Deformation-prevention heat treatment method for large thin-wall steel casting

A heat treatment method and technology for steel castings, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as deformation and deformation of steel castings, and achieve the effect of reducing external stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

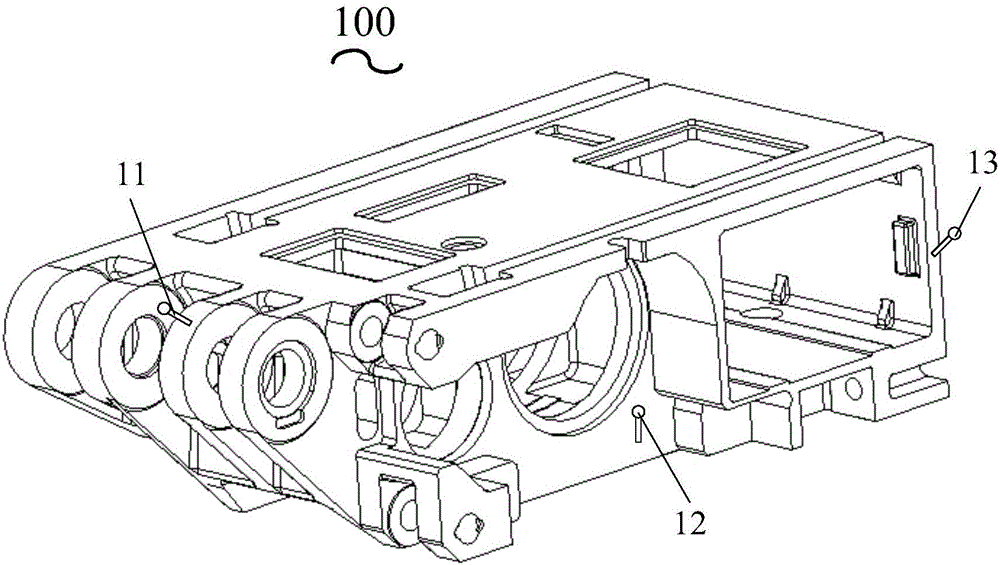

[0040] see figure 1 , for the shell casting 100 of thin-wall complex structure for coal mining machinery, the outline size of the casting is 3048×1600×864mm, the weight is 11t, the thinnest wall thickness is 25mm, and the maximum wall thickness is 80mm. When heat treatment is carried out according to the method of the present invention, the heat treatment holding time is 80mm×1~1.5min / mm=80~120min, respectively at the thickest wall thickness, the thinnest wall thickness and the middle position of the steel casting. The external temperature measuring device 11, the external temperature measuring device 13, and the external temperature measuring device 12 are installed, and the shaft hole, the large plane of the cavity, and the axis of the steel casting are not deformed after heat treatment.

Embodiment 2

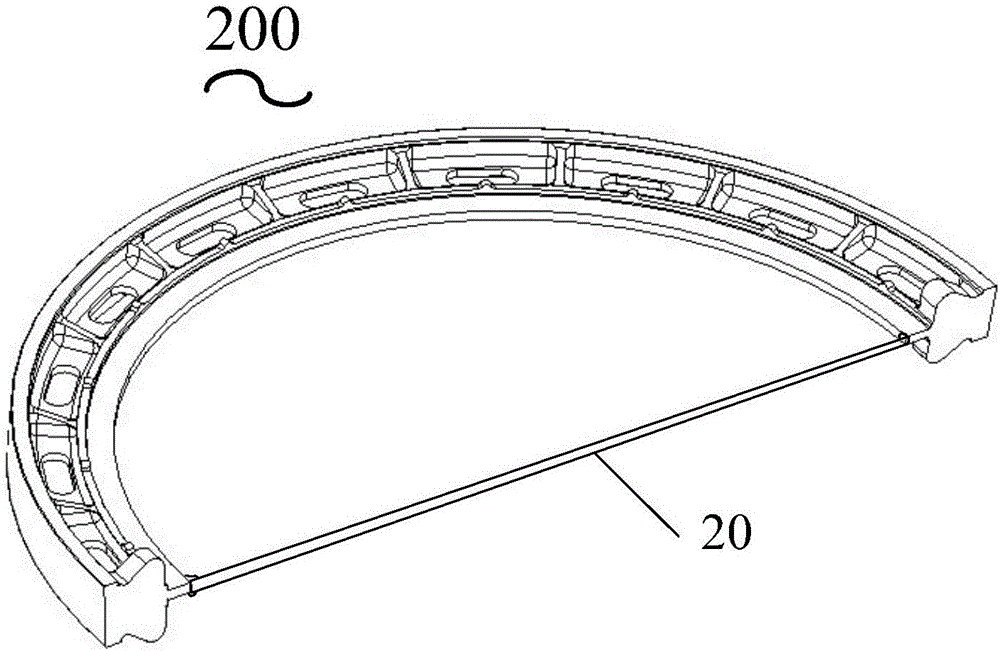

[0042] see figure 2 , for high-strength large-scale thin-walled ring gear castings for mining machinery, such as the two ring gears 200, the outline size of the ring gear casting is Φ5036*400mm, the net weight of the steel casting is 17t, and the maximum wall thickness 170mm, minimum wall thickness 30mm. The contour size of another ring gear steel casting is φ9892*900mm, the net weight of the steel casting is 100t, the maximum wall thickness is 200mm, and the minimum wall thickness is 50mm. Two kinds of steel castings are molded and heat-treated in two halves, and the single-half steel casting is C-shaped, and a tie bar 20 is set at the opening of the C-shaped ring gear casting. After heat treatment is carried out according to the method of the present invention, the casting There is no opening, shrinkage and obvious warping deformation of steel parts.

[0043] According to the method provided by the present invention, carry out the casting production of deformable steel ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com