Permeation device and method

一种渗透装置、传动装置的技术,应用在炉子控制装置、炉、电荷操纵等方向,能够解决被渗透磁体温度不一致、升温降温速度不一致等问题,达到消除磁体温度差异、保证一致性、提高升温速度和降温速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

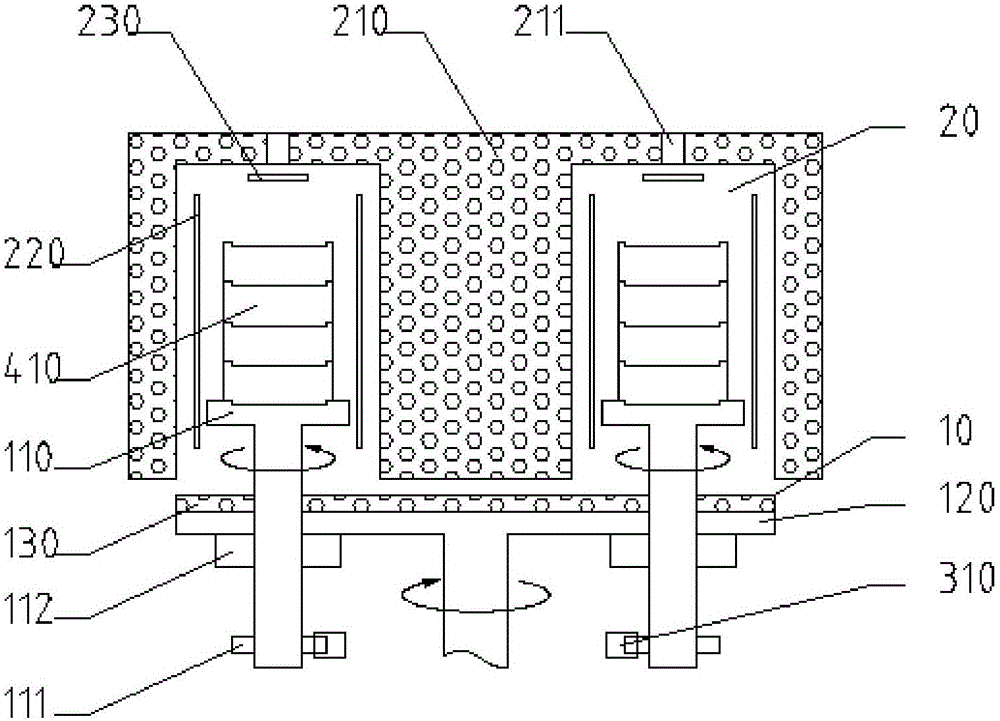

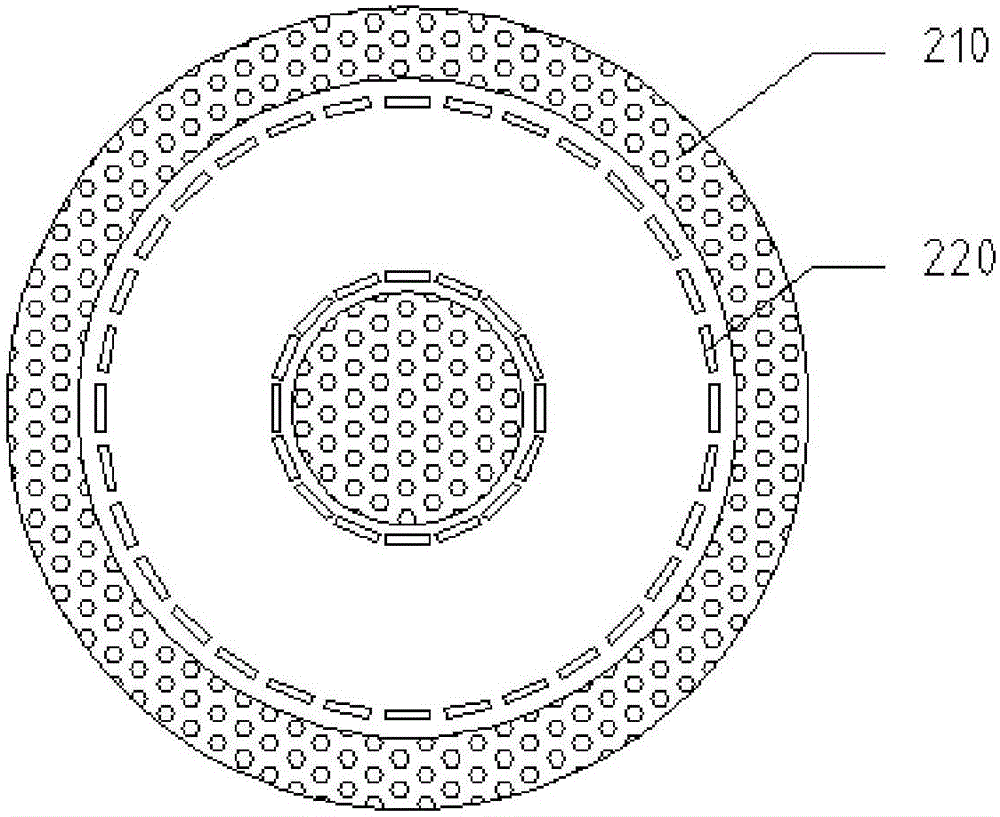

[0074] Such as figure 1 As shown, the permeation device includes components such as a rotating tray 10, a rotating bracket 110, a heating chamber 20, and a cartridge 410.

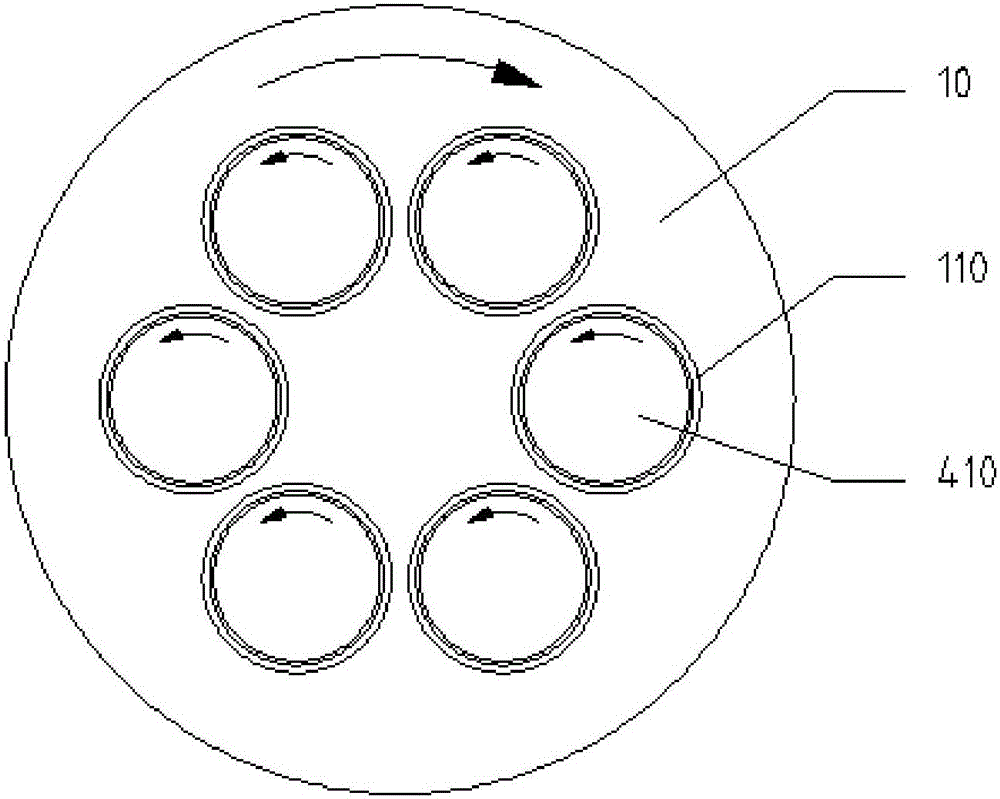

[0075] The rotary bracket 110 is installed on the rotary tray 10 below it, and multiple rotary brackets are installed on the rotary tray 10 in a circular array, which can perform high temperature penetration on multiple magazines. The material of the rotating bracket 110 is heat-resistant steel. The rotating bracket 110 is integrated with the rotating tray 10 through a rotating mechanism 112, and the rotating tray 10 is provided with a hole, and a bearing is installed in the hole, and the rotating bracket 110 is installed on the rotating tray through the bearing.

[0076] See attached figure 1 and Figure 4 , a first transmission that drives the rotation of the rotating tray 10 is installed below it. A second transmission is installed below the rotating bracket 110 so that the rotation of the rotating b...

Embodiment 2

[0083] The working process of the infiltration method according to the present invention will be described in detail below by taking a sintered NdFeB magnet infiltrated with dysprosium fluoride and coated with dysprosium fluoride ultrafine powder as an example in conjunction with the accompanying drawings. Of course, those skilled in the art can also use the infiltration method of the present invention to perform relevant high-temperature infiltration operations on other magnets.

[0084] In the present embodiment, concrete technological process is:

[0085] In the charging stage, the annular array of sintered NdFeB magnets coated with dysprosium fluoride ultrafine powder is loaded into the cylindrical material box 410, and the magnets can be placed in a single layer or stacked in several layers in the material box 410. The rotary tray 10 and the rotary bracket 110 are lowered as a whole by a lifting mechanism, wherein the lifting mechanism may be powered by a hydraulic cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com