Motor rotor automatic assembling machine

A technology for automatic assembly machines and motor rotors, which is applied to assembly machines, electric components, electromechanical devices, etc., can solve the problems of unguaranteed assembly quality and accuracy, increased operating costs of enterprises, and many processing and assembly procedures, etc., to achieve easy operation and Production line layout, small footprint, single and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

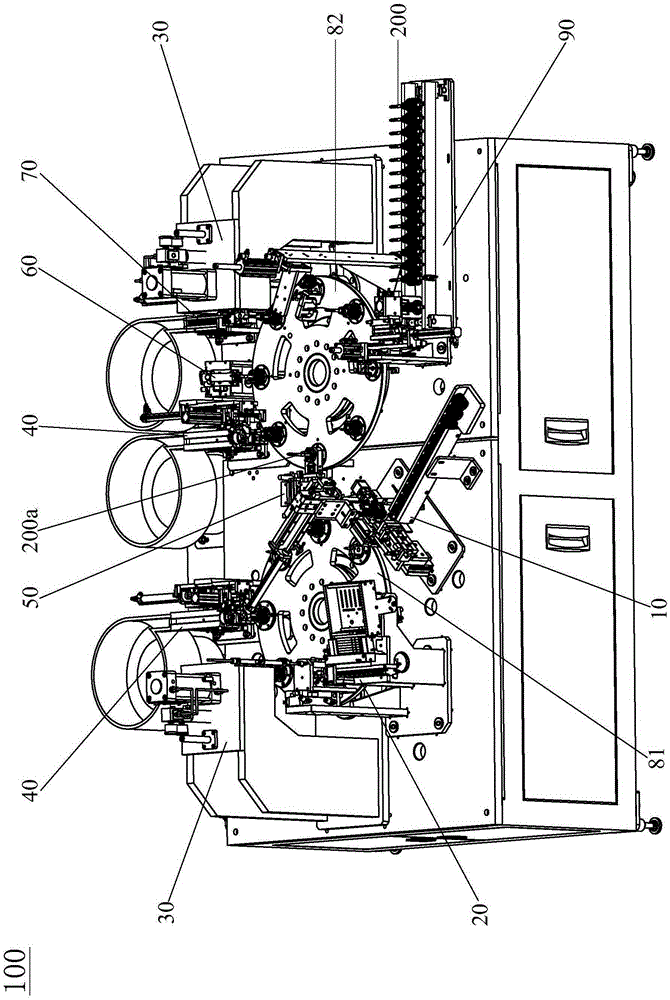

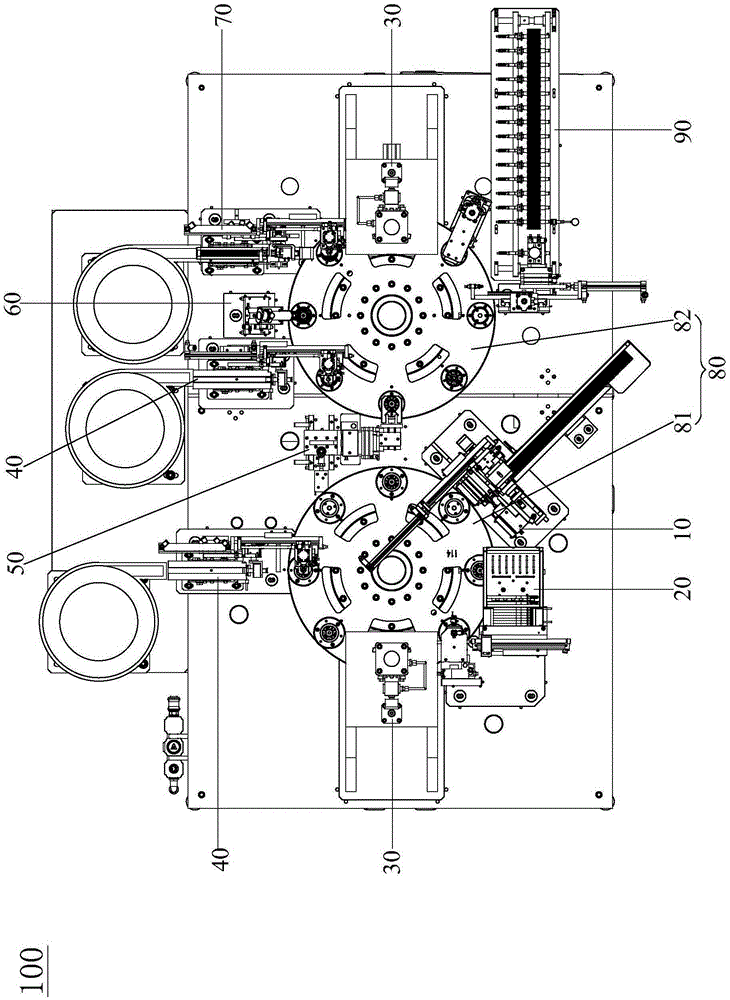

[0033] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0034] see Figure 1 to Figure 16 , the motor rotor automatic assembly machine 100 of the present invention is suitable for electrical connection with a controller (not shown in the figure), and the motor rotor automatic assembly machine 100 of the present invention is controlled by the controller to further improve the motor rotor automatic assembly machine of the present invention. 100 degree of automation, wherein the controller is an existing controller whose structure and control principle are well known in the art, so no detailed description is given here.

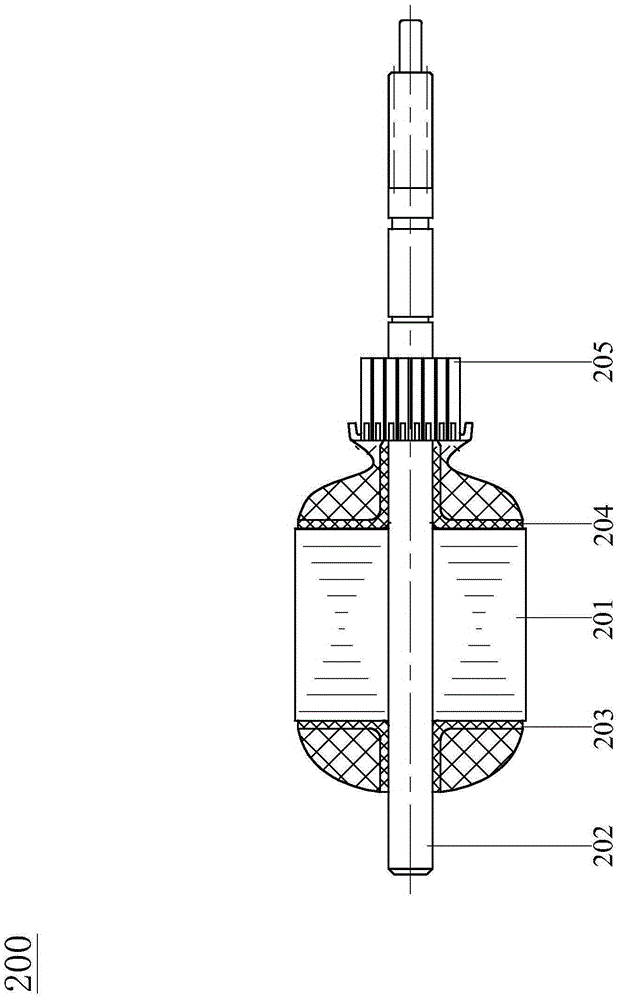

[0035] see Figure 1 to Figure 16 , The motor rotor automatic assembly machine 100 disclosed in the present invention is suitable for assembling the motor rotor 200 , the motor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com