Quantum dot transfer printing method

A technology of quantum dots and stamps, applied in the field of quantum dots, can solve problems such as incompleteness and defective quantum dot patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030]Further, the preparation method of the initial embedded body includes: providing a shape-memory polymer, a curing agent and an accelerator; mixing the shape-memory polymer, the curing agent and the accelerator, adding to the In the first mold of the initial embedded body described above, curing treatment is carried out to obtain the initial embedded body shown. The curing agent is selected from methyltetrahydrophthalic anhydride and / or polyoxypropylene diamine, but not limited to these; the accelerator is selected from decylamine and / or 2-ethyl-4-methyl Kiimidazoles, but not limited to these types. In a specific preferred embodiment, the molar ratio of the shape memory polymer, the curing agent and the accelerator is 4:1:2, and the performance of the intercalation body prepared under this molar ratio is the best. In another preferred embodiment, the step of curing includes: firstly heating at 100°C for 1.5h, and then heating at 130°C for 1h, and the curing effect is the...

Embodiment 1

[0039] 1. Preparation of deformable inserts of shape memory polymers:

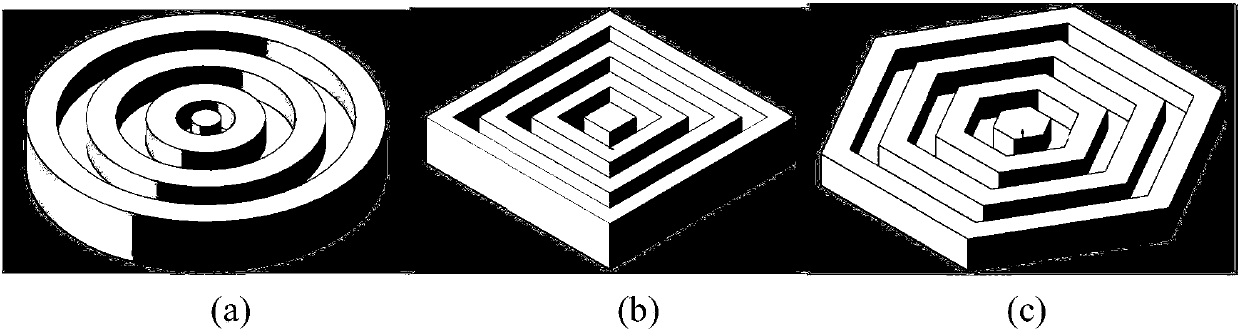

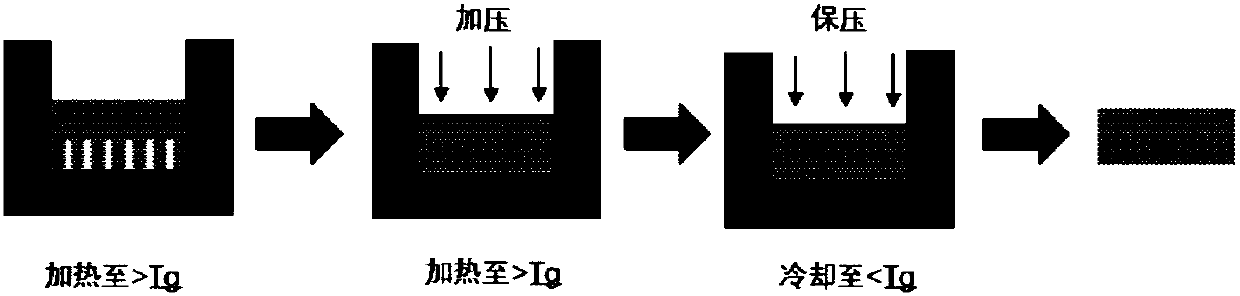

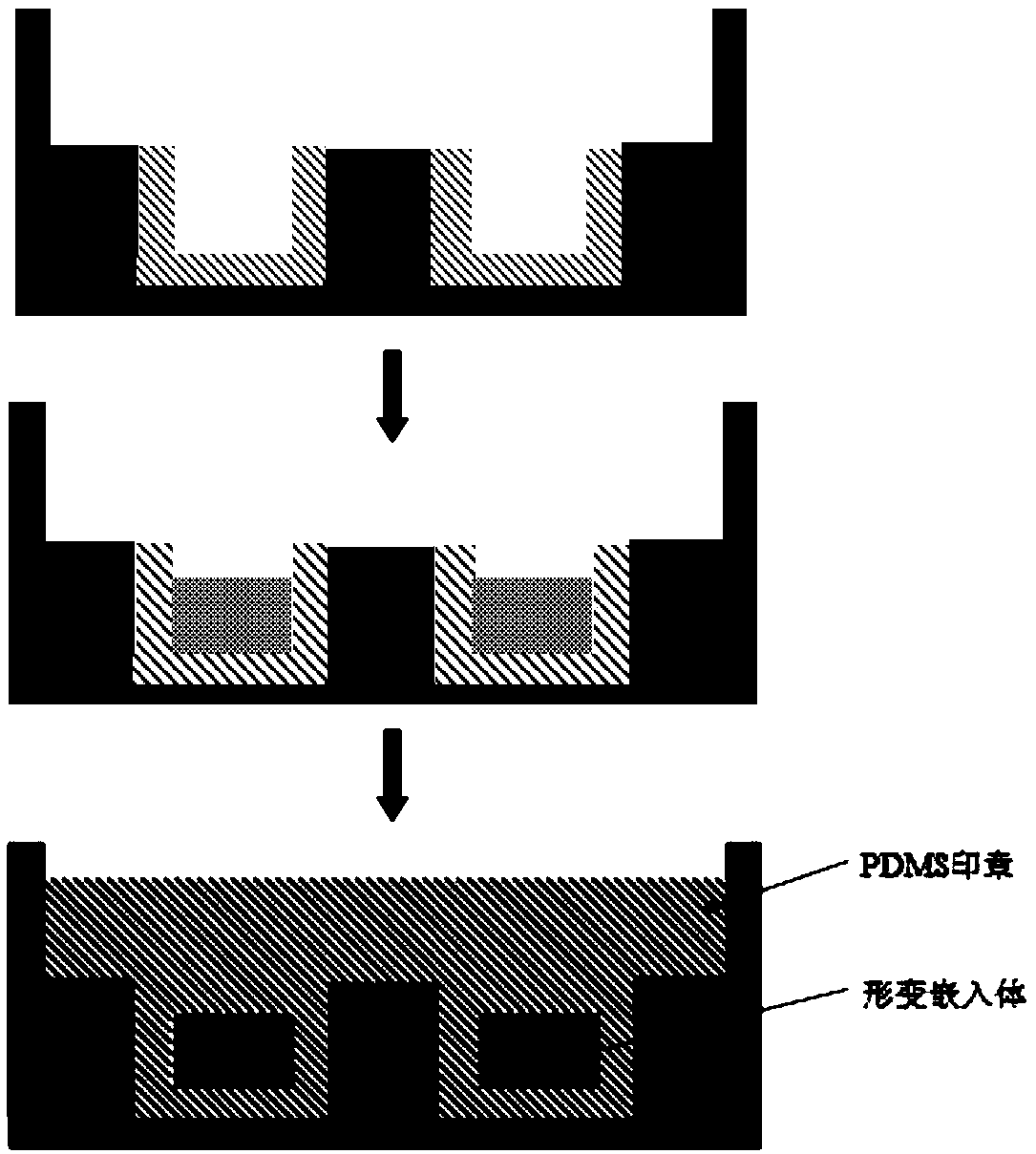

[0040] Utilize mold preparation such as figure 1 The initial embedding body of structure a: heat epoxy resin EP826 to 70 degrees Celsius and melt, add polyoxypropylene diamine epoxy curing agent and decylamine accelerator and mix, wherein the molar ratio of epoxy resin, curing agent, and decylamine is 4:1:2, shake evenly and pour into the mold, heat at 100 degrees Celsius for 1.5 hours to cure, and then heat at 130 degrees Celsius for 1 hour to post-cure. Separating the shape memory polymer from the mold to obtain an initial shape memory polymer embedded body, the glass transition temperature of which is 50-70 degrees Celsius; placing the shape memory polymer initial embedded body with the side facing down with the surrounding wall facing down. into a flat mold, such as figure 2 As shown, heat to 80 degrees Celsius, and then apply uniform pressure to deform the side with the surrounding wall until the s...

Embodiment 2

[0046] 1. Preparation of deformable inserts of shape memory polymers:

[0047] Utilize mold preparation such as figure 1 The initial embedding body of structure b: heat epoxy resin EP826 to 70 degrees Celsius and melt, add polyoxypropylene diamine epoxy curing agent and decylamine accelerator and mix, wherein the molar ratio of epoxy resin, curing agent, and decylamine is 4:1:2, shake evenly and pour into the mold, heat at 100 degrees Celsius for 1.5 hours to cure, and then heat at 130 degrees Celsius for 1 hour to post-cure. Separating the shape memory polymer from the mold to obtain an initial shape memory polymer embedded body, the glass transition temperature of which is 50-70 degrees Celsius; placing the shape memory polymer initial embedded body with the side facing down with the surrounding wall facing down. into a flat mold, such as figure 2 As shown, heat to 80 degrees Celsius, and then apply uniform pressure to deform the side with the surrounding wall until the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com