Construction method for waterproofing of energy-saving self-protection roof

A construction method and technology of self-adhesive waterproof membrane, applied in the direction of roof, roof covering, tools for roof engineering, etc., can solve the problems of metal corrosiveness, easy failure of waterproof layer, reducing mortar strength, etc., to improve the strength. , the effect of eliminating fire hazards and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

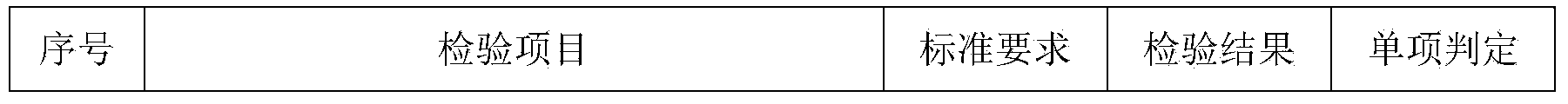

[0045] Weigh 100 parts of raw materials by mass, including 35 parts of soap grains, 4 parts of sodium hydroxide, 0.25 parts of sodium silicate, 8 parts of potassium dichromate, 0.2 parts of tributyl phosphate, and 1.0 parts of sodium dodecylbenzenesulfonate , 0.1 part of cellulose, and the rest is water. Put the soap grains and water in the reaction furnace to heat and dissolve, the temperature is 80-100°C; then cool down to 60-70°C, add sodium hydroxide and potassium dichromate and stir at a constant temperature; when the temperature drops to 30-60°C, add Stir tributyl phosphate, sodium dodecylbenzene sulfonate, and cellulose evenly; heat at 60-90°C, stop heating when the reactant becomes thick; and obtain a waterproofing agent after cooling.

[0046] The raw materials used should meet the following requirements:

[0047] Cement: Use Portland cement, ordinary Portland cement or slag Portland cement with a strength grade of 32.5MPa and above.

[0048] Sand: medium sand, mud ...

Embodiment 2

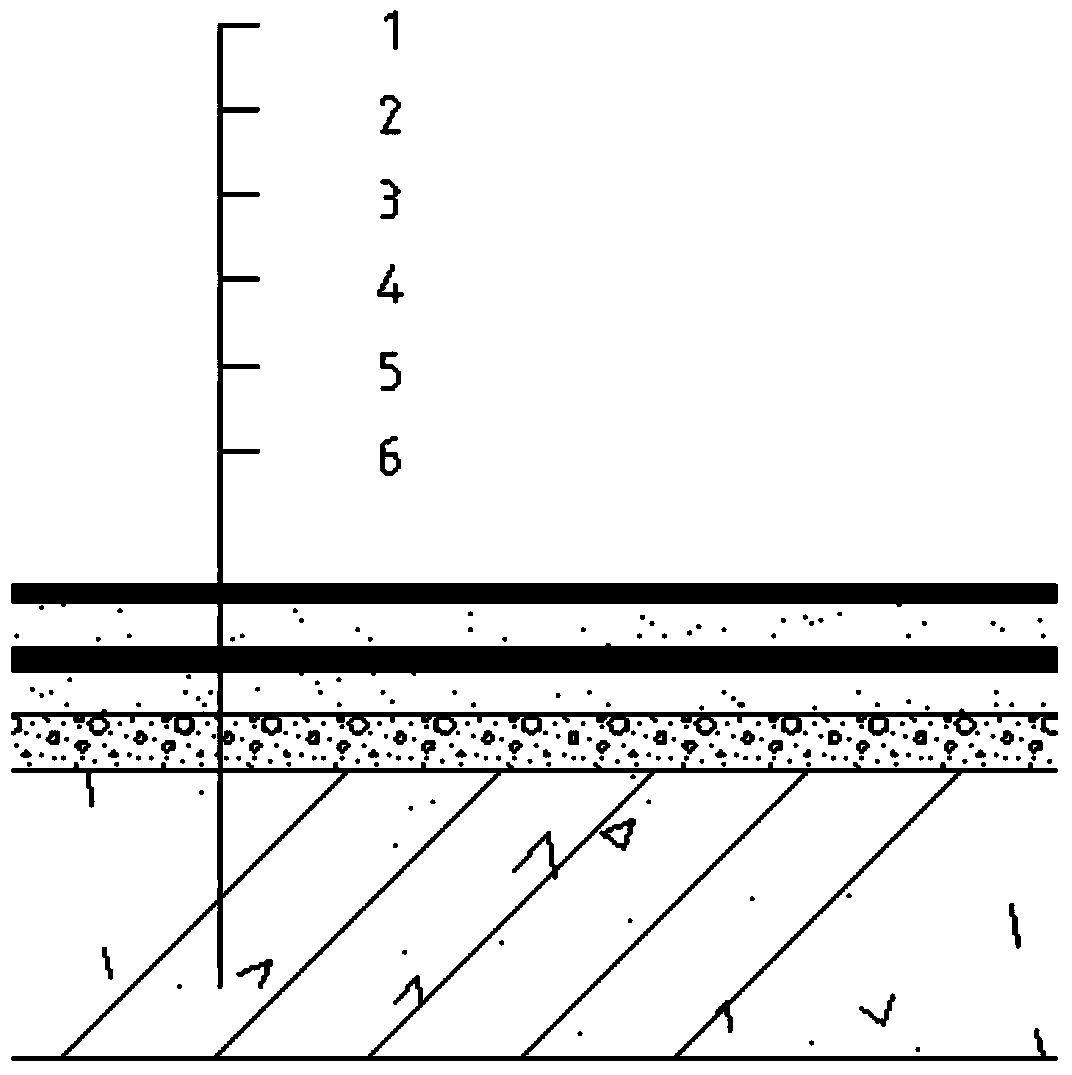

[0056] Using the above waterproofing agent to carry out energy-saving self-protective roof waterproofing construction method, the schematic diagram is as follows figure 1 shown.

[0057] In June 2012, the roof of the laboratory of Hebei Aotelai Waterproof Material Co., Ltd. was constructed using this process.

[0058] So far, the waterproof and heat insulation effect is good.

[0059] 1. Clean the concrete roof structure layer: remove debris.

[0060] 2. Hydrophobic slope and insulation layer: Lay waterproofing agent, cement, vitrified microbeads on the roof structure layer: add water to mix and stir the slope and insulation layer at the thinnest part of 20mm thick to find a 2% slope. The ratio is: vitrified microbeads: cement: waterproofing agent: 1.5:1:0.01-3.

[0061] 3. Self-waterproof mortar leveling layer: lay a 20mm thick leveling layer mixed with waterproofing agent, cement mortar and water on the slope finding and insulation layer, and smooth it. The mass ratio is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com