Metal roofing shingle, metal roofing shingle system, and method of installing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

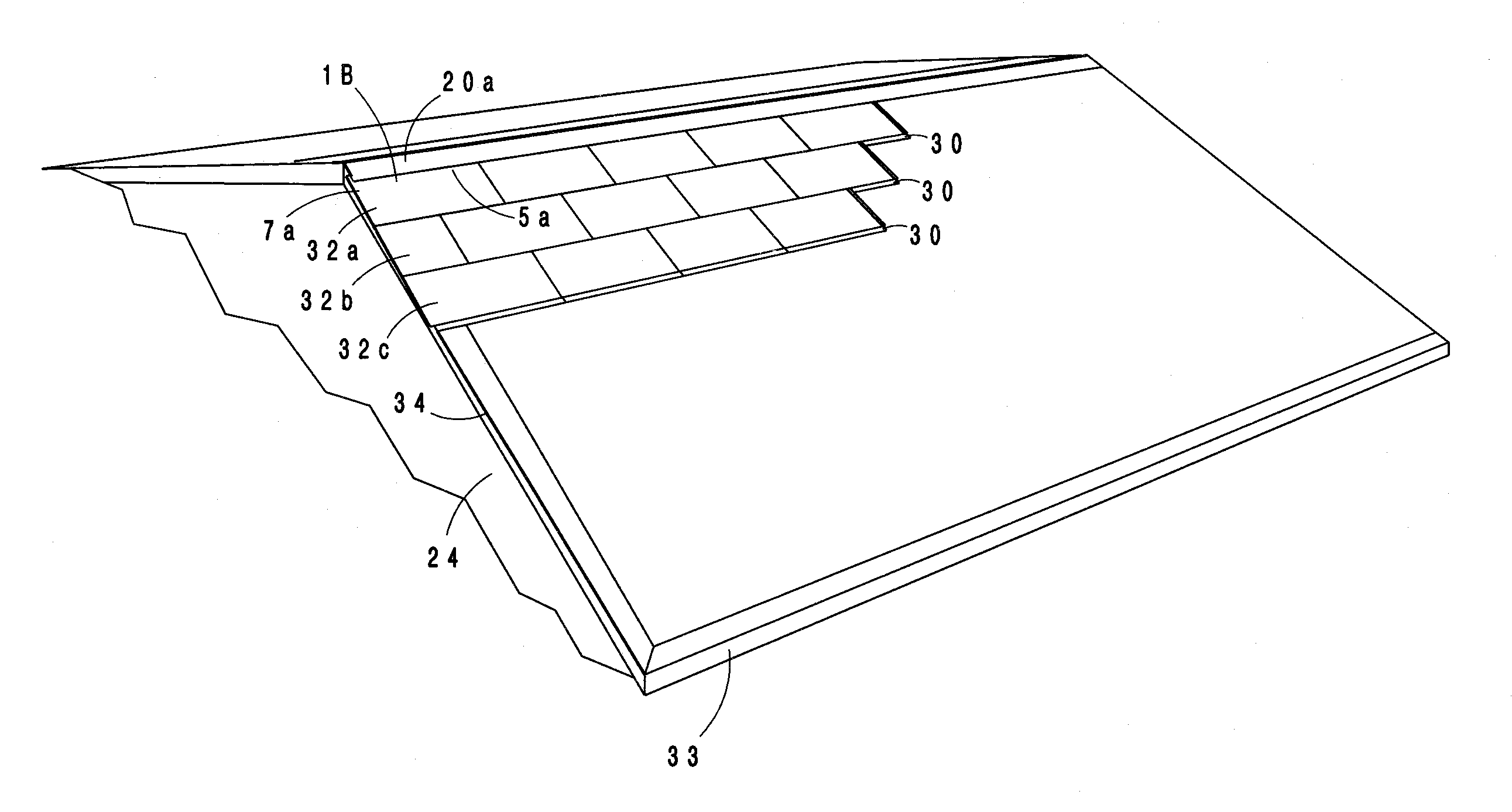

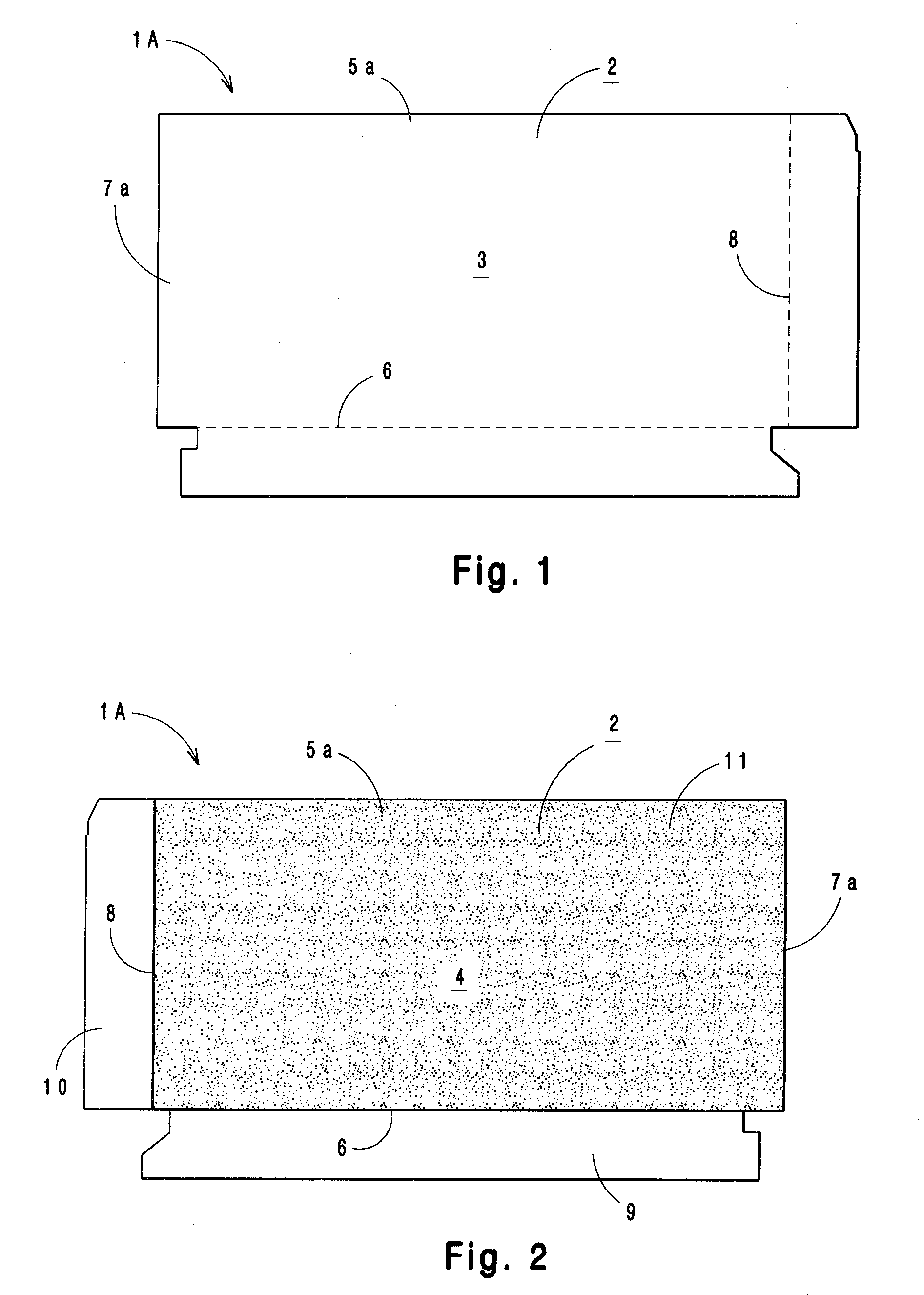

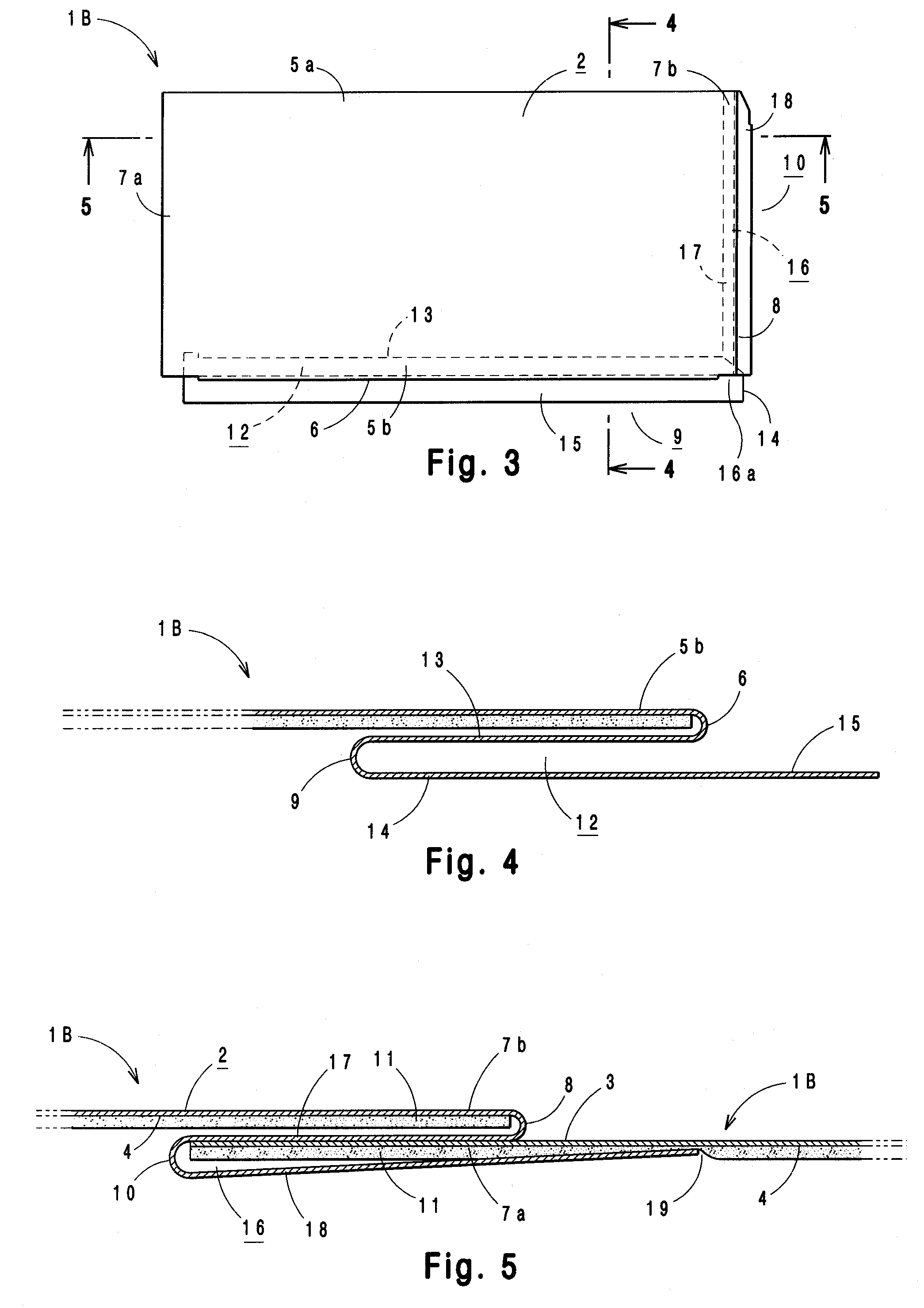

Embodiment Construction

[0039]There have been various attempts in the past to provide metal roofing shingles, for example, shingles manufactured from sheet steel, aluminum, copper or other like metallic materials, to improve service life, insulation characteristics, and appearance in metal roof systems. Such past attempts have had marginal success. State of the art metal shingles are prone to water penetration between adjacent shingles. This is because past mechanical connections between adjacent metal shingles extend along the top or external surface of the shingles where they are exposed to weather conditions. Such exposed joints or connections require the on-sight application of caulks or gaskets along the connection joints to provide watertight integrity. Moreover, the need to apply caulks, adhesives, or like sealants at the job sight is problematic in that, unreliable workers may forget to apply the required sealant, may apply an ineffective amount of sealant material, or apply a poor quality caulk be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com