Pre-stress fibre restriction concrete member and construction method thereof

A technology for restraining concrete and construction method, applied in the field of concrete structures, can solve the problems of insufficient material strength, unsatisfactory application effect, small lateral deformation of components, etc., and achieve the effects of improving bearing capacity and ductility, improving work efficiency, and saving work processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

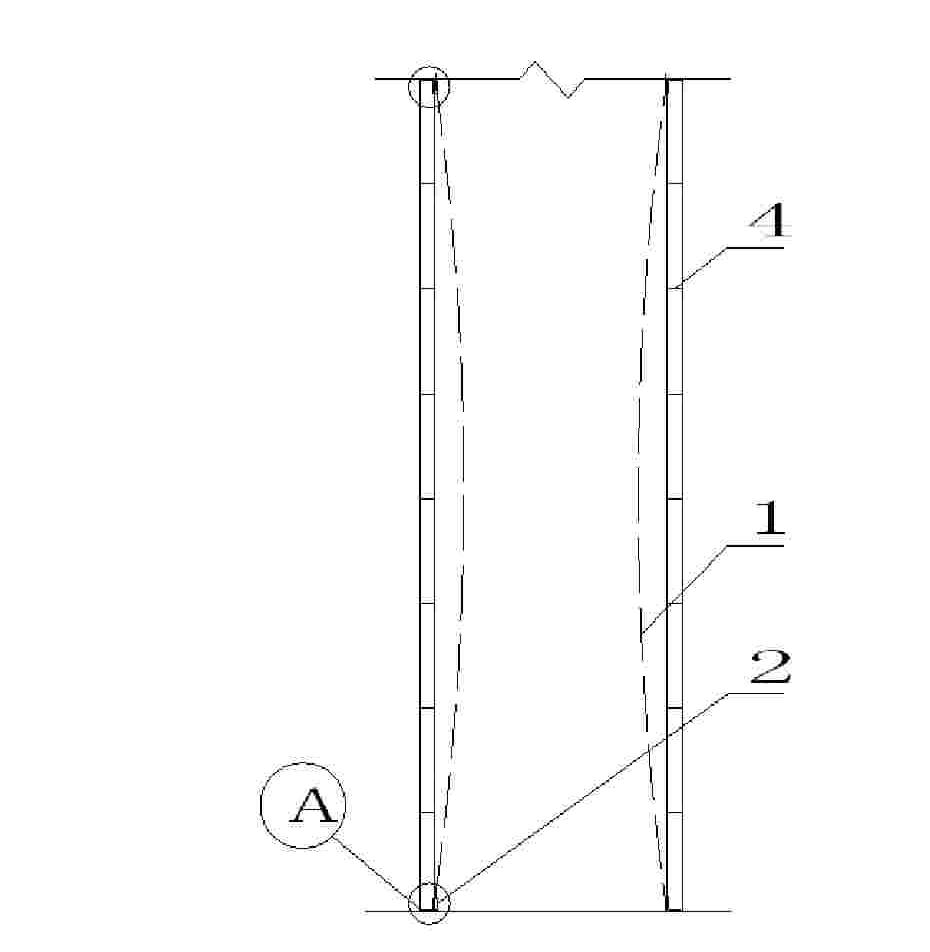

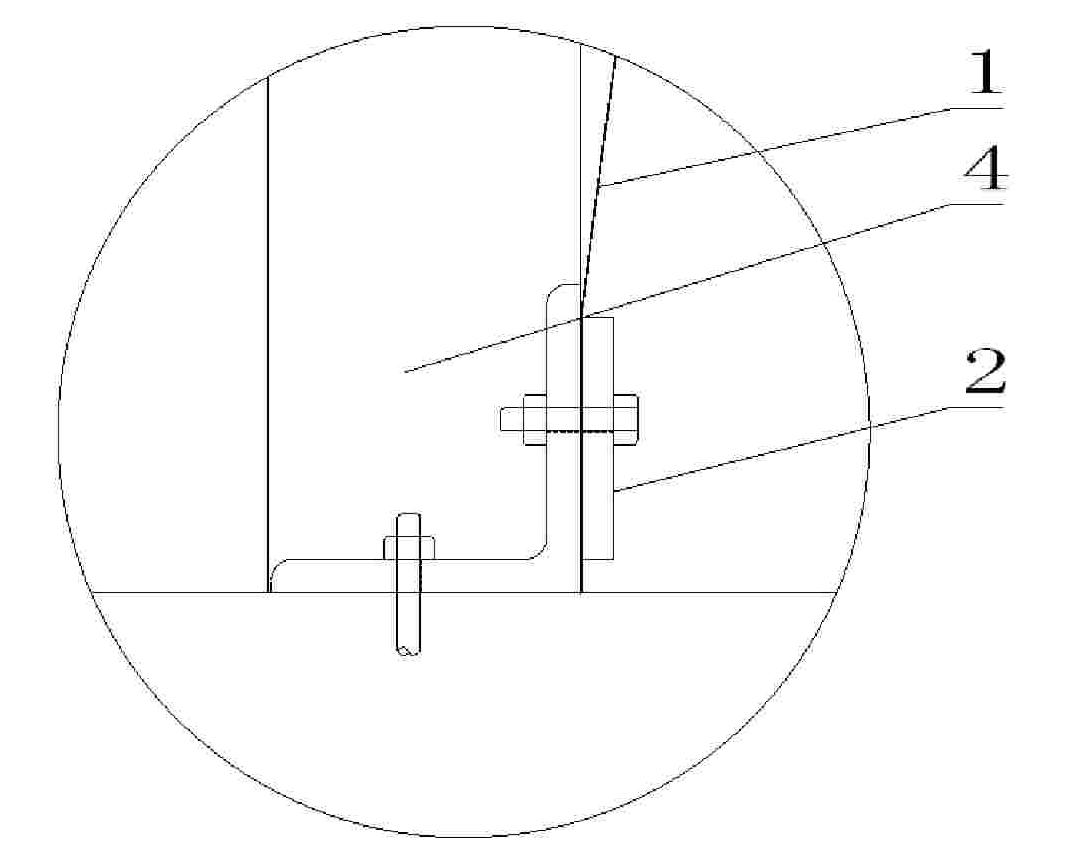

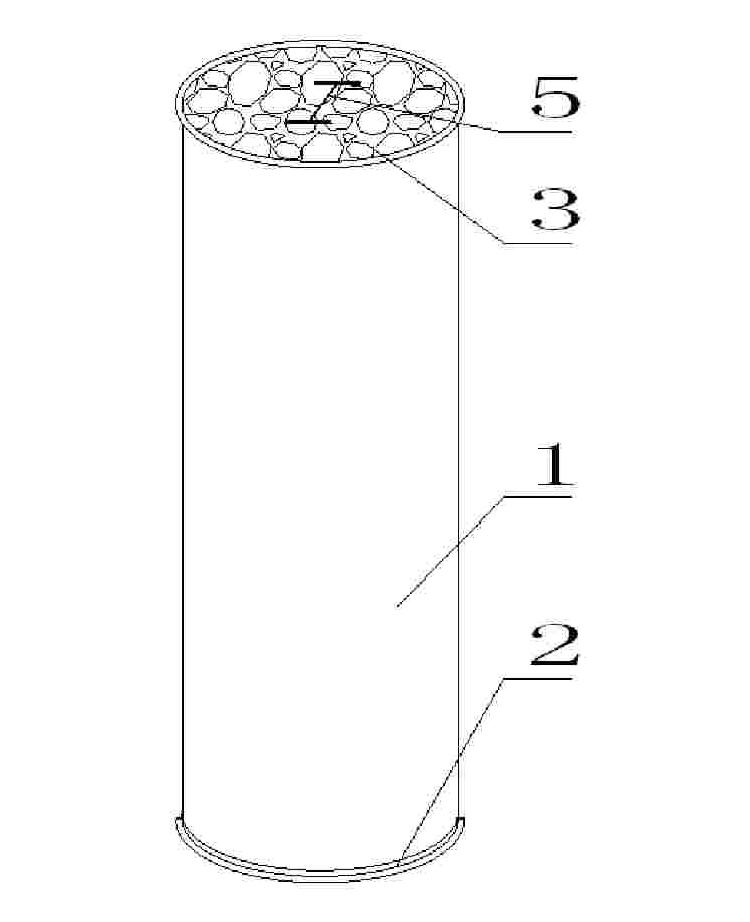

[0026] Embodiment 2 of the present invention: a, first roll the high-strength fiber cloth into a tube, and brush epoxy resin glue on the overlapping parts of the fiber cloth to obtain the fiber cloth tube 1, whose diameter and number of overlapping layers are determined by design.

[0027] b. Make the end clamp 2, the clamp clamps the fiber cloth drum 1, erects the steel formwork 4 outside the fiber cloth drum 1, installs the section steel 5 in the fiber cloth drum to form a rigid prestressed fiber-constrained concrete member, to improve Shear force on concrete members.

[0028] c, prepare concrete, add expansion agent in concrete 3, expansion agent selects UEA expansion agent for use, its weight is 20% of the cement weight in concrete, then pour concrete 3 in fiber cloth tube 1, compact, to fiber cloth tube 1 Generate pressure and form a prestress.

[0029] d. After the concrete 3 reaches its strength, the steel formwork 4 is removed, and the volume of the concrete 3 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com