End effector of apple picking robot

A technology of end effector and picking robot, which is applied in the direction of picking machine, manipulator, harvester, etc., can solve the problems of increasing the difficulty of system control and the complexity of the mechanism, affecting the practicality and commercialization, and the durability is not very ideal. To achieve the effect of simple, compact and compact structure, high reliability and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical scheme of the present invention is described in more detail below in conjunction with accompanying drawing:

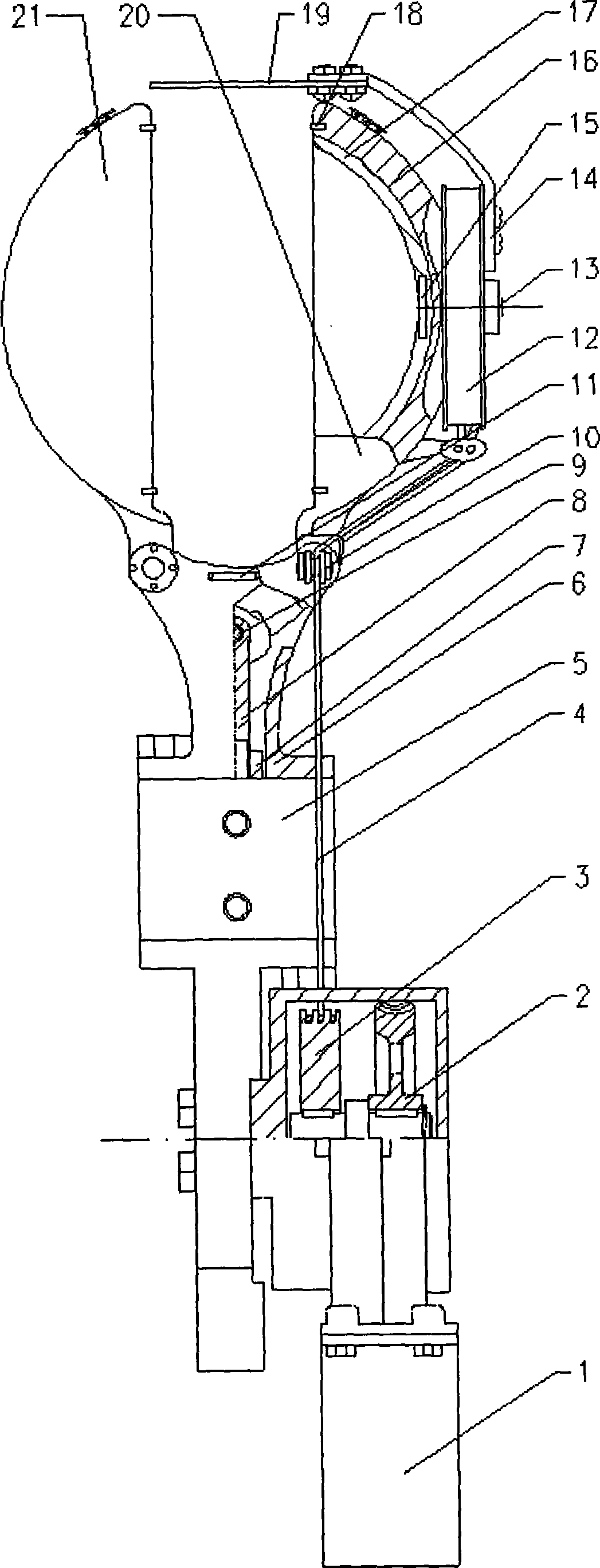

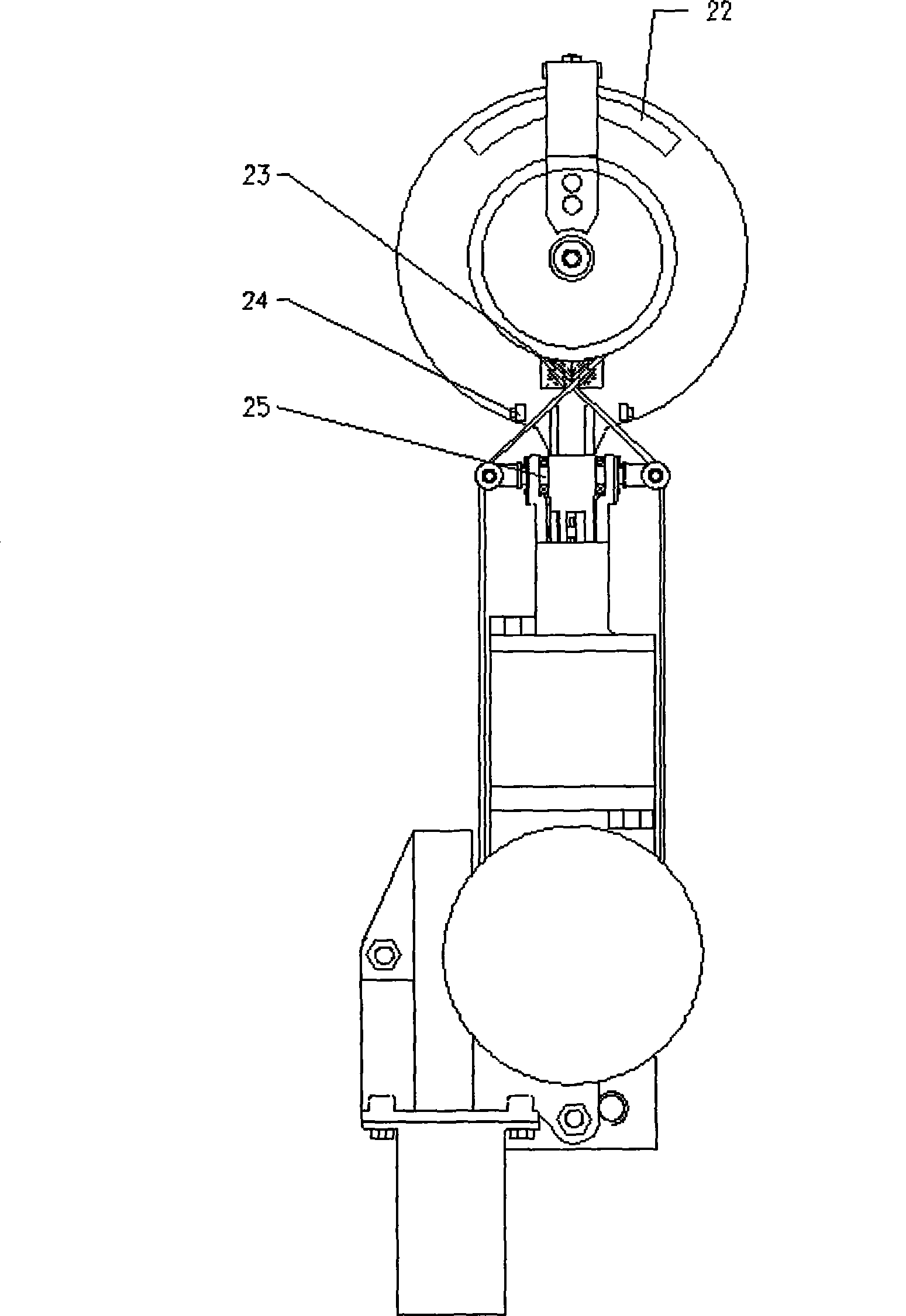

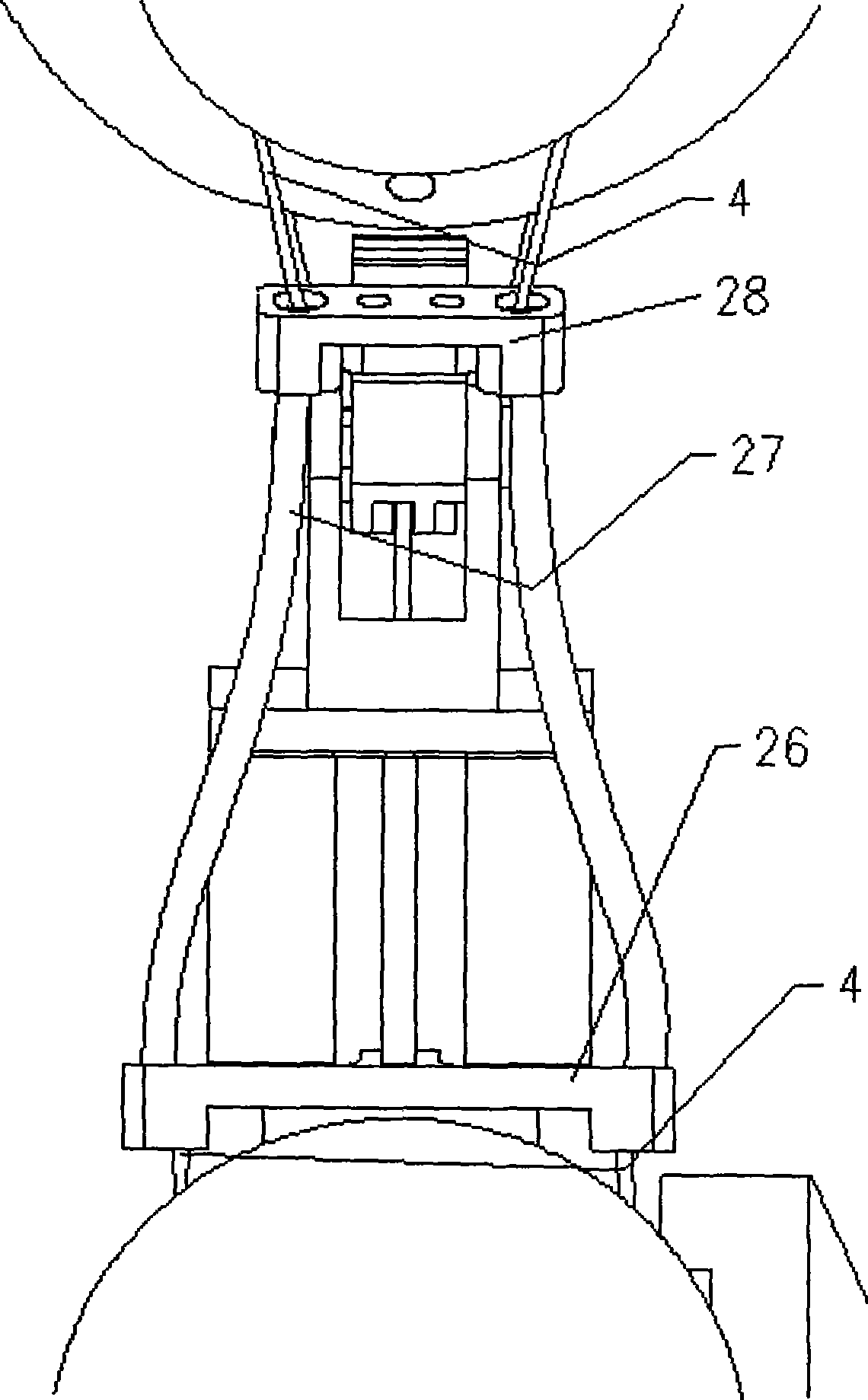

[0021] Such as figure 1 , figure 2 As shown, the end effector consists of three parts: clamping system, cutting system and sensing system.

[0022] The clamping system is mainly made up of double-acting miniature cylinder 5, piston rod 7, tappet 8, bearing pin 9, left finger 21, right finger 20, finger support 6, finger rotating shaft 25. Wherein left and right fingers are covered with sponge material 16 and rubber material 17. The double-acting miniature cylinder 5 can drive the tappet 8 threadedly connected with the piston rod 7 to carry out telescopic movement. There is a smooth small hole at the end of the tappet 8, and a chute with the same width as the pin shaft 9 is line-cut at the ends of the two fingers. 9 passes through the small hole of the tappet 8 and the chute of the two fingers simultaneously, so that when the tappet 8 performs l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com