Preparation method of two-dimensional perovskite single crystal with high luminous purity

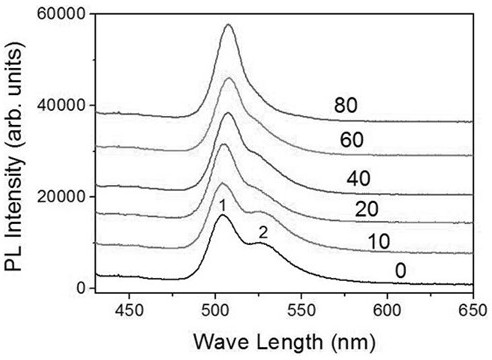

A perovskite and purity technology, applied in the field of preparation of two-dimensional perovskite single crystals, can solve the problems of reduced component purity and insignificant effect, and achieve the effects of improving luminescence purity, improving luminescence purity, and avoiding accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

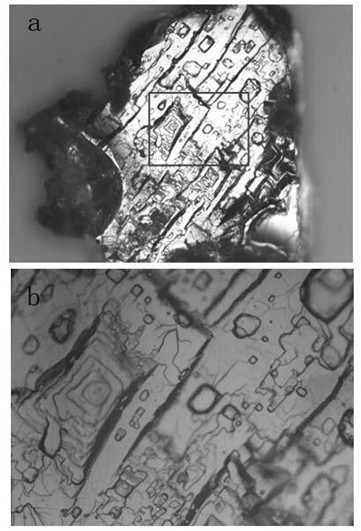

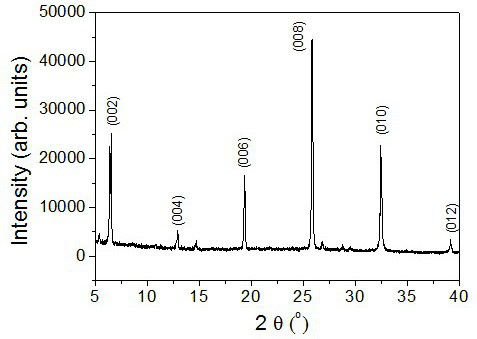

Examples

Embodiment 1

[0024] The preparation method of the two-dimensional perovskite single crystal with high luminous purity in this embodiment is as follows:

[0025] (1) Dissolve 2.232 g of lead oxide (PbO) into 10 ml of hydroiodic acid (HI) and 1.7 ml of hypophosphorous acid (H 3 PO 2 ) in the mixed solution, heated to 100°C to obtain a transparent solution, and kept warm in a constant temperature water tank.

[0026] (2) Slowly add 0.924 ml of n-butylamine to 5 ml of hydroiodic acid solution to obtain a transparent solution.

[0027] (3) Slowly add the transparent solution of step (2) into the solution of step (1) under magnetic stirring to obtain a transparent orange-yellow precursor solution.

[0028] (4) Quickly transfer the perovskite precursor solution with a volume of 2.5, 5, 10, 15 and 20 ml in step (3) into the inner tank of the hydrothermal kettle preheated at 80 °C, and close the hydrothermal tank in time. kettle. The filling degrees of the above-mentioned 5 parts of solutions i...

Embodiment 2

[0041] A method for preparing a two-dimensional perovskite single crystal with high luminescence purity, the steps are as follows:

[0042] (1) Dissolve lead oxide in a mixture of hydroiodic acid and hypophosphorous acid (the volume ratio of hydroiodic acid and hypophosphorous acid is 10:1.7), heat to 100°C to obtain a transparent solution A, and keep it warm in a constant temperature water tank , the concentration of solution A is 0.9 mol / L;

[0043] (2) Slowly add n-butylamine into the hydroiodic acid solution to obtain a transparent solution B, the concentration of which is 1.5 mol / L;

[0044] (3) Slowly add solution B of step (2) to solution A of step (1) under magnetic stirring to obtain a transparent orange precursor solution, and the volume ratio of solution B to solution A is 1:1.67;

[0045] (4) Quickly transfer the precursor solution in step (3) into the liner of the hydrothermal kettle preheated at 80°C, and close the hydrothermal kettle in time. The filling degree...

Embodiment 3

[0047] A method for preparing a two-dimensional perovskite single crystal with high luminescence purity, the steps are as follows:

[0048] (1) Dissolve lead oxide in a mixture of hydroiodic acid and hypophosphorous acid (the volume ratio of hydroiodic acid and hypophosphorous acid is 10:1.7), heat to 100°C to obtain a transparent solution A, and keep it warm in a constant temperature water tank , the concentration of solution A is 0.8 mol / L;

[0049] (2) Slowly add n-butylamine into the hydroiodic acid solution to obtain a transparent solution B, the concentration of which is 2.5 mol / L;

[0050] (3) Slowly add solution B in step (2) to solution A in step (1) under magnetic stirring to obtain a transparent orange-yellow precursor solution. The volume ratio of solution B to solution A is 1: 3.12;

[0051] (4) Quickly transfer the precursor solution in step (3) into the liner of the hydrothermal kettle preheated at 80°C, and close the hydrothermal kettle in time. The filling de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com