Adjustable welding restraint stress testing device

A welding restraint and test device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of harsh test conditions, cumbersome test methods, complex structure, etc., and achieve the effect of ensuring strength, ensuring continuous stress, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

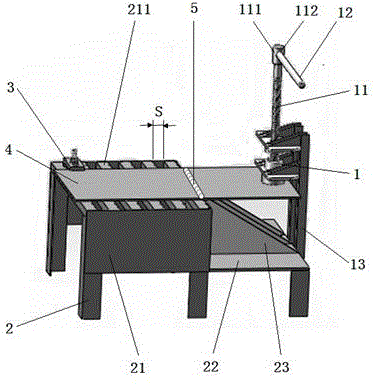

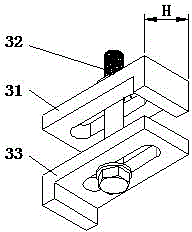

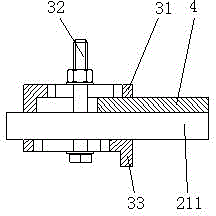

[0025] With reference to the accompanying drawings, the present invention is realized in the following way: a welding restraint stress adjustable test device, which includes a force applying unit 1, a clamp unit 3, and a main unit 2, and the clamp unit 3 is arranged on two lateral sides of the main unit 2. Between the rods 211 , the force applying unit 1 is arranged corresponding to the weldment 4 on the main body unit 2 , and applies pressure to the weldment 4 through the adjustable screw 11 .

[0026] Such as figure 1 with Figure 4 As shown, the force applying unit 1 of the present invention includes an adjustable screw 11, a lever 12, a fixing device 13 and a stress applying base 14; the adjustable screw 11 can apply pressure to the weldment 4 through the stress applying base 14; the adjustable One end of the adjustable screw 11 is provided with a cylindrical step 111, and the cylindrical step 111 is provided with a through hole 112. The other end of the adjustable screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com