Infrared radiation temperature measurement calibration device and calibration method for chemical vapor deposition equipment

A chemical vapor deposition and infrared radiation technology, which is applied in the field of infrared radiation temperature measurement and calibration devices, can solve the problems of inconvenient operation, inaccurate relative temperature readings of the tester, and inability to meet the requirements of measurement accuracy, so as to eliminate the influence of emissivity. Temperature, relative temperature accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

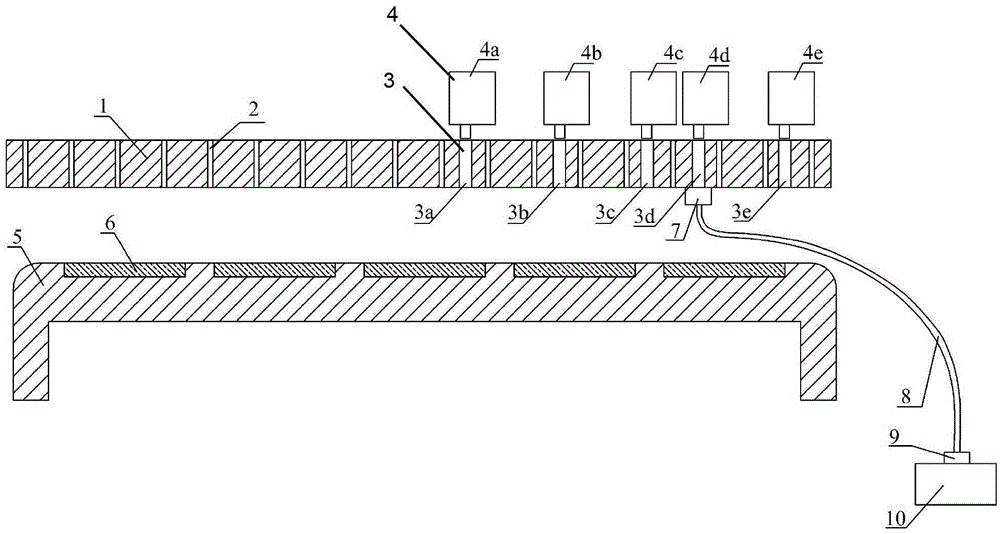

[0019] see figure 1 , The infrared radiation temperature measurement and calibration device of the present invention includes an infrared radiation temperature tester 4, an optical detection hole 3, a black body furnace 10, an optical fiber or a light beam 8, a detection hole end clamp 7 and a black body furnace end clamp 9. The optical detection hole 3 is a through hole that can transmit light. There are five optical detection holes 3 in this implementation, which are respectively arranged in the shower plate 1, and are optical detection hole one 3a, optical detection hole two 3b, and optical detection hole three. 3c, optical detection hole four 3d, optical detection hole five 3e, four infrared radiation temperature testers 4 are also provided: infrared radiation temperature tester one 4a, infrared radiation temperature tester two 4b, infrared radiation temperature tester three 4c, infrared radiation temperature tester 4 4d, infrared radiation temperature tester 5 4e, the fiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com