Process for constructing metal roof of building with super-large space

A metal roof and construction technology technology, applied in the direction of construction, building structure, roof insulation materials, etc., can solve the problems of self-tapping screw penetration, reduce thermal insulation performance, deterioration, etc., to solve the problem of moisture resistance and ensure thermal performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

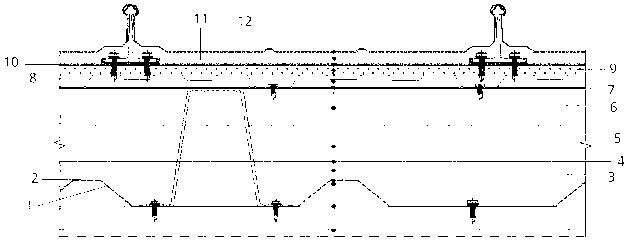

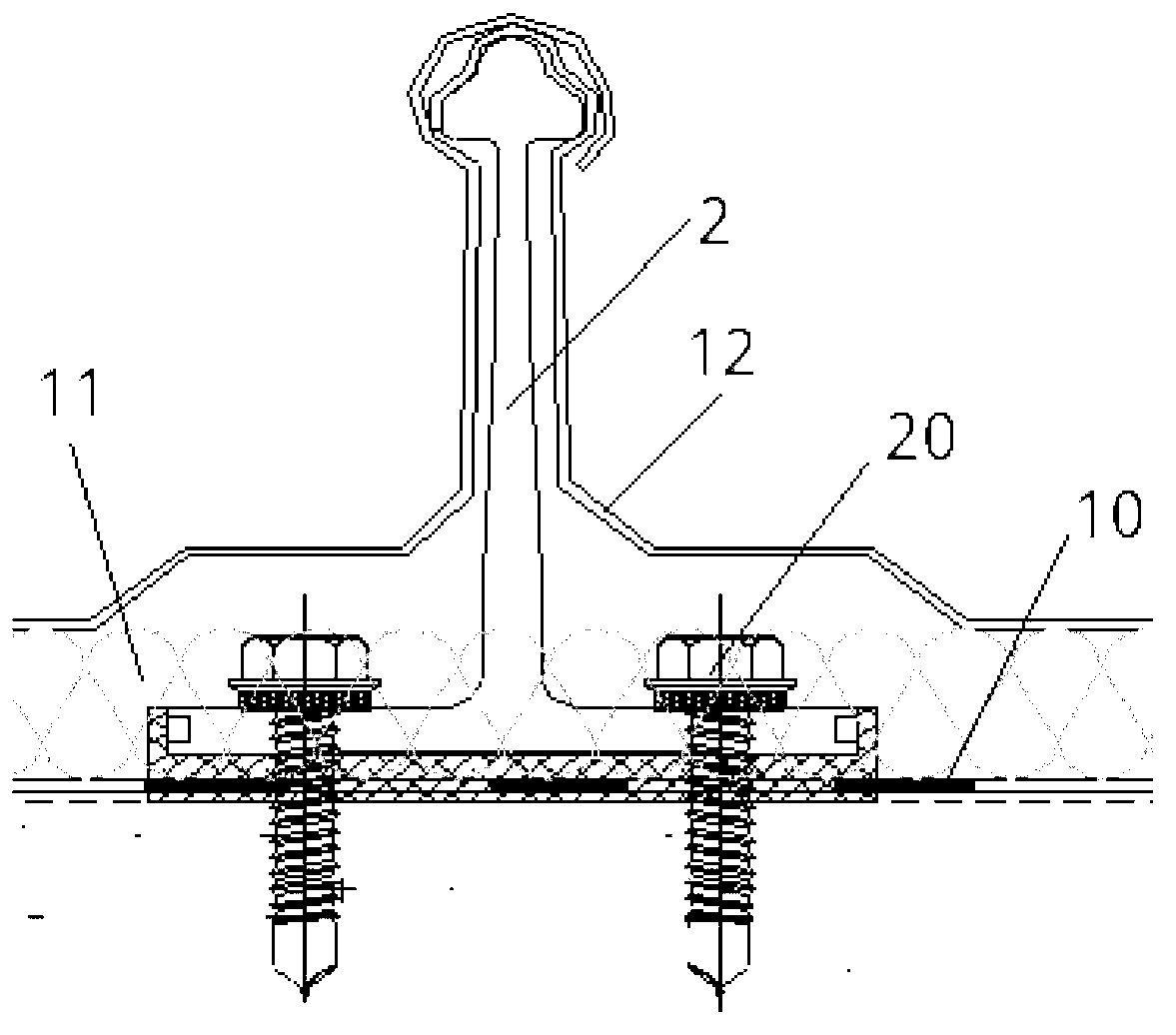

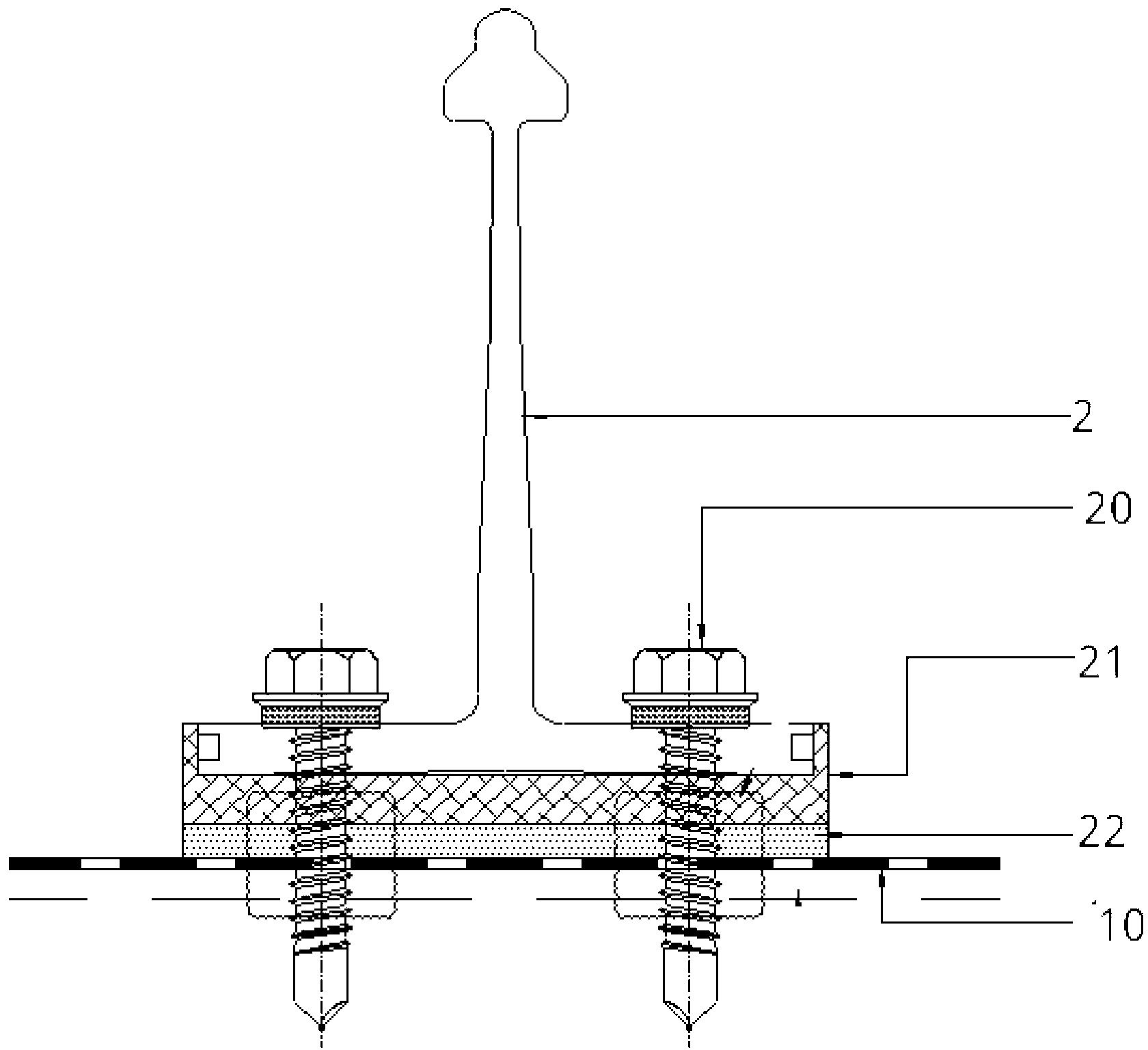

[0044] Combine below Figure 1 to Figure 3 Specifically illustrate the metal roof structure of the ultra-large space building in the present invention, the bottom layer of the roof structure is a steel inner lining board 1, and the uppermost layer of the roof structure is an aluminum-magnesium-manganese alloy roof panel 12, between the aluminum-magnesium-manganese alloy roof panel and the inner lining board A supporting steel plate 8 and a gypsum fiberboard 9 are also provided between them, wherein the supporting steel plate is supported on the bottom of the gypsum fiberboard, and an anti-noise layer 11 of ultrafine glass wool is filled between the aluminum-magnesium-manganese alloy roof panel and the gypsum fiberboard, and the bottom of the supporting steel plate Supported by support purlins 7, the inner lining board 1 is laid with a non-woven dust-proof layer 2, and a glass wool sound-absorbing layer 3 is arranged on the non-woven dust-proof layer, and the glass wool sound-ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com