Vehicular lamp

A technology for lamps and vehicles, applied in road vehicles, motor vehicles, cooling/heating devices of lighting devices, etc., can solve problems such as optical design errors of projection lenses, light sources and reflectors, thermal deformation of lens frames, and small heat release. Achieve the effect of avoiding the decline of light distribution performance, improving light distribution performance and avoiding position shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

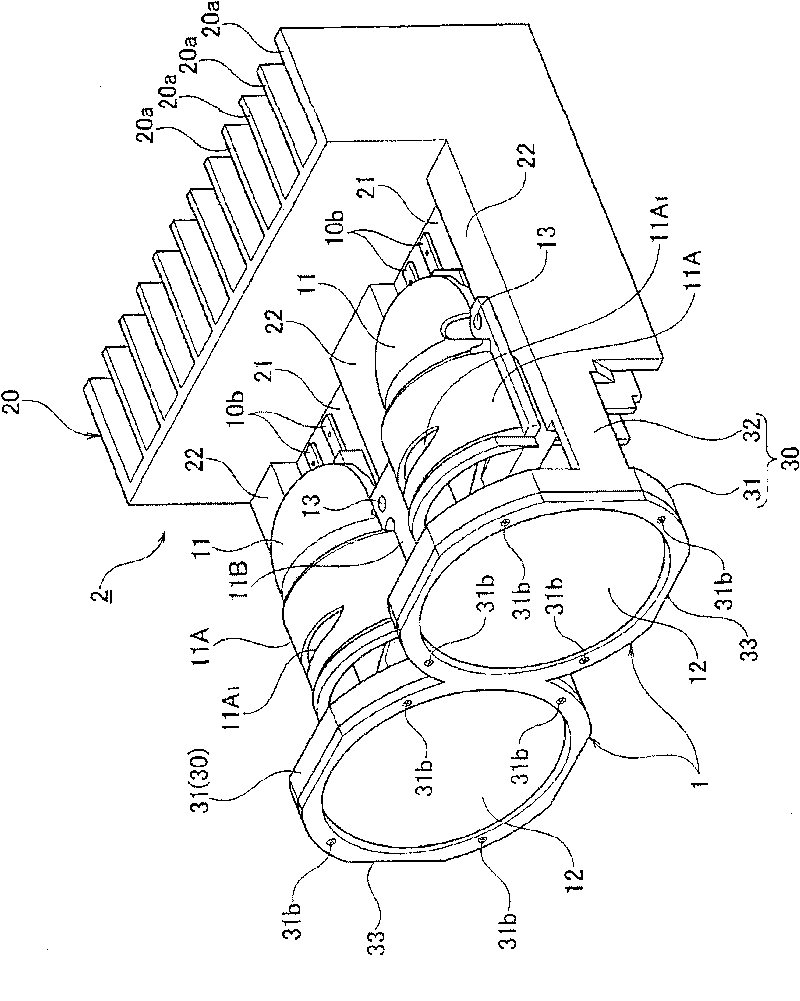

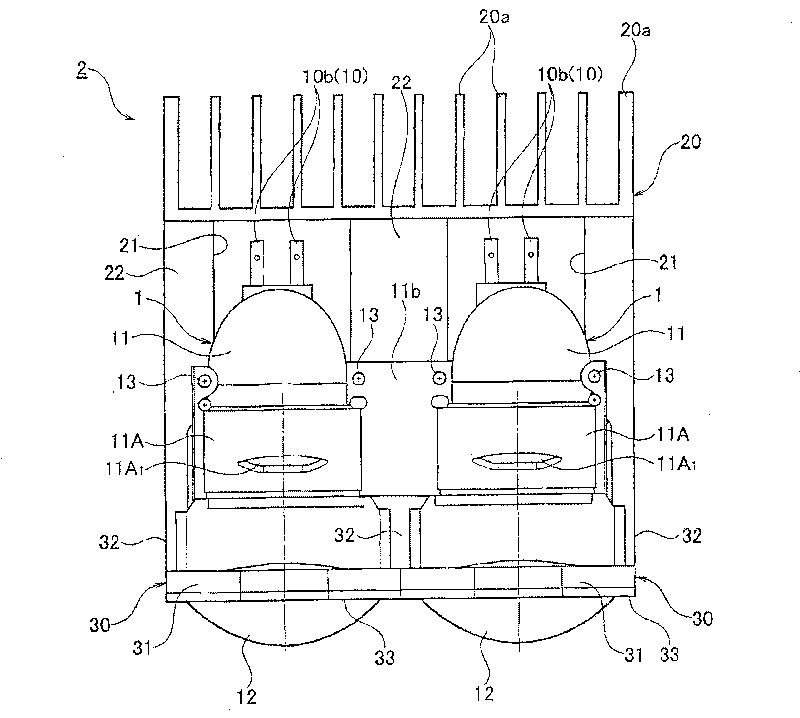

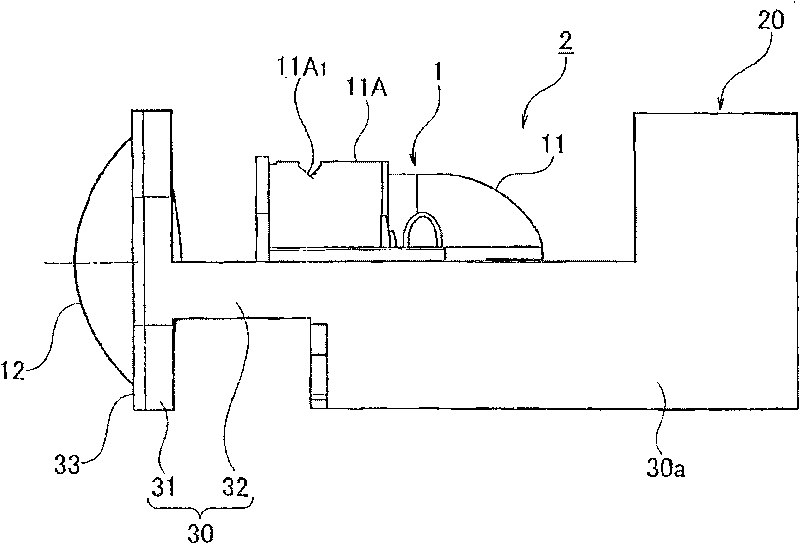

[0028] Hereinafter, an embodiment of the present invention will be described in detail by taking a vehicle headlight as an example in conjunction with the accompanying drawings.

[0029] Figure 1 to Figure 5 The lamp unit of the shown headlight is constituted as a projection type lamp unit using a semiconductor-type light source as a light source, and it is provided with: a semiconductor-type light source 10; Concave reflective surface 11a; projection lens 12, which converges the direct light of semiconductor-type light source 10 and the reflected light of above-mentioned reflector 11 and irradiates to the front of the lamp; heat sink 20, which is connected with semiconductor-type light source 10, reflector 11, projection The lenses 12 are collectively arranged.

[0030] The light source unit 1 is constituted by the semiconductor light source 10 , the reflector 11 , and the projection lens 12 , and the lamp unit 2 is constituted by the combination of the light source unit 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com