Purified wet-process technique for producing phosphoric acid and equipment thereof

A wet-process phosphoric acid and production process technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems that have not been seen in the industrialized production of purified wet-process phosphoric acid, large quality fluctuations, large consumption of raw materials, etc., to achieve Reduced volatilization area, reduced purification cost, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

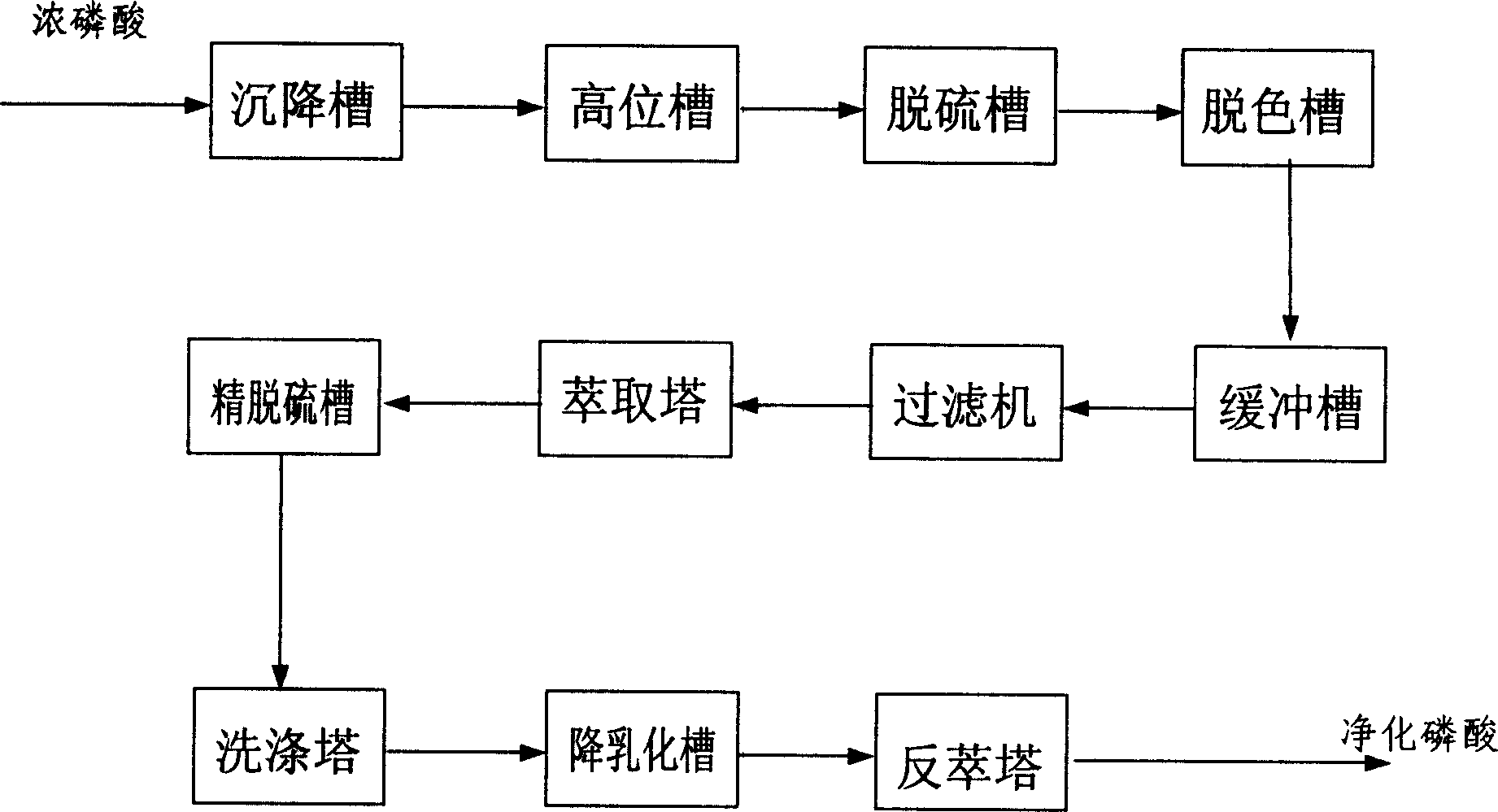

[0022] Embodiment 1: The specific technological process of 5,000 tons / year wet-process phosphoric acid purification is as follows:

[0023] Concentration from acid tank about 48% P 2 o 5 Concentrated phosphoric acid enters the desulfurization and decolorization tank after being metered, and the desulfurization agent phosphate rock powder and calcium carbonate are metered and then enter the desulfurization and decolorization tank. 3 reaction to generate CaSO 4 2H 2 O achieves the purpose of desulfurization, and calcium carbonate is also combined with F - The reaction produces CaF 2 Precipitation; decolorizing agent sodium carbonate and diatomaceous earth are added to the desulfurization and decolorization tank to react with fluorosilicate (salt) in phosphoric acid to produce sodium fluorosilicate precipitation; at the same time, activated carbon is quantitatively added to the desulfurization and decolorization tank and phosphoric acid for decolorization reaction to remove p...

Embodiment 2

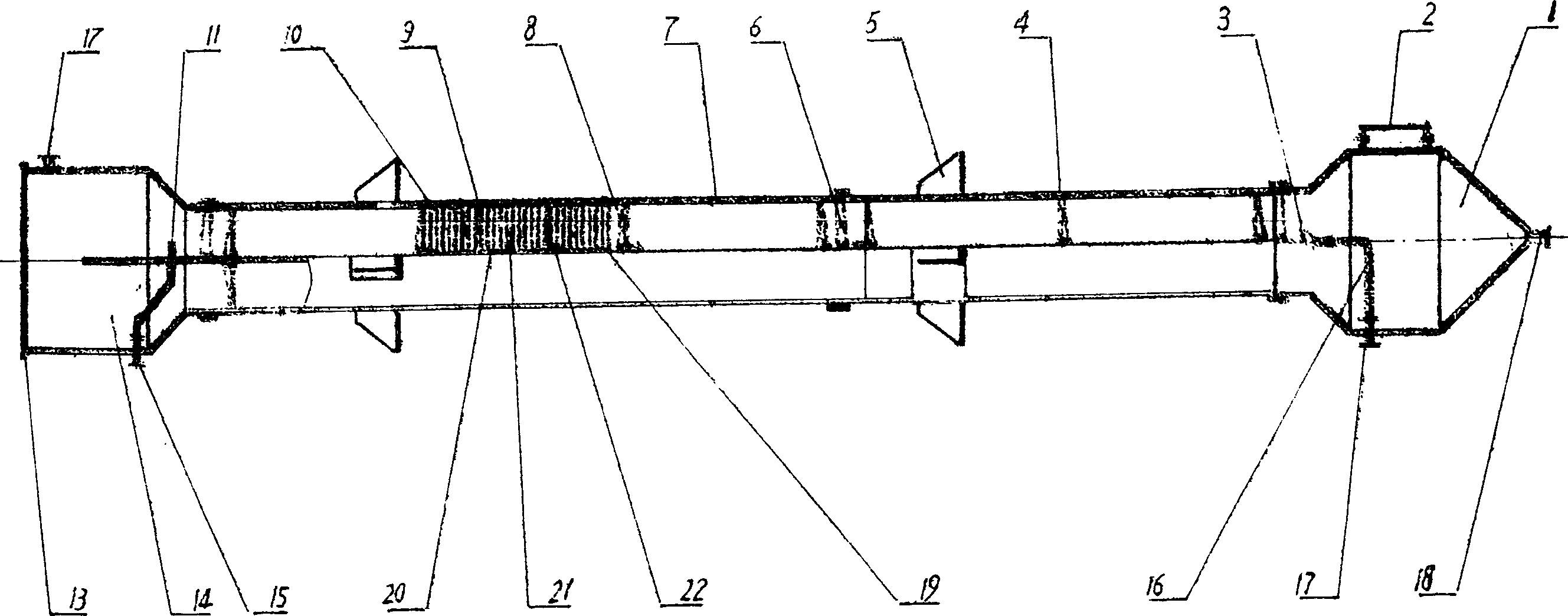

[0026] Embodiment 2: The used rotary vibrating sieve plate tower of 5,000 tons / year wet-process phosphoric acid purification production process is as attached figure 2 shown.

[0027] The tower is composed of an upper clarification chamber 14, a tower body 7, and a lower clarification chamber 1, with a total height of 11,908mm; a cover plate 13 is provided on the top of the tower; The 7 rooms of the tower body are connected by upper cones; the outer diameter of the tower body 7 is 800 mm, and there are 70 to 115 sieve plates 9 in total, and the sieve hole diameter is 12 mm; the upper clarification chamber 14 has a phosphoric acid (heavy phase) inlet pipe 15, and the lower clarification chamber 1 has an extractant (light phase) inlet pipe 17 inside, and a glass liquid level gauge 2 outside; there is a rotating shaft 8 in the tower; two sets of B-shaped ear supports 6 are outside the tower body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com