Manufacturing process of decompression and drainage well in basement anti-floating and sealing process

A production process and basement technology, which is applied in basic structure engineering, excavation, protection devices, etc., can solve the problems of unacceptable engineering conditions, affecting the construction work surface, and complicated procedures, so as to solve the problem of basement floating, shorten the construction period, and simplify the construction. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

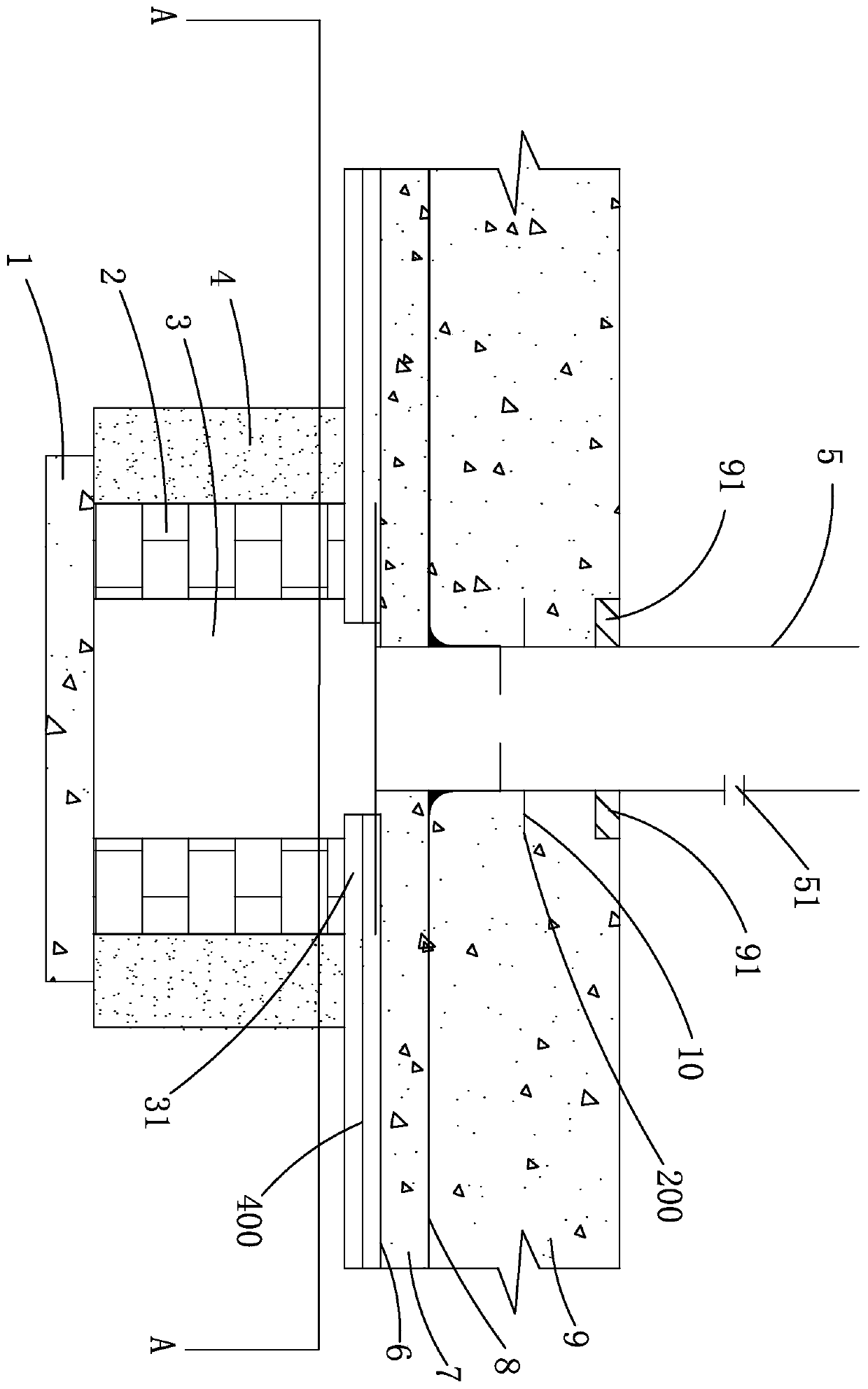

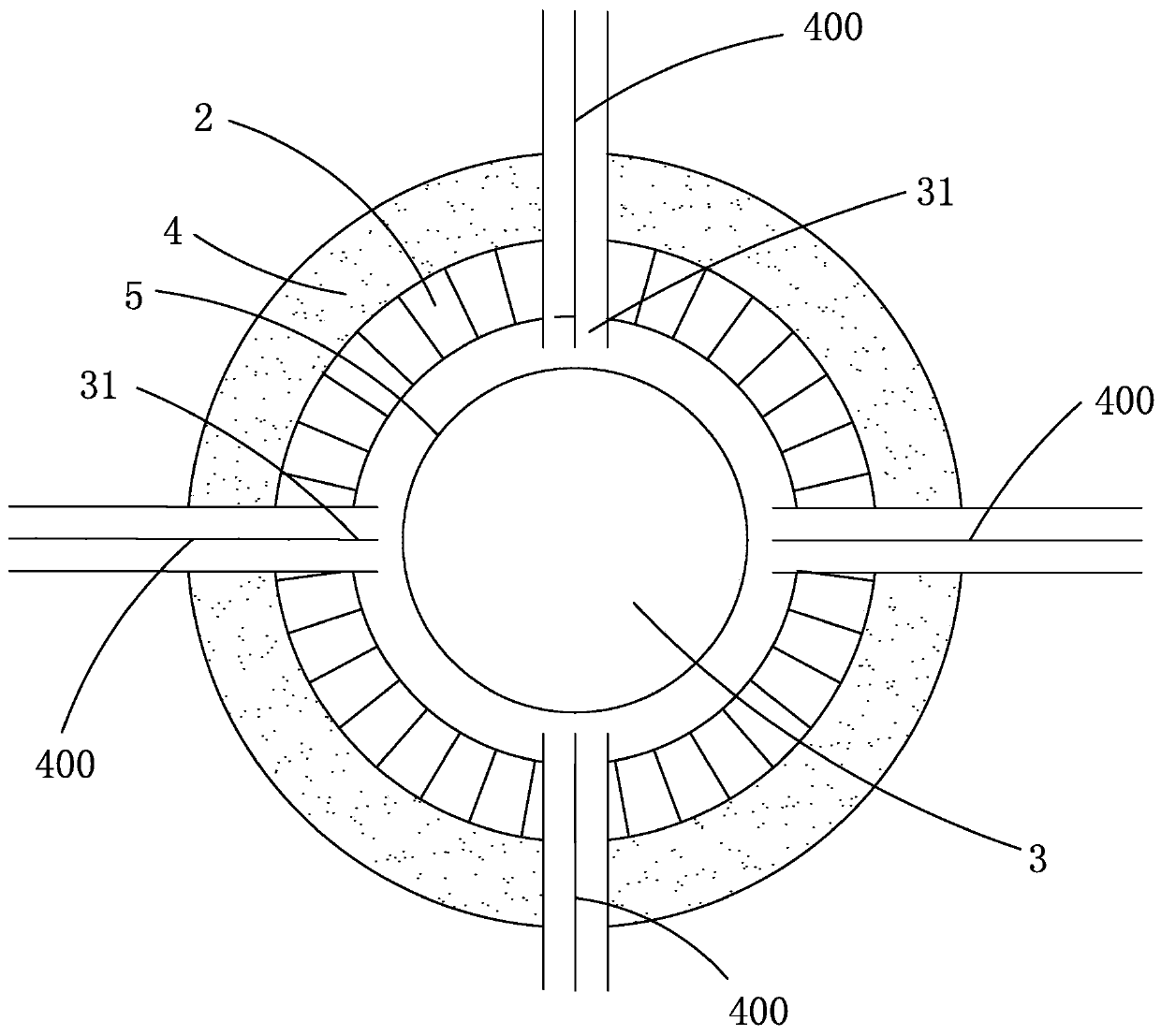

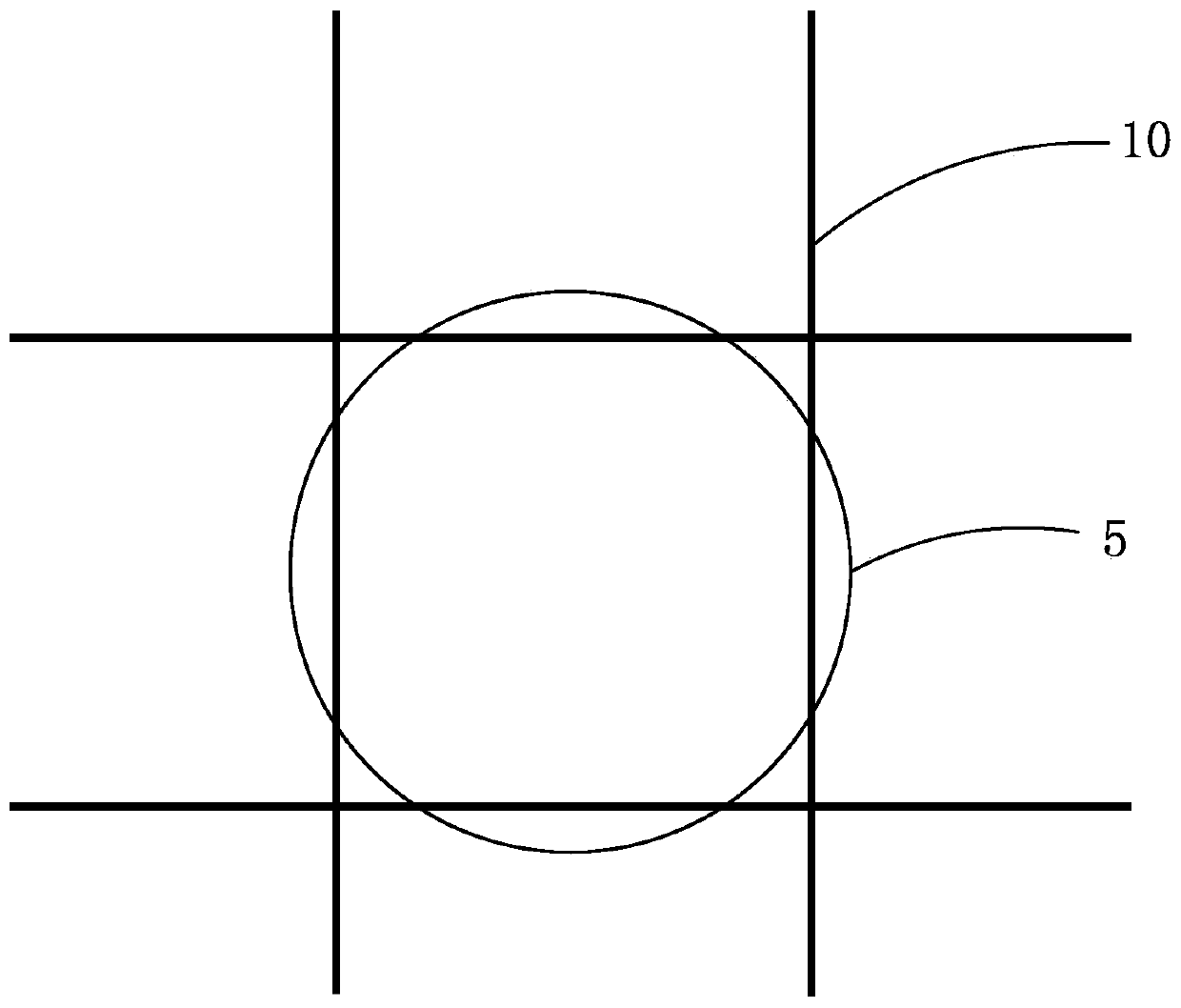

[0055] Example, combined with Figure 1 to Figure 4 Shown, a kind of manufacturing process of anti-floating decompression drainage well in basement,

[0056]Step 1: Dig a well with a depth of 50 cm in the basement;

[0057] Step 2: pouring a concrete cushion 1 at the bottom of the well;

[0058] Step 3: build permeable bricks 2 on the concrete cushion 1, and the permeable bricks 2 enclose the drainage well 3;

[0059] Step 4: backfill the periphery of the drainage well 3 with coarse sand or debris to form a permeable layer 4;

[0060] Step 5: the upper part of the drainage well 3 is spaced with a drainage port 31 along its circumferential direction;

[0061] Step 6: Fix the water-stop steel ring cover 5, insert the lower end of the water-stop steel ring cover 5 into the drain well 3, and the upper end of the water-stop steel ring cover 5 is exposed outside the bottom plate 6 of the basement;

[0062] Step 7: base plate 6 pouring base plate cushion 7;

[0063] Step 8: layi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com