Metal roof system

A metal roofing and roofing panel technology, which is applied to roofing, roofing cladding, and roofs using flat/curved panels, etc., can solve problems such as poor sealing performance, unreasonable structure, and unreasonable fan base structure, so as to ensure product quality. and function, to ensure complete performance, and the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

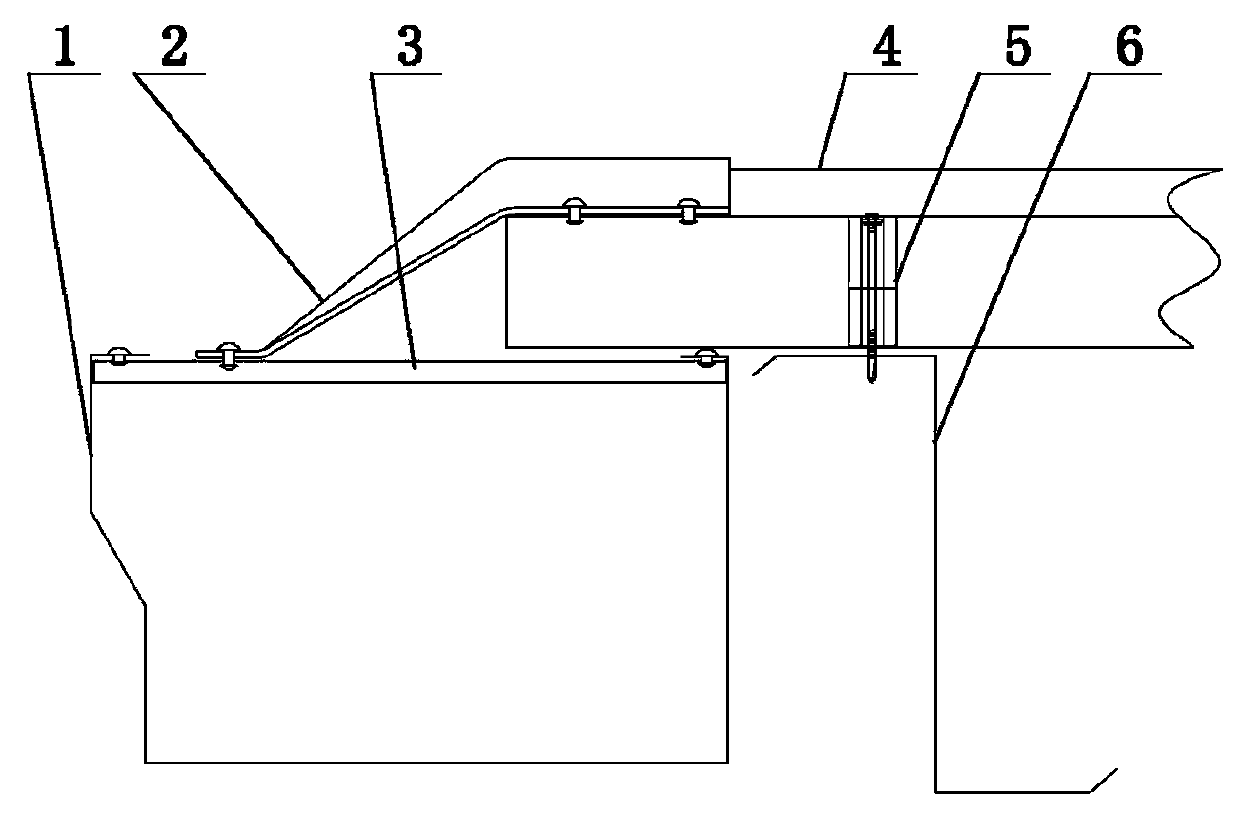

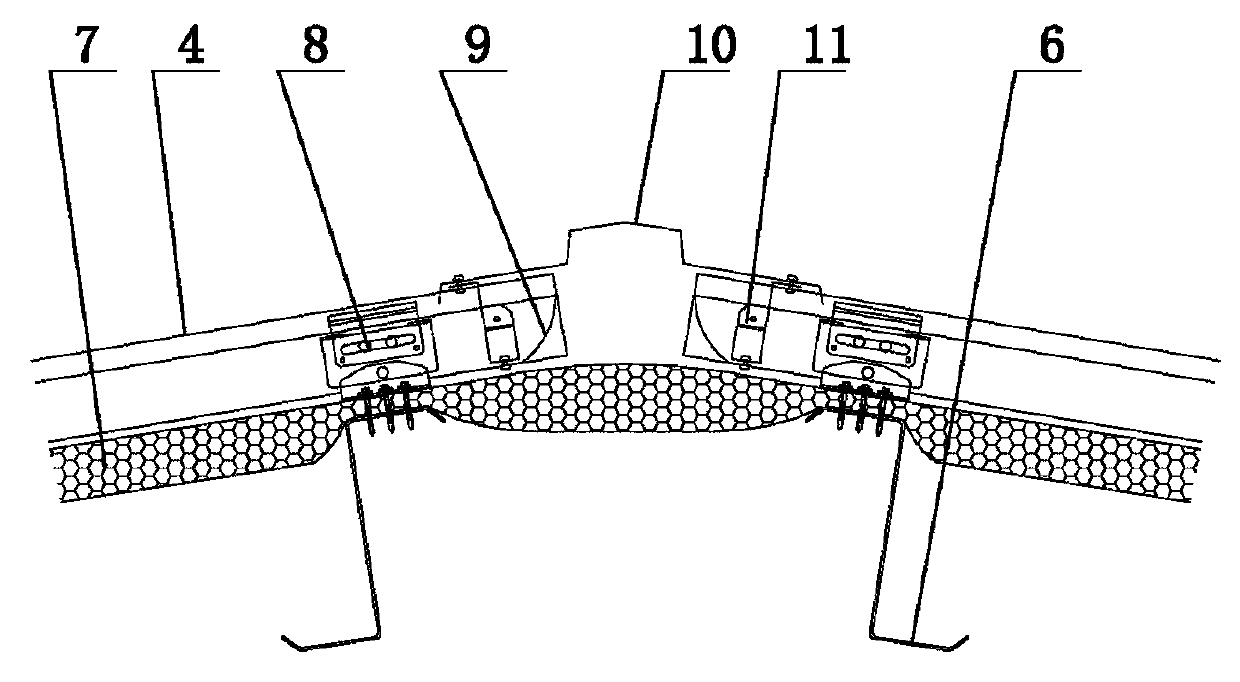

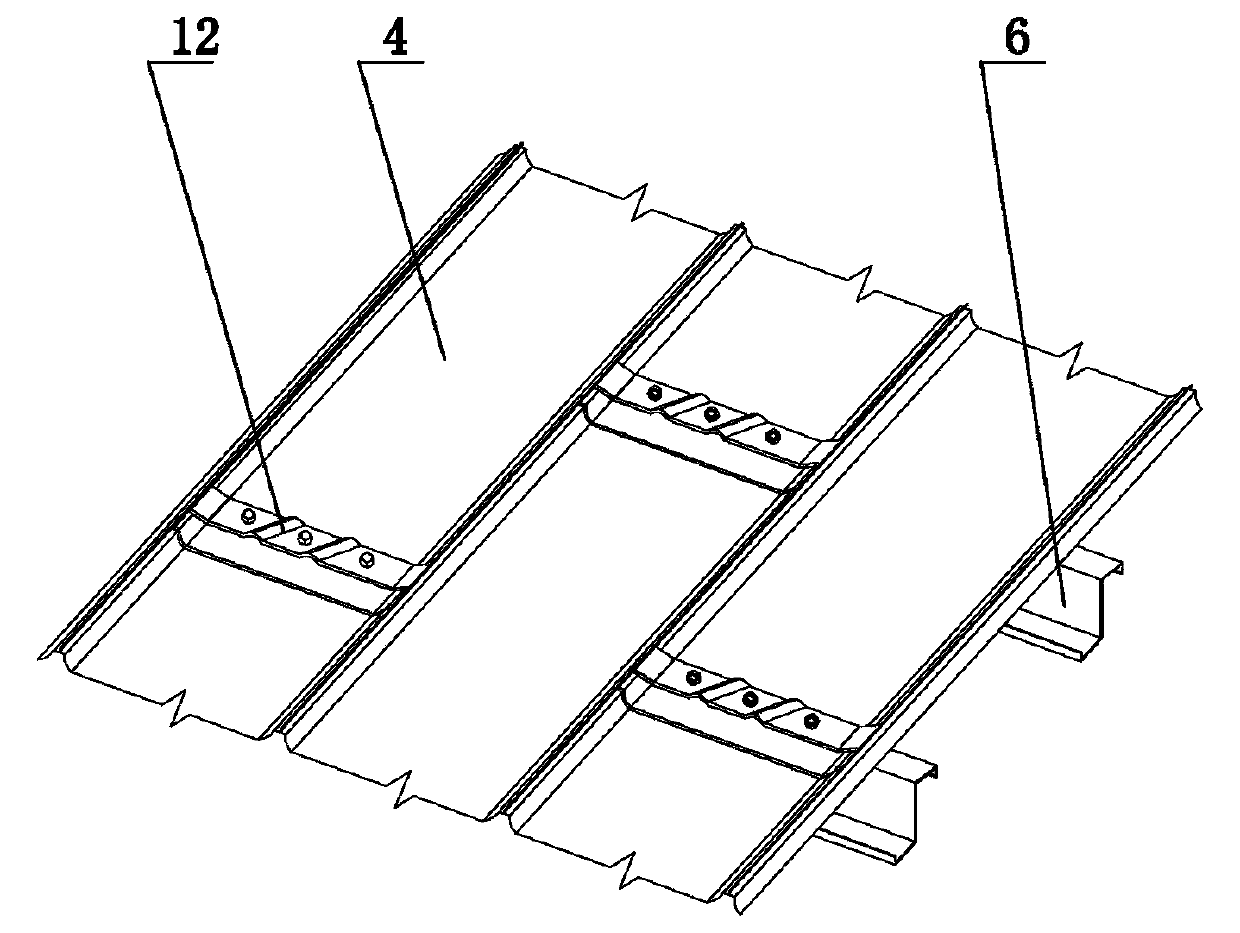

[0054] The present invention includes the color steel roof panel 4 arranged on the purlin 6, the gutter 1 is arranged corresponding to the end of the color steel roof panel 4, the side of the color steel roof panel 4 is the same as the gable edge 17 of the wall outer panel 16 Connected, characterized in that: the color steel roof panels 4 are connected to each other by lap fasteners 12, and the lap fasteners 12 include a tray 13 arranged below the overlap of the color steel roof panels 4 and a tray 13 arranged on the The bead 14 above the overlap of the color steel roof panel 4, the pallet 13 is provided with a riveting screw 44, and the bead 14 is fixed with the riveting screw 44 passing through the overlap of the color steel roof panel 4; The above-mentioned bead 14 is provided with an arc-shaped water outlet.

[0055] Further, the water outlet is arranged obliquely.

[0056] The head of the riveting screw 44 is embedded in the tray 13 .

[0057] The pallet 13 is a galvani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com