Probe package structure of human body pressure measuring sensor

A technology for measuring sensors and packaging structures, which is applied in pressure sensors, sensors, and intracranial pressure measurement. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

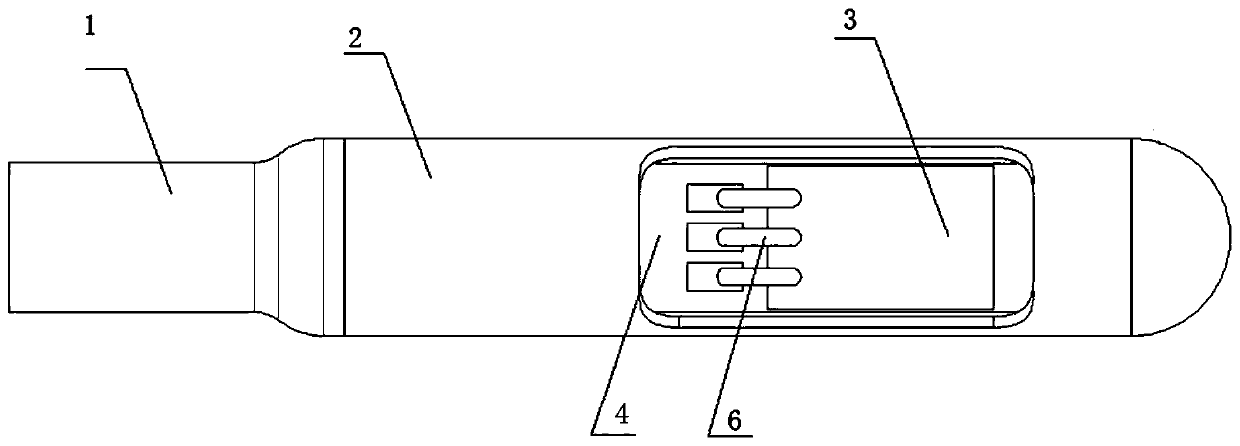

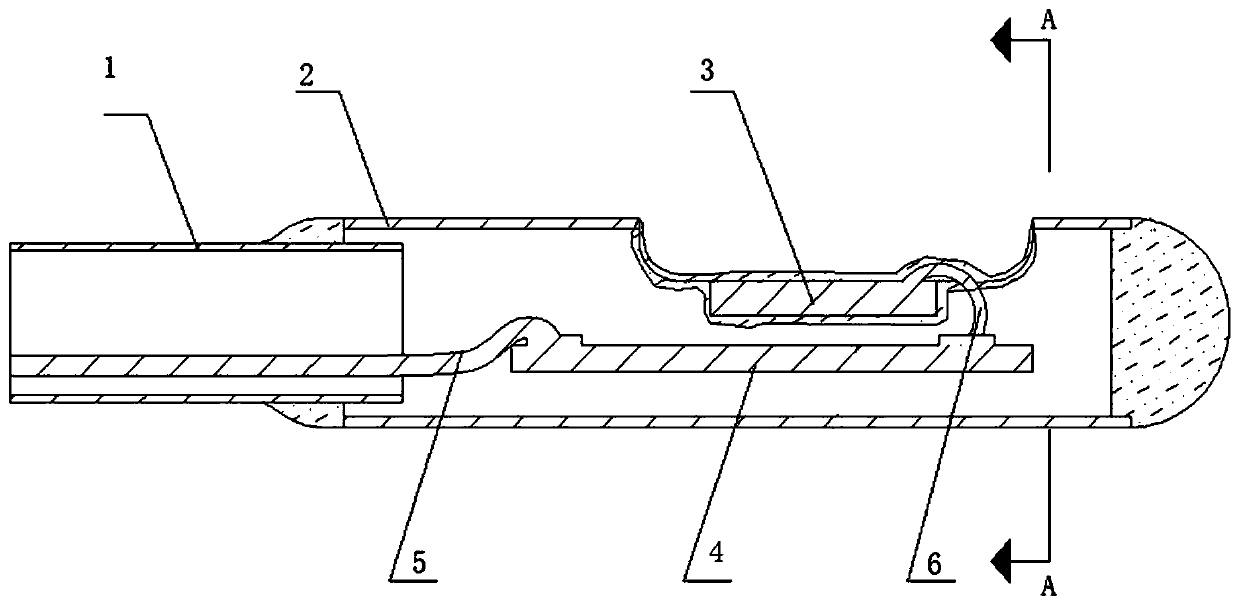

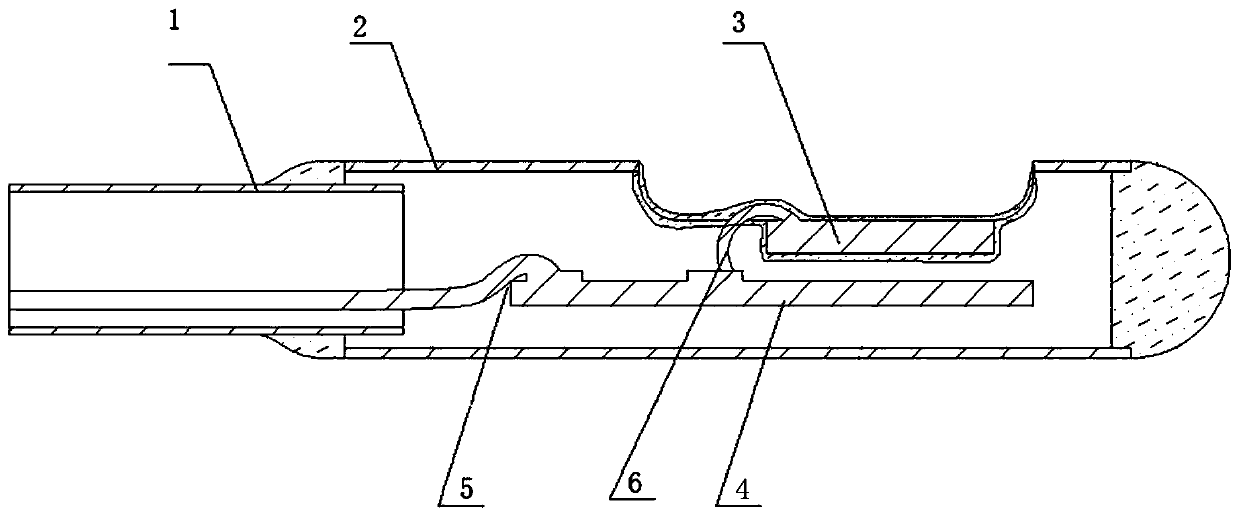

[0034] combined with figure 1 , figure 2 with 4 As shown, a probe package structure of a human body pressure measurement sensor, including:

[0035] The wire 5 is placed in the plastic conduit 1, and the first end of the wire 5 is connected to the signal processing circuit;

[0036] The protective tube 2 is provided with a groove, and one end of the protective tube 2 is in sealing communication with the plastic conduit 1, and the other end is a closed end;

[0037] Miniature PCB4, placed in the groove, the size of the miniature PCB4 matches the inner diameter of the protection tube 2, so that it can be placed in the groove, and the gap between the miniature PCB4 and the side wall of the protection tube 2 is filled with protective glue, so that the position of the miniature PCB4 Fixed, the signal output end of the micro PCB4 is connected to the second end of the wire 5;

[0038] The pressure chip 3 is placed in the groove and its sensing surface is perpendicular to the ope...

Embodiment 2

[0045] On the basis of Embodiment 1, the closed end is a closed end integrally formed with the protection tube 2 .

[0046] Further, the outer layers of the protective tube 2 and the closed end are made of relatively magnetically inert and biocompatible materials, which are relatively magnetically inert, that is, do not contain magnetic metals such as iron, and are made of relatively magnetically inert and biocompatible materials Including titanium-based metals, cobalt-based metals, ceramics or Peek polymer materials, which have no sensitization, carcinogenicity, or distortion in contact with the human body, and can be well combined with bone tissue, epithelium, and connective tissue.

Embodiment 3

[0048] On the basis of Example 1, the closed end is a closed end made of encapsulating soft glue. Further, the gap formed by the height difference between the sensing surface of the pressure chip 3 and the protection tube 2 is also potted with The soft glue is encapsulated so that the protective tube 2 can transition smoothly when it is inserted into the human body. The lubricating and protective function of the encapsulating soft glue is also a protective glue, and silica gel or epoxy glue can be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com