Pneumatic tire

A technology for pneumatic tires and tires, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of easy reduction of lateral rigidity of the tread portion and reduced handling stability on dry road surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

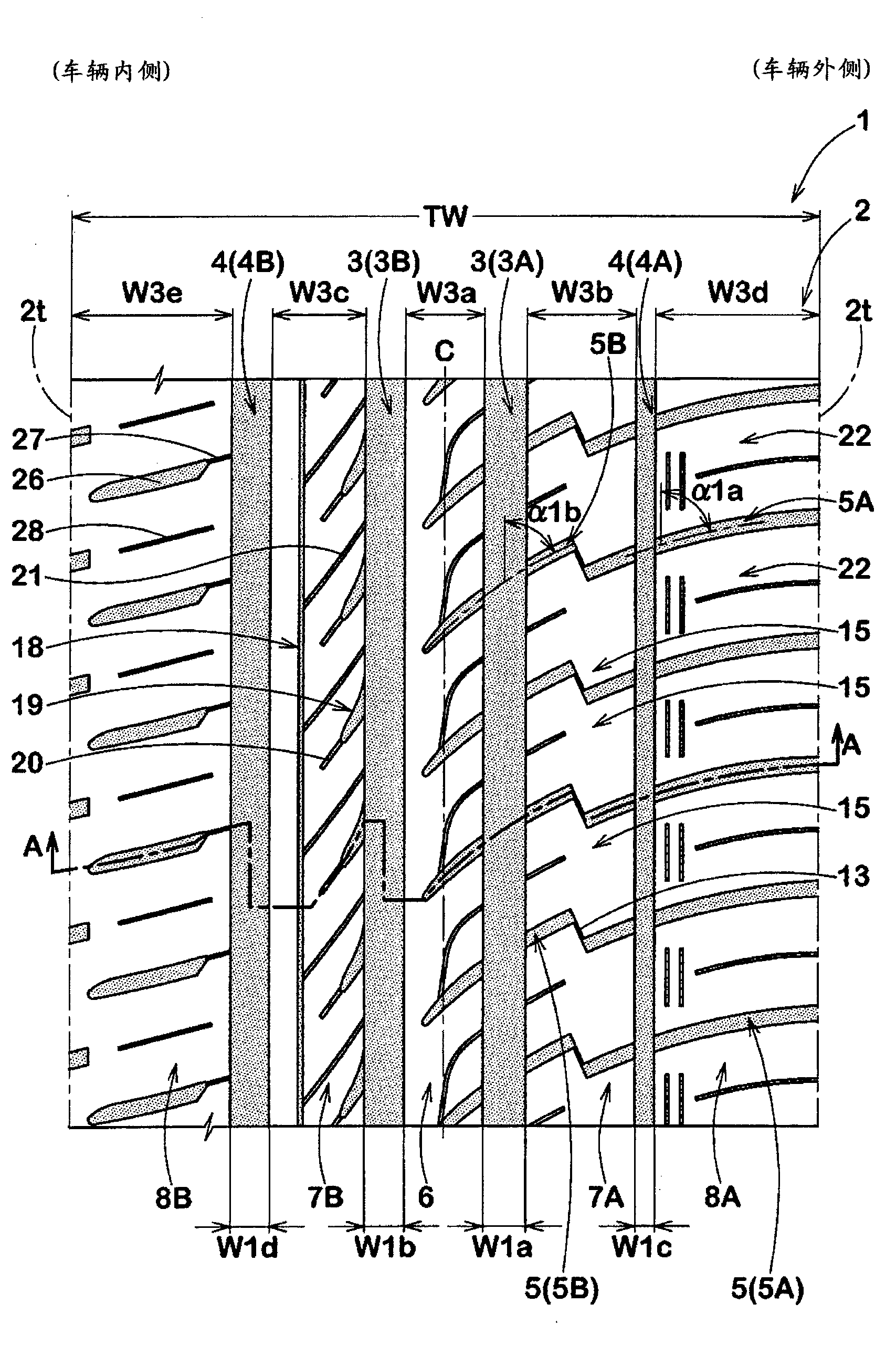

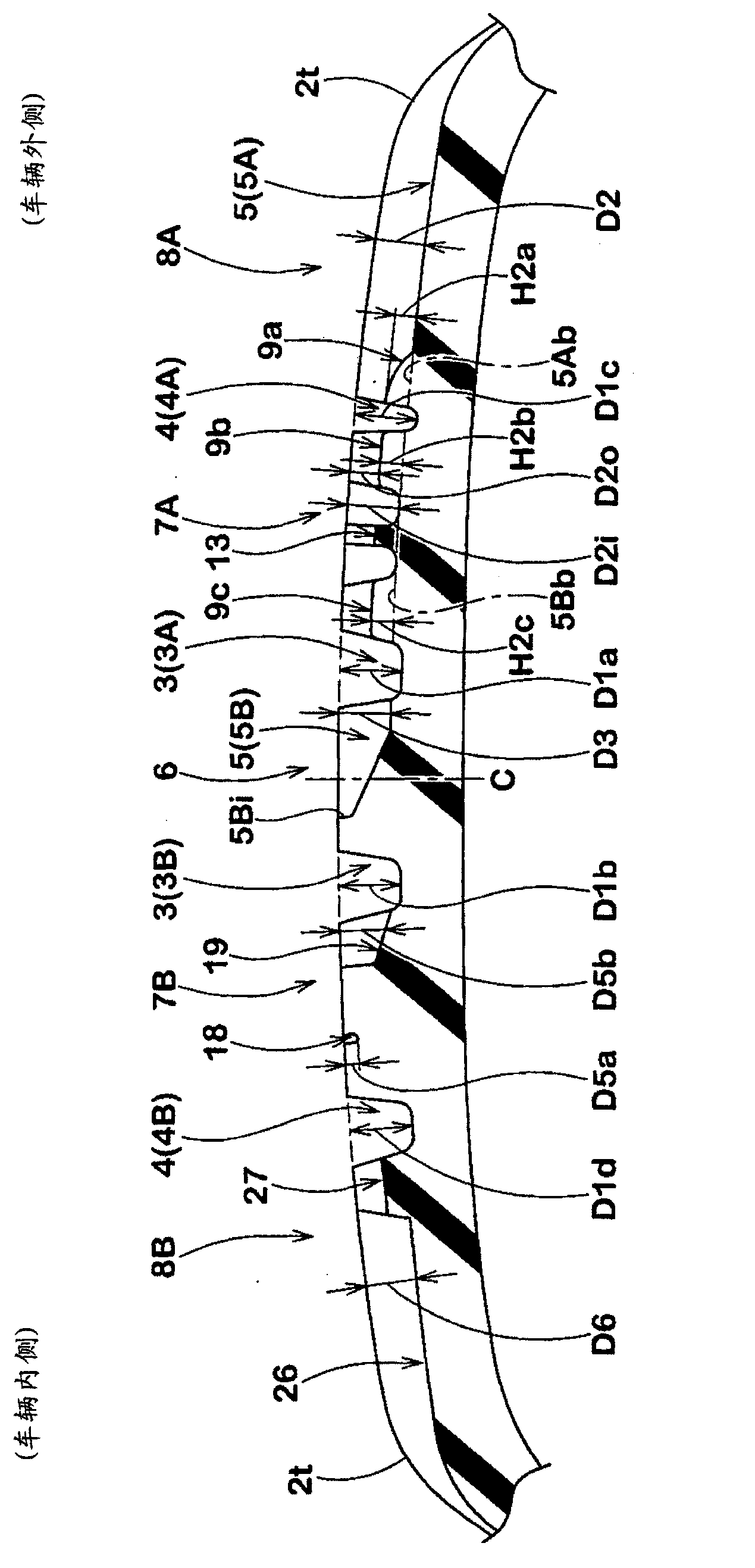

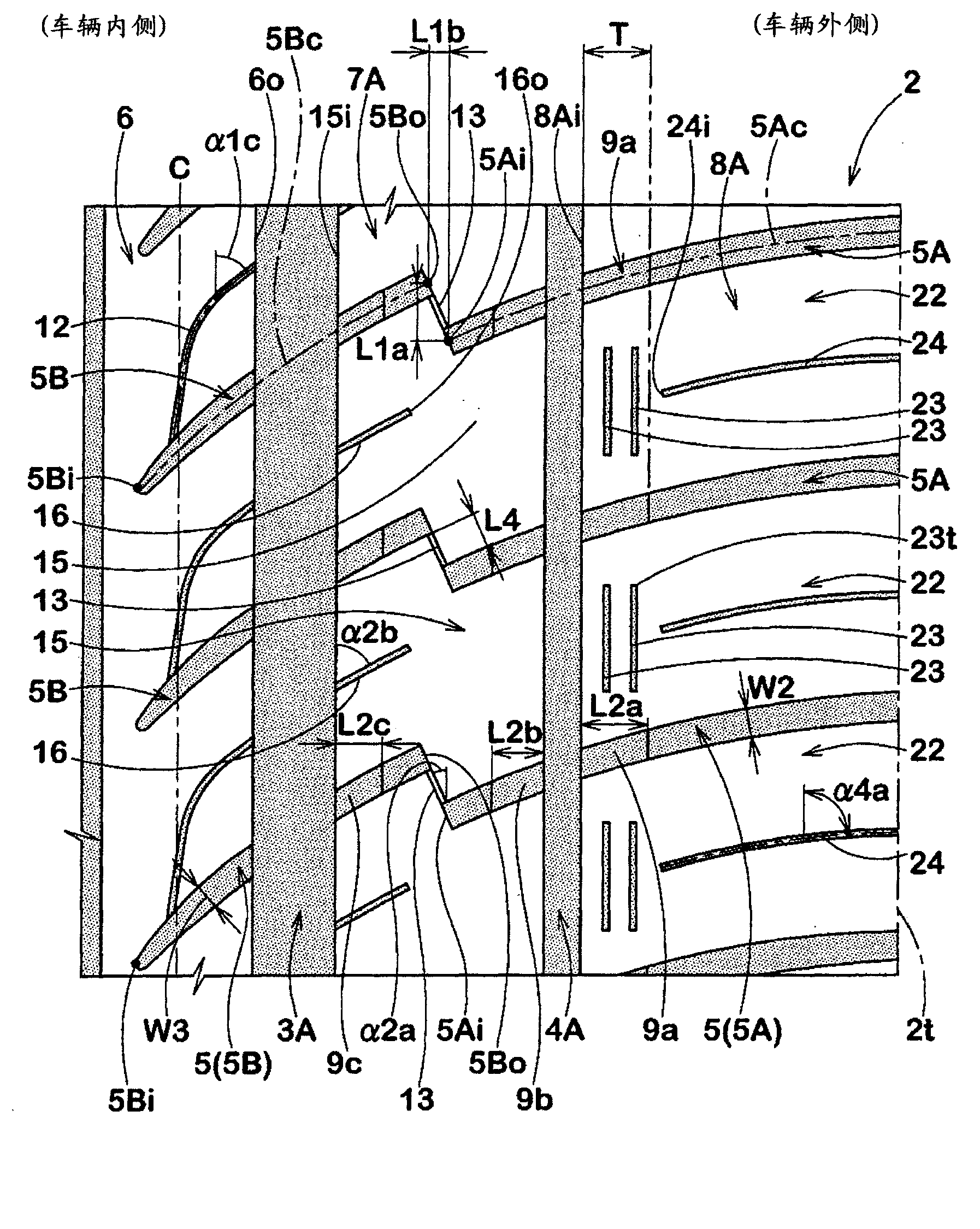

[0087] Made to form figure 1 The tires with the basic structure shown in Table 1 and with the longitudinal grooves, transverse grooves and sipes shown in Table 1, and their performances were evaluated.

[0088] In addition, the same evaluation was performed on the following tires as a comparison, namely: Figure 5 A tire shown in (a) in which the inner shoulder land portion is divided into blocks and does not have an inner shoulder auxiliary groove (comparative example 1), Figure 5 A tire in which the outer shoulder land portion shown in (b) is formed of straight ribs (Comparative Example 2), and Figure 5 The tire shown in (c) without the inner middle sub groove and the inner middle sipe (comparative example 3). In addition, common specifications are as follows.

[0089] Tread contact width TW: 194mm

[0090] Lateral central longitudinal groove:

[0091] Groove width W1a: 11.4mm, maximum groove depth D1a: 9.5mm

[0092] Medial central longitudinal groove:

[0093] Gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com