Patents

Literature

35results about How to "Solve the floating problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

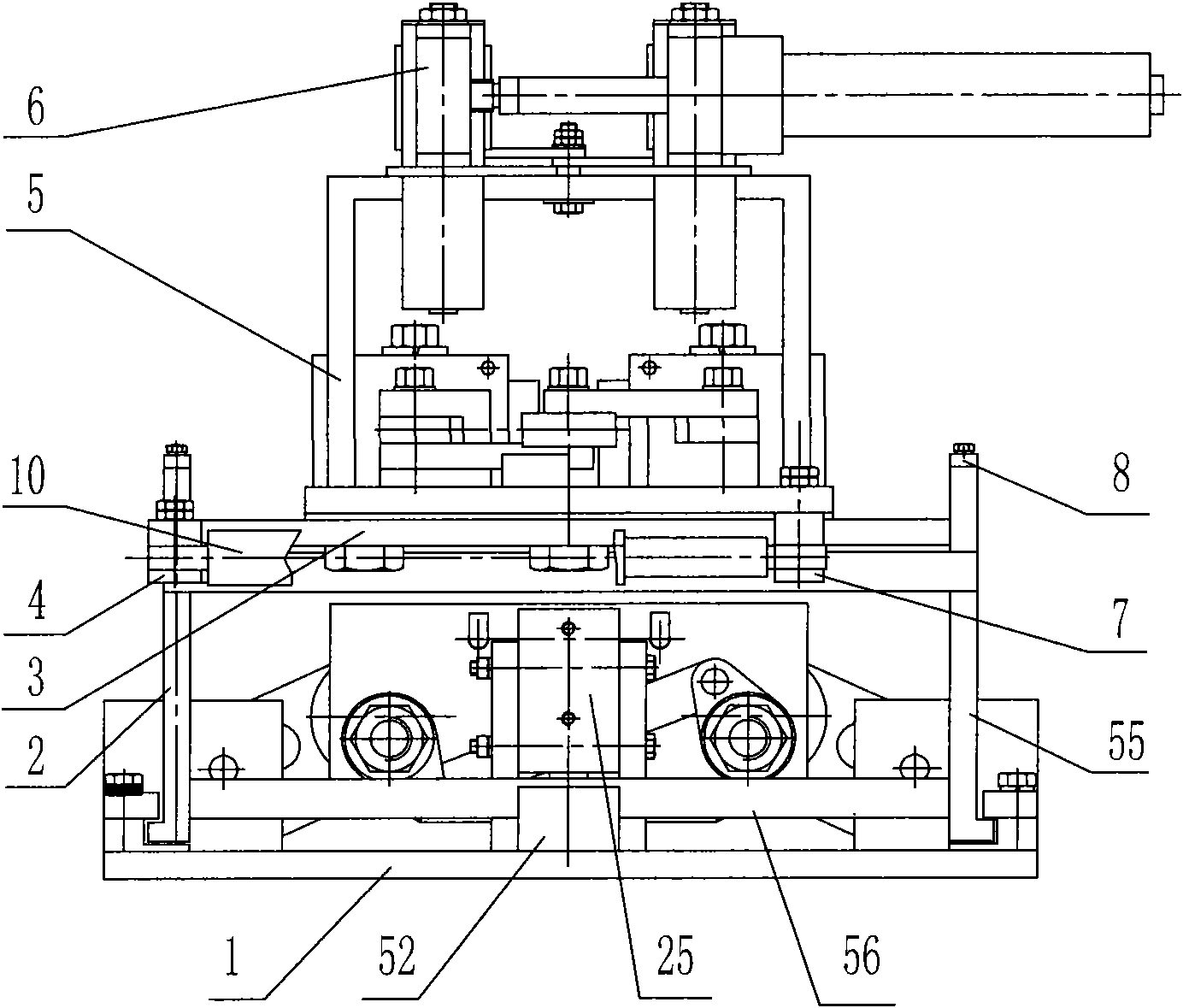

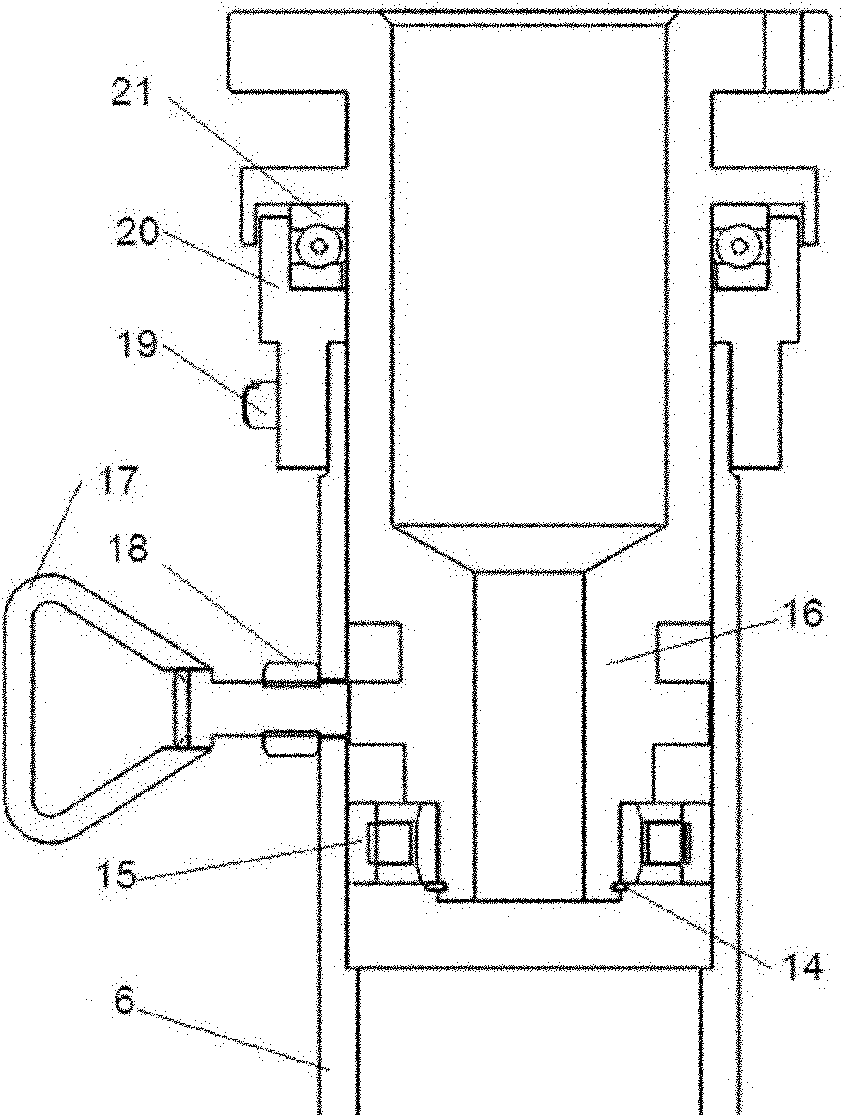

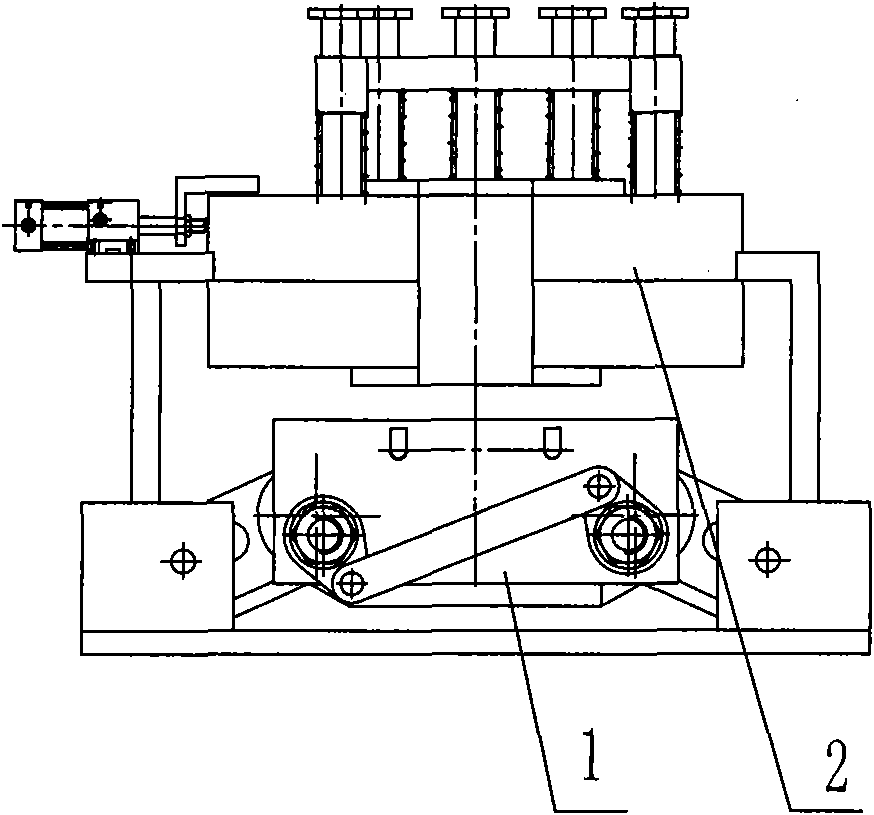

High-torque hydraulic pipe-wrenching machine for wrenching and disassembling outer-flat drilling rod

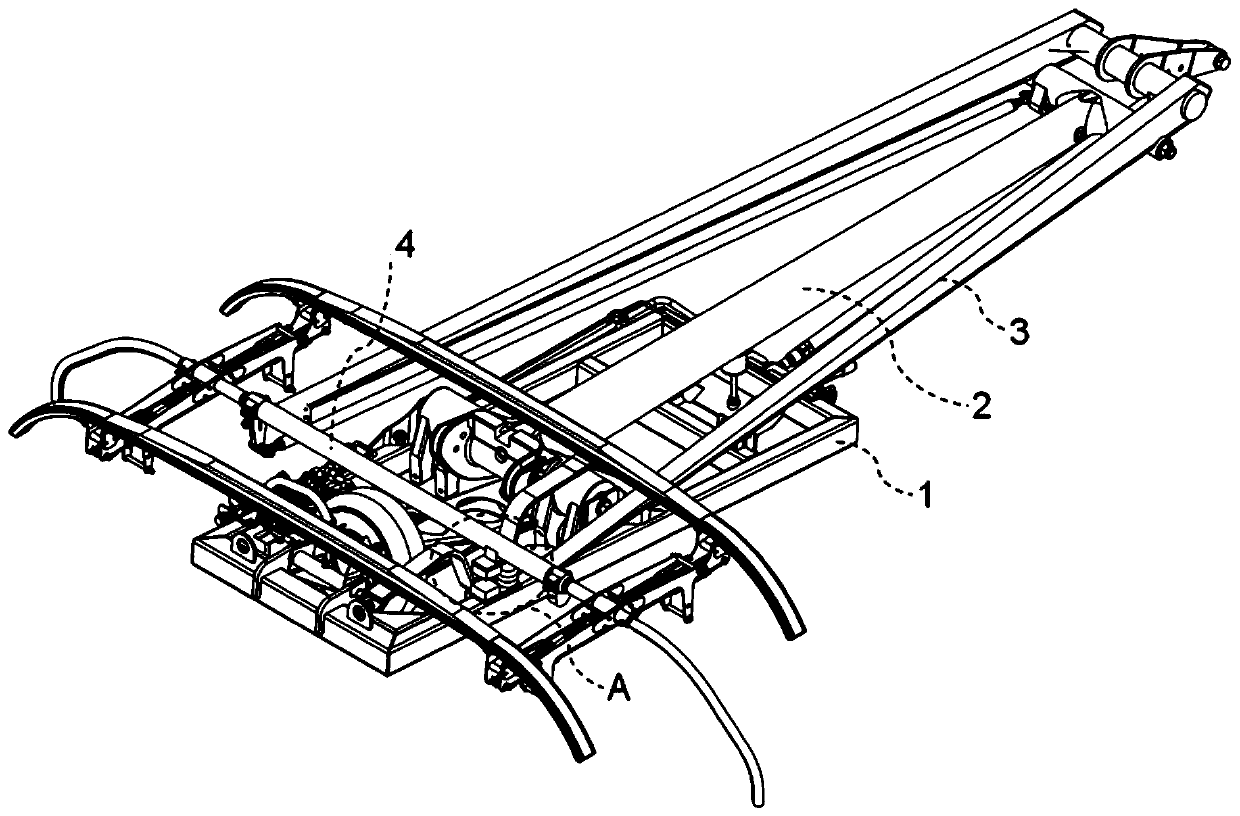

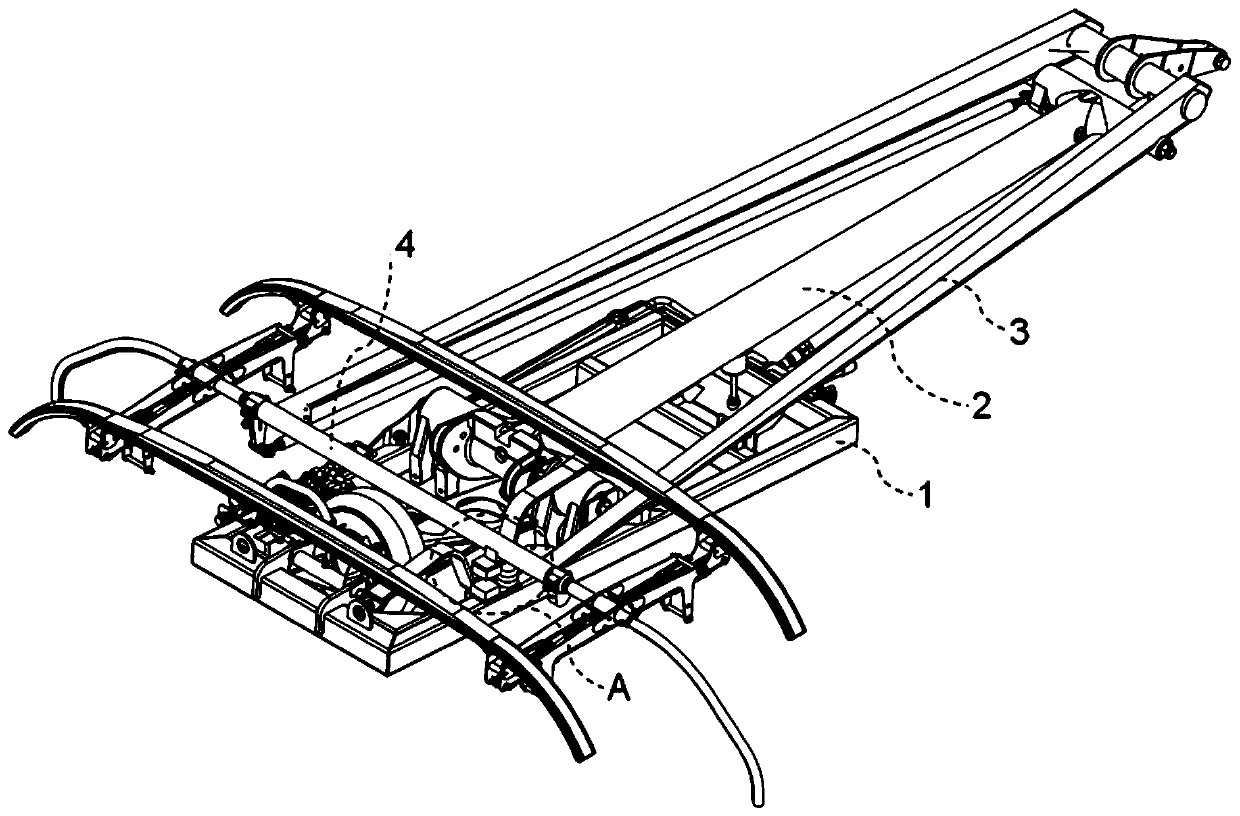

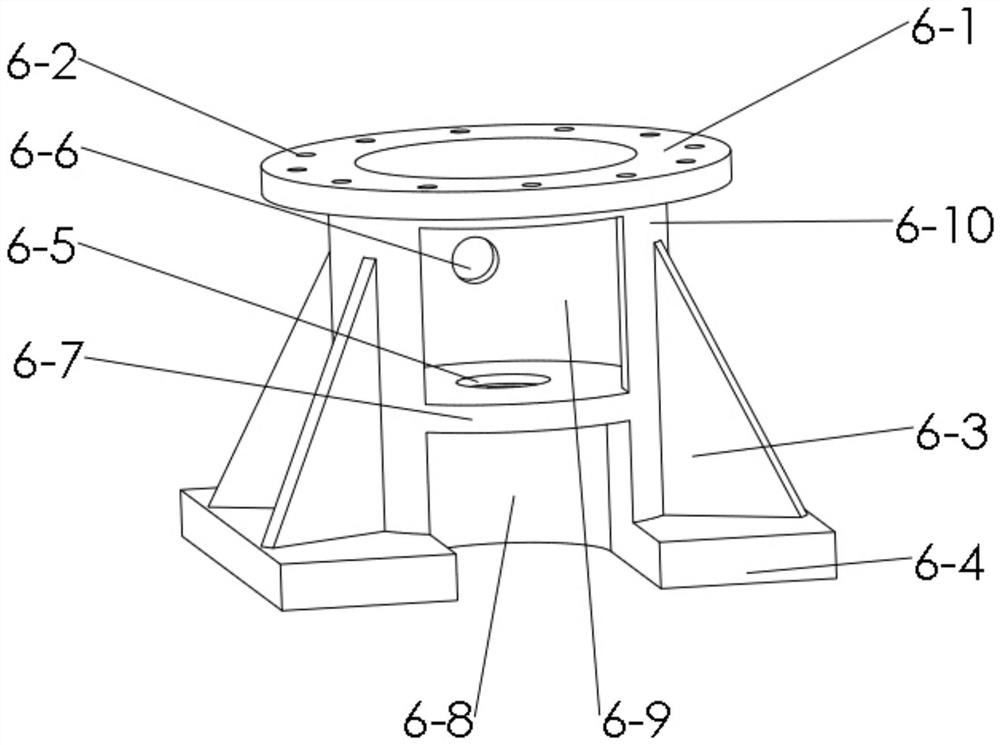

The invention relates to high-torque hydraulic wrenching and disassembling equipment suitable for an outer-flat drilling rod, belonging to the field of drilling and exploring machineries. The high-torque hydraulic pipe-wrenching machine for wrenching and disassembling the outer-flat drilling rod is characterized by comprising lower clamping tongs, a floating device, clasp punching tongs, an orifice leaving oil cylinder, a sliding block at the lower end part of a left floating post and a sliding block at the lower end part of the right floating post of the floating device respectively correspond to the insides of a left chute and a right chute of a lower clamping tongs support of the lower clamping tongs, the body of the orifice leaving oil cylinder is fixed at the rear end part of the lower clamping tongs support, and a piston rod of the orifice leaving oil cylinder is articulated with a floating frame; and the clasp punching tongs are arranged on a floating plate of the floating device, and clasp turning tongs are arranged on a bottom plate of the clasp punching tongs. The invention adopts an integral structure of clamping, clasp turning, clasp punching / pre-tightening and is suitable for the wrenching and the disassembling of the outer-flat drilling rod.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

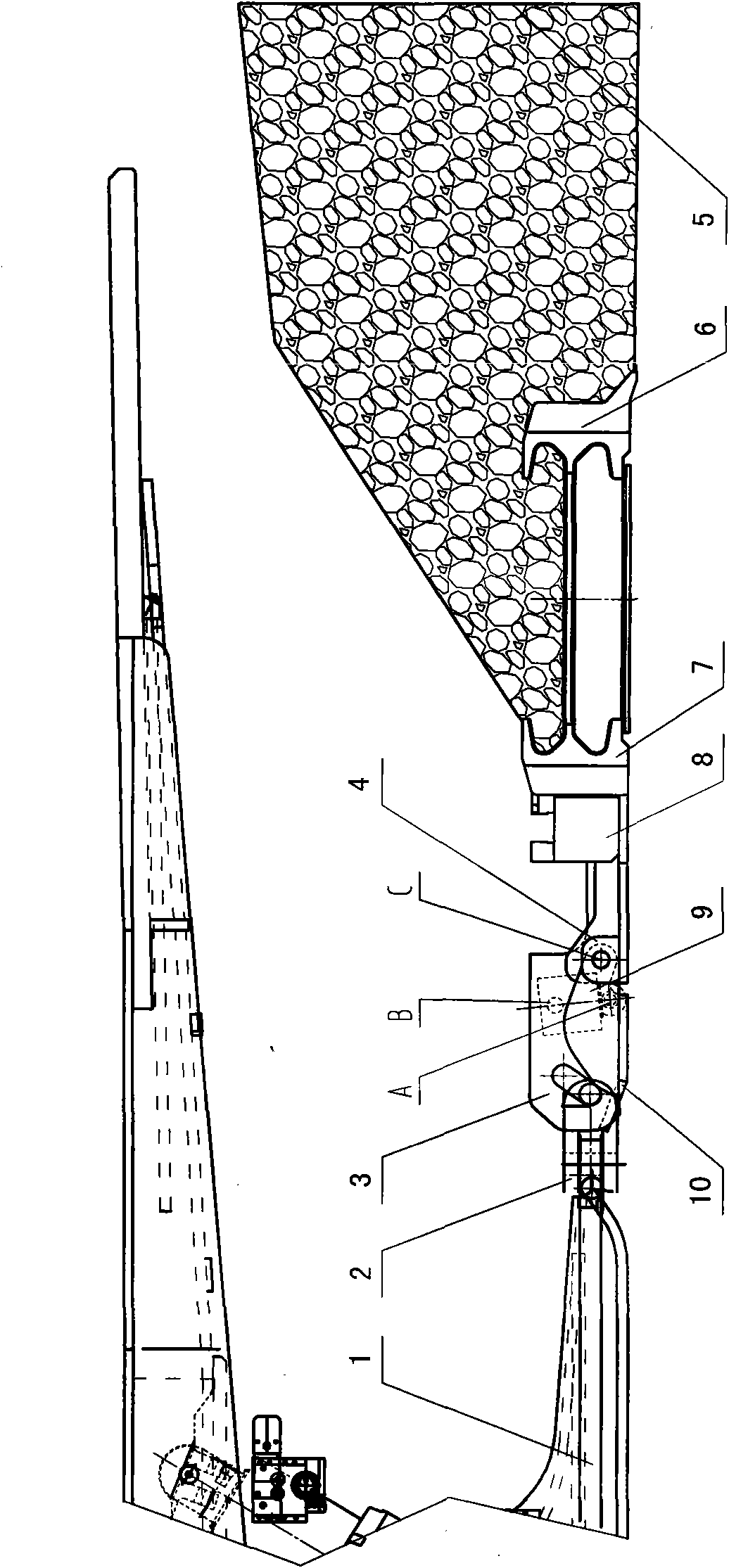

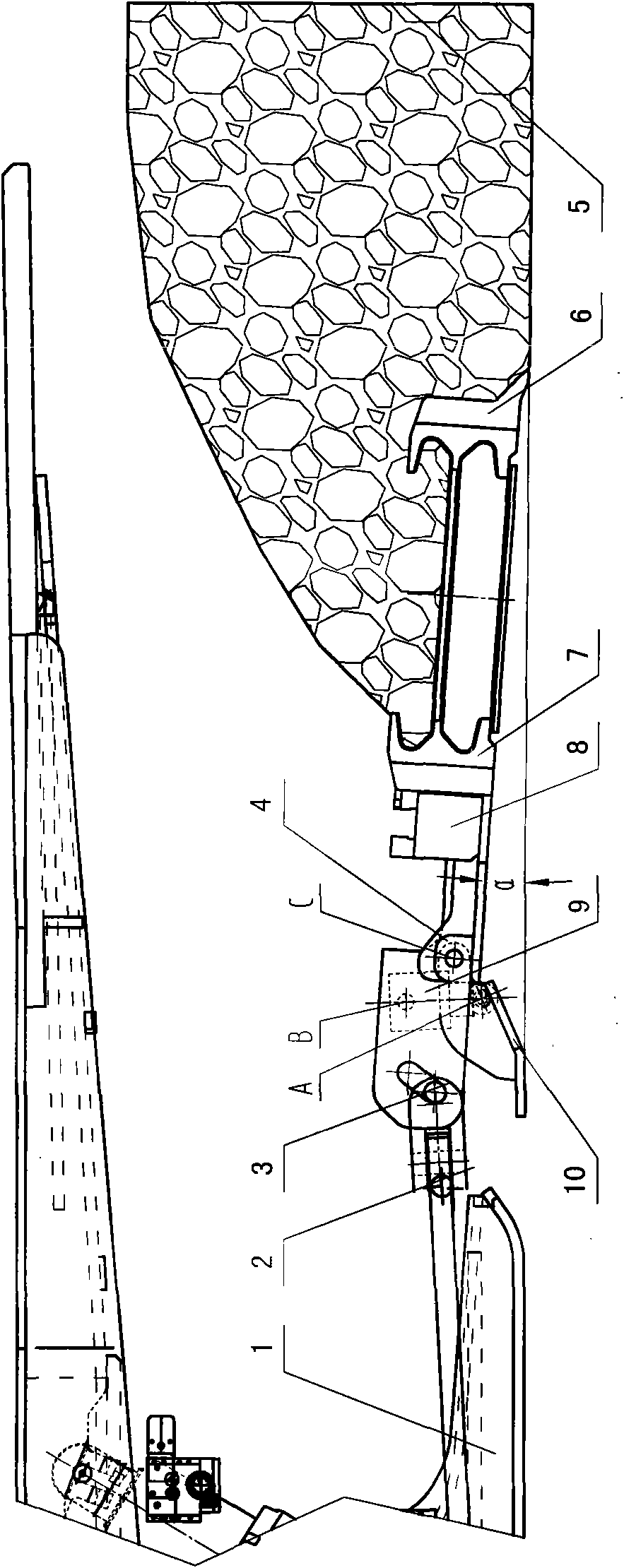

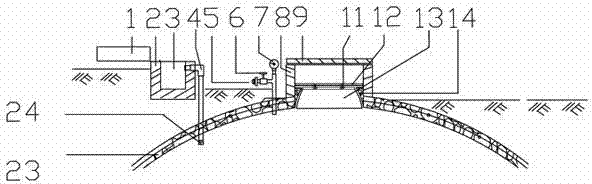

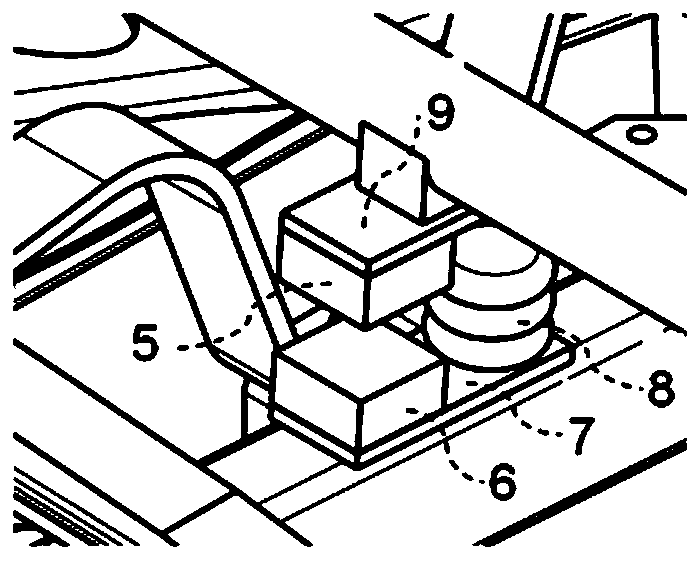

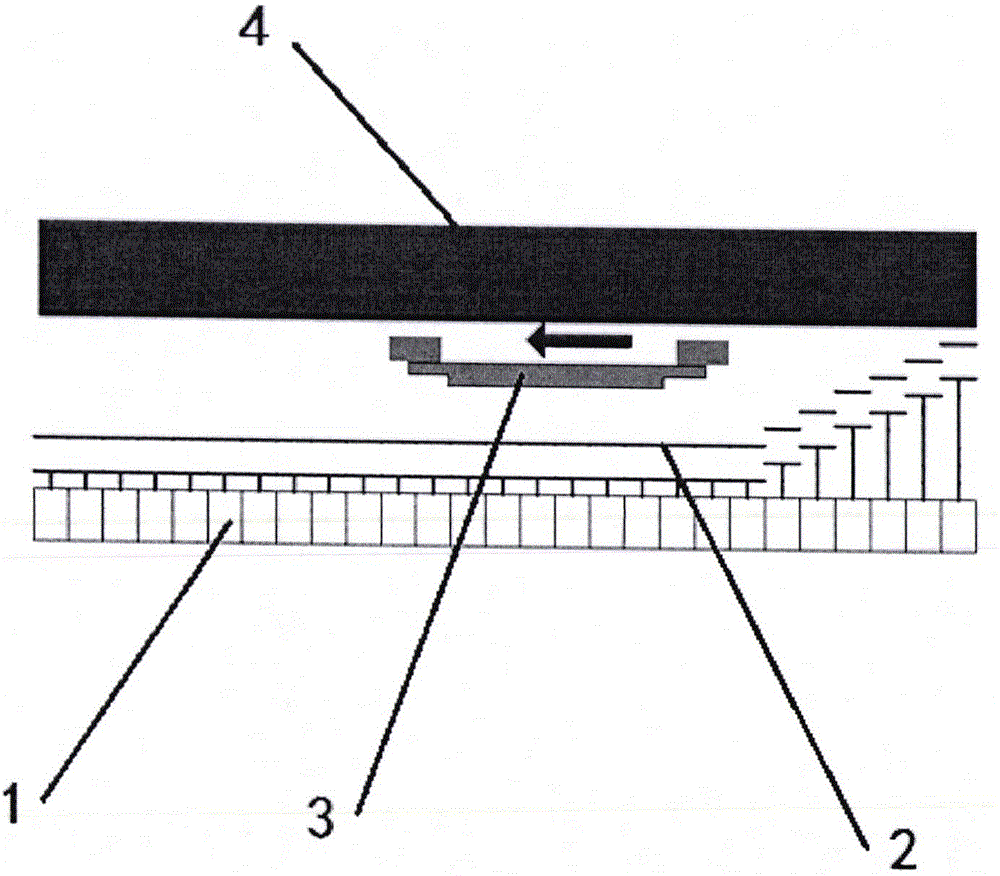

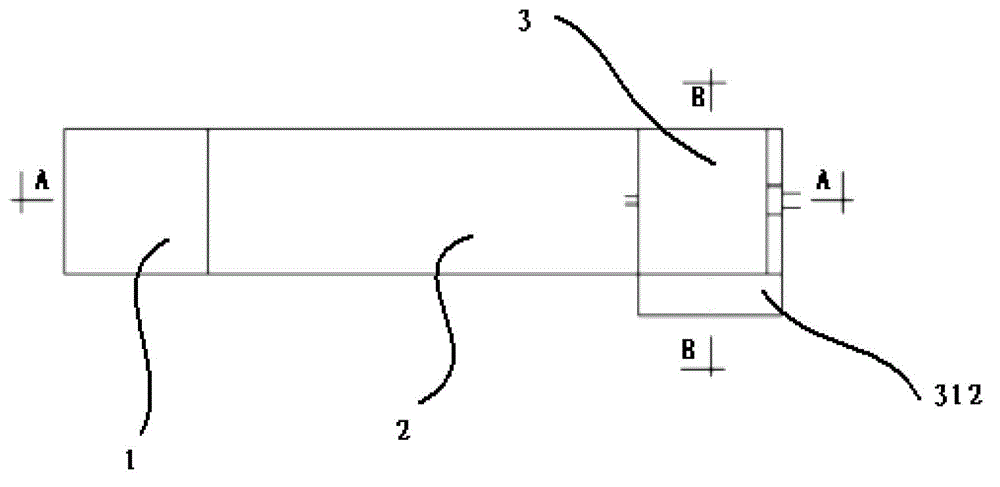

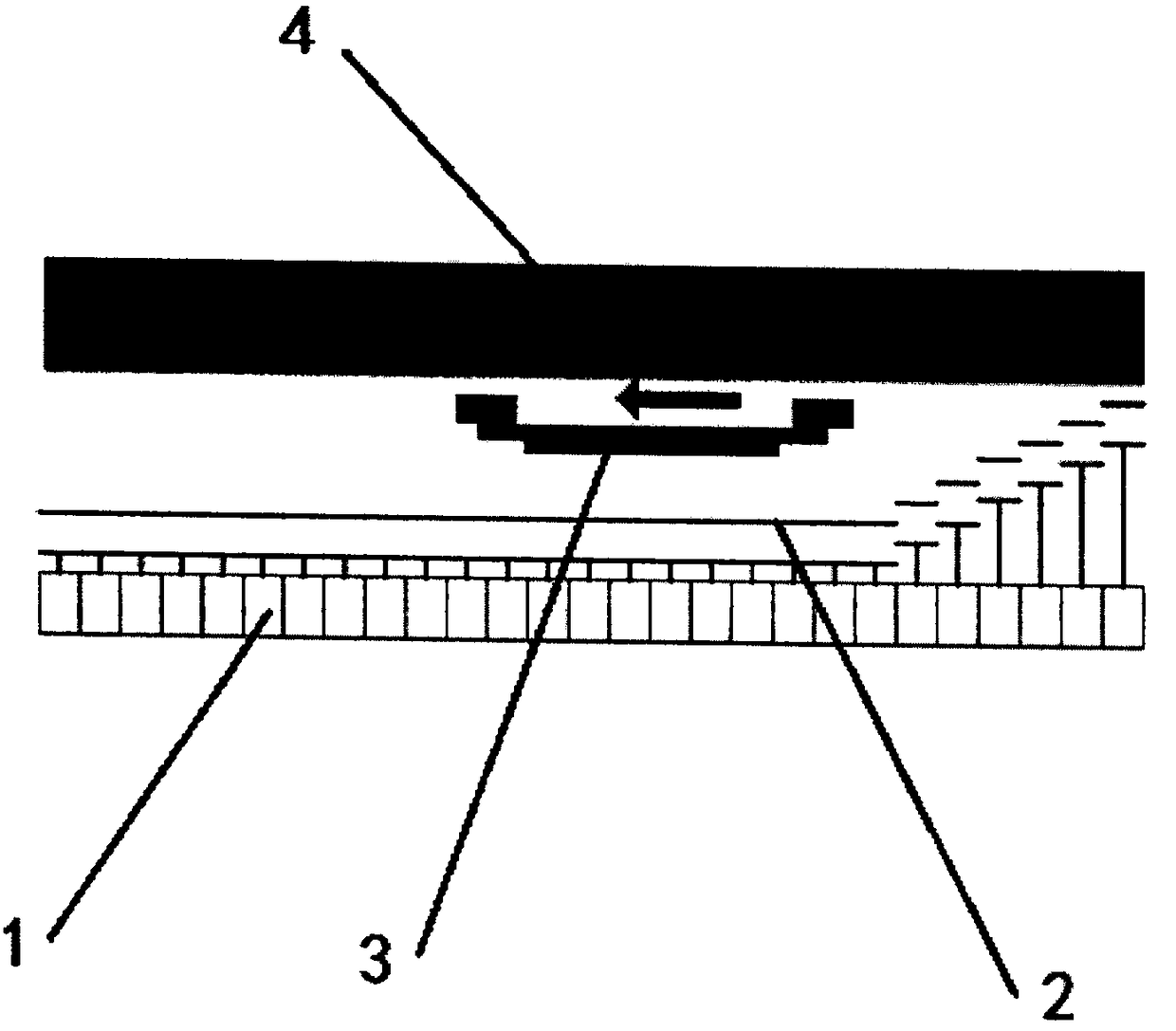

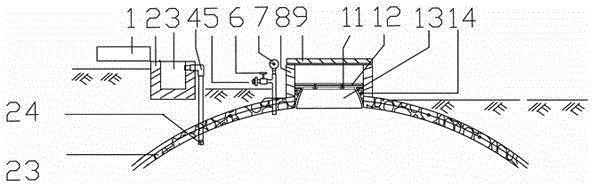

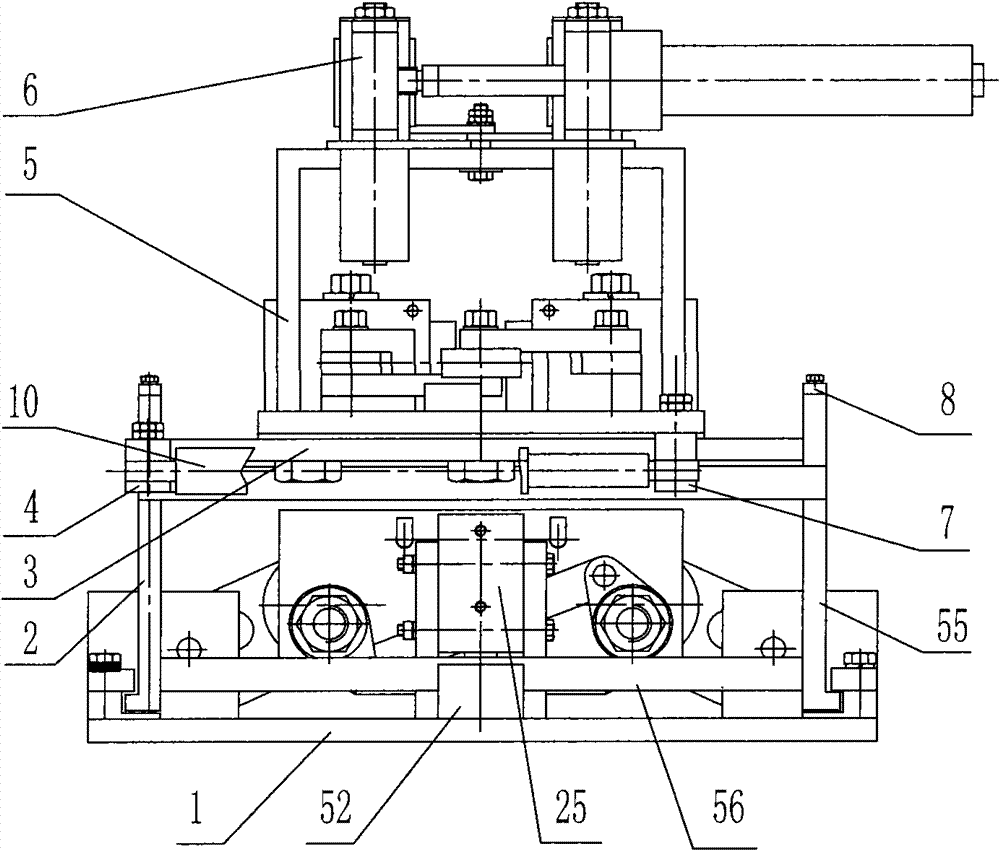

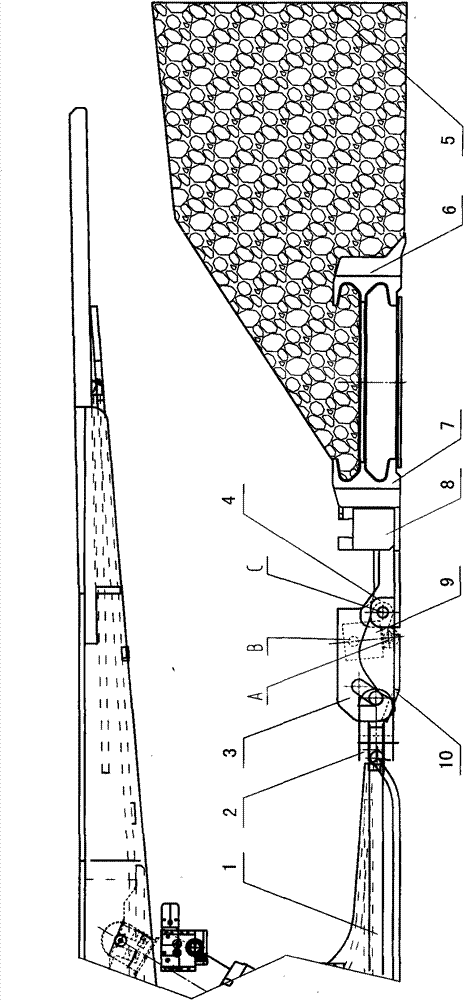

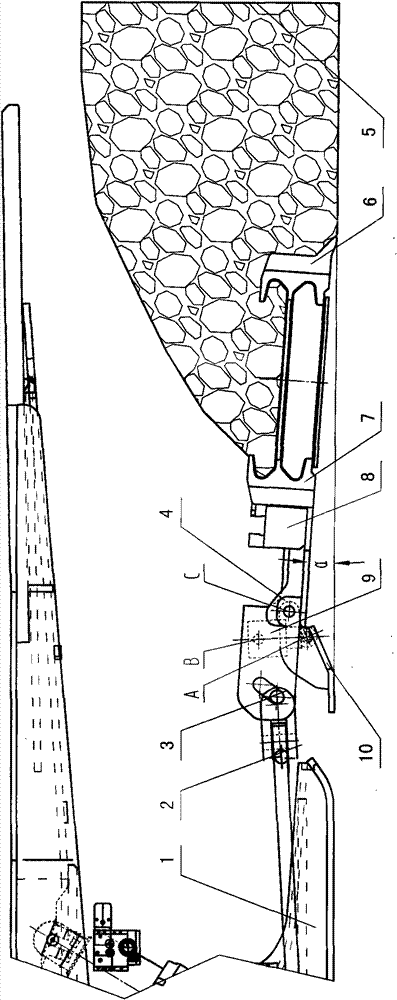

Slope adjusting device for middle trough of fully-mechanized scraper conveyor for thin seam

InactiveCN102120523AImprove bottoming abilitySolve the floating problemConveyorsEarth drilling and miningEngineering

The invention relates to a slope adjusting device for a middle trough of a fully-mechanized scraper conveyer for a thin seam, comprising a middle trough pushing and connecting device 8, a base lifting device, a supporting mechanism, and the like, wherein the middle trough pushing and connecting device 8 is arranged at the side of a middle trough baffle; except for an original middle trough pushing lug plate 3, the middle trough pushing and connecting device 8 is additionally provided with a middle articulating piece and an outside articulating piece; the base lifting device mainly comprises a cylinder 9; the supporting mechanism mainly comprises a supporting beam 10; the cylinder is positioned in the middle of the middle trough pushing lug plate; the body of the cylinder is articulated on the middle articulating piece of the middle trough pushing and connecting device; the head of a piston rod of the cylinder is articulated with the middle articulating piece in the middle of the front part of the supporting beam directly or through a connecting rod; and front ends at two sides of the supporting beam 10 extend forwards and are then articulated to the outside articulating piece of the middle trough pushing and connecting device. The slope adjusting device improves the bottom rolling capacity of pushing the middle trough by controlling the cylinder to stretch to adjust the height of the middle trough baffle side of the scraper conveyer and well solves the problem that the middle trough of the pushing scraper conveyer of a fully-mechanized working face of the thin seam frequently drifts.

Owner:兖矿能源集团股份有限公司

Ultrashort fine and soft fiber poly wool yarn and production method thereof

The invention relates to ultrashort fine and soft fiber poly wool yarn and a production method thereof, and belongs to the field of spinning. According to the ultrashort fine and soft fiber poly wool yarn and the production method thereof, pretreatment of increasing proportion through a intermediate-temperature oxygen bleaching method is conducted to ultrashort fine soft kapok fiber, organic cotton fiber and the like, the problem that the fiber floats during opening and carding is solved, and the performance characteristics of the ultrashort fine soft kapok fiber and the organic cotton fiber is not influenced. Cotton carding process is conducted through a small-proportion mixing technique in which Australian wool top, organic cotton and kapok fiber are mixed in rolling layers, and a uniform blending bar is obtained. After a second drawing and roving process, the yarn is spun through a poly wool spinning technique on a spinning machine, the ultrashort fine and soft fiber poly wool yarn of the organic cotton fiber or the kapok fiber or noil fiber is manufactured after a meridian tube process, wherein the Ntex of the ultrashort fine and soft fiber poly wool yarn is 9.7-28 tex. By means of the ultrashort fine and soft fiber poly wool yarn spinning technique adopted in a cotton spinning system, partial technical problem that kapok, cashmere and combing noil are spun into yarn difficultly in cotton spinning equipment is solved, and medium high yarn which is good in yarn levelness, high in strength, compact in structure, bright and clean and good in wear-resisting property and has little hairiness is obtained.

Owner:YANCHENG INST OF IND TECH

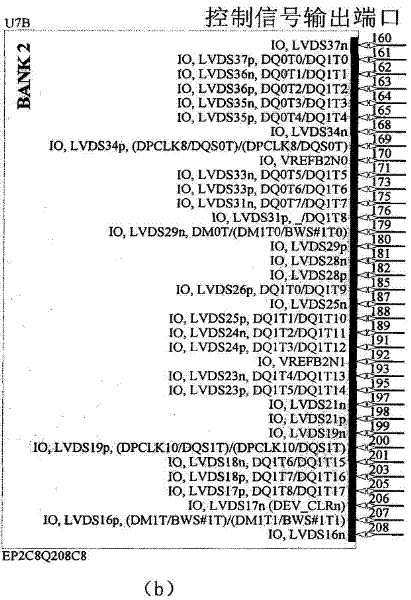

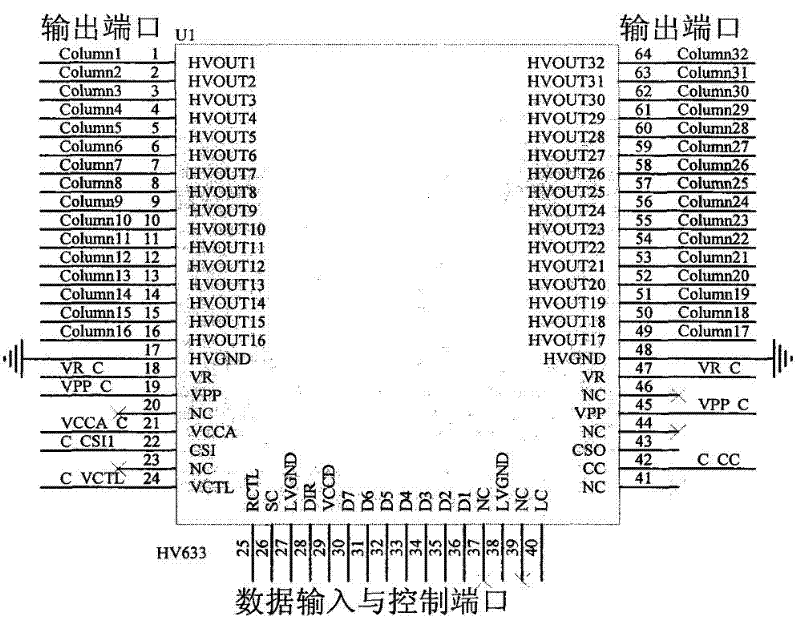

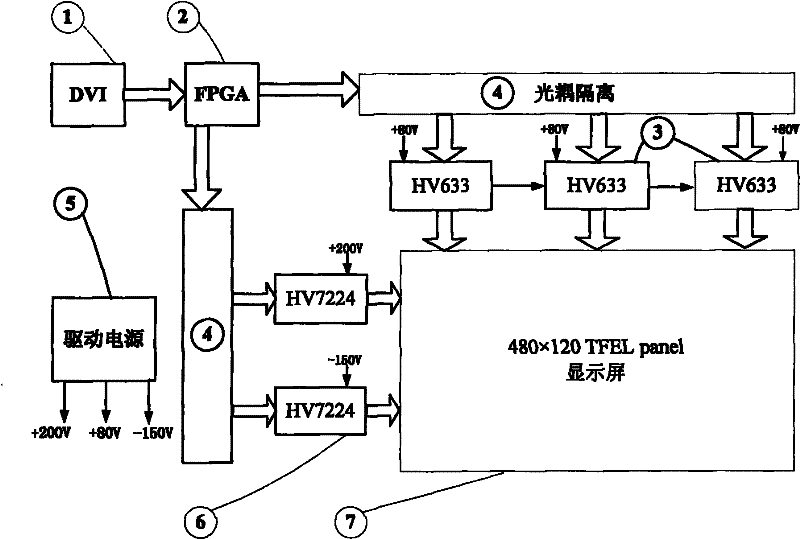

Film electroluminescence display driver

InactiveCN101751851ASatisfies the conditions of alternating high-voltage lightingSatisfy the condition of alternating high voltage lightingStatic indicating devicesDigital videoElectricity

The invention relates to a film electroluminescence display driver which comprises a DVI transmission circuit and an FPGA controller. Video signals are connected to the FPGA controller through the DVI transmission circuit, two ways of output of the FPGA controller are respectively connected to a film electroluminescence display through a line drive chip and a column drive chip after passing through an optical coupling circuit separation module, and a drive power module supplies a work power supply to each component device. The invention receives digital video signals which are received, calculated and sent by the DVI, the digital video signals are in image processing by the FPGA, and the FPGA generates a control time sequence to control the line drive chip and the column drive chip so as to enable the line drive chip and the column drive chip to output different drive voltages at different pixel point positions, thereby enabling different pixel points to emit lights with different intensities, therefore, images are displayed on a TFEL screen. A drive circuit drives the TFEL screen with a 120*480 lattice so as to realize 128 level gray scale display with the scanning frequency achieving 100Hz.

Owner:SHANGHAI UNIV

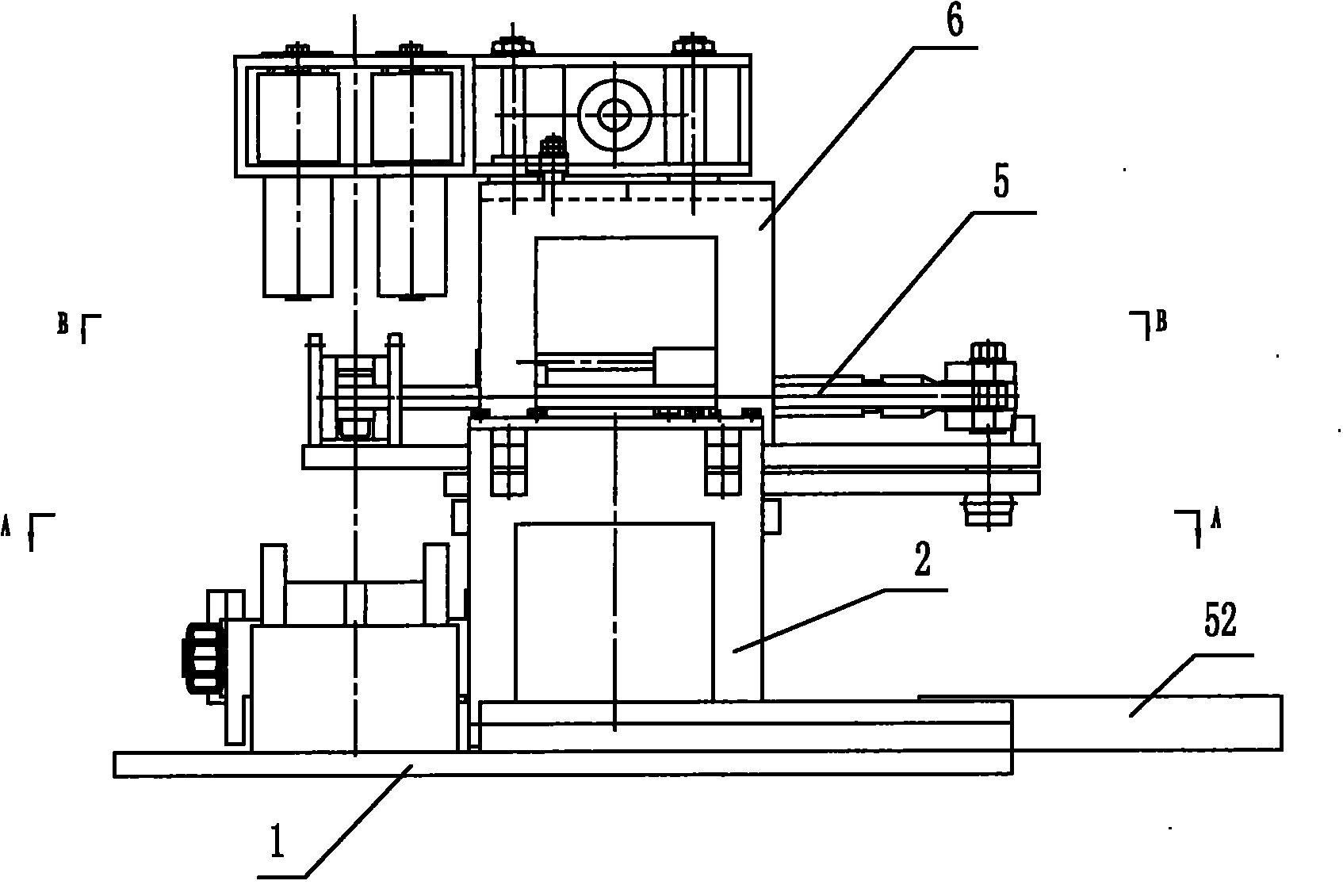

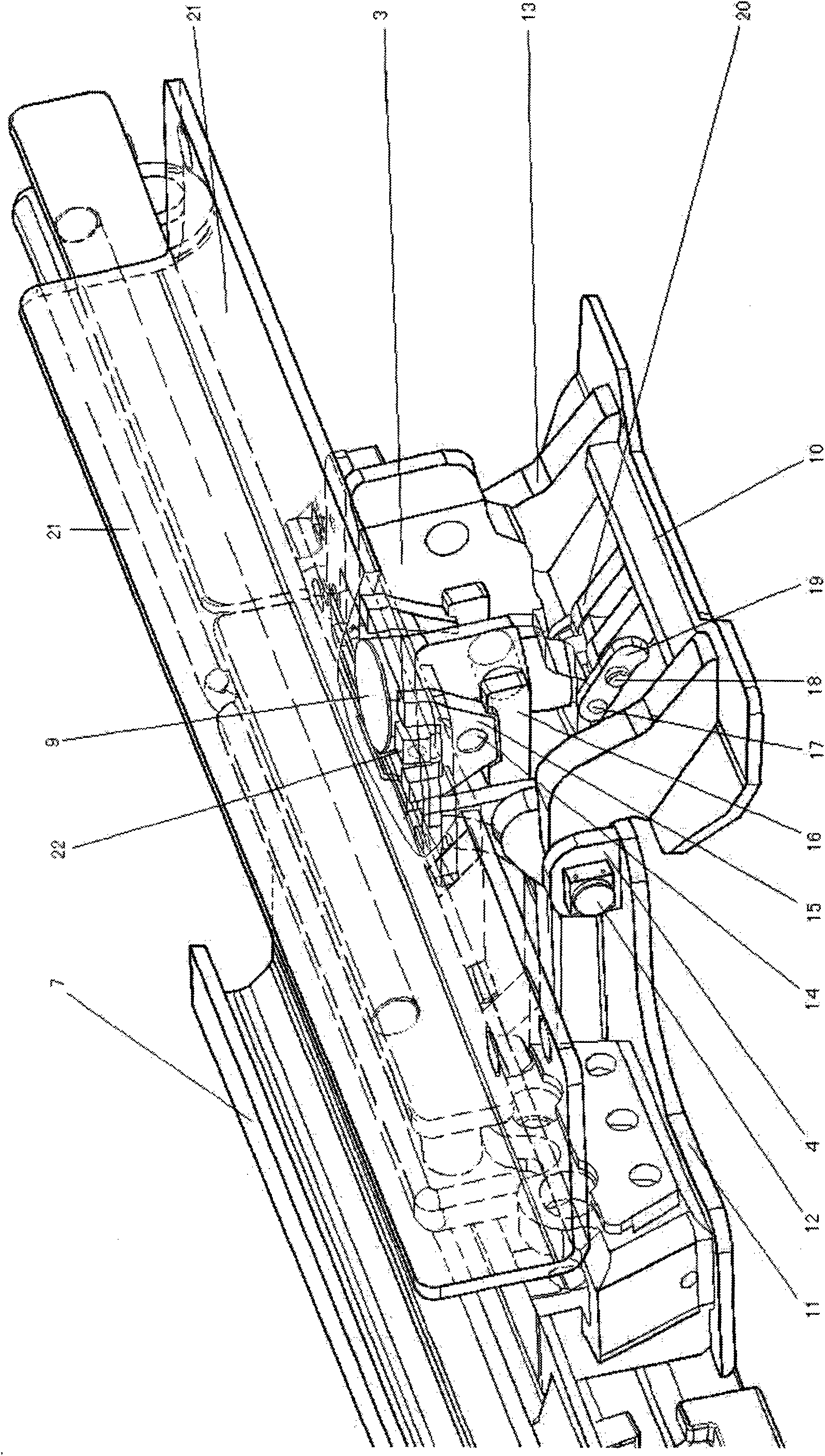

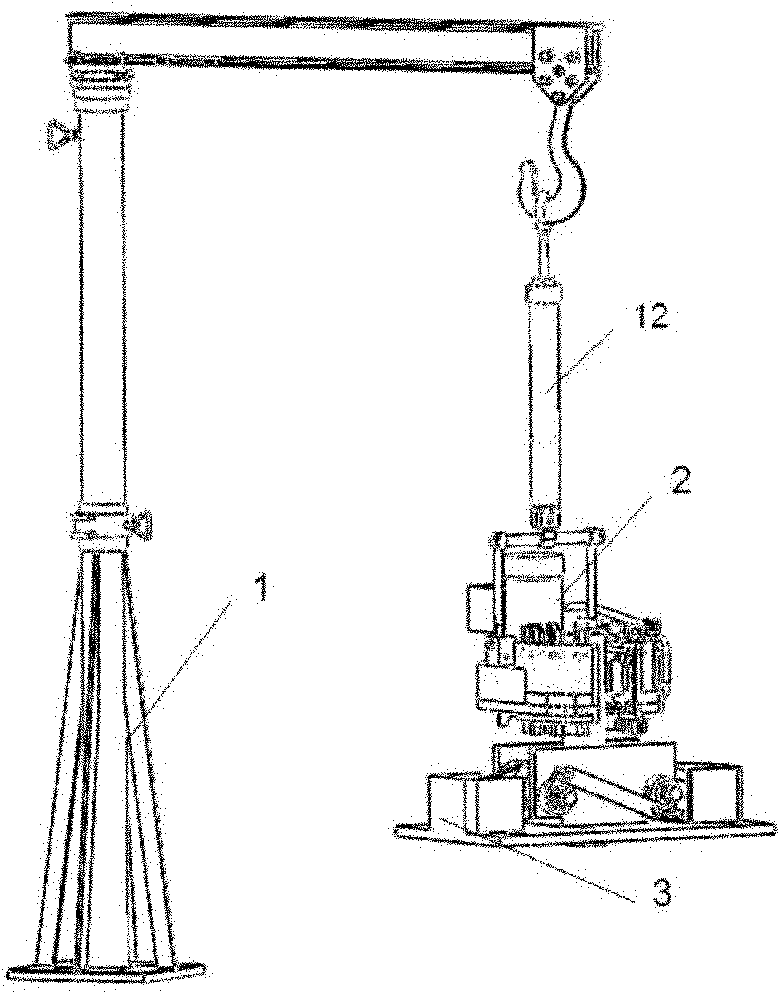

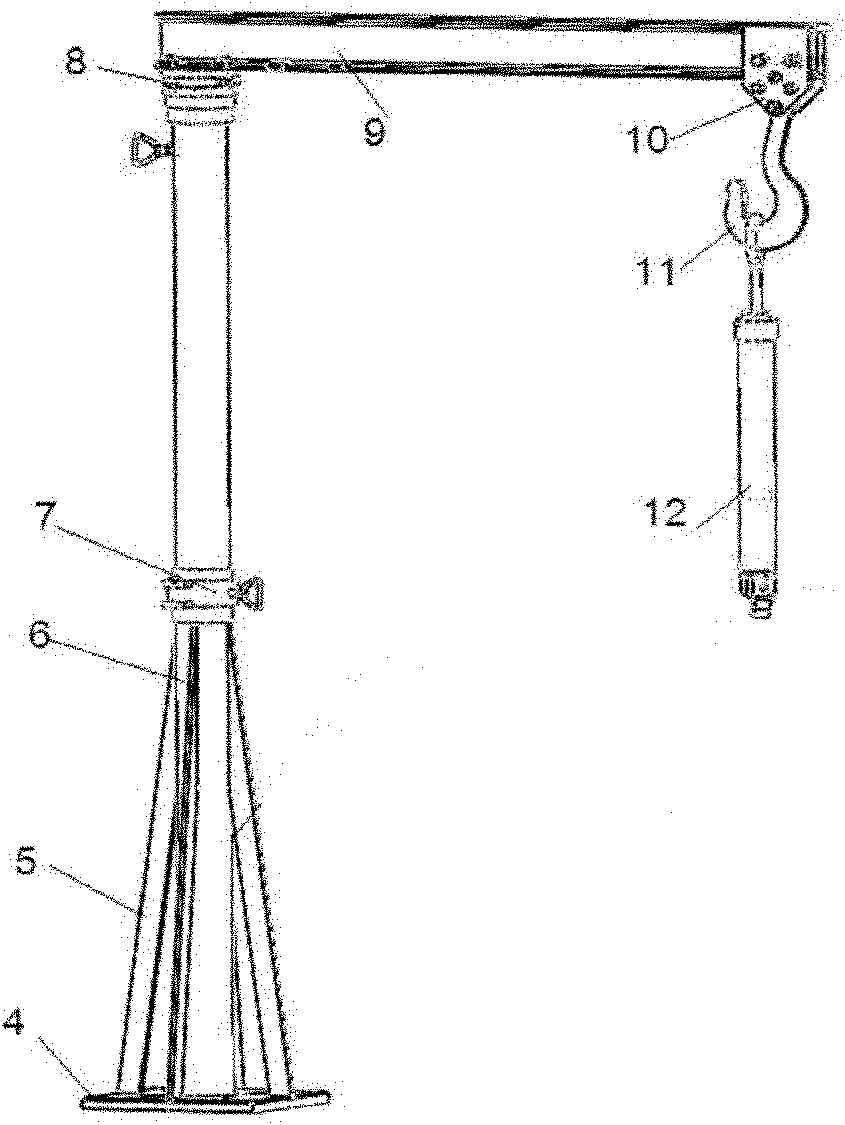

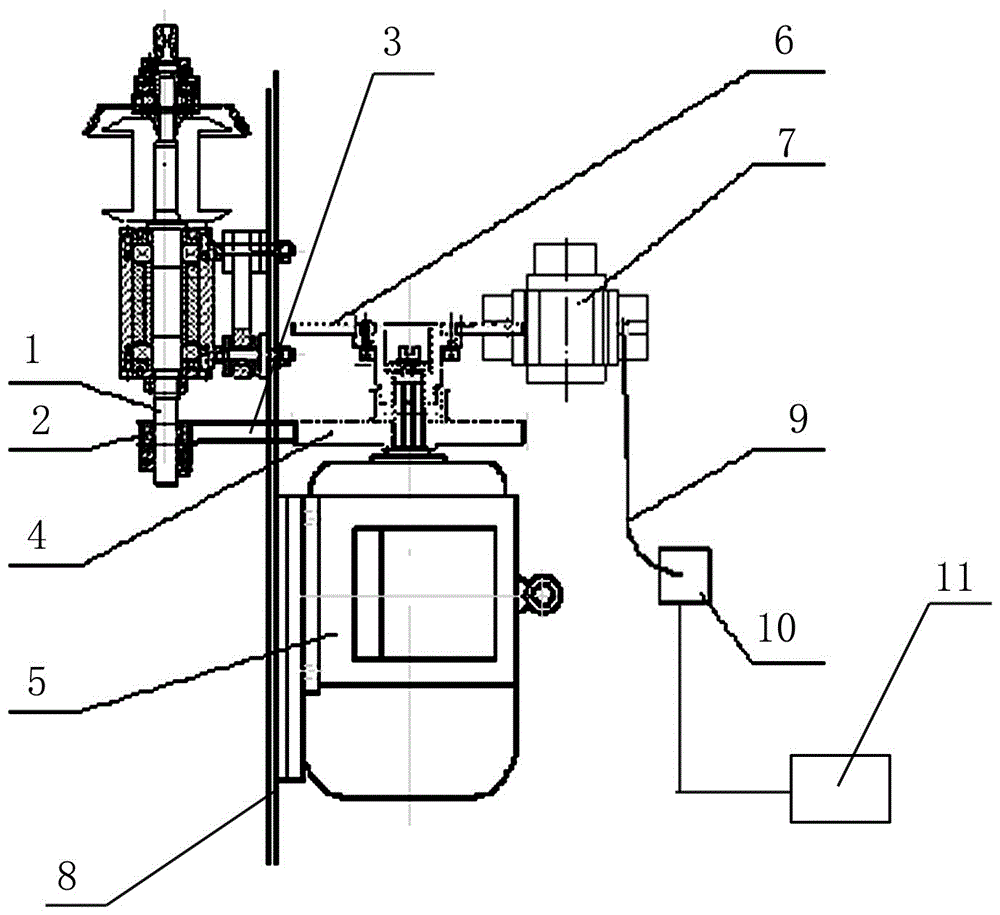

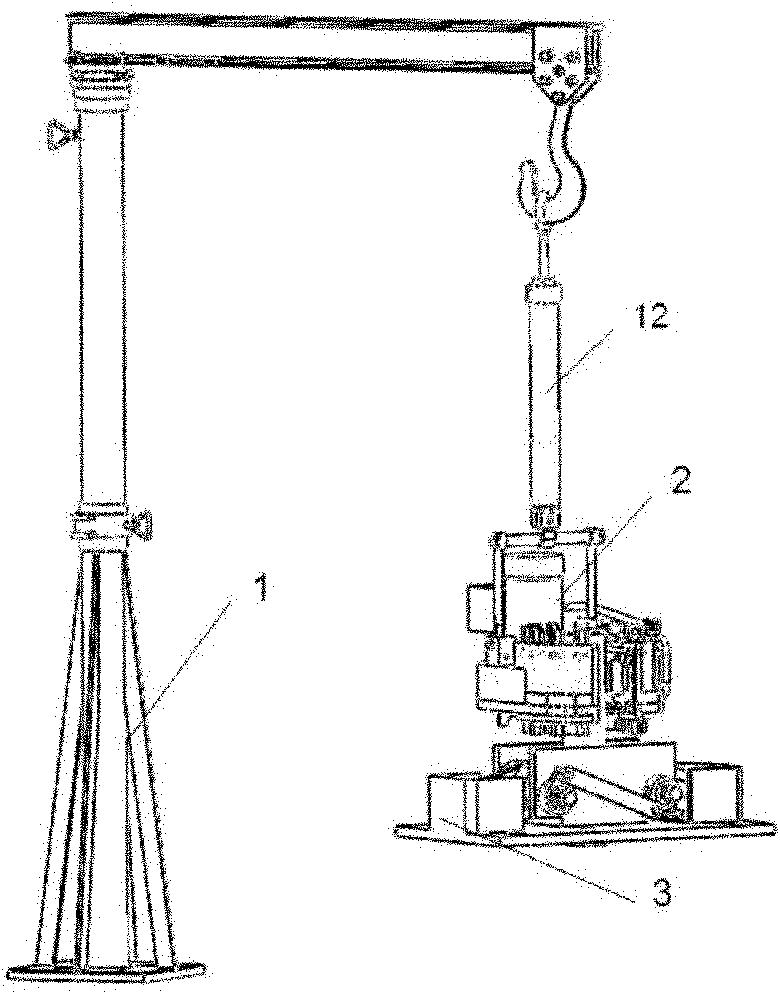

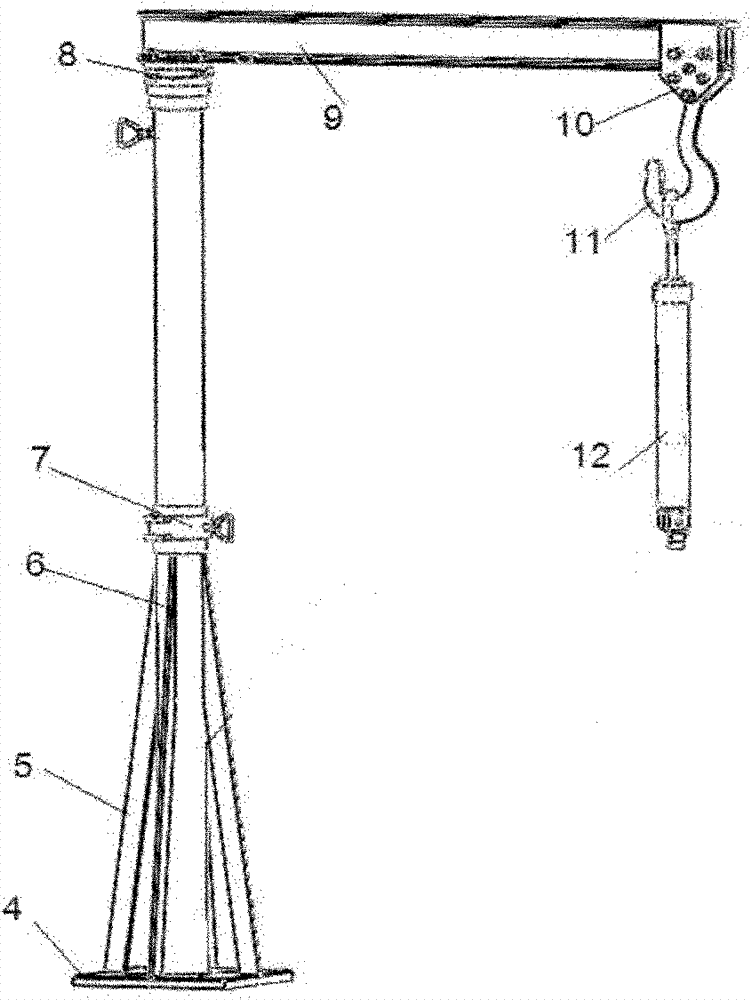

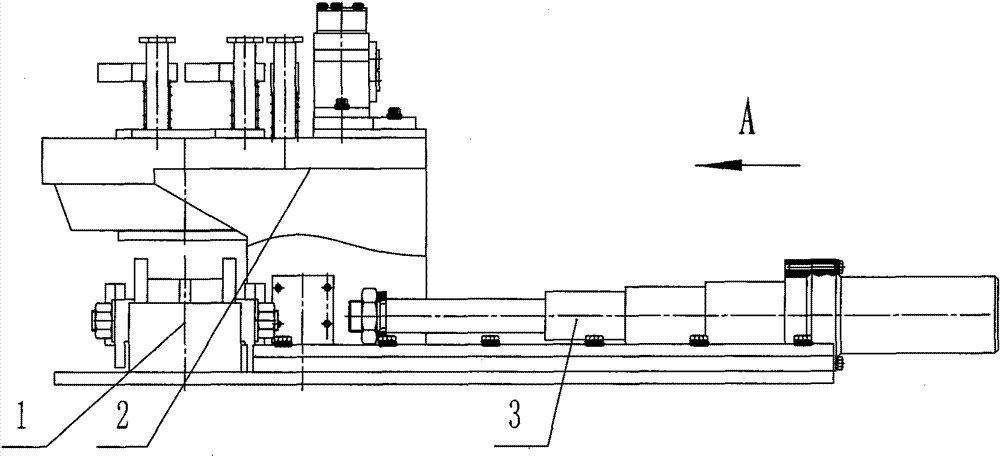

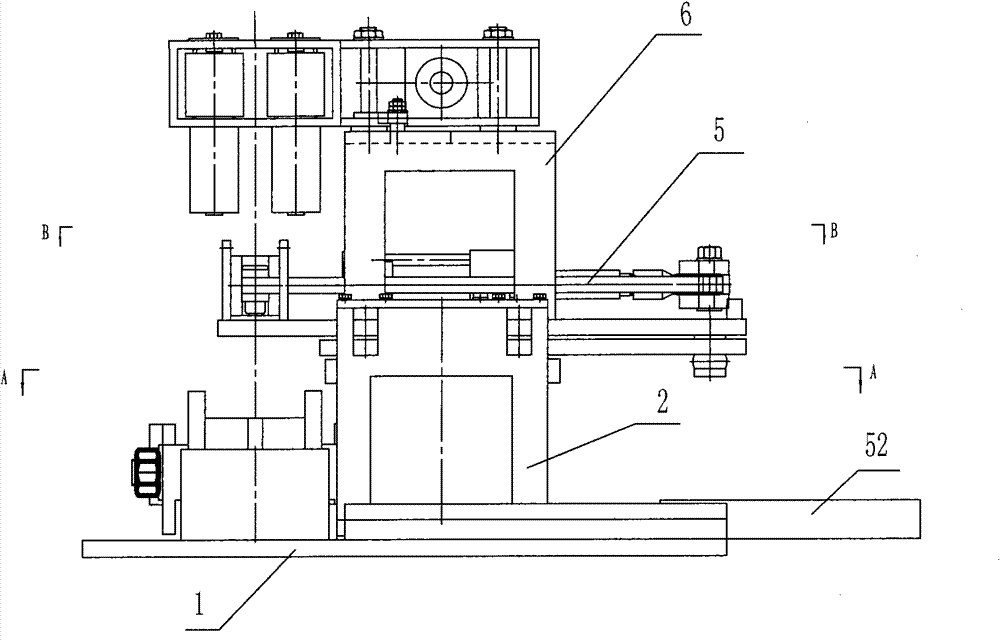

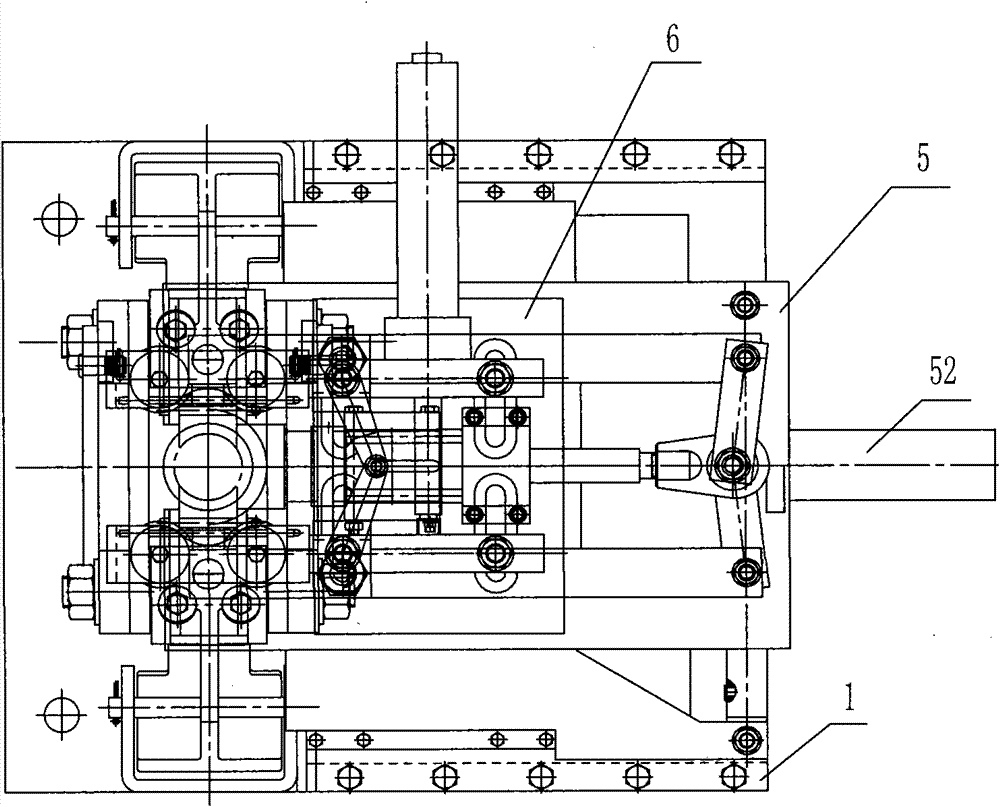

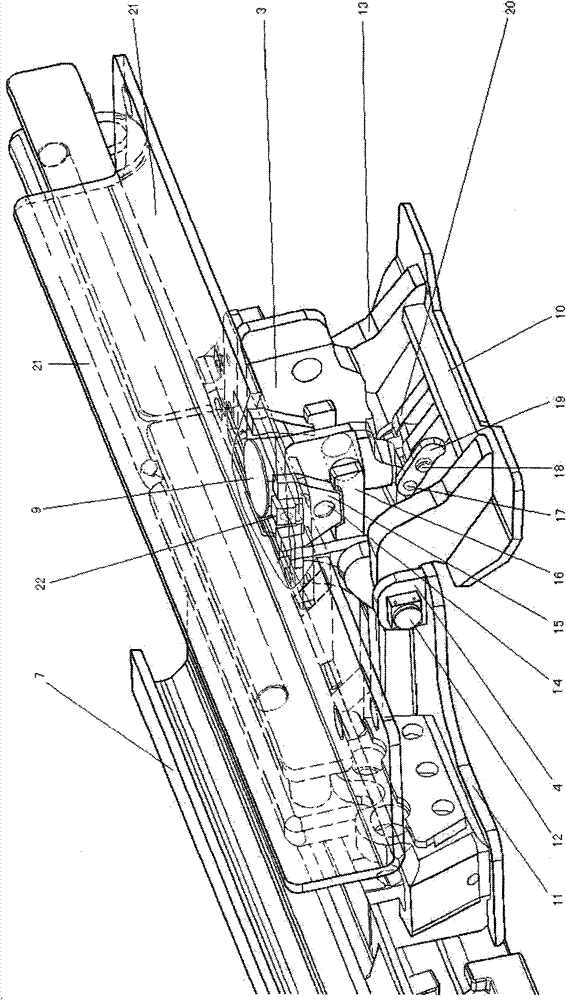

Hydraulic pipe screwing machine for screwing and unscrewing outer flat drill pipe and being capable of keeping off orifice

InactiveCN102031939ASmall solution spaceEasy to operateDrilling rodsDrilling casingsWell drillingOperational safety

The invention discloses a hydraulic pipe screwing machine for screwing and unscrewing an outer flat drill pipe and being capable of keeping off an orifice, which relates to the field of engineering drilling. The hydraulic pipe screwing machine mainly comprises an upper pincer body, a lower pincer body and hanging pincers, wherein the lower pincer body is fixed to the orifice and used for clampinga drill pipe in a hole and preventing the generation of a rod falling event; the upper pincer body is a main part of the pipe screwing machine, is used for realizing the large-torque screwing, unscrewing and buckling of the upper drill rod and has the effects of clamping the drill rod and screwing and unscrewing the drill rod; and the hanging pincers are mainly used for keeping the pipe screwing machine off the orifice, thereby reducing the area of a drilling well platform and the drilling cost. The pipe screwing machine of the invention is suitable for screwing and unscrewing various drill rods, can realize the working processes of screwed buckling, pretensioning, large-torque punched buckling, and the like of the drill rod and has the advantages of small size, light weight, large torque, safety and convenience for work and operation, and the like.

Owner:WUHAN GOLD PROSPECTING MACHINERY LIMITED +1

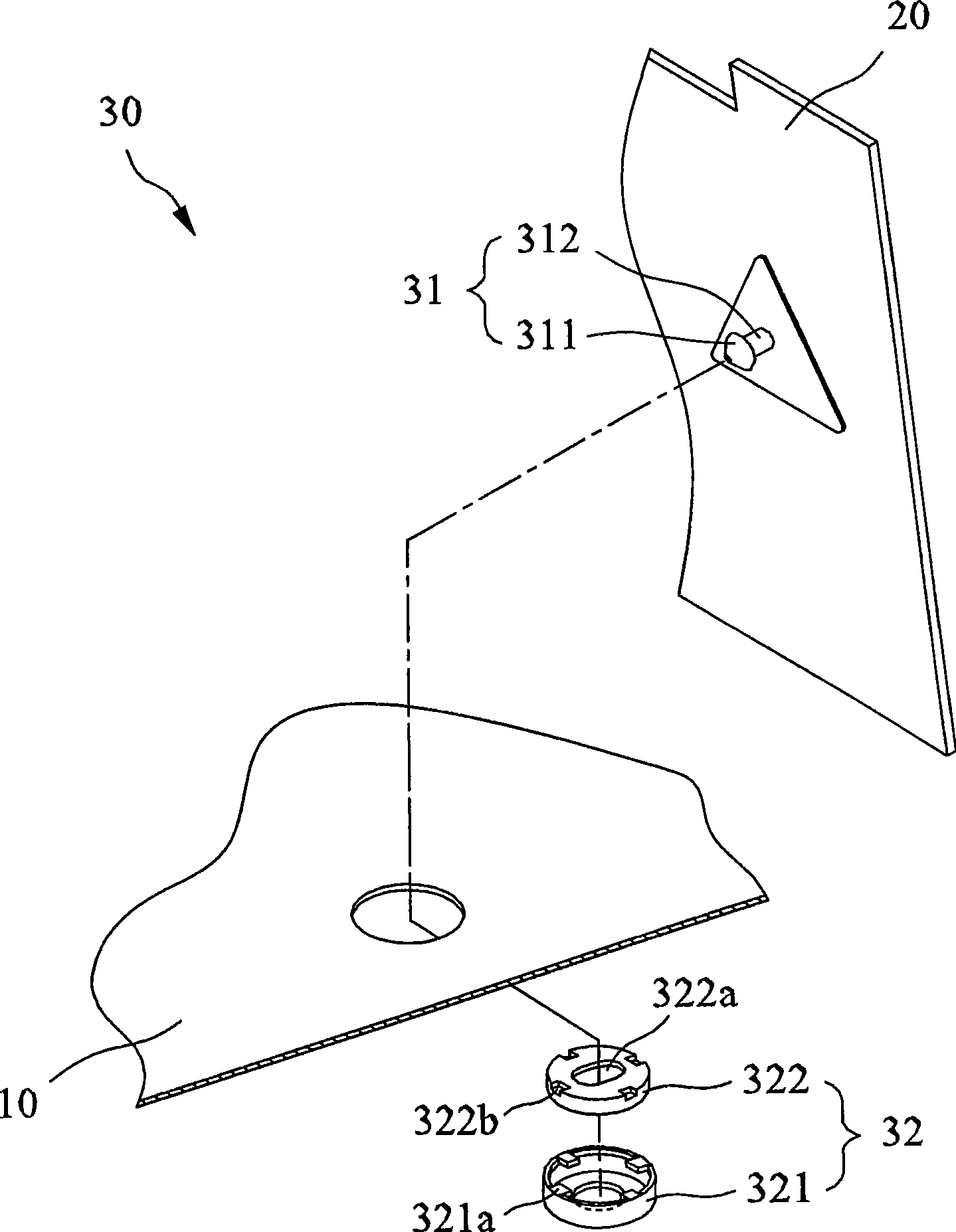

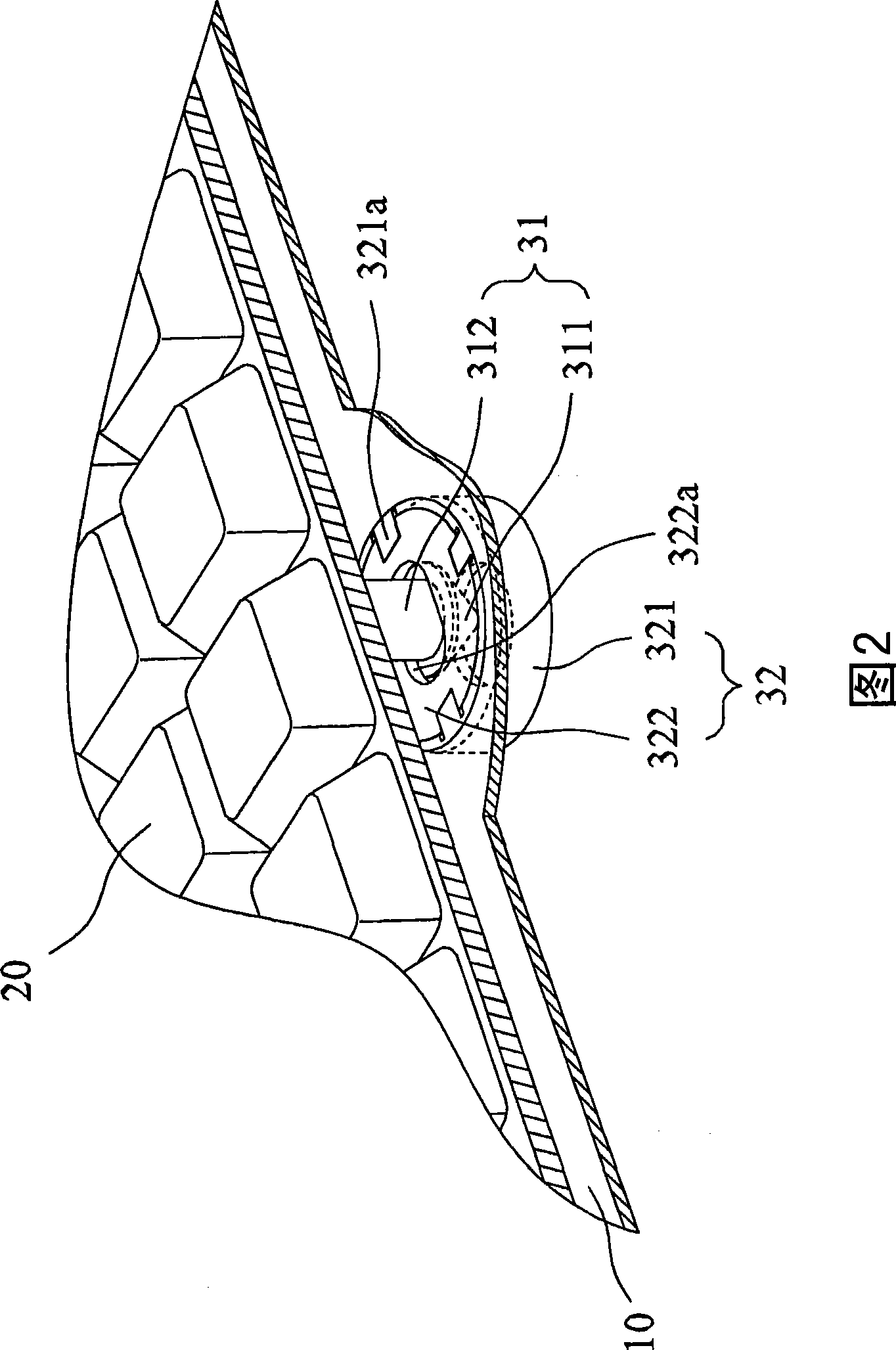

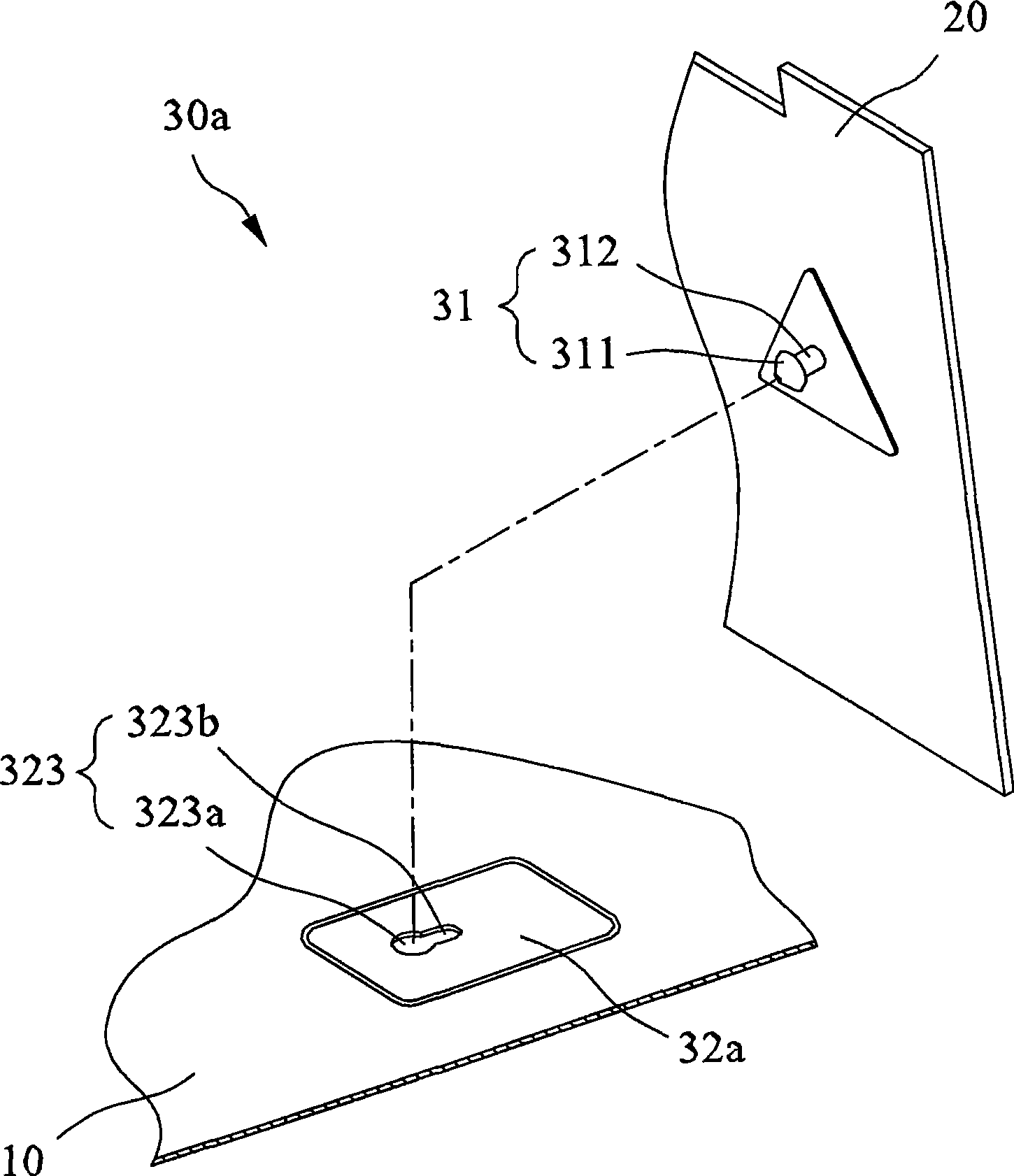

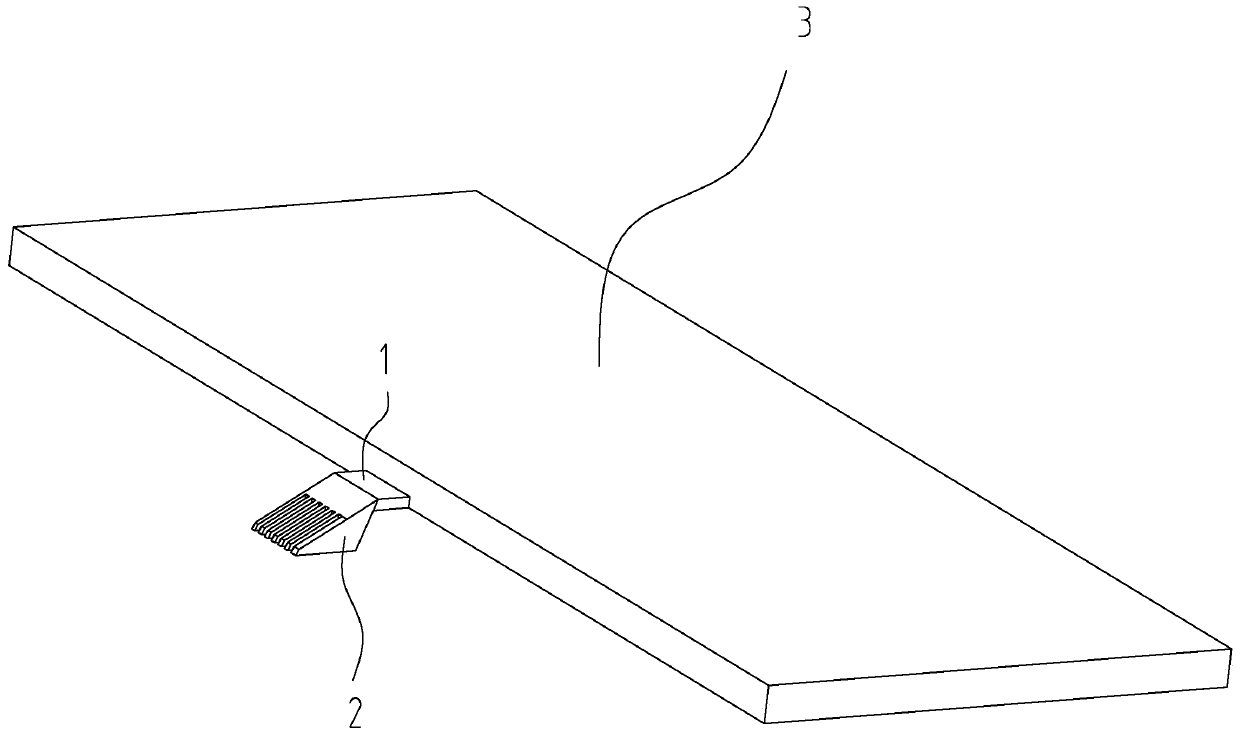

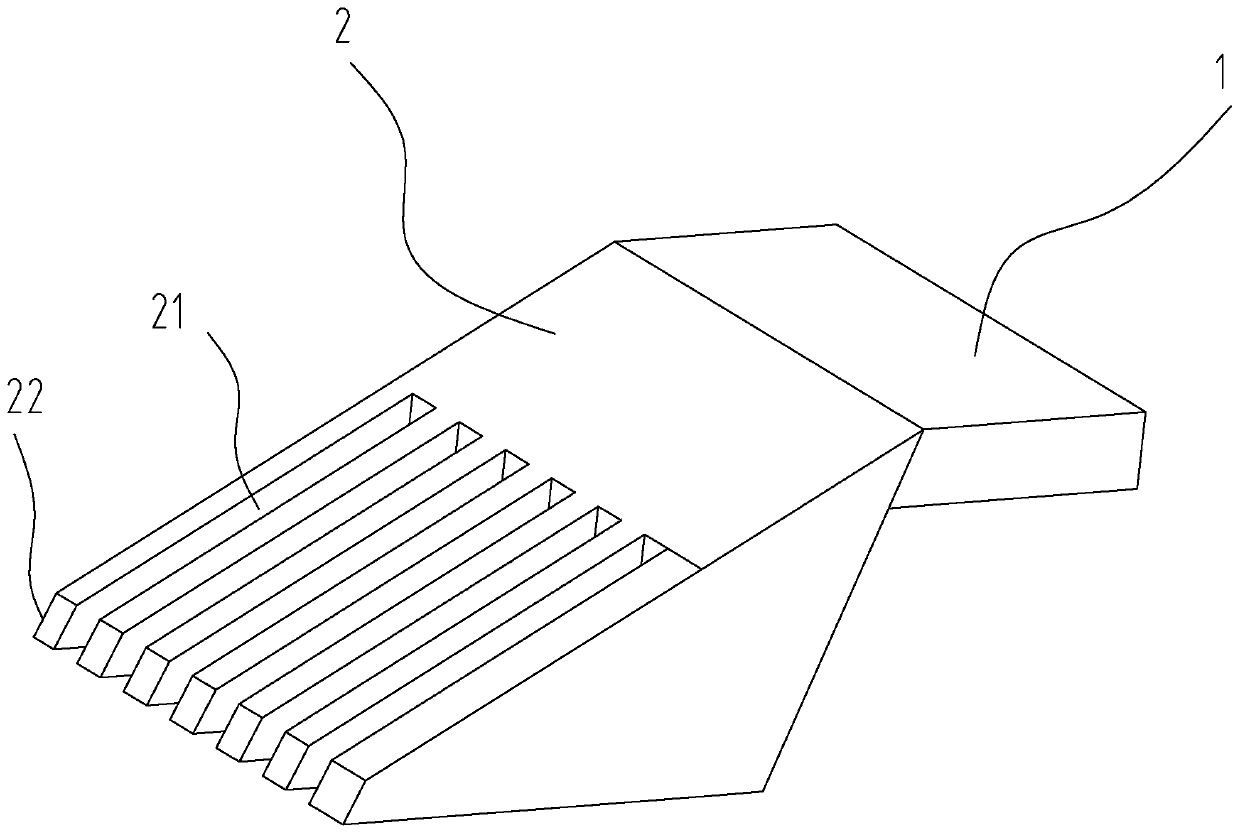

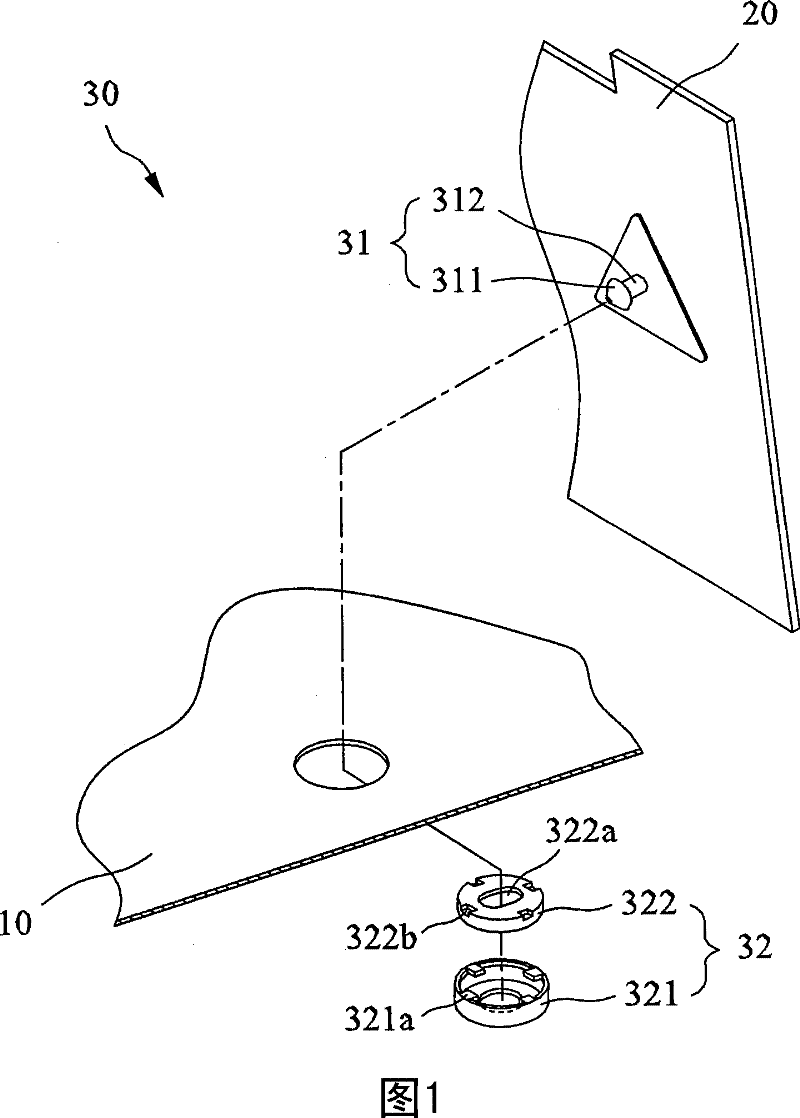

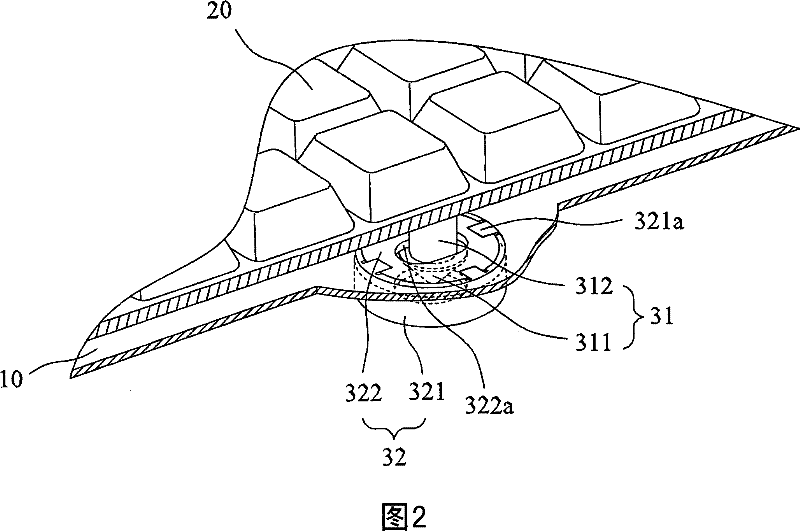

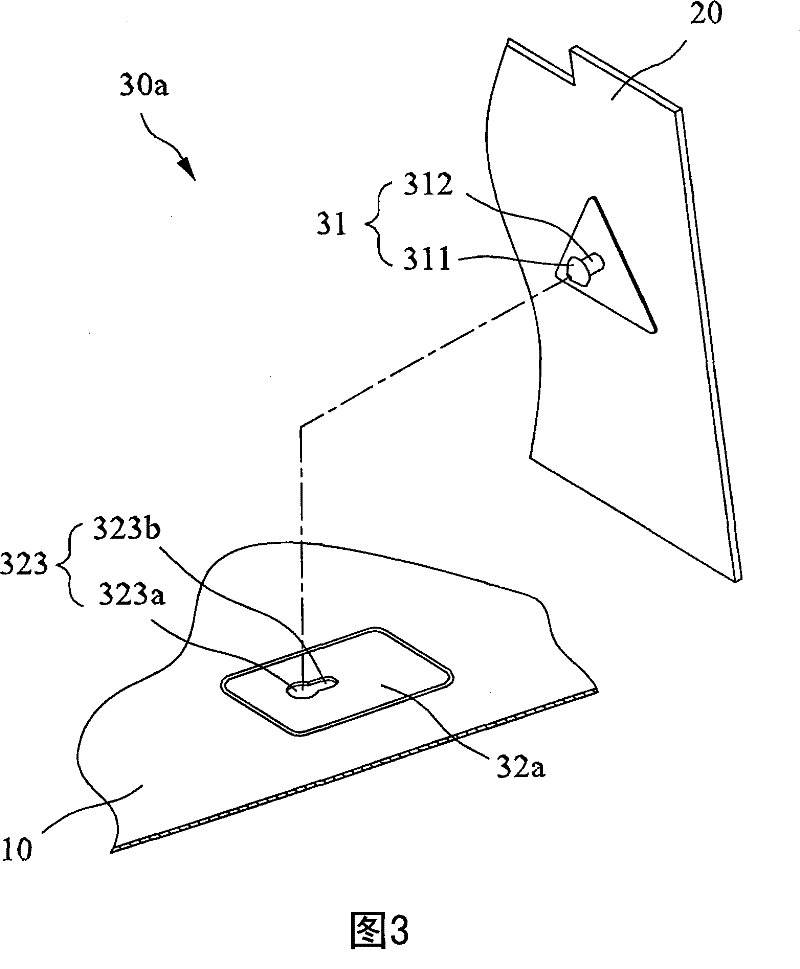

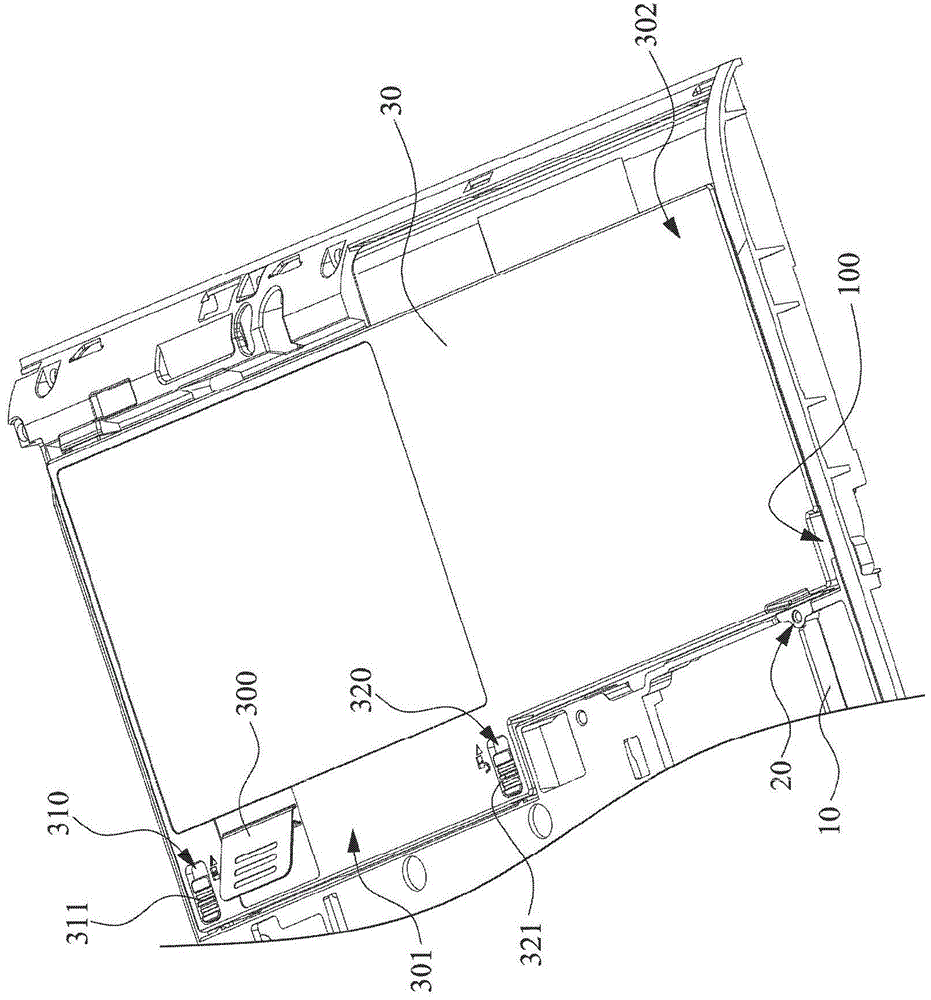

Portable computer and its keyboard fixing structure

ActiveCN101430586ASolve the floating problemSave assembly timeSnap-action fastenersDigital data processing detailsEngineeringPortable computer

The invention relates to a keyboard fixing structure for a portable computer, comprising a positioning part and a positioning structure. The positioning part is arranged on one side of a keyboard module and comprises a cone part and a cylinder part. The cone part is connected with the cylinder part. The maximum external diameter of the cone part is larger than the diameter of the cylinder part. The positioning structure is arranged on a casing of the portable computer. The arrangement position of the positioning structure is corresponding to the positioning part and the positioning structure is used for blocking and fixing the positioning part, thus the casing is combined with the keyboard module. The floating problem of the keyboard module can be solved by the combination of the keyboard fixing structure with the casing of the portable computer and the keyboard module. The assembly time and the cost of the keyboard module can be saved.

Owner:ASUSTEK COMPUTER INC

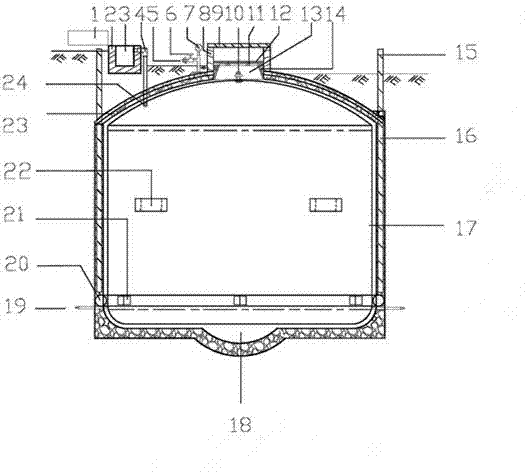

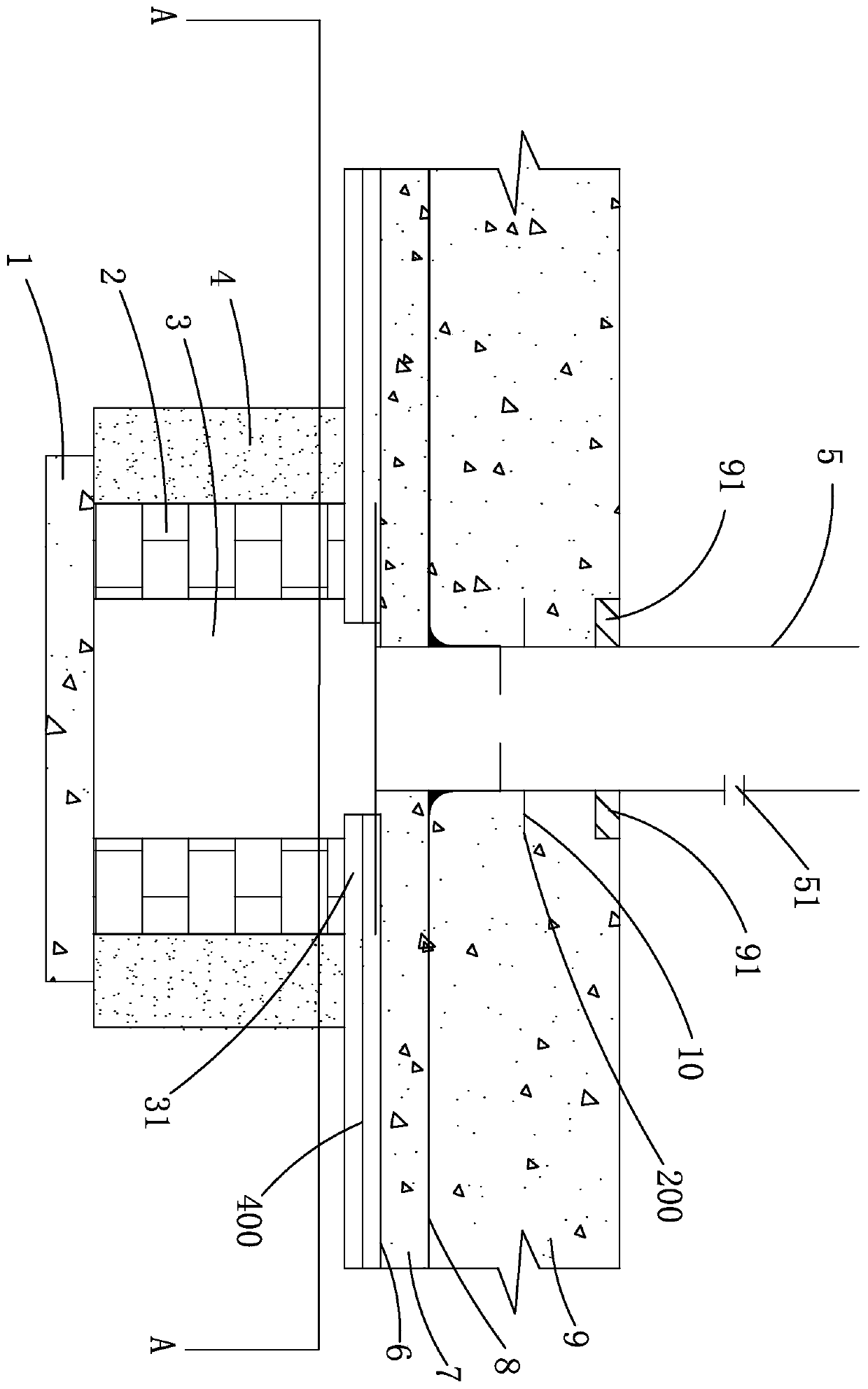

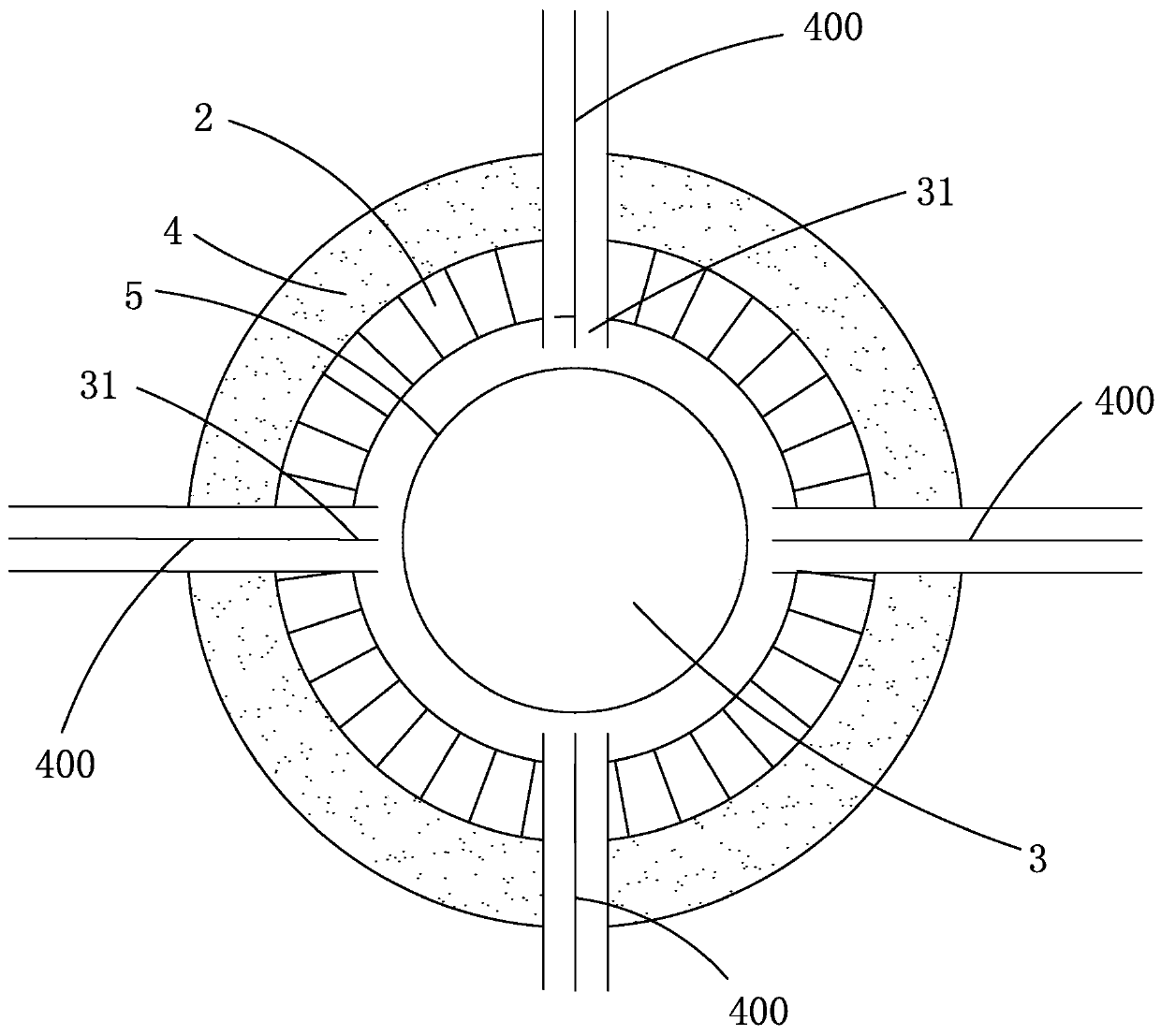

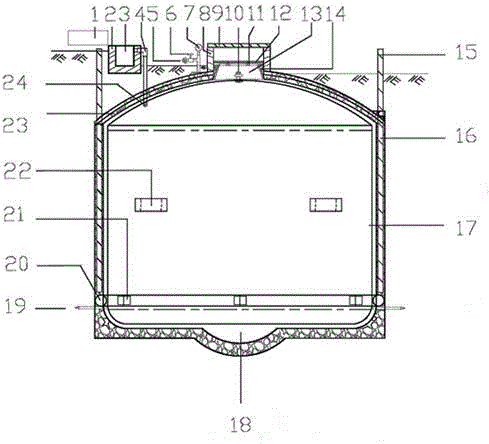

Air mold pouring polymerization concrete air inflation detection type small water cellar, construction method of small water cellar, application of small water cellar in biogas digester construction and inflatable model special for small water cellar

ActiveCN103541573ASolve the floating problemSolve the problem of unsafe top construction operationGas production bioreactorsBulk storage containerSludgeSilt

The invention relates to a small water cellar, a construction method of the small water cellar, the application of the small water cellar in biogas digester construction and an air mold special for the small water cellar. A regular splay air sealing port is formed in the position where a concrete cellar body is connected with a cellar mouth, the regular splay air sealing port is sealed with a detachable air sealing pot, and a concave dredging pit which is used for converging sludge at the bottom and cleaning the sludge conveniently is reserved at the bottom of the concrete cellar body. Pouring is achieved by means of the cylindrical air mold, and the problems that when an ordinary steel or wood mold concrete pouring method is used, the amount of transported concrete is large, and a large amount of time and a large amount of labor are consumed for mold installation and dismantling are effectively solved; the bottom of the concrete cellar body is a plane, a circle of anti-floating ring is placed on the lower middle portion of the pit, mortar is prevented from flowing to the bottom of the concrete cellar body to generate buoyancy force, the problem of floating of the air mold is solved, and the problem that the bottom of the spherical air mold is difficult to place stably is solved; due to the fact that pouring is carried out on the upper wall and the top of the concrete cellar body and then pouring is carried out on the bottom of the concrete cellar body, the problem of unsafe top construction of the cellar is solved; due to the fact that the regular splay air sealing port is formed in the position of the cellar mouth, accuracy of detection of the airtightness of the small water cellar is improved.

Owner:刘安华

Modified waste and old rubber, preparation method thereof and sound insulation mortar

InactiveCN112209648AHigh densityImprove hydrophilicitySolid waste managementPolymer scienceWaste rubber

The invention relates to modified waste and old rubber, a preparation method thereof and sound insulation mortar. The preparation method of the modified waste and old rubber comprises the following steps: taking 100-mesh waste rubber particles with the particle size of 50 meshes, soaking in an alkaline solution, taking out, drying, freezing at the temperature of -20 DEG C to 15 DEG C to prepare arubber particle intermediate, mixing the rubber particle intermediate and cement, adding water, and standing for 10 hours to enable the cement to be subjected to prehydration reaction. The waste and old rubber particles are physically and chemically modified in advance, so that the hydrophilicity of the waste rubber particles is improved, the air entraining effect of the waste rubber particles ina cement-based material is reduced, the waste rubber particles are more tightly combined with a hydration product of a gel material, the overall mechanical strength of the sound insulation mortar is kept, and the sound insulation mortar is not prone to cracking. Meanwhile, the density of the waste rubber particles is increased, the waste rubber particles are not prone to floating upwards after being added into cement mortar, and the sound insulation effect is good.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

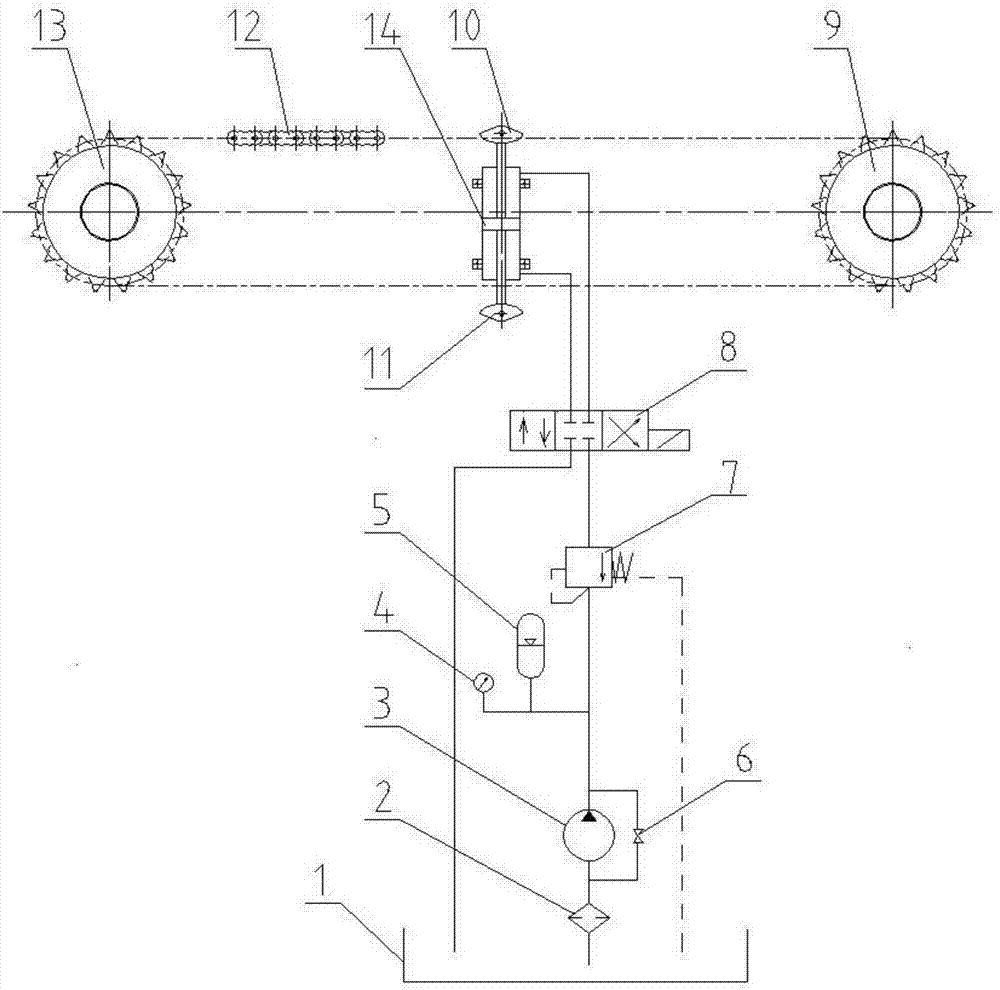

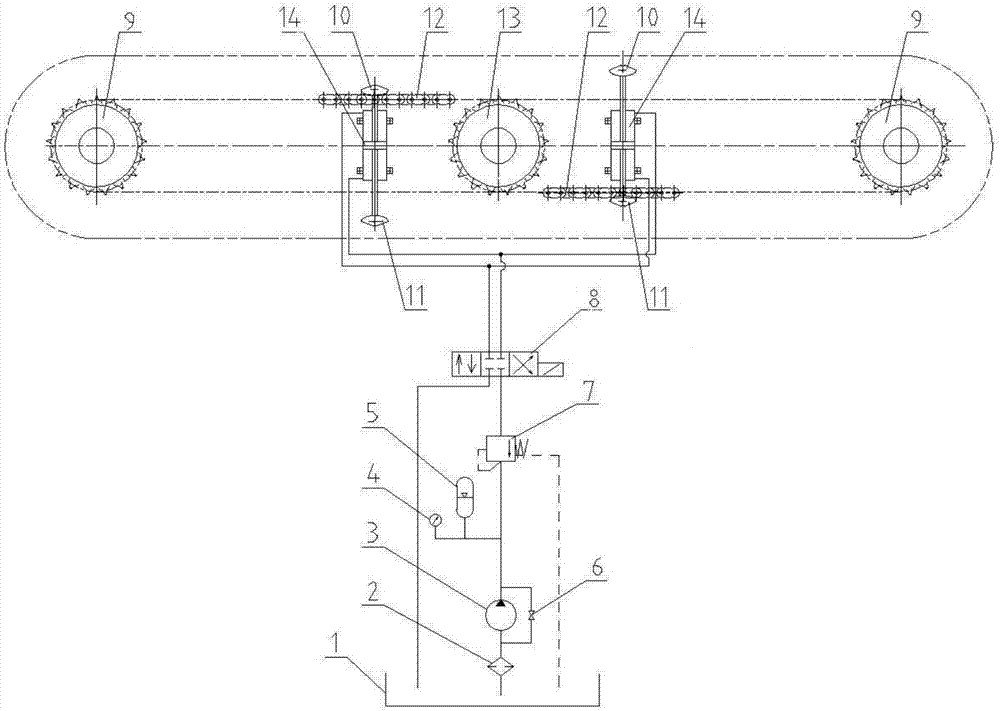

Forward-reverse-rotation transmission chain tensioning device and land leveler balance box

The invention relates to chain transmission and provides a forward-reverse-rotation transmission chain tensioning device in order to solve the problem that existing chain transmission is prone to generating tooth jumping and chain falling. The forward-reverse-rotation transmission chain tensioning device comprises a driving sprocket and driven sprockets which are rotatably connected through chains in the same direction and is characterized in that the forward-reverse-rotation transmission chain tensioning device further comprises upper tensioning sliding seats, lower tensioning sliding seats and two-way acting hydraulic oil cylinders; the two-way acting hydraulic oil cylinders push the upper tensioning sliding seats and the lower tensioning sliding seats to move in the perpendicular direction of the upper edges of the perpendicular chains, so that the upper tensioning sliding seats downwards compress the upper edges of the chains or the lower tensioning sliding seats upwards compress the lower edges of the chains; and the two-way acting hydraulic oil cylinders are connected with a chain tensioning control system. Engaged wrap angles of the chains and the driving sprocket are increased, the contact areas of the sprockets abraded after the long-term use and the chains are increased, when the chains are in forward-rotation transmission or reverse-rotation transmission, the phenomena such as shaking, skidding, floating, tooth jumping and chain falling of the transmission chains are overcome, the reliability of chain transmission is greatly improved, and the life of the chains is prolonged.

Owner:GUANGXI LIUGONG MASCH CO LTD

Manufacturing process of decompression and drainage well in basement anti-floating and sealing process

InactiveCN110258660AReduce buoyancySimple and fast constructionProtective foundationExcavationsBasementBrick

The invention relates to a manufacturing process of a decompression and drainage well in a basement anti-floating and a sealing process.The manufacturing process of the decompression and drainage well in the basement anti-floating and a sealing processcomprises the steps that 1, a well with a depth of 50 to 60 cm is dug in the basement; 2,a concrete underlayer is poured at the bottom of the well; 3,a permeable brick is built on the concrete cushion, and the permeable bricks are enclosed as drainage wells; 4,the backwater is filled with coarse sand or slag to form a permeable layer; 5,a drain is opened at intervals along the circumference of the drain well; 6,the water-stop steel ring sleeve is fixed, the lower end of the water-stop steel ring sleeve is inserted into the drainage well, and the upper end of the water-stop steel ring sleeve is exposed outside the bottom plate of the basement; 7,the bottom layer is casted on the bottom plate; 10, the drain hole is formed in the bottom of a 200 to 250CM water stop ferrule. According to the manufacturing process of the decompression and drainage well in the basement anti-floating and the sealing process, the buoyancy of the groundwater to the basement floor can be effectively reduced, which is economical and effective, construction is simple and quick, and the problem of the floating of the basement in the construction stage can be fundamentally solved.

Owner:广东龙越建筑工程有限公司

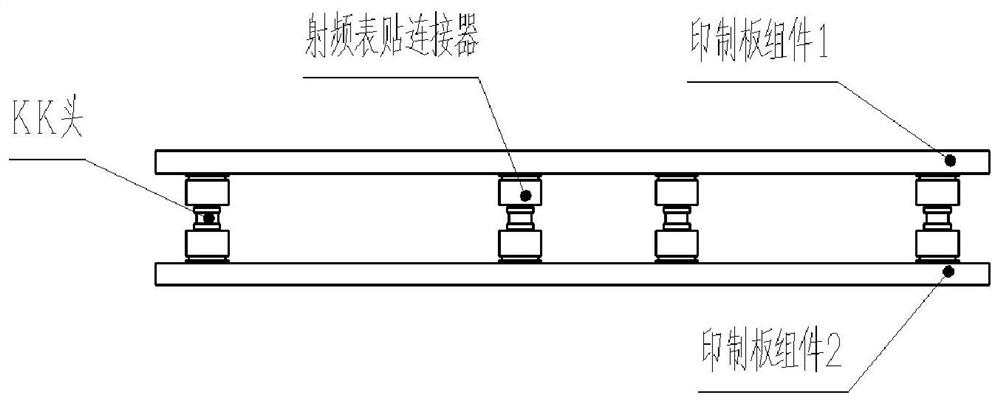

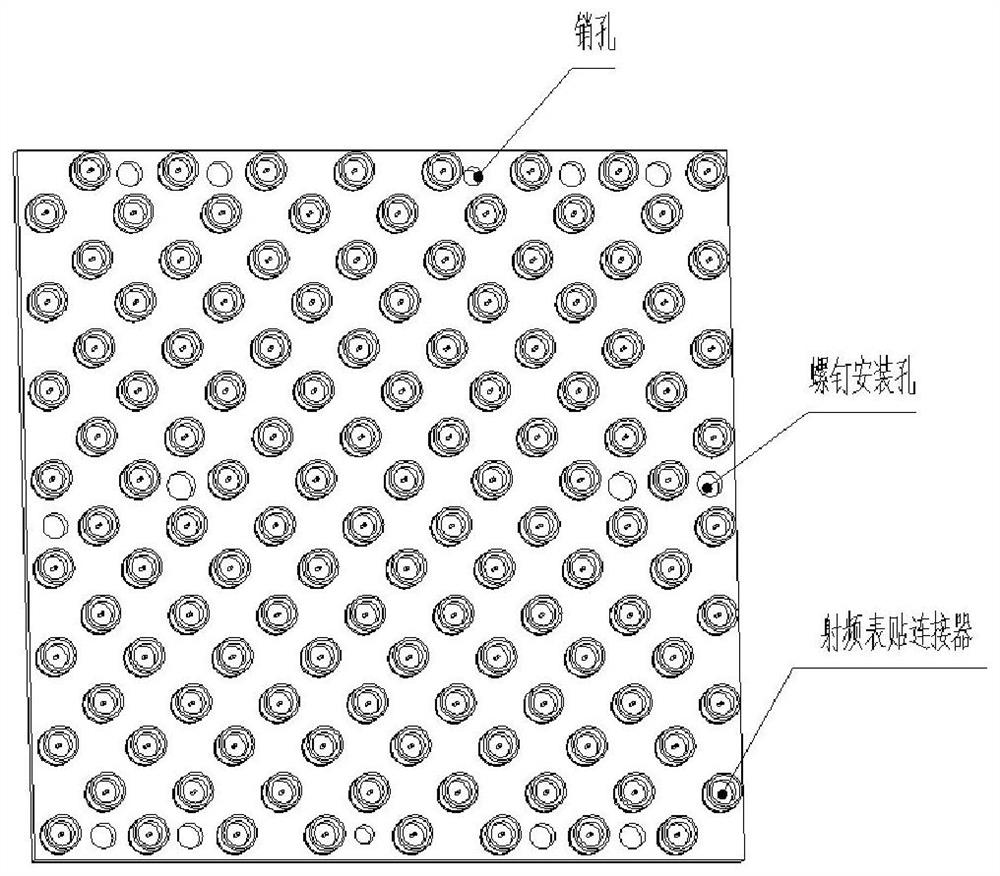

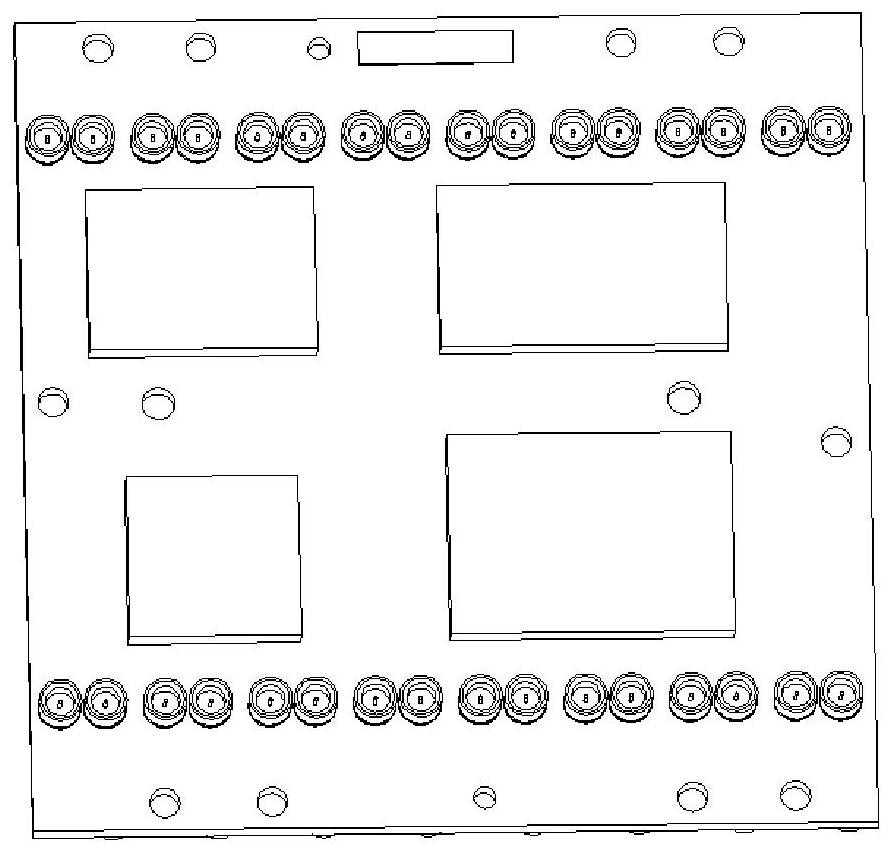

Welding device and welding method for printed board assembly based on inter-board vertical interconnection

ActiveCN113305385AGuaranteed success rateGuarantee the quality of signal transmissionPrinted circuit assemblingSoldering apparatusSoldering processWelding process

The invention relates to the technical field of electronic equipment, and discloses a welding device and welding method for a printed board assembly based on inter-board vertical interconnection. The welding device comprises a positioning plate, a supporting plate, pins and screws, wherein the positioning plate is arranged above a printed board, the supporting plate is arranged below the printed board, the positioning plate, the supporting plate and the printed board are positioned through the pins, and the positioning plate, the supporting plate and the printed board are fixed together through the screws. According to the welding device and welding method, the welding device is adopted to mount and position a surface-mounted connector on the printed board assembly, the buckling deformation of the printed board in the welding process is controlled, accurate positioning and reliable welding of the surface-mounted connector based on inter-board vertical interconnection are realized, the problems of the position offset of the surface-mounted connector on the printed board assembly, the inclination and flotation of the connector and the buckling deformation of the printed board can be solved, and therefore the realizability and reliability of inter-board vertical interconnection are improved.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

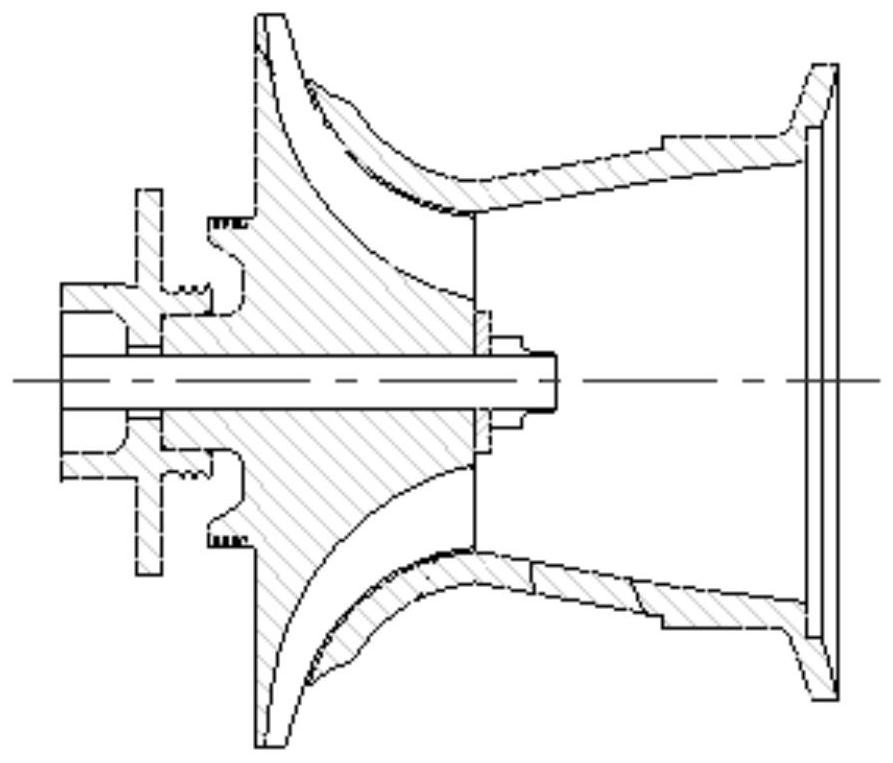

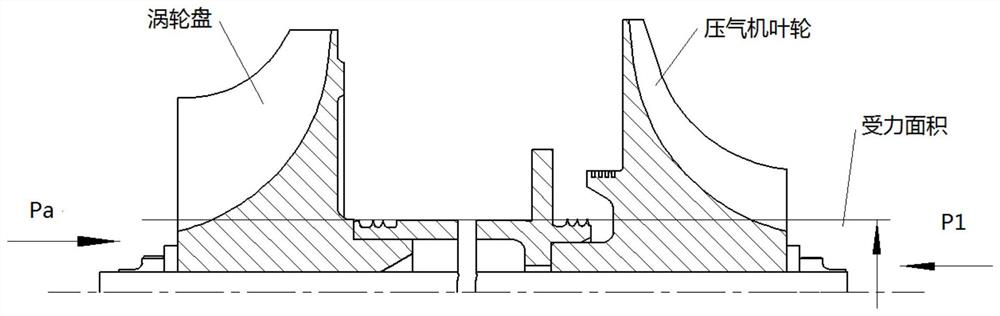

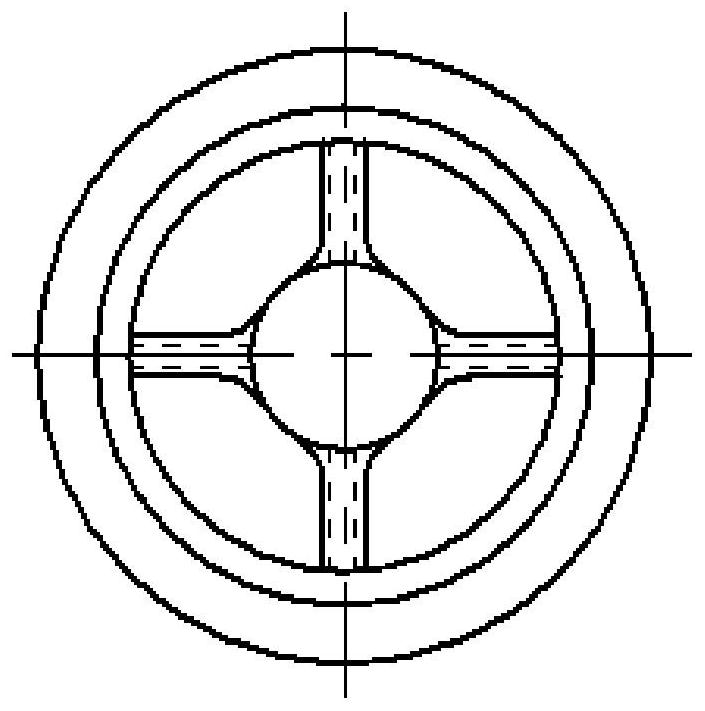

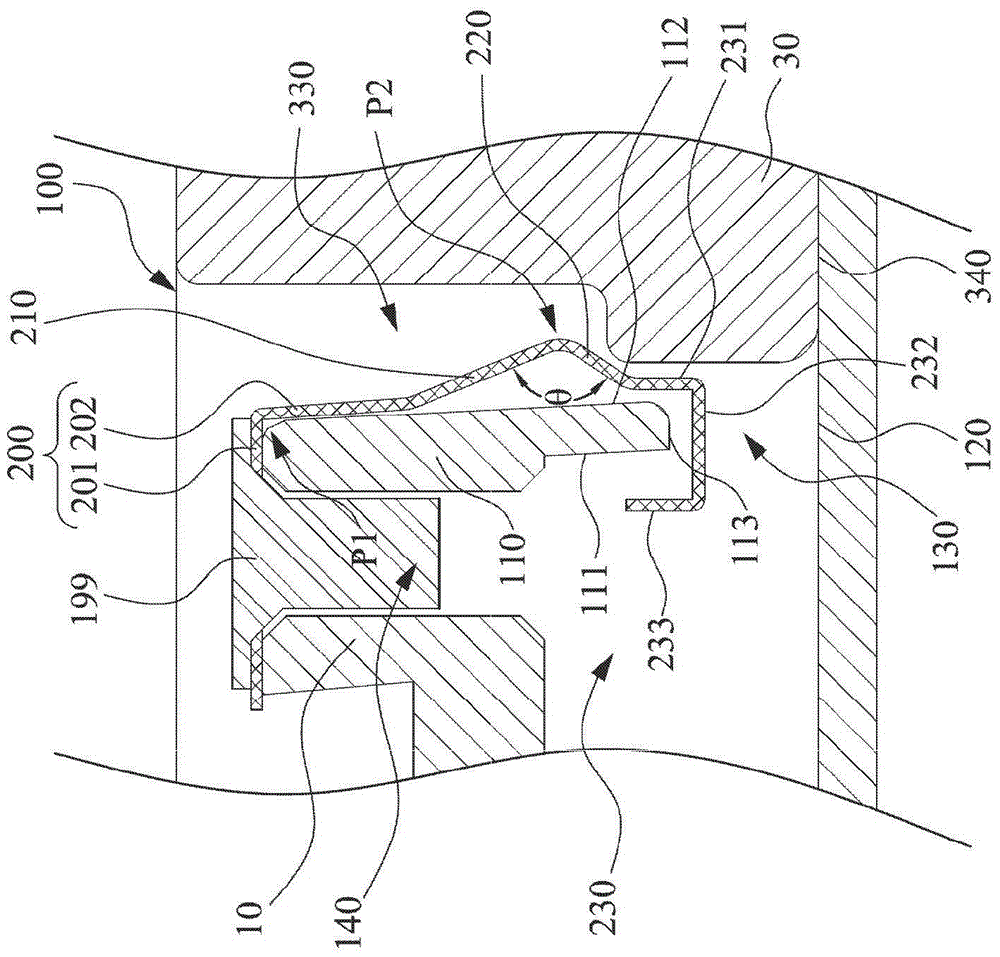

Axial force balance structure of boost air flotation turbine cooler

ActiveCN111765114ASolve the floating problemPump componentsTurbine/propulsion engine coolingAviationFriction torque

The invention belongs to the technical field of aviation turbine coolers, and relates to axial force balance of a pod environmentally controlled turbine cooler, in particular to an axial force balancestructure of a pod environmentally controlled boost air flotation turbine cooler. The structure is composed of a compressor volute, a compressor impeller, a shaft, a dynamic sealing ring, a self-locking nut and a pull rod. The compressor impeller is pressed into a hole of the shaft, the pull rod penetrates through the shaft and the compressor impeller, the dynamic sealing ring is arranged on a shaft head of the compressor impeller, and the self-locking nut is installed on the pull rod and compresses the dynamic sealing ring; the compressor volute is fixed to a housing through screws; a diversion device is arranged at an inlet of the compressor volute, a hole is formed in the middle of the diversion device to form a seal with the dynamic sealing ring, and the compressor volute and the dynamic sealing ring form a cavity A. A novel structure floating device greatly reduces or even eliminates the axial force and additional friction torque during the rotor starting process, the floating problem of a boost air flotation turbine is fundamentally solved, and compared with a general structure, the novel structure has great advantages.

Owner:XINXIANG AVIATION IND GROUP +1

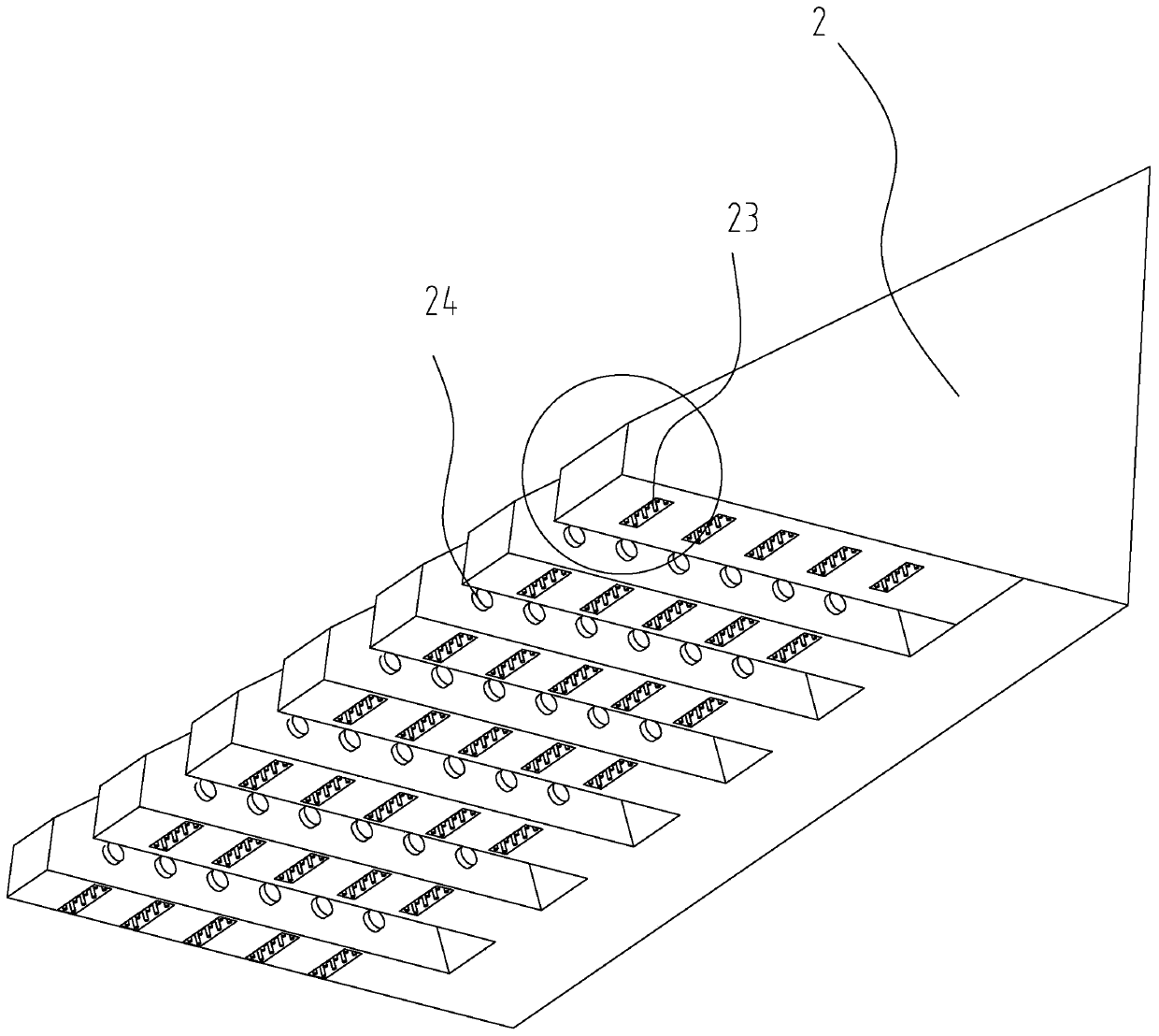

Pin used on component

PendingCN109962050AReduce thicknessSolve WeldingSemiconductor/solid-state device detailsSolid-state devicesEngineeringSolder paste

The invention discloses a pin used on a component, and belongs to the technical field of component pins. The pin comprises a pin connecting plate and a pin bottom plate. The left end surface of the pin connecting plate is fixedly provided with the pin bottom plate, and the left end part of the pin bottom plate is a climbing inclined surface, wherein the climbing inclined surface is an inclined surface which is obliquely upwards arranged on the bottom surface of the pin bottom plate. The pin bottom plate is provided with a plurality of parallel solder paste storage grooves, and the solder pastestorage grooves are through grooves which penetrate through the pin bottom plate. The pin is used for solving the technical problems that floating and insufficient welding are liable to happen when atraditional pin is welded.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Wrapping machine motor braking device

InactiveCN105914941ASolve the floating problemReduce repairMechanical energy handlingYarnEngineeringMechanical engineering

The invention discloses a wrapping machine motor braking device. A horizontal synchronous belt wheel I (4) is connected on the output shaft of a motor (5). A synchronous belt wheel II (2) is arranged at the side surface of the synchronous belt wheel I (4). The synchronous belt wheel II (2) sleeves a wrapping main shaft (1). The synchronous belt wheel I (4) and the synchronous belt wheel II (2) are connected in a transmission way through a synchronous belt (3). A braking disc (6) is arranged on the upper part of the synchronous belt wheel I (4). A braking cylinder is installed at one side of the braking disc (6). An air pipe (9) is connected on the braking cylinder (7). One end of the air pipe (9) is connected with the braking cylinder (7), and the other end of the air pipe (9) is provided with an electromagnetic valve (10). A PLC (11) is connected on the electromagnetic valve (10).

Owner:JIANGSU XINGDA STEEL TYPE CORD

Multifunctional high-speed pantograph auxiliary pantograph lifting device

The invention discloses a multifunctional high-speed pantograph auxiliary pantograph lifting device. The device comprises a pantograph bottom frame, a lower arm, an upper arm and an upper cross pipe,a connecting plate is fixed to the pantograph bottom frame, a permanent magnet material and an auxiliary pantograph lifting air bag are fixed to the connecting plate, a connecting support is fixed tothe upper cross pipe, and another permanent magnet material is fixed to the connecting support. The upper portions and the lower portions of the two permanent magnet materials correspond to each other, and the upper portion of the auxiliary pantograph lifting air bag corresponds to the connecting support. The device has the characteristics of the simple structure, the low cost, the high reliability and the like, solves the problems that the high-speed pantograph of the existing motor train unit cannot be lifted and the pantograph floats up when the pantograph is used as a standby folding pantograph to operate, can ensure the operation order, and improves the application efficiency of the motor train unit.

Owner:BEIJING CED RAILWAY ELECTRIC TECH

Automatic pushing-rolling control method for thin coal seam

ActiveCN105422156ARealize automated miningSolve the floating problemMine roof supportsMining engineeringControl system

Disclosed is an automatic pushing-rolling control method for a thin coal seam. A hydraulic support electrohydraulic control system with the automatic following function is adopted. A hydraulic support set is composed of a plurality of hydraulic supports. An inclination adjusting jack is designed on each hydraulic support so as to be linked with pushing-rolling actions. The three functions of inclination adjustment, linkage and multi-wheel pushing-rolling can be selected to be enabled according to site condition execution. The linkage function of the inclination adjustment action and the pushing-rolling action is achieved, and the problems of bottom pricking and floating rolling of a scraper conveyor in the thin coal seam environment are effectively solved; the front bottom pricking function of the scraper conveyor is achieved through inclination adjustment before pushing-rolling, and the problems of float coal removal and scraper conveyor floating are solved; the multi-wheel pushing-rolling action strategy is achieved, coal mining and coal transportation flow are balanced, and the problem that mining and transportation are not matched is solved; the multi-wheel pushing-rolling strategy is applied to automatic following, the problem that full-automatic mining cannot be achieved due to the fact that mining and transportation are not matched in the following process is solved, and automatic mining of the thin coal seam is achieved.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD

Ultra-short soft fiber poly-velvet spinning and its production method

The invention relates to ultrashort fine and soft fiber poly wool yarn and a production method thereof, and belongs to the field of spinning. According to the ultrashort fine and soft fiber poly wool yarn and the production method thereof, pretreatment of increasing proportion through a intermediate-temperature oxygen bleaching method is conducted to ultrashort fine soft kapok fiber, organic cotton fiber and the like, the problem that the fiber floats during opening and carding is solved, and the performance characteristics of the ultrashort fine soft kapok fiber and the organic cotton fiber is not influenced. Cotton carding process is conducted through a small-proportion mixing technique in which Australian wool top, organic cotton and kapok fiber are mixed in rolling layers, and a uniform blending bar is obtained. After a second drawing and roving process, the yarn is spun through a poly wool spinning technique on a spinning machine, the ultrashort fine and soft fiber poly wool yarn of the organic cotton fiber or the kapok fiber or noil fiber is manufactured after a meridian tube process, wherein the Ntex of the ultrashort fine and soft fiber poly wool yarn is 9.7-28 tex. By means of the ultrashort fine and soft fiber poly wool yarn spinning technique adopted in a cotton spinning system, partial technical problem that kapok, cashmere and combing noil are spun into yarn difficultly in cotton spinning equipment is solved, and medium high yarn which is good in yarn levelness, high in strength, compact in structure, bright and clean and good in wear-resisting property and has little hairiness is obtained.

Owner:YANCHENG INST OF IND TECH

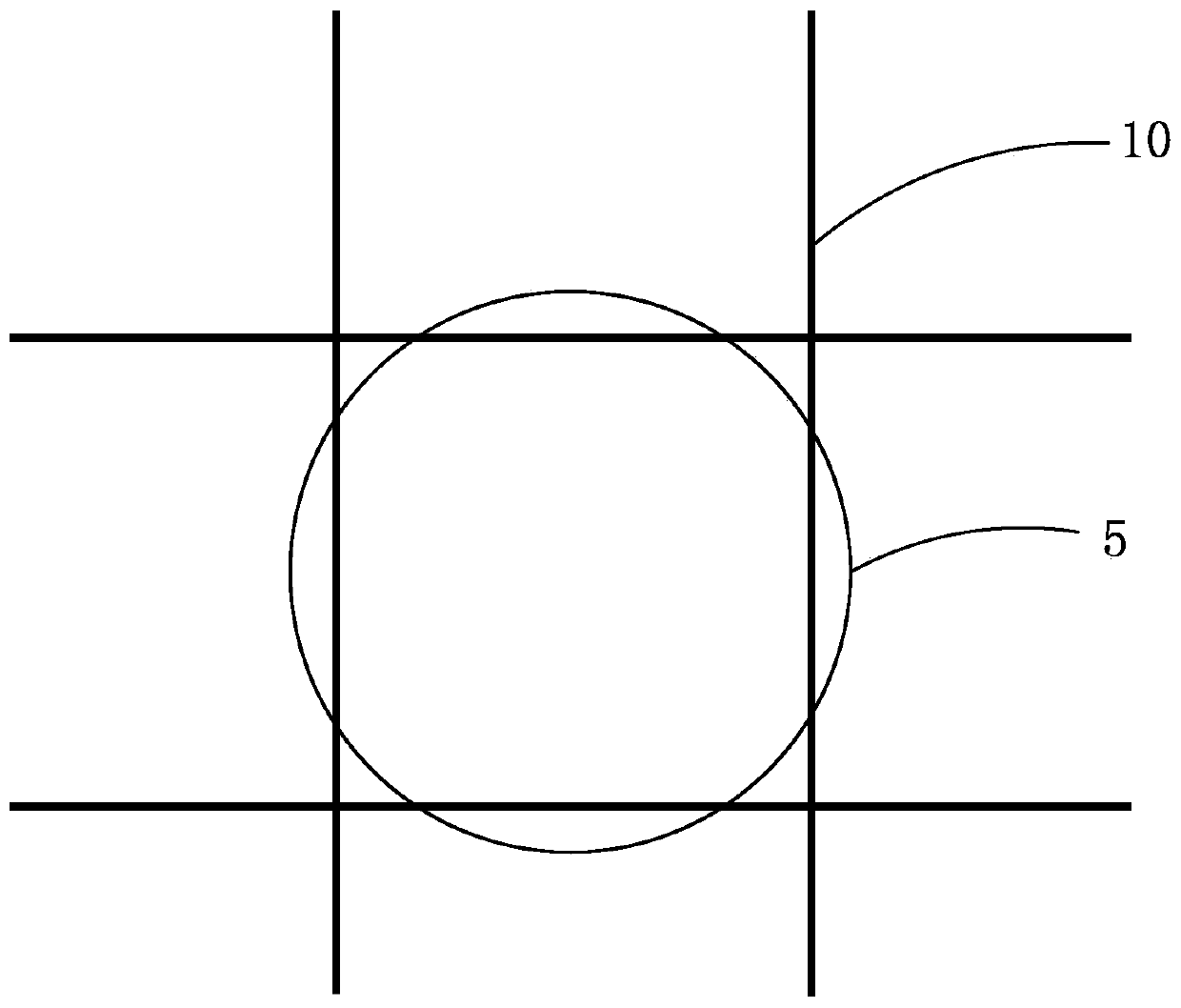

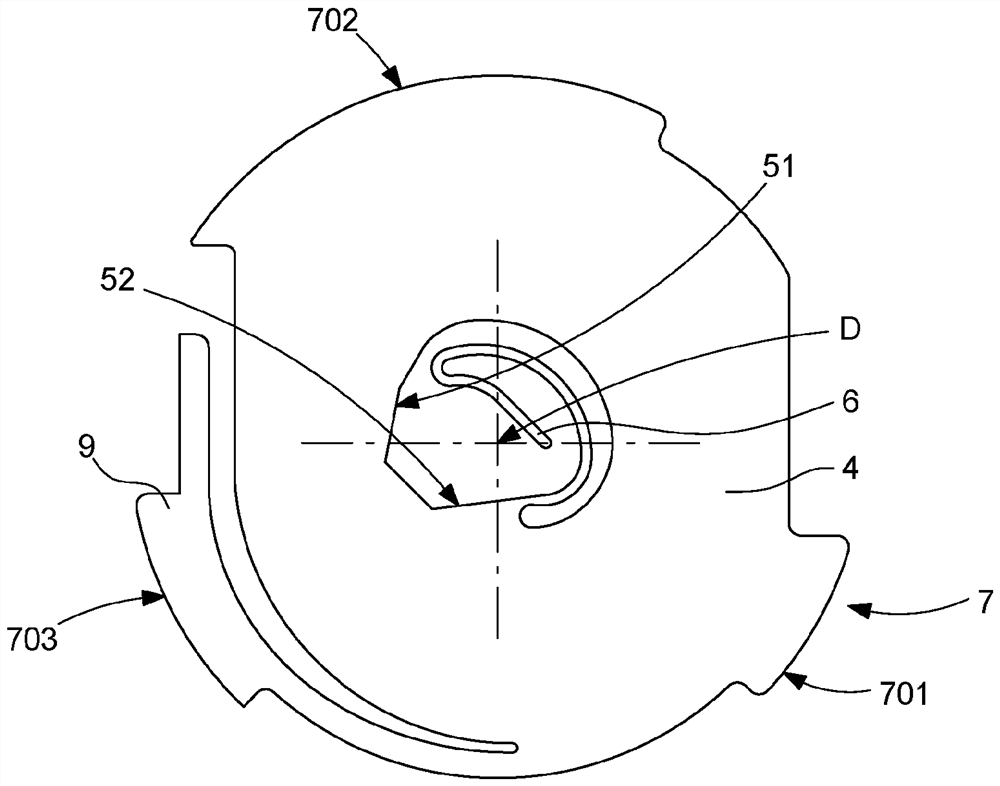

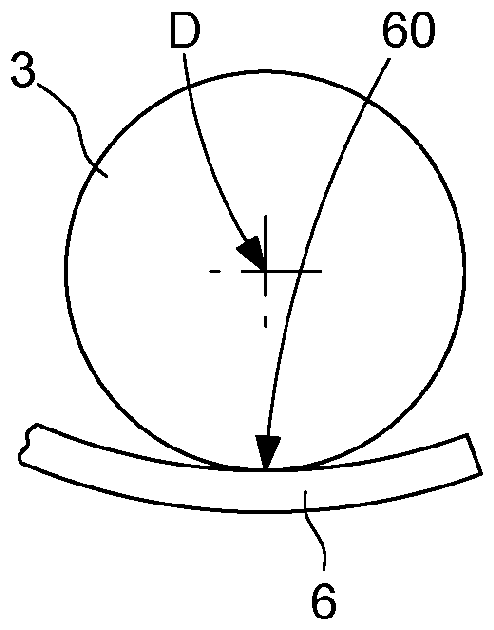

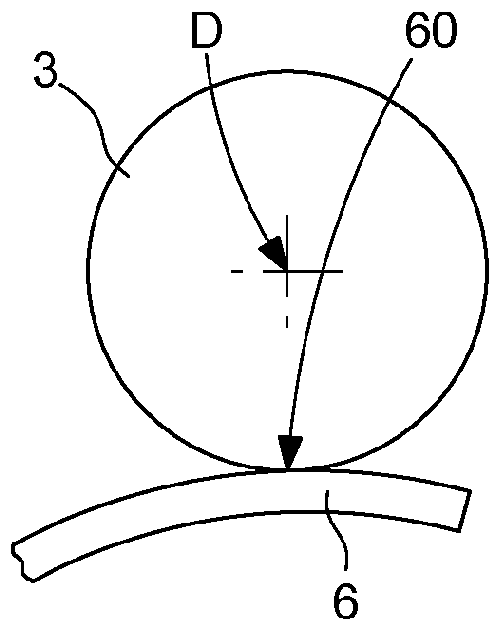

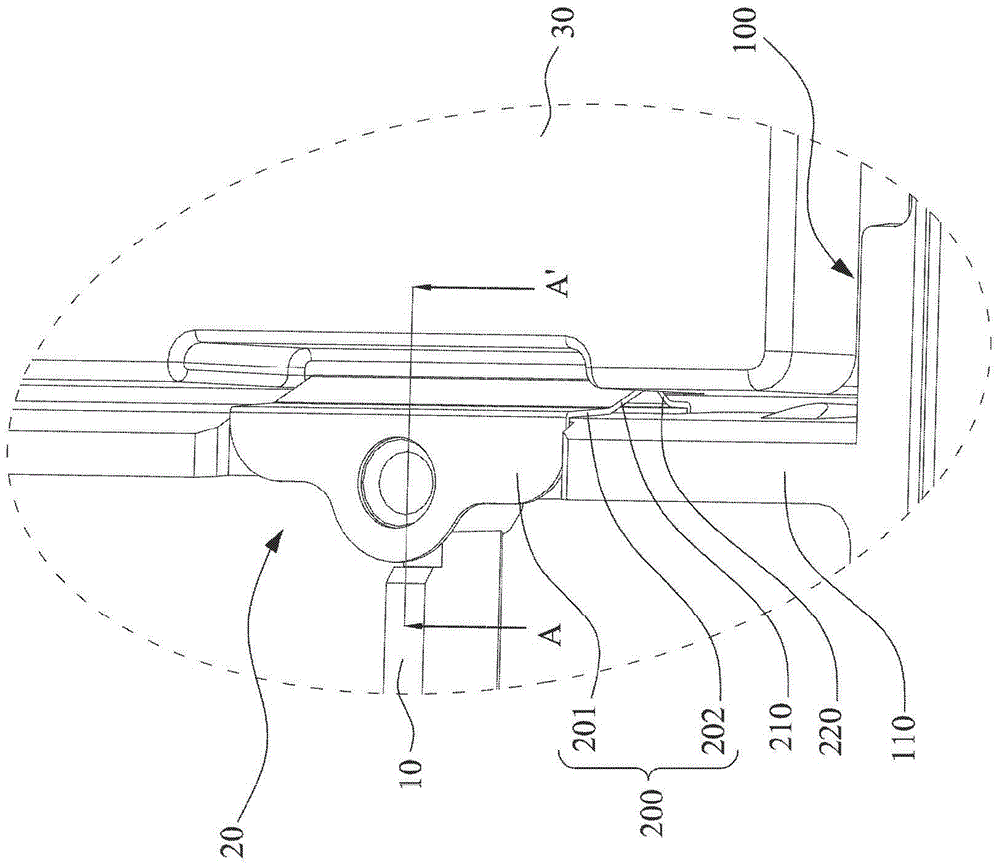

Timepiece display mechanism

PendingCN114787721ASolve the floating problemAvoid contactGearworksVisual indicationDisplay deviceSupport surface

A timepiece display mechanism (100) comprising at least one display (10) comprising a shaft (3), and comprising at least one main cleat (101) and / or cleat (102) carrying at least one guide device (1) for carrying and guiding the shaft (3) about an axis (D), the guide device (1) comprising, on a first side of said axis (D), a support surface (5) comprising a V-shape or a pad, according to the invention, the guide device (1) comprises, on an opposite second side, at least one holding element (6), which is substantially diametrically opposite to the support surface (5), and which is arranged on the support surface (5), said holding element (6) being symmetrical with respect to a bisecting plane (P) passing through the axis (D) such that the axis of the shaft (3) is centered on the bisecting plane (P) of the support surface (5). All said retaining elements (6) exert a resultant elastic restoring force on the shaft (3) towards said axis (D) and prevent the shaft (3) from radially exiting from any of the guide bearings (4), which are platforms having two parallel faces.

Owner:ETA SA MFG HORLOGERE SUISSE

Biological nitrogen removal system and process thereof

ActiveCN104003571AEfficient removalAchieve interchangeMultistage water/sewage treatmentNitrogen removalWastewater

The invention provides a biological nitrogen removal system and a process thereof. The system comprises a primary anaerobic system, a primary anoxic system and a sedimentation system. The primary anaerobic system, the primary anoxic system and the sedimentation system are arranged and communicated in sequence; the primary anaerobic system is a tank body provided with a plug-flow stirring device; the primary anoxic system is a tank body provided with a plug-flow stirring device and an aeration device; the tank bodies of the primary anaerobic system and the primary anoxic system are connected; a separation wall is provided with an opening; the sedimentation system comprises a primary sedimentation tank and a secondary sedimentation tank; the top of primary sedimentation tank is provided with an overflow channel; the bottom of the secondary sedimentation tank is provided with a mud bucket; the upper part of the mud bucket is communicated to the primary sedimentation tank and is provided with an effluent overflow port; and the second sedimentation tank is provided with a baffle plate for preventing short flow. The biological nitrogen removal system can effectively realize interexchange of mud and water, realize synchronous nitrification and denitrification, effectively remove nitrogen-containing pollutants in wastewater and reduce cost. A production flow is compact and floor space can be saved.

Owner:NINGBO HENGJIE WATER DEV

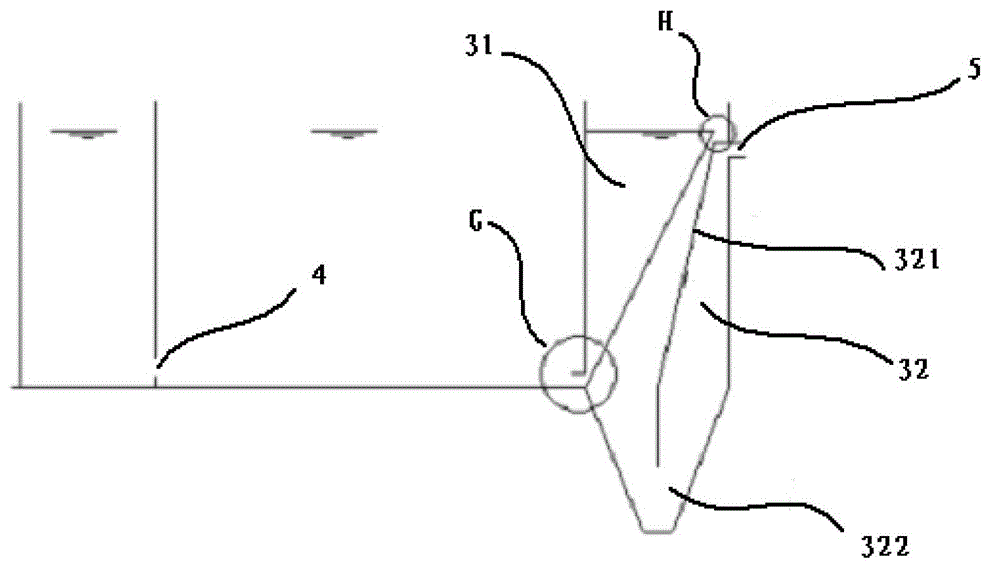

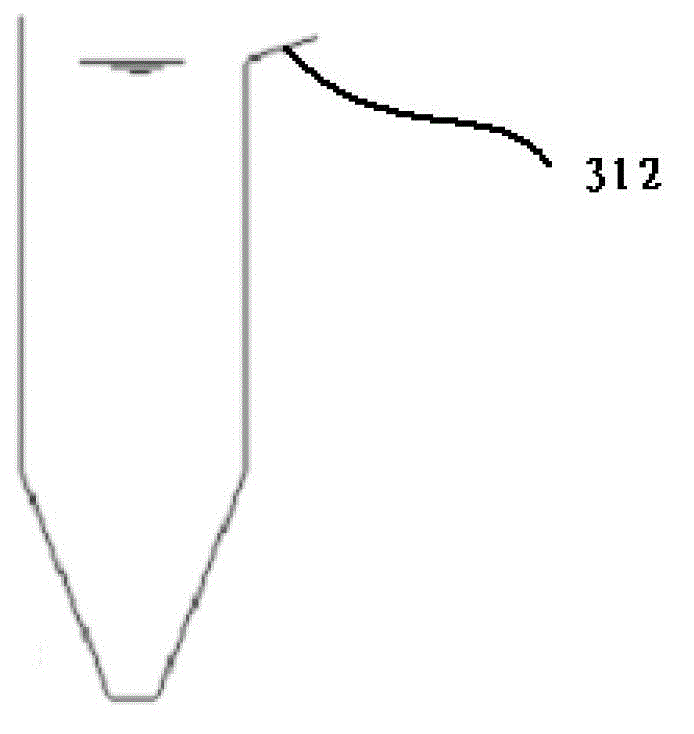

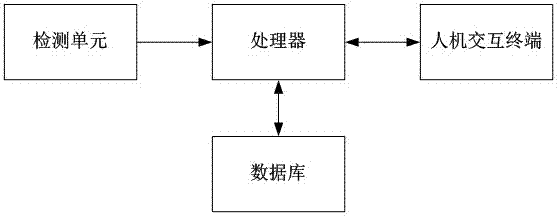

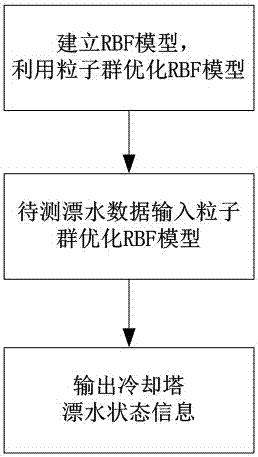

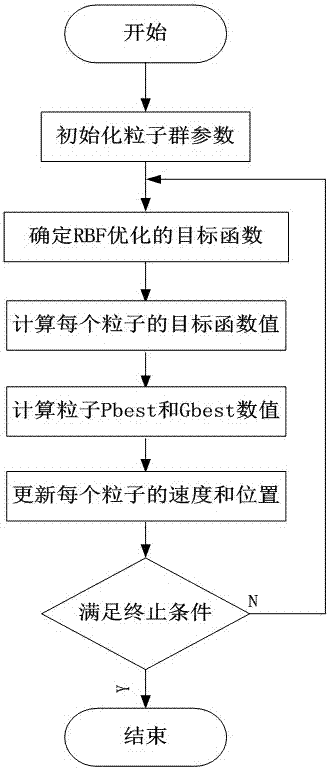

A cooling tower drift adjustment system and method thereof

ActiveCN104713409BSolve the floating problemRepair in timeHeat exchange apparatusCooling towerEngineering

The invention relates to a cooling tower drift adjustment system and a method thereof, which belong to the field of cooling tower systems. The system includes: a detection unit for detecting the ventilation rate at the cooling tower vent, the circulating water volume of the cooling tower and the speed of the water distribution device; The detector is connected to the detection unit and receives the signal of the detection unit; the human-computer interaction terminal is connected to the processor and displays the processed data of the processor. The system of the present invention can detect the ventilation volume in the cooling tower, the circulating water volume of the cooling tower and the rotating speed of the water distribution device, analyze the floating water problem of the cooling tower, and solve the problems caused by excessive circulating water volume, excessive ventilation volume or excessive rotating speed of the water distribution device. Serious cooling tower drift problems caused by fast and other reasons. In the present invention, the particle swarm optimization RBF model is used to analyze the parameters to be measured, thereby obtaining a solution to the problem of water drift adjustment, which solves the shortcomings of the prior art in the analysis of the water drift problem of cooling towers and the limitations of the solution to the water drift problem. improper.

Owner:ZAOZHUANG HAIDI ENERGY TECH

A thin coal seam automatic pushing control method

ActiveCN105422156BRealize automated miningSolve the floating problemMine roof supportsMining engineeringControl system

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD

Portable computer and its keyboard fixing structure

ActiveCN101430586BSolve the floating problemSave assembly timeSnap-action fastenersDigital data processing detailsEngineeringPortable computer

The invention relates to a keyboard fixing structure for a portable computer, comprising a positioning part and a positioning structure. The positioning part is arranged on one side of a keyboard module and comprises a cone part and a cylinder part. The cone part is connected with the cylinder part. The maximum external diameter of the cone part is larger than the diameter of the cylinder part. The positioning structure is arranged on a casing of the portable computer. The arrangement position of the positioning structure is corresponding to the positioning part and the positioning structure is used for blocking and fixing the positioning part, thus the casing is combined with the keyboard module. The floating problem of the keyboard module can be solved by the combination of the keyboardfixing structure with the casing of the portable computer and the keyboard module. The assembly time and the cost of the keyboard module can be saved.

Owner:ASUSTEK COMPUTER INC

Air-casting high-performance polymer concrete inflatable inspection type small water cellar, construction method, application and special inflatable mold

ActiveCN103541573BSolve the floating problemSolve the problem of unsafe top construction operationGas production bioreactorsBulk storage containerSludgeBuoyancy

The invention relates to a small water cellar, a construction method of the small water cellar, the application of the small water cellar in biogas digester construction and an air mold special for the small water cellar. A regular splay air sealing port is formed in the position where a concrete cellar body is connected with a cellar mouth, the regular splay air sealing port is sealed with a detachable air sealing pot, and a concave dredging pit which is used for converging sludge at the bottom and cleaning the sludge conveniently is reserved at the bottom of the concrete cellar body. Pouring is achieved by means of the cylindrical air mold, and the problems that when an ordinary steel or wood mold concrete pouring method is used, the amount of transported concrete is large, and a large amount of time and a large amount of labor are consumed for mold installation and dismantling are effectively solved; the bottom of the concrete cellar body is a plane, a circle of anti-floating ring is placed on the lower middle portion of the pit, mortar is prevented from flowing to the bottom of the concrete cellar body to generate buoyancy force, the problem of floating of the air mold is solved, and the problem that the bottom of the spherical air mold is difficult to place stably is solved; due to the fact that pouring is carried out on the upper wall and the top of the concrete cellar body and then pouring is carried out on the bottom of the concrete cellar body, the problem of unsafe top construction of the cellar is solved; due to the fact that the regular splay air sealing port is formed in the position of the cellar mouth, accuracy of detection of the airtightness of the small water cellar is improved.

Owner:刘安华

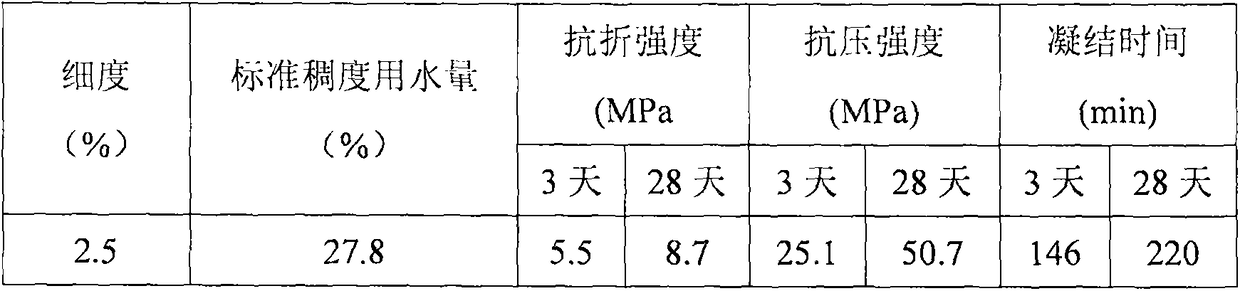

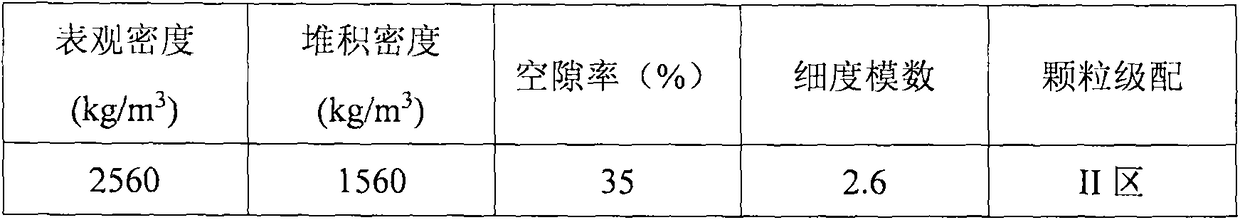

Stabilizer for preventing granule floating in stirring process of glass bead heat-preservation concrete

The invention relates to a stabilizer for preventing granule floating in a stirring process of glass bead heat-preservation concrete. The stabilizer comprises the following raw materials in parts by weight: 2-5 parts of a thickening agent, 25-55 parts of a water reduction agent, 2-3 parts of an air entraining agent, 300-400 parts of nano kaolin and 350-400 parts of coal ash. Due to scientific andreasonable matching of the functional components, the granule stabilizer provided by the invention is capable of ensuring flowability and peaceability of the glass bead heat-preservation concrete, andmeanwhile is capable improving cohesiveness of the concrete, improving the floating resistance of granules and cement slurry, maintaining uniform distribution of the granules in the cement slurry, and reducing a layering degree. By adopting the stabilizer, the difficulties of low strength, poor thermal insulation, non-homogeneity of materials, and the like caused by granule non-uniformity in thestirring process of the glass bead heat-preservation concrete are perfectly solved.

Owner:NANJING FORESTRY UNIV

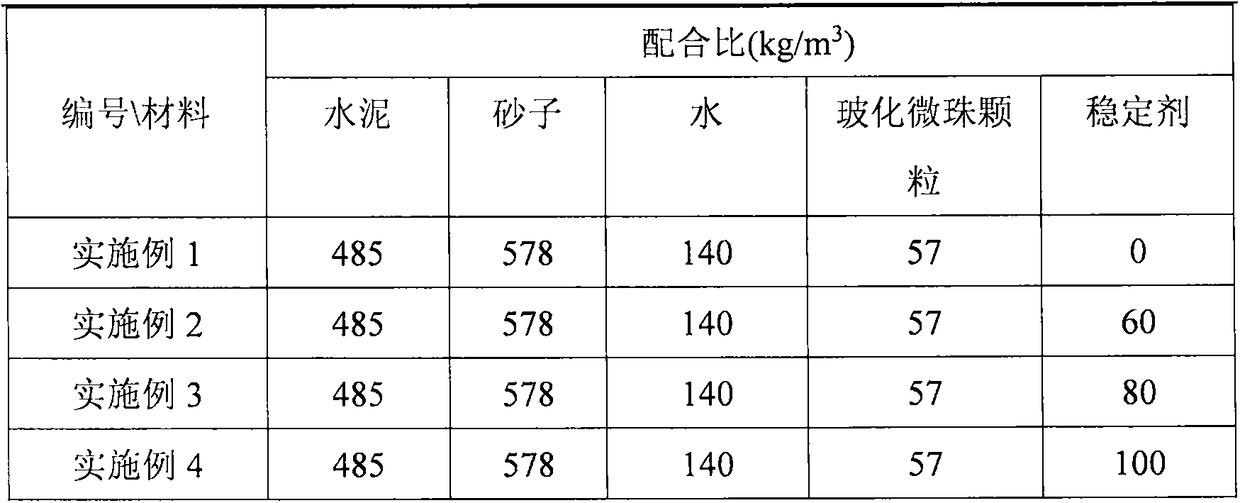

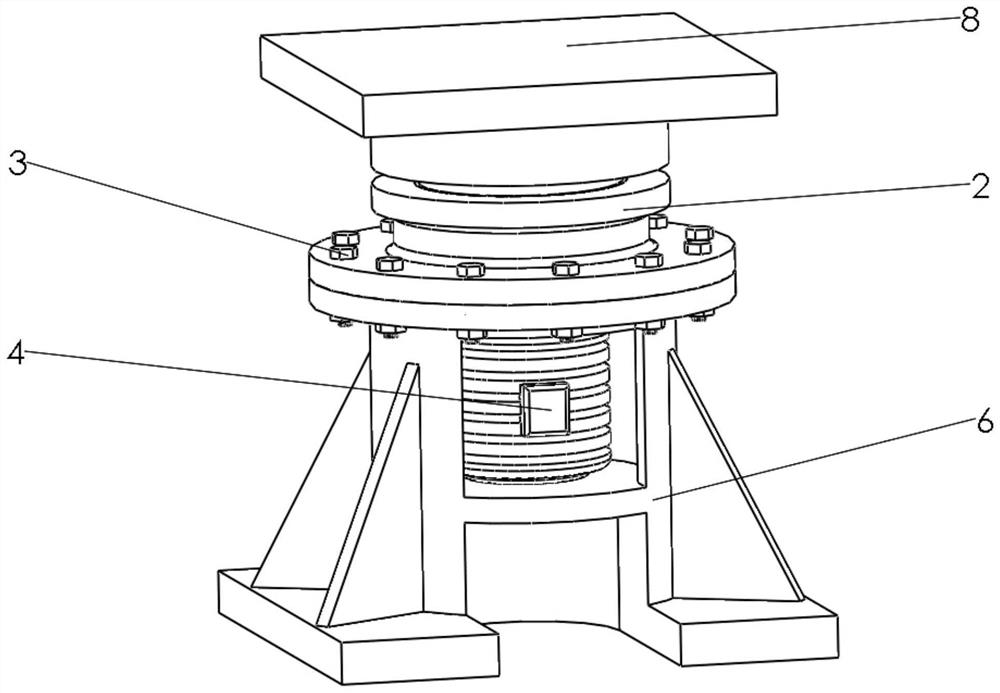

Supporting device for coal quantity weighing of raw coal bunker of thermal power plant and weighing raw coal bunker

PendingCN113044421AMeet weighing needsMeet the needs of weighingLarge containersWeighing apparatus detailsThermodynamicsBunker

The invention relates to a supporting device for coal quantity weighing of a raw coal bunker of a thermal power plant and a weighing raw coal bunker. The supporting device comprises a base, a positioning sleeve, an upper supporting seat and a weighing sensor, a sensor groove is arranged at the middle of the base, the weighing sensor is arranged in the sensor groove, and the positioning sleeve covers the base. A positioning hole is formed in the middle of the positioning sleeve, the upper supporting seat is movably inserted into the positioning hole, the bottom face of the upper supporting seat penetrates through the positioning hole to abut against the top face of the weighing sensor, and the raw coal bunker adopts the supporting device. Compared with the prior art, according to the supporting device for coal quantity weighing of the raw coal bunker of the thermal power plant and the weighing raw coal bunker, the weighing requirement of the raw coal bunker is effectively met, the structure is simple, safety and reliability are achieved, installation is convenient, the weighing requirement of the raw coal bunker can be met, the requirements of firm fixation and safe operation of the raw coal bunker can be guaranteed, and meanwhile the function that the weighing sensor is convenient to overhaul and replace is achieved.

Owner:HUANENG POWER INT INC

Hydraulic pipe screwing machine for screwing and unscrewing outer flat drill pipe and being capable of keeping off orifice

InactiveCN102031939BSmall solution spaceEasy to operateDrilling rodsDrilling casingsPetroleum engineeringDrill pipe

The invention discloses a hydraulic pipe screwing machine for screwing and unscrewing an outer flat drill pipe and being capable of keeping off an orifice, which relates to the field of engineering drilling. The hydraulic pipe screwing machine mainly comprises an upper pincer body, a lower pincer body and hanging pincers, wherein the lower pincer body is fixed to the orifice and used for clampinga drill pipe in a hole and preventing the generation of a rod falling event; the upper pincer body is a main part of the pipe screwing machine, is used for realizing the large-torque screwing, unscrewing and buckling of the upper drill rod and has the effects of clamping the drill rod and screwing and unscrewing the drill rod; and the hanging pincers are mainly used for keeping the pipe screwing machine off the orifice, thereby reducing the area of a drilling well platform and the drilling cost. The pipe screwing machine of the invention is suitable for screwing and unscrewing various drill rods, can realize the working processes of screwed buckling, pretensioning, large-torque punched buckling, and the like of the drill rod and has the advantages of small size, light weight, large torque, safety and convenience for work and operation, and the like.

Owner:WUHAN GOLD PROSPECTING MACHINERY LIMITED +1

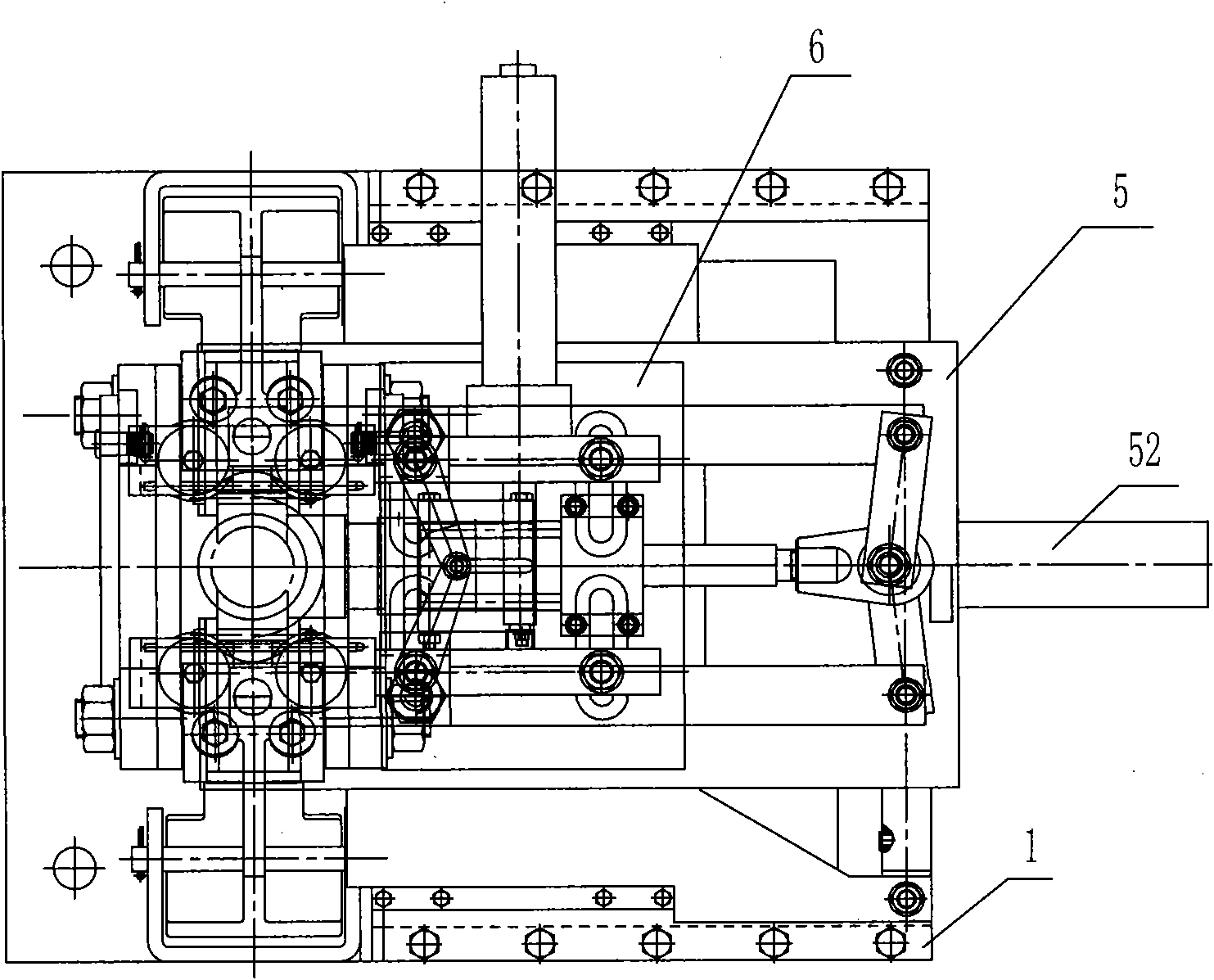

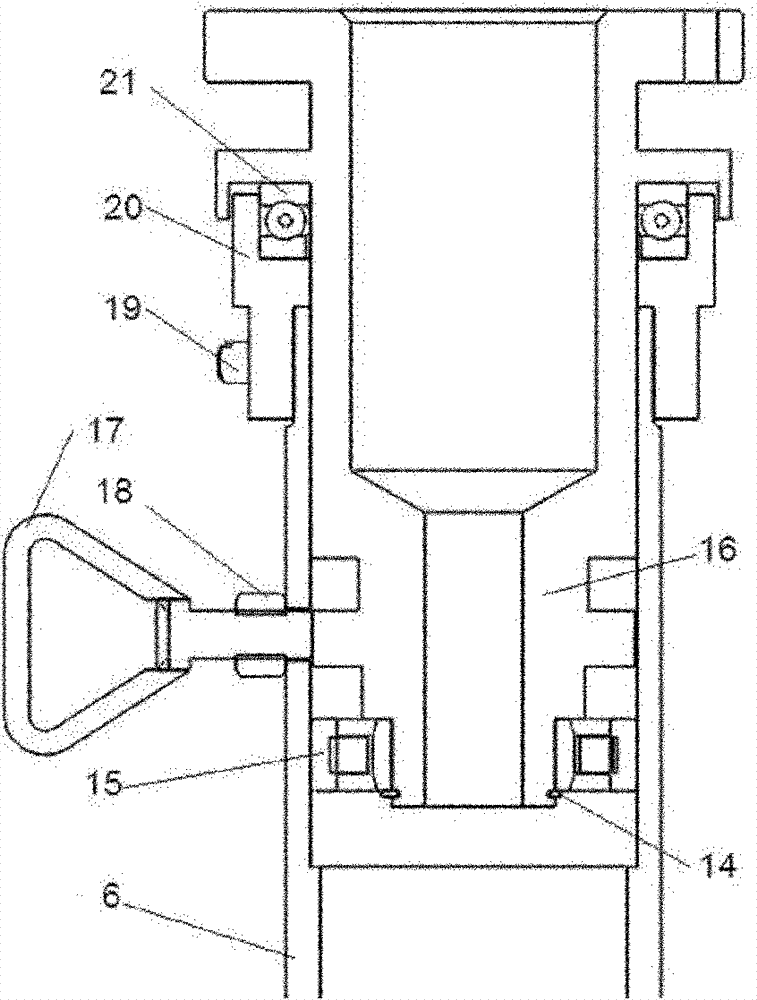

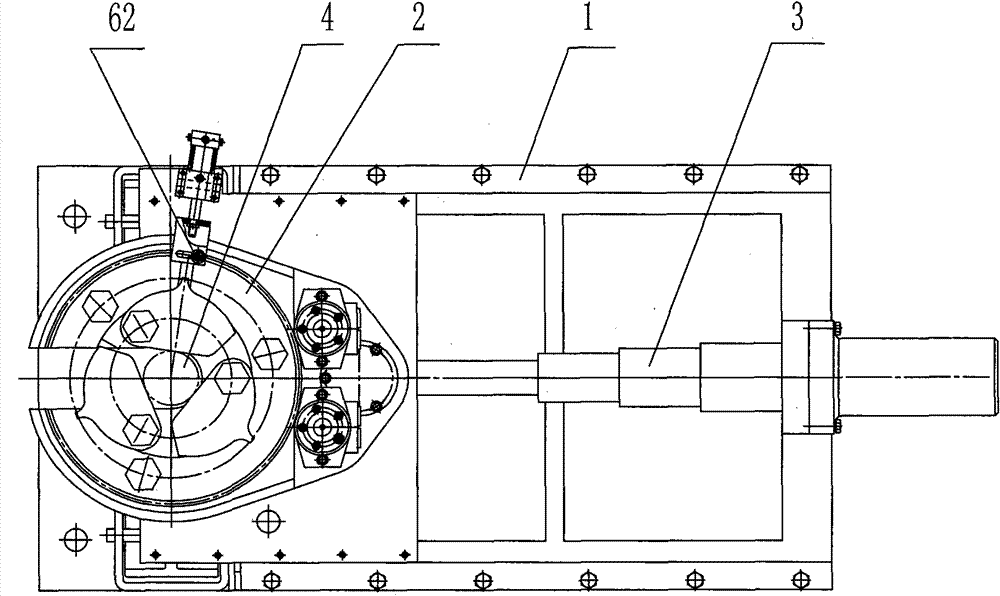

High-efficiency hydraulic twisting machine capable of staggering orifice

InactiveCN101832114BHigh torqueReduce volumeDrilling rodsDrilling casingsHydraulic cylinderControl engineering

The invention relates to high-torque hydraulic twisting equipment applied to an external flush drill stem and belongs to the field of drilling and exploring machinery. A high-efficiency hydraulic twisting machine capable of staggering an orifice is characterized by comprising a lower tong, an upper tong, and a horizontally moving hydraulic cylinder. A lower end slider of a frame of the upper tongis positioned in an upper tong sliding guide slot on a lower tong frame of the lower tong; a cylinder body of the horizontally moving hydraulic cylinder is fixed on a horizontally moving hydraulic cylinder fixing plate on the lower tong frame of the lower tong; and a piston rod of the horizontally moving hydraulic cylinder is hinged with the lower part of the frame of the upper tong. The twistingmachine is applied to mechanical twisting for the external flush drill stem, can realize all technical actions of centering, screwing, floating, punching / pre-tightening, and has the advantages of high torque, small volume, reliable and safe work, and simple operation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

High-torque hydraulic pipe-wrenching machine for wrenching and disassembling outer-flat drilling rod

The invention relates to high-torque hydraulic wrenching and disassembling equipment suitable for an outer-flat drilling rod, belonging to the field of drilling and exploring machineries. The high-torque hydraulic pipe-wrenching machine for wrenching and disassembling the outer-flat drilling rod is characterized by comprising lower clamping tongs, a floating device, clasp punching tongs, an orifice leaving oil cylinder, a sliding block at the lower end part of a left floating post and a sliding block at the lower end part of the right floating post of the floating device respectively correspond to the insides of a left chute and a right chute of a lower clamping tongs support of the lower clamping tongs, the body of the orifice leaving oil cylinder is fixed at the rear end part of the lower clamping tongs support, and a piston rod of the orifice leaving oil cylinder is articulated with a floating frame; and the clasp punching tongs are arranged on a floating plate of the floating device, and clasp turning tongs are arranged on a bottom plate of the clasp punching tongs. The invention adopts an integral structure of clamping, clasp turning, clasp punching / pre-tightening and is suitable for the wrenching and the disassembling of the outer-flat drilling rod.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Electronic device with battery snap mechanism

ActiveCN104659296BSolve the floating problemDigital data processing detailsCell component detailsElectrical batteryStructural engineering

Owner:INVENTEC CHONGQING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com