A Blind Insertion Structure of Vertical Interconnection between Boards and Its Realization Method

An implementation method and blind-mating technology, which are applied in the directions of printed circuits, printed circuits, and electrical components connected with non-printed electrical components, can solve the problem of high production costs, inability to use multiple connectors, and multi-layer blind-mating connections and structures. complex and other problems, to achieve the effect of reducing external stress and high reliability of vertical interconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

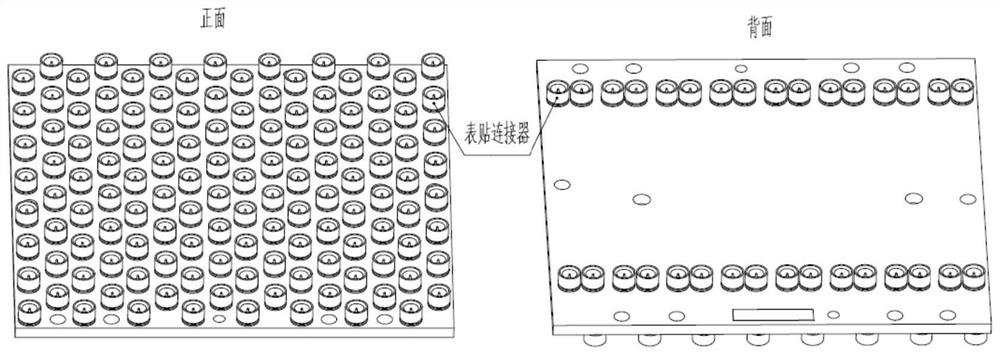

[0046] This embodiment provides a blind insertion structure for vertical interconnection between boards, such as Figure 9 As shown, the structure includes a mounting plate 1, a backing plate, a printed board assembly, a pressure plate, a mounting plate 2 and a spacer.

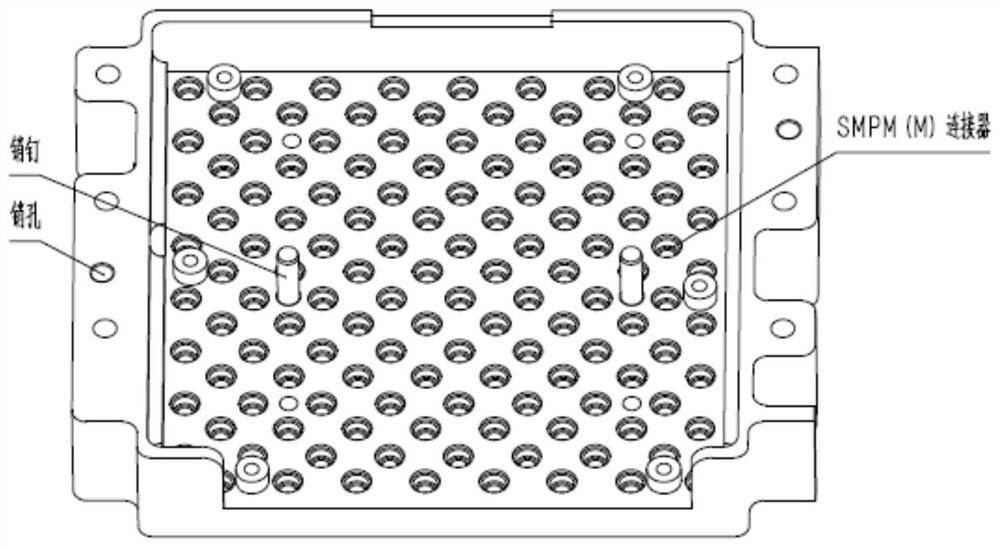

[0047] Among them, such as figure 2 As shown, there is a concave cavity on the mounting board 1, and the backing plate, the printed board assembly and the pressure plate are sequentially put into the concave cavity for positioning and assembly. The bottom of the cavity is equipped with an SMPM-M connector. There are two positioning pins at the bottom of the cavity. At the same time, pin holes are designed on the corresponding positions of the backing plate, printed board and pressure plate. The gap between the positioning pins and the pin holes is 0.02. -0.05mm, the chamfer of the pinhole opening is 0.3mm×45°; the left and right edges of the mounting plate 1 are also provided with positioning holes.

[0048...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com