Windproof clamp for metal roof plates

A metal roof and roof panel technology, which is applied to roofs, roof cladding, and roofs using flat/curved panels, etc., can solve the problems of roof panel and fixing seat detachment, easy opening, and roof panel detachment, etc., to avoid Easy to speak effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

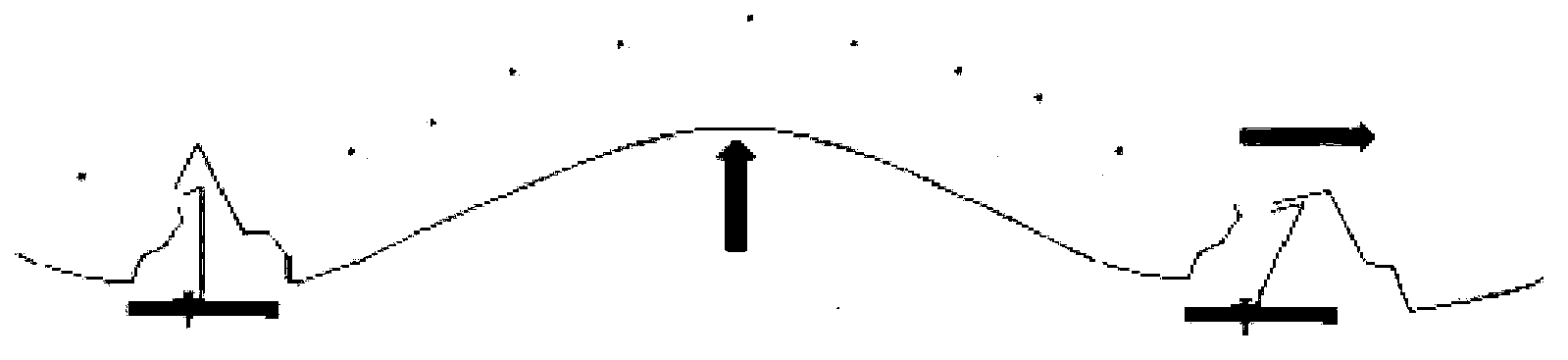

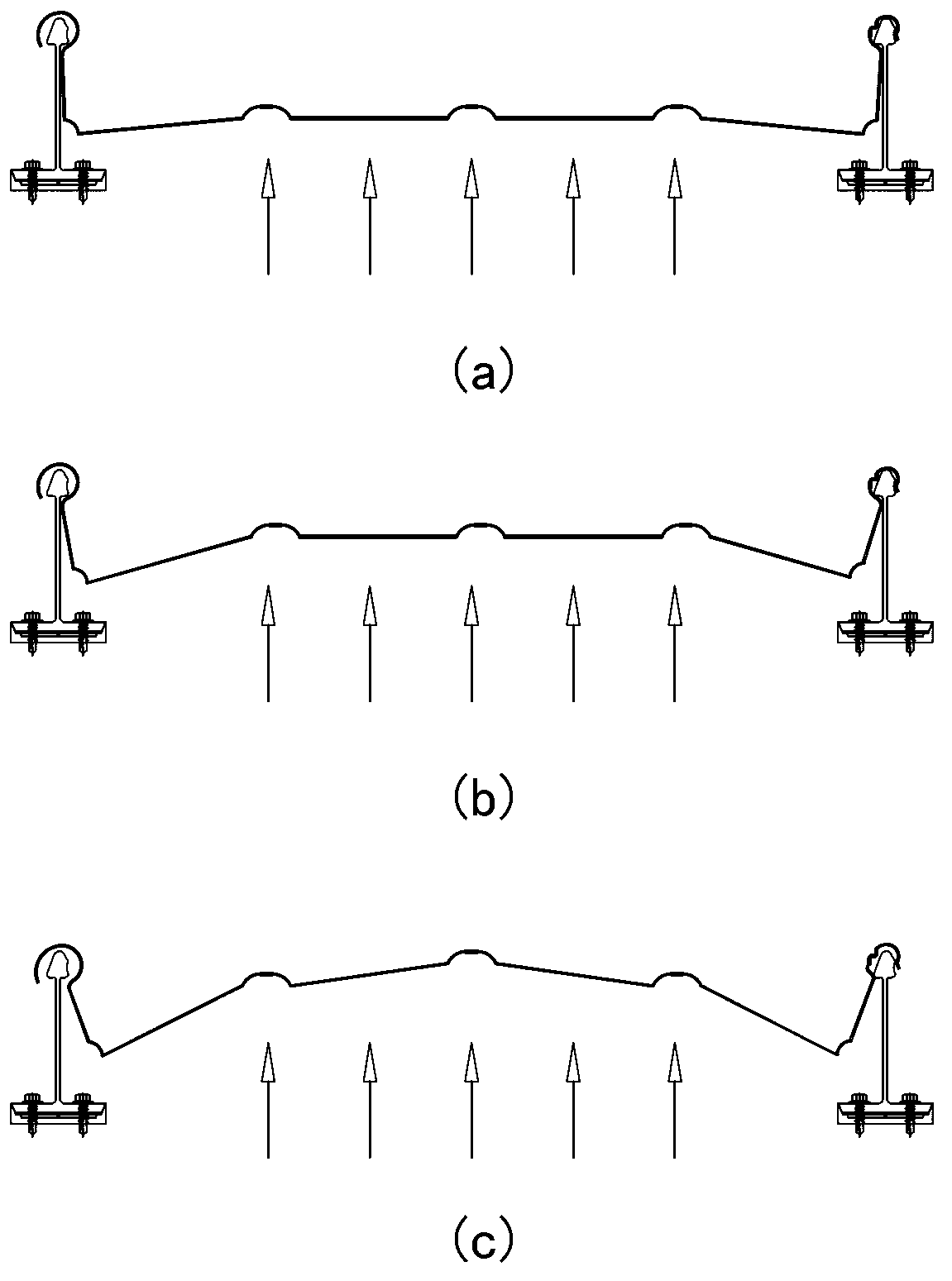

Problems solved by technology

Method used

Image

Examples

Embodiment 1

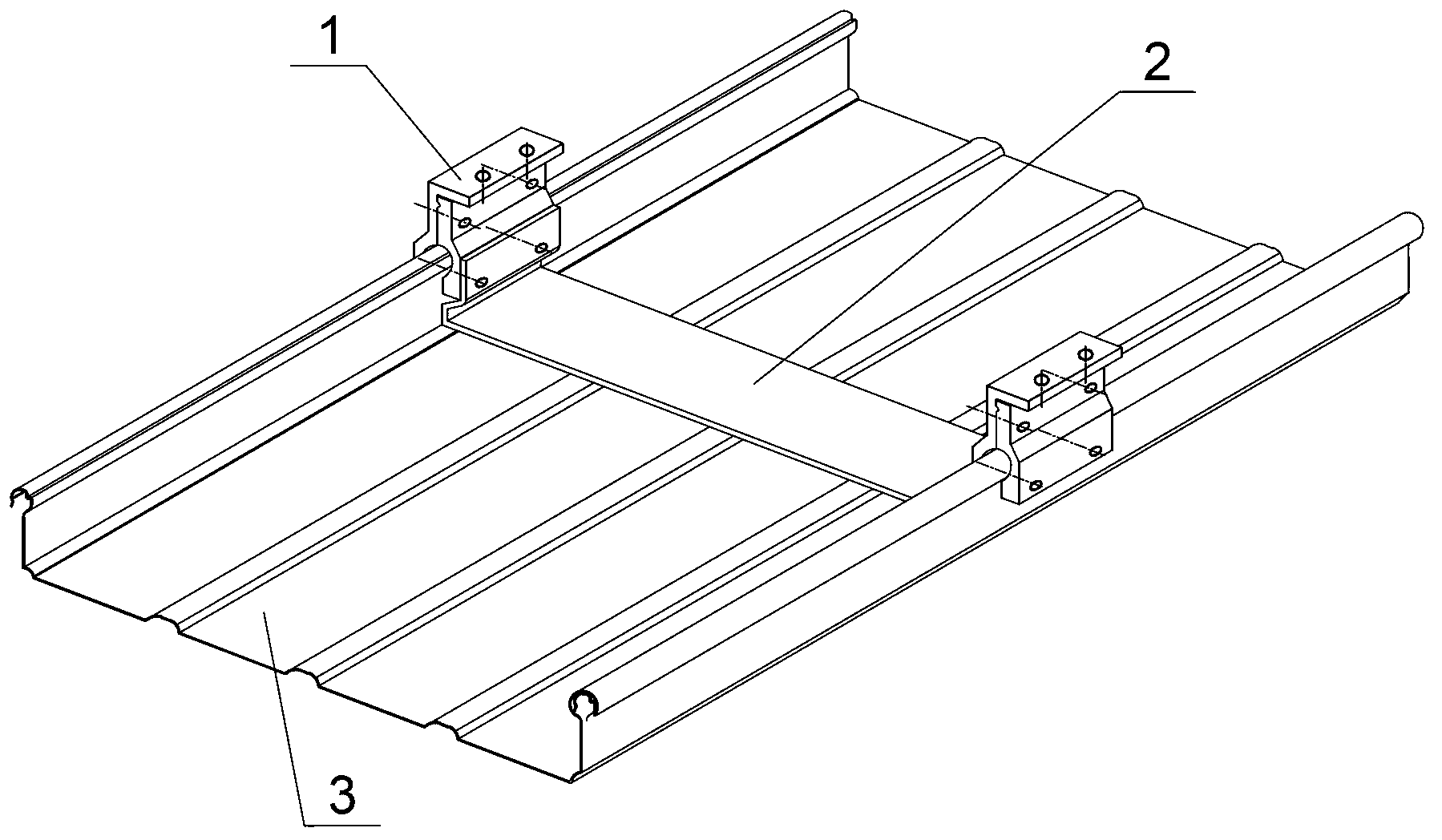

[0027] like Figure 3 ~ Figure 5 , Figure 9 , Figure 10As shown, this embodiment includes a fastening clip assembly 1, a reinforcing clip 2, a metal roof panel 3, and a roof panel fixing seat 4. Ribs 31, second vertical ribs 33, the top of the first vertical rib 31 is provided with a first fastening portion 32, and the top of the second vertical rib 33 is provided with a second fastening portion 34. The adjacent metal roof panels 3 are fastened and connected by the first fastening part 32 and the second fastening part 34 and fastened and fixed with the roof panel fixing seat 4. The fastening The clip assembly 1 is clamped on the fastened first fastening part 32 and the second fastening part 34, so as to clamp the adjacent metal roof panels 3 from the top, and the reinforcing clip 2 is located between the first vertical rib 31 and the second vertical rib 33 of each of the metal roof panels 3, and the two ends are respectively fixedly connected with one of the fastening cli...

Embodiment 2

[0029] like Figure 6 ~ Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that: the bottom panel 20 is provided with reinforcing ribs 23 along the length direction to further strengthen the rigidity of the reinforcing clip 2 and improve the stability of the metal roof panel ; The reinforcing clip 2 is made of steel.

[0030] The remaining features of this embodiment are the same as those of Embodiment 1.

[0031] In the present invention, the fastening clip assembly 1 is clamped on the fastened first fastening part 32 and the second fastening part 34, and the adjacent metal roof panels 3 are clamped from the top. , so that the top of the metal roof panel 3 is tightly fastened, avoiding the disadvantages of easy opening due to the loose fastening of the fastening parts of two adjacent metal roof panels; in addition, the reinforcing clip 2 is located Between the first vertical rib 31 and the second vertical rib 33 of each metal roof panel 3 , and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com