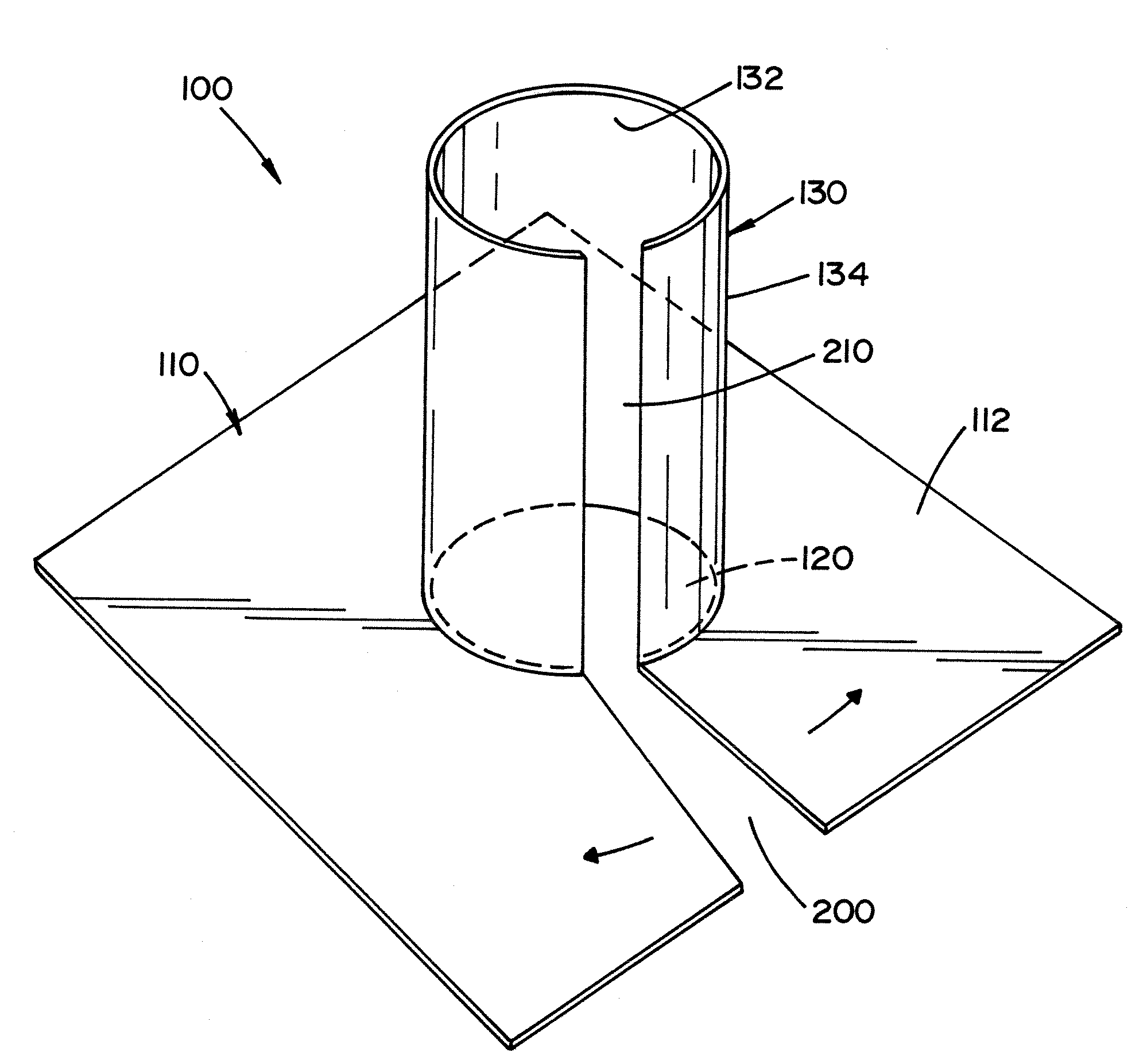

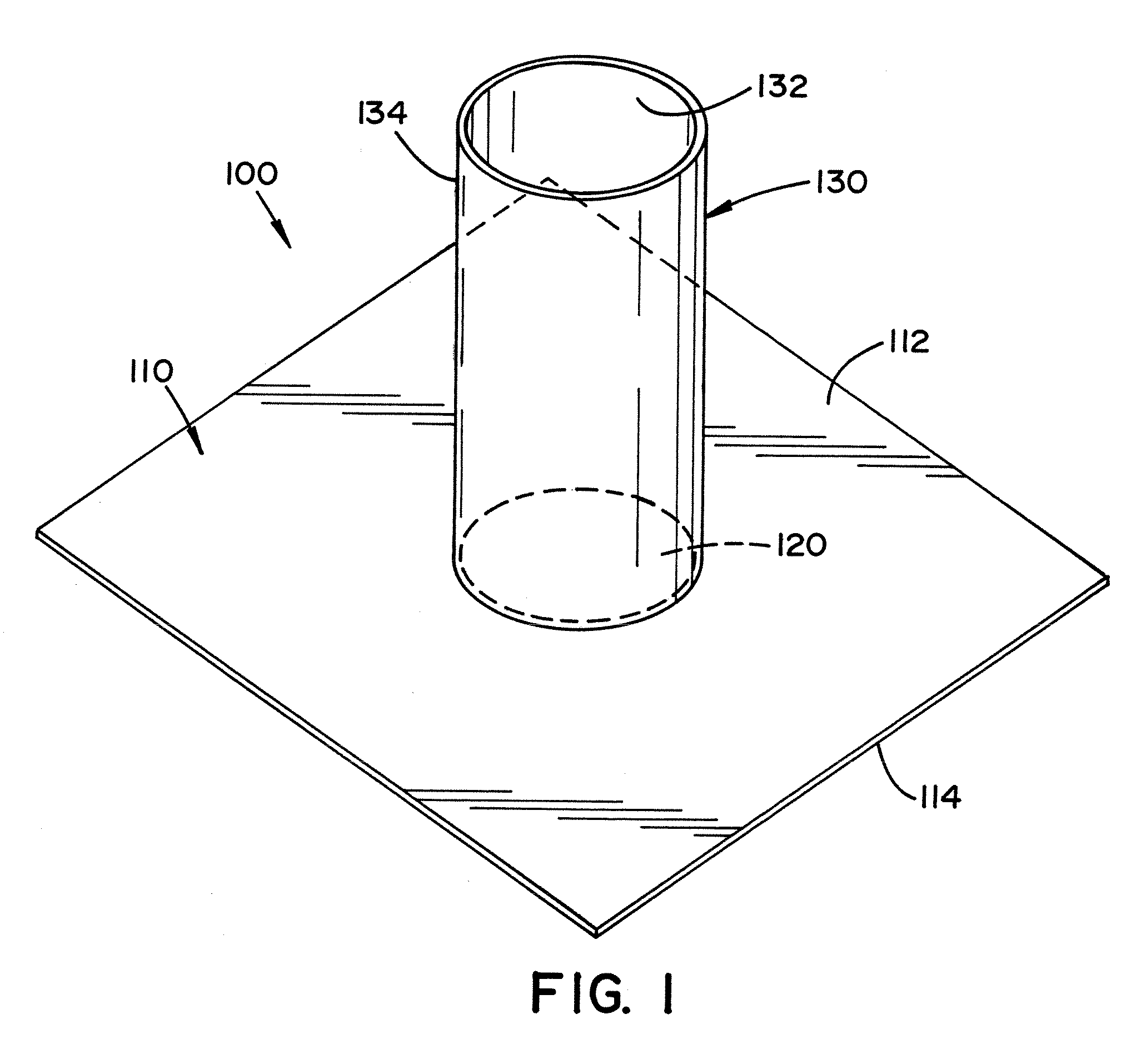

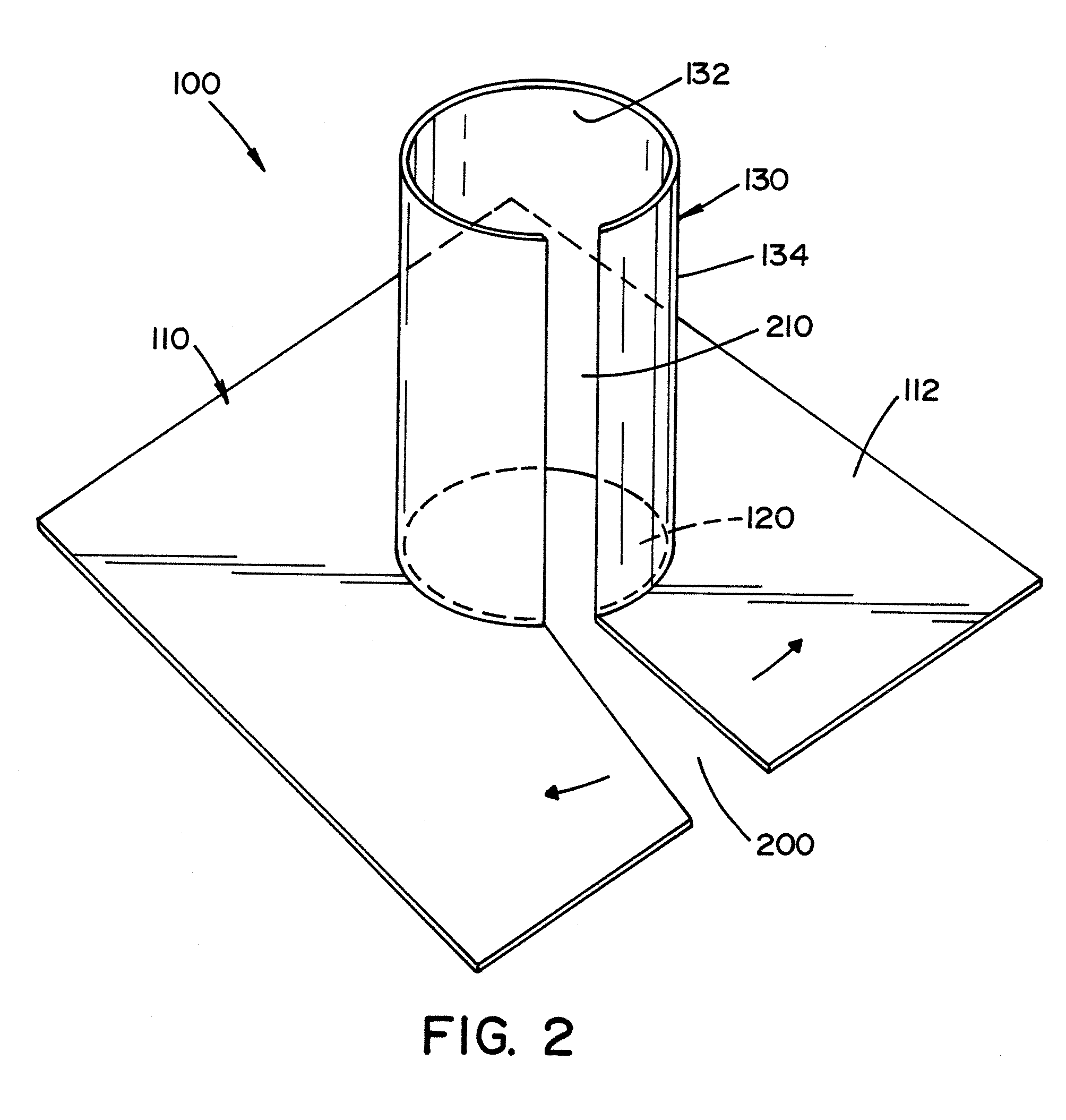

Zinc flashing for roof penetrations

a zinc flashing and roof technology, applied in snow traps, manufacturing tools, building repairs, etc., can solve the problems of inability the zinc flashing formed of titanium zinc alloy exhibits the same malleability problems, and cannot be used in-of-the-self to waterproof the region about the roof. , to achieve the effect of facilitating the securing of zinc flashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example a

[0053]

ComponentWeight Percentzinc91.1-99.99%aluminumup to 0.9%cadmiumup to 0.9%chromiumup to 0.9%copperup to ironup to 0.9%leadup to 0.9%magnesiumup to 0.9%nickelup to 0.9%tinup to 0.9%titaniumImpurities

example b

[0054]

ComponentWeight Percentzinc91.1-99.9%aluminumup to 0.7%cadmiumup to 0.7%chromiumup to 0.5%copperup to 0.7%ironup to 0.5%leadup to 0.7%magnesiumup to 0.5%nickelup to 0.5%tinup to 0.7%titaniumup to 0.12%Impurities

example c

[0055]

ComponentWeight Percentzinc91.2-99.9%aluminumup to 0.5%cadmiumup to 0.5%chromiumup to 0.3%copperup to 0.5%ironup to 0.3%leadup to 0.5%magnesiumup to 0.3%nickelup to 0.3%tinup to 0.5%titaniumup to 0.1%Impurities

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com