Waterproof heat-insulating fireproof metal roof system

A technology for metal roofing and insulation layers, applied to roofing, roof covering, and roofs using flat/curved panels, etc., can solve the problems of non-flammable roofing materials, difficult fire suppression, economic losses, etc., and achieve good air tightness , easy connection, precise control and accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

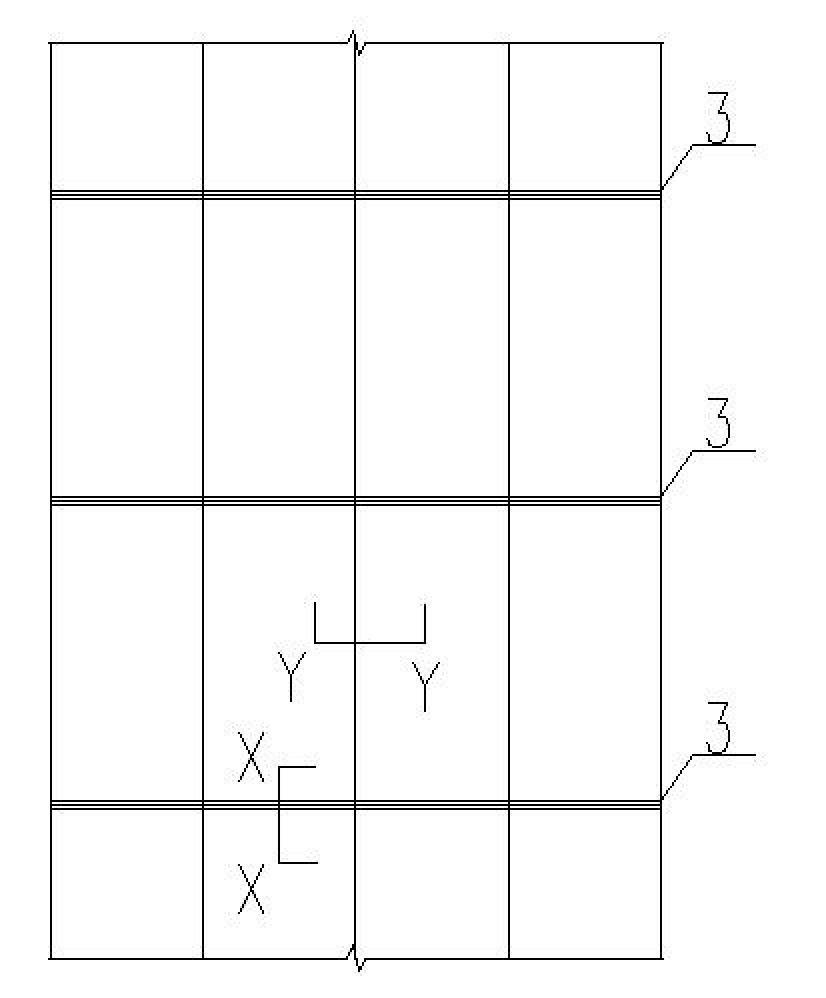

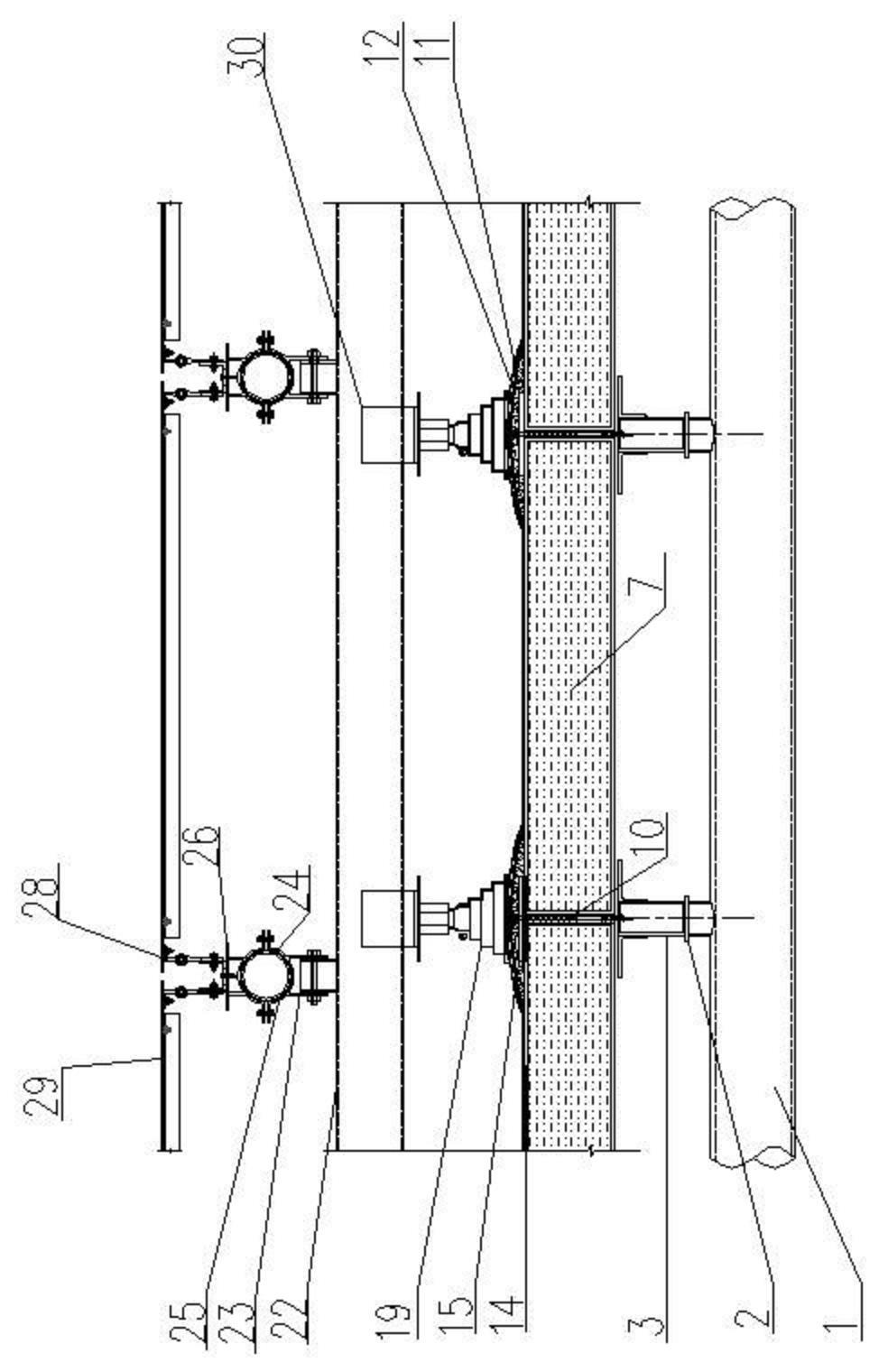

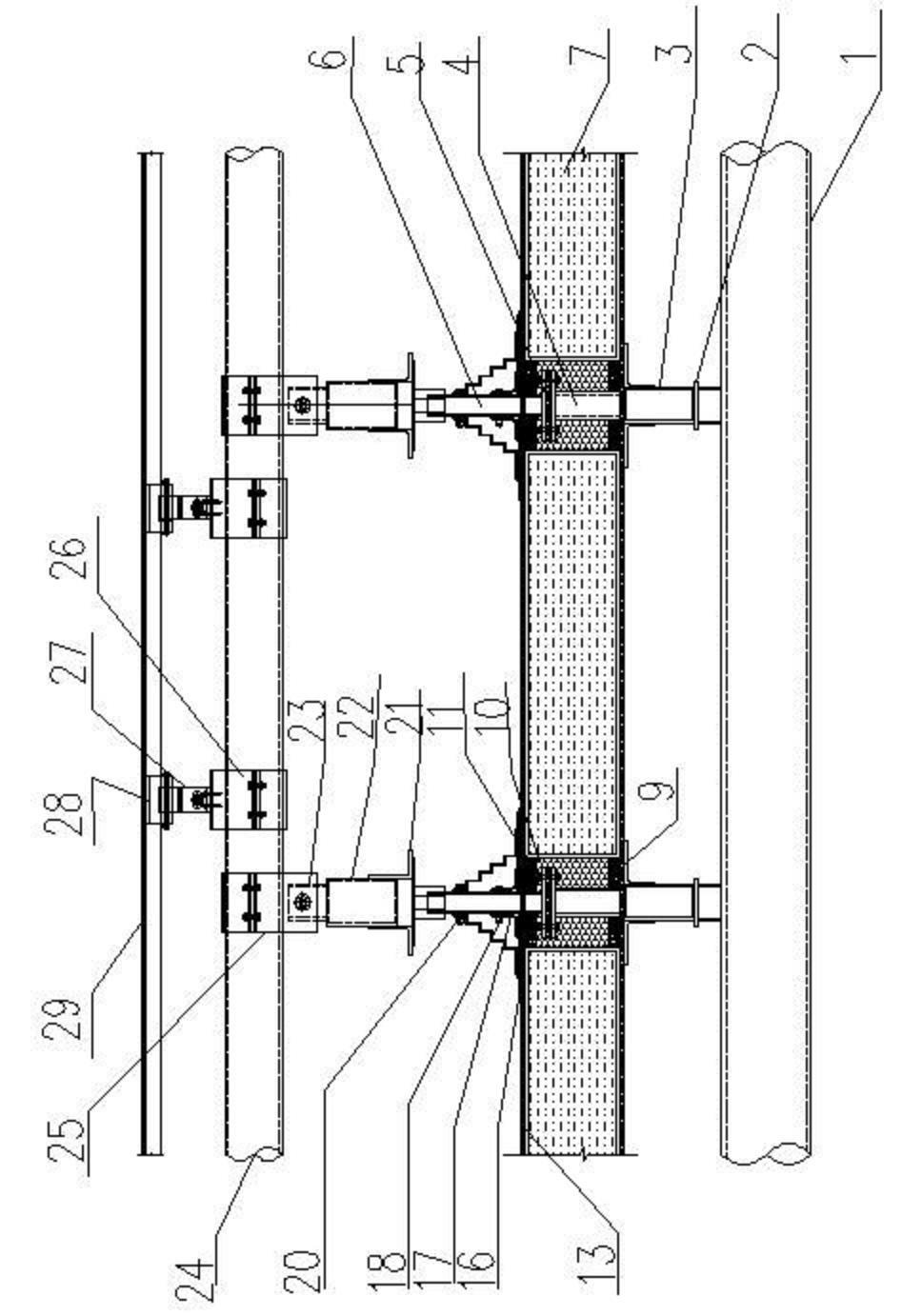

[0032] A waterproof, heat-insulating and fireproof metal roofing system, which consists of: decorative board 29, decorative board main keel 22 and secondary keel 24, pipe boots, purlin 3, lower main structure 1, the decorative board is fixed on the finished aluminum hinge 28 Above, the other end of the finished aluminum hinge 28 is fixed to the secondary keel through an aluminum corner code 27, and the main keel 22 of the decorative panel is fixed to the purlin 3 through an adjusting support, and the composite heat preservation The board thermal insulation layer 7 is pressed on the purlin, the waterproof gas barrier layer 13 is provided on the thermal insulation layer 7 of the composite thermal insulation board, and the purlin 2 supports the purlin 3 on the lower main structure 1.

Embodiment 2

[0034] In the waterproof, heat-preserving and fireproof metal roofing system of embodiment 1, the finished aluminum hinge 28 is pin-connected by the upper aluminum corner code and the socket through the upper end of the lower aluminum connecting plate, and the lower connecting plate of the finished aluminum hinge 28 passes The bolts are connected to the aluminum corner code 27, and the lower part of the aluminum corner code 27 is fixed on the connecting fastener 26, and the connecting fastener 26 and the connecting fastener 25 are connected to the secondary keel 24 by bolts. In this way, the connecting fastener 26 and the connecting fastener 25 can be rotated on the secondary keel 24 during the installation process, and the aluminum corner 27 fixed on the connecting fastener 26 has a long flat hole. The aluminum corner 27 and the finished aluminum The hinge 28 is connected by bolts, and the height is adjusted within the long flat hole. The finished aluminum hinge 28 rotates aro...

Embodiment 3

[0036] In the waterproof, heat-preserving and fireproof metal roofing system of embodiment 1, the adjusting support member includes a base 4 fixed on the purlin 3, and the base 4 and the upper adjusting member 6 are bolted through the heat insulation pad 5 , The tube shoe 17 is sleeved on the outer side of the upper adjusting member 6 and clamped from the upper end of the outside by the clamping ring 18, and the lower part is glued to the waterproof vapor barrier layer 13, and the tube shoe 17 is connected with A finished rubber pad 16 is added between the vapor barrier 13 to protect the vapor barrier. The tube shoe 17 is covered with a pointed tube shoe 19, and the pointed tube shoe 19 passes through another A clamping ring 20 is clamped from the upper end of the outside, and the lower part is glued to the waterproof gas barrier layer 13 with the finished rubber pad 16. The top end of the upper adjusting member 6 is used for the decoration through the angle steel 30. The main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com