Ship thick plate welding process

A welding process and ship technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve problems such as unqualified, product breakage, etc., achieve the effects of less difficult operation, reduce external stress, and avoid crack defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to deepen the understanding of the present invention, the present invention will be further described in detail below. This embodiment is only used to explain the present invention, and does not constitute a limitation to the protection scope of the present invention.

[0037] Ship thick plate welding process of the present invention,

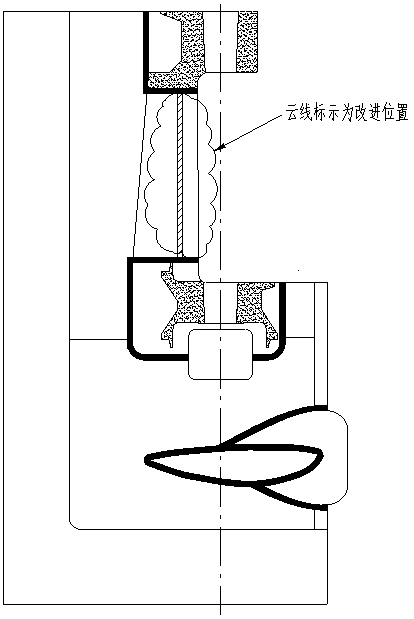

[0038] image 3 As shown, (1) First of all, the welding method of the ship’s thick plate is no longer the welding method of overhead welding, but instead of flat welding and symmetrical welding. The preheating temperature is 100℃<t<250℃. Effective preheating can reduce weld cooling speed, reduce the risk of hardening; give the absorbed hydrogen a chance to diffuse out, thereby reducing the occurrence of cracks; remove moisture in the weld; improve the fusion of the overall weld; ensure the expansion and contraction distribution of the weld metal and the base metal uniform, thereby reducing stress levels.

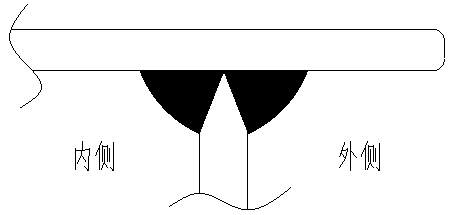

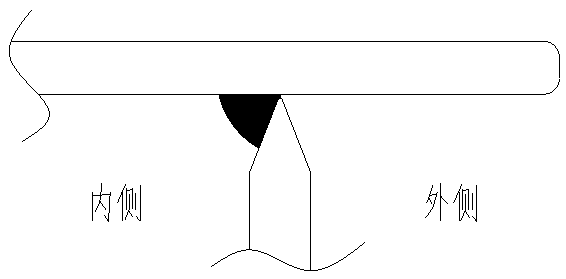

[0039] Figure 3a A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com