Welding device and welding method for printed board assembly based on inter-board vertical interconnection

A technology of welding device and welding method, which is applied in the direction of welding equipment, printed circuit manufacturing, manufacturing tools, etc., can solve the problem of floating height and warping deformation of printed boards, position deviation of surface-mounted connectors on printed boards, connectors Problems such as inclination can be solved to achieve the effect of reducing external stress, improving high reliability and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

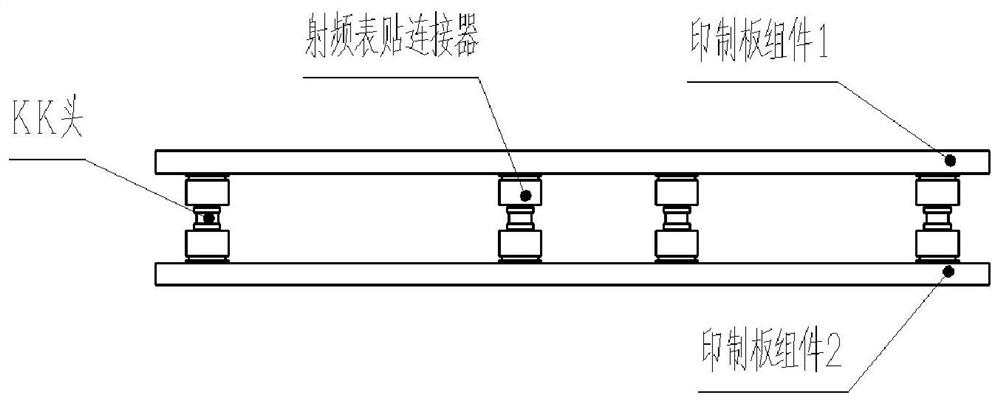

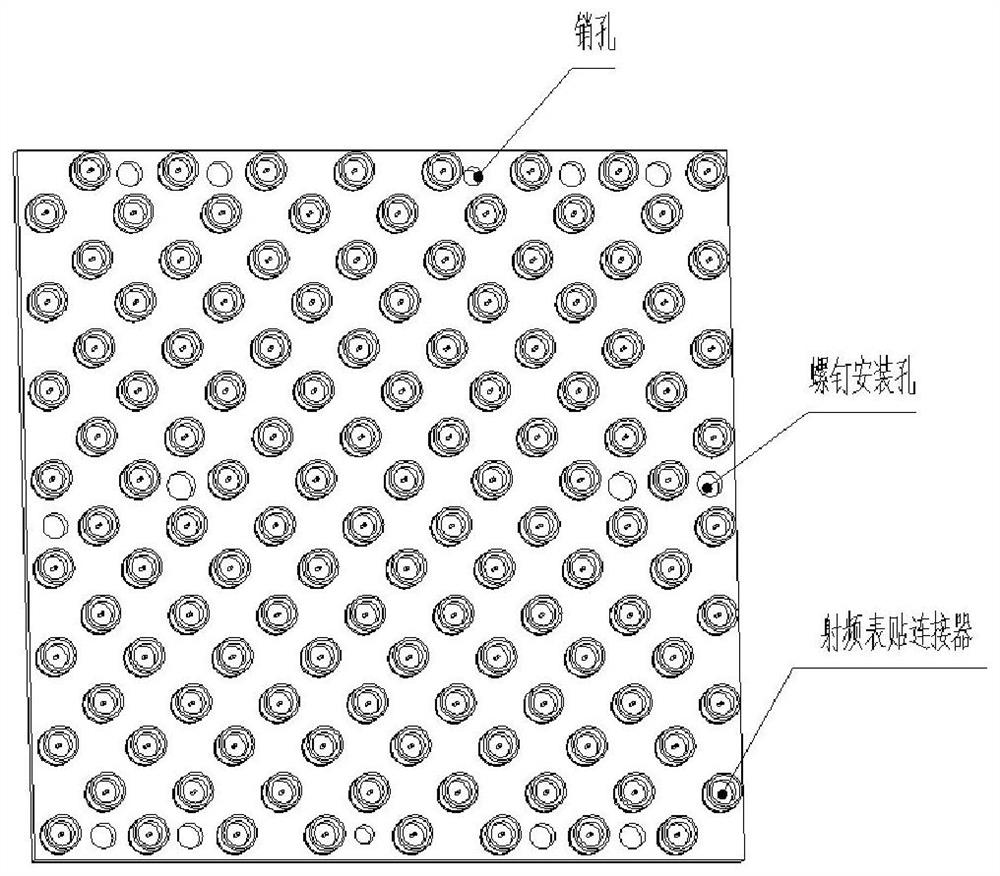

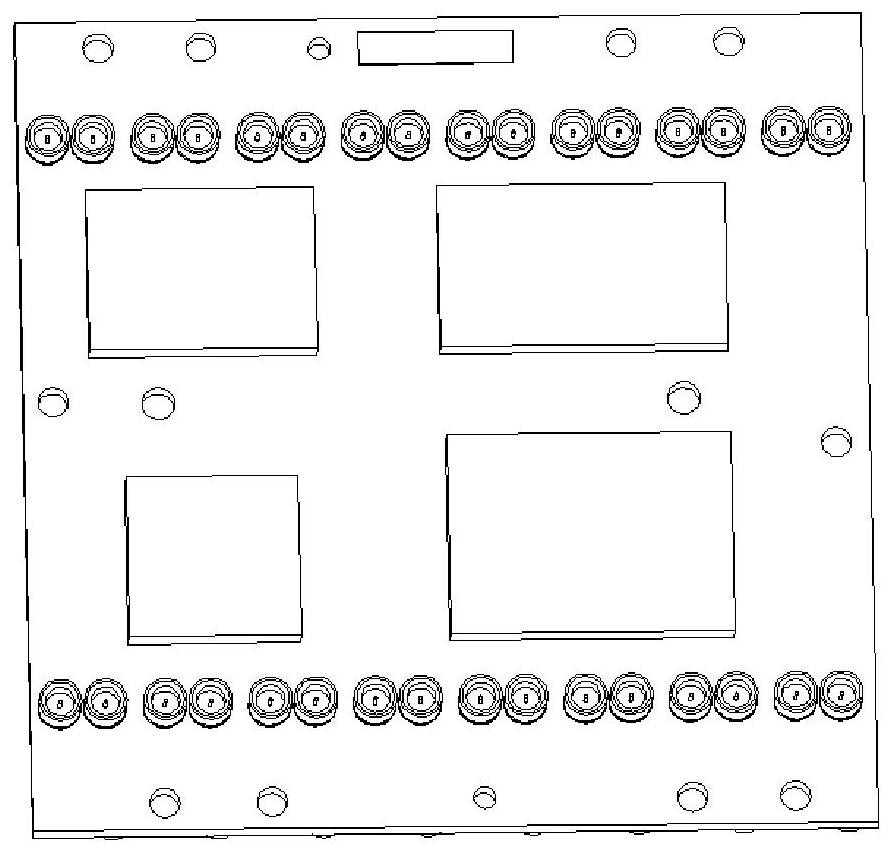

[0059] This embodiment provides a welding device based on vertically interconnected printed board assemblies between boards, the welding device is used for such as figure 1 The welding of the vertically interconnected printed board assembly between the boards shown, the vertically interconnected printed board assembly between the boards includes two printed board assemblies containing radio frequency surface mount connectors and KK heads for interconnection and transfer, such as figure 2 and image 3 As shown, the printed board assembly contains multiple RF surface mount connectors, pin holes, screw mounting holes and other components.

[0060] like Figure 4 As shown, a welding device based on the vertically interconnected printed board assembly provided by this embodiment includes a positioning plate 1 and a supporting plate 2, and is used to realize the positioning between the positioning plate, the printed board assembly, and the supporting plate. The pin 3 and the scre...

Embodiment 2

[0098] This embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, surface mount connectors are to be welded on both sides of the printed board assembly, so the welding method provided in this embodiment is the same as that provided in Embodiment 1. On the basis of method steps 1-5, it also includes:

[0099] S6, fixing the surface mount connector by dispensing glue.

[0100] like Figure 11 As shown, after the first side of the printed board assembly is soldered, fix all surface-mount connectors with Loctite 3619 glue at symmetrical points, and bake at 125°C for 15 minutes to prevent the surface-mount connectors from falling off during reflow soldering on the second side of the printed board. and position offset.

[0101] S7, repeat S2-S5, and complete the soldering of the surface mount connector on the second side of the printed board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com