Coating equipment

A technology of coating equipment and rack, applied in the direction of coating, device for coating liquid on the surface, spray device, etc. It is prone to wrinkling and other problems, to achieve the effect of reducing friction, better overlapping effect, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further detailed explanation through specific implementation mode below:

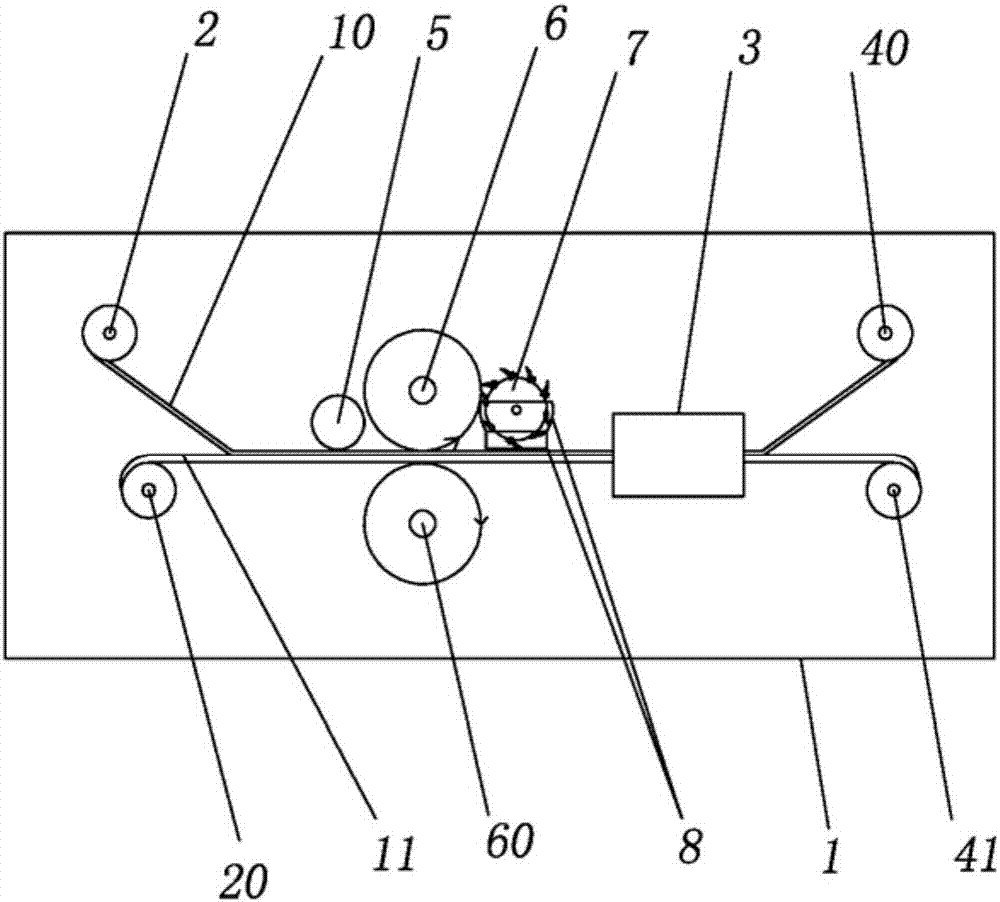

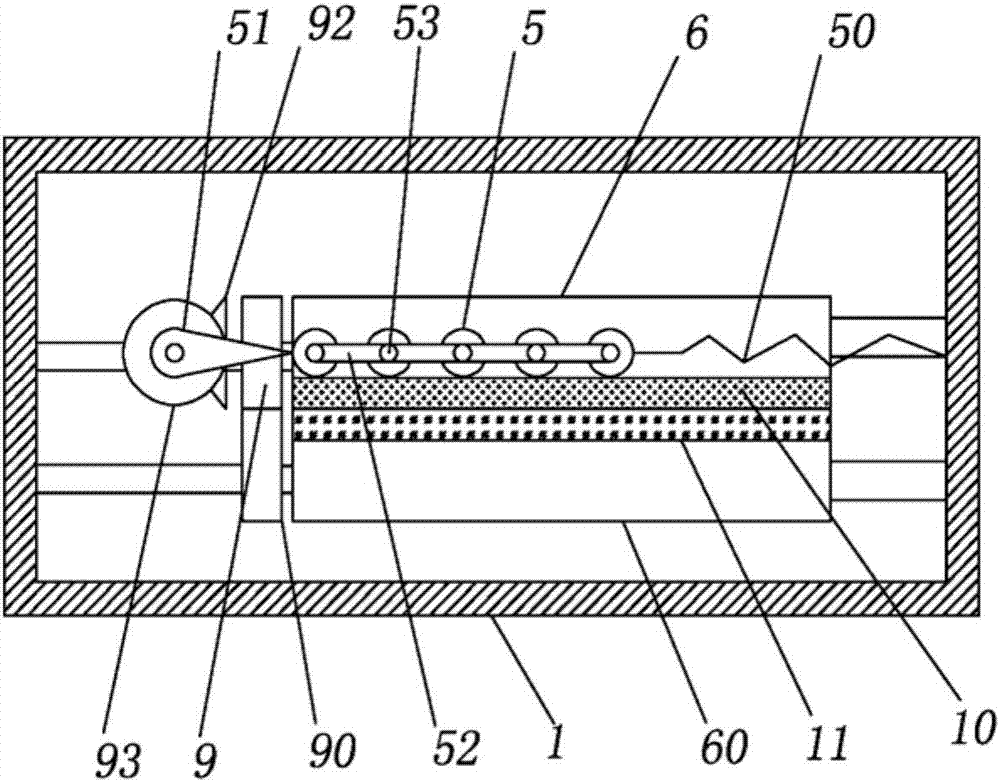

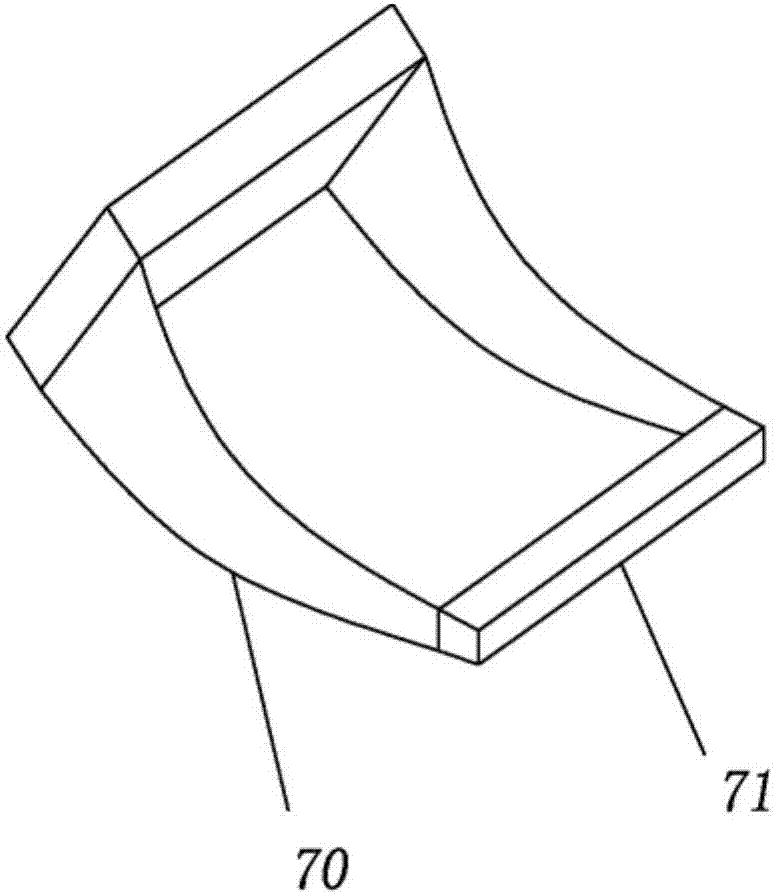

[0024] The reference signs in the accompanying drawings of the description include: frame 1, base cloth 10, transfer paper 11, base cloth feeding roller 2, transfer paper feeding roller 20, oven 3, base cloth receiving roller 40, transfer paper receiving roller 41 , steel ball 5, compression spring 50, cam 51, connecting rod 52, rotating shaft 53, upper roller 6, lower roller 60, drum 7, cleaning piece 70, sponge layer 71, cleaning tank 8, upper cleaning tank 80, lower cleaning Groove 81, upper roller gear 9, lower roller gear 90, drum gear 91, driving bevel gear 92, driven bevel gear 93.

[0025] The embodiment is basically as attached figure 1 Shown: a coating device, including a frame 1, on which a feeding unit, a bonding unit, a drying unit and a discharging unit are sequentially arranged. Feeding unit, drying unit and discharging unit can directly adopt prior art, for example feeding unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com