Construction method of temporary single diagonal bracing bridge tower

A technology of single-slant bridge towers and construction methods, which is applied to bridges, bridge construction, bridge parts, etc., and can solve problems such as high cost, difficulty in setting horizontal braces, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

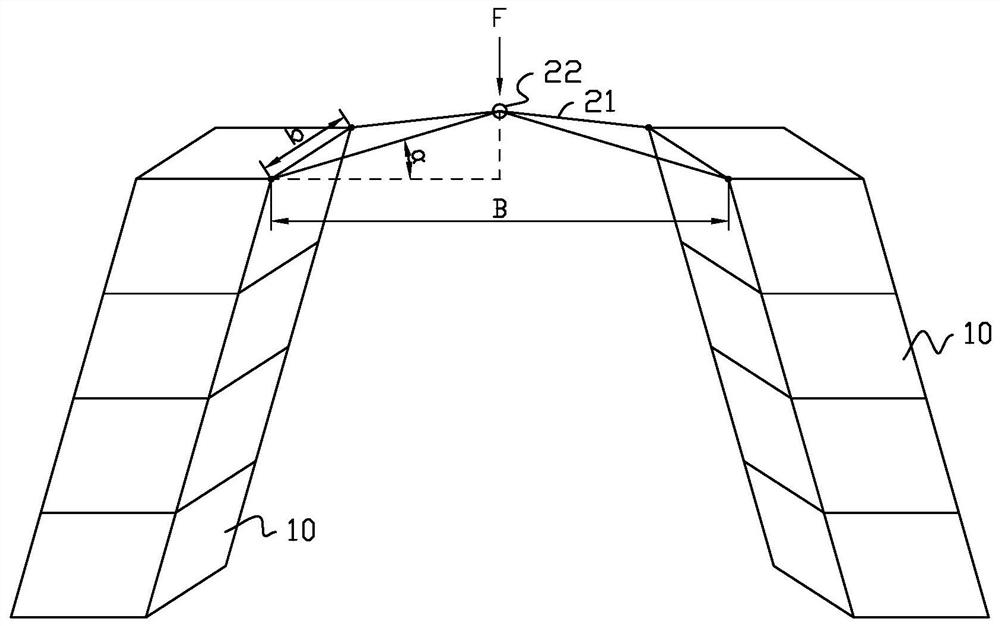

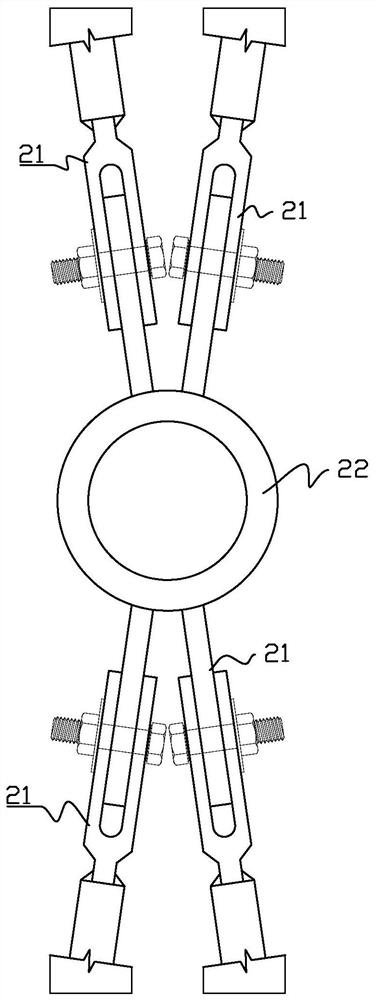

[0055] Embodiment one: tension force F=200kN is set, the height h=28m of bridge pylon column being subjected to horizontal lateral force, changes α angle (from small to large), calculates and obtains f 横向 and the stress σ outside the root of the pylon column, and verify whether the structure is safe.

[0056] Table 2

[0057]

[0058] It can be seen from Table 2 that when F and h are constant, the smaller the α angle, the larger the lateral f of the diagonal brace member 21 decomposed, which can effectively offset the stress σ generated by the self-weight of the pylon column 10. From the data in Table 2, it can be seen that when the α angle is within 45°, the stress σ of the concrete outside the 10 roots of the bridge tower column does not exceed 1MPa; when the α angle is less than 1°, the σ 钢筋 It is 201.377MPa, which exceeds the yield stress of the steel bar ([σ]=145MPa), so the α angle should not be less than 1°. To sum up, the value range of α angle should be 2°-45°. ...

Embodiment 2

[0059] Embodiment two: tension force F=400kN, bridge pylon column 10 are subjected to the height h=28m of horizontal transverse force, change α angle (from small to large), calculate and obtain the stress of f transverse direction and bridge pylon column 10 root outsides σ, and verify that the structure is safe.

[0060] table 3

[0061]

[0062] It can be seen from Table 3 that when F and h are constant, the smaller the α angle is, the larger the lateral f of the diagonal bracing member 21 will be, which can effectively offset the stress σ generated by the self-weight of the pylon column 10. From the data in Table 2, it can be seen that when the α angle is within 45°, the stress σ of the concrete outside the 10 roots of the bridge tower column does not exceed 1MPa; when the α angle is less than 1°, the σ 钢筋 It is 201.377MPa, which exceeds the yield stress of the steel bar ([σ]=145MPa), so the α angle should not be less than 1°. To sum up, the value range of α angle shoul...

Embodiment 3

[0063] Embodiment three: tension force F=200kN is set, the height h=32m of the bridge pylon column 10 subjected to the horizontal lateral force, the angle α is changed (from small to large), and the stress σ on the outside of the f transverse direction and the bridge pylon column root is calculated , and verify that the structure is safe.

[0064] Table 4

[0065]

[0066] It can be seen from Table 4 that when F and h are constant, the smaller the α angle, the larger the lateral f of the diagonal bracing member 21, which can effectively offset the stress σ generated by the self-weight of the pylon column 10. From the data in Table 2, it can be seen that when the α angle is 40°, the stress σ of the concrete outside the 10 roots of the pylon column exceeds 1 MPa; when the α angle is less than 1°, the σ 钢筋 It is 197.618MPa, which exceeds the yield stress of the steel bar ([σ]=145MPa), so the α angle should not be less than 1°. To sum up, the value range of α angle should be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com