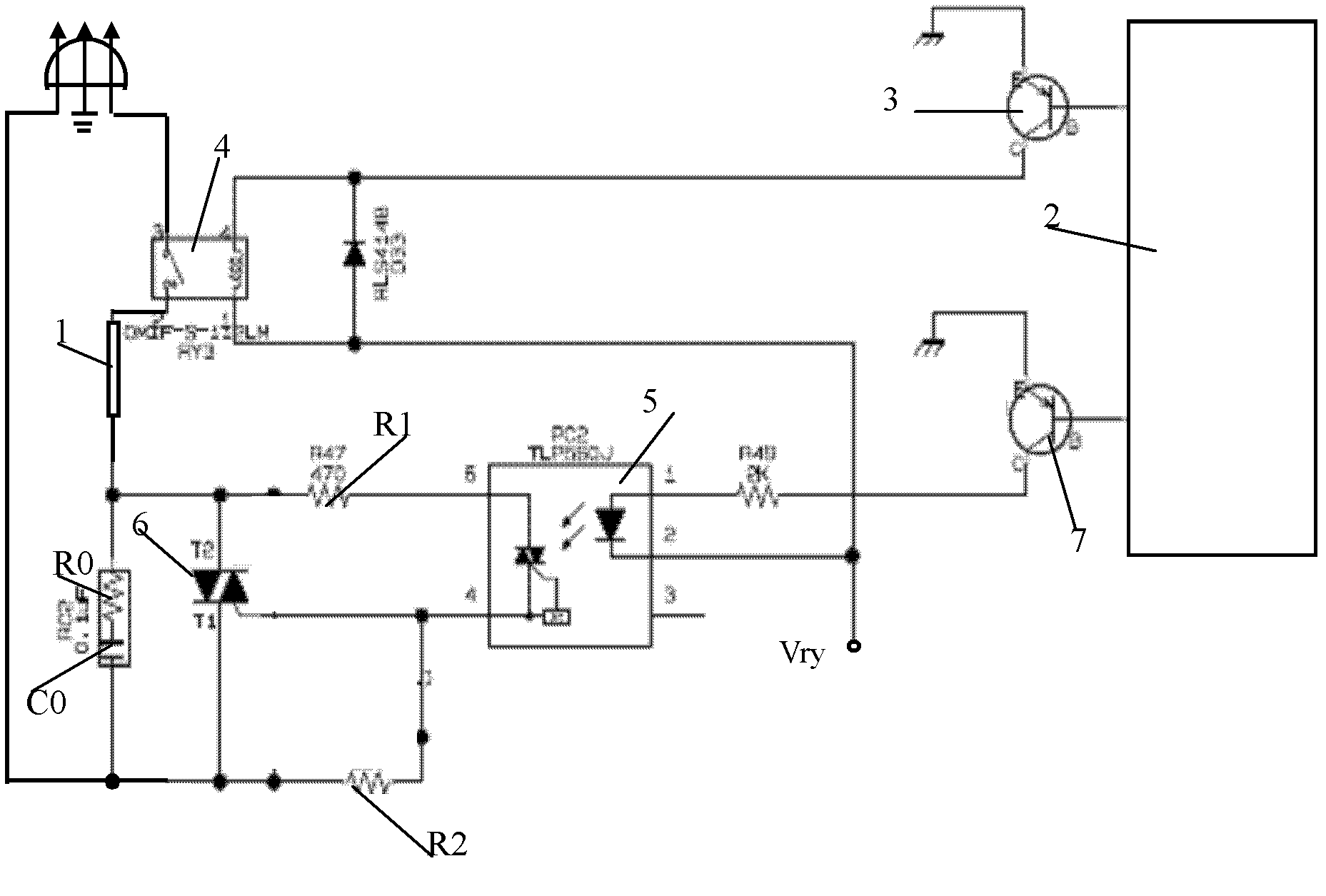

Microwave oven grilling tube power conditioning circuit

A technology of power adjustment and barbecue tube, applied in the field of control, can solve the problems of not being able to achieve the expected grilling effect, not fully reflecting the characteristics of food, and the time is not delicate enough, so as to improve product competitiveness, increase user experience, and fine time control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0011] A general-purpose microwave oven includes: a casing, a rear panel, and an oven door; the casing is basically in the shape of a cuboid, and is formed by bending a rectangular metal plate multiple times to form the appearance of the upper side and the left and right sides of the microwave oven; the rear panel constitutes the appearance of the microwave oven. The rear appearance of the microwave oven; the oven door is used to open / close the front opening of the microwave oven, and the side of the microwave oven has an exhaust hole. A cooking chamber is formed inside the microwave oven, and the cooking chamber is a cuboid-shaped space with an open front, and food is cooked inside it. A container for holding food can be placed inside the cooking chamber, and the microwave generated by the magnetron irradiates the food in the container to heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com