Wrapping machine motor braking device

A technology of motor braking and outer winding machine, which is applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of untwisted outer winding wire, affecting the production efficiency of machine tools, affecting the quality of cord products, etc., to prevent The effect of lifting the outer winding wire, solving the floating of the outer winding wire, and reducing the hidden danger of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

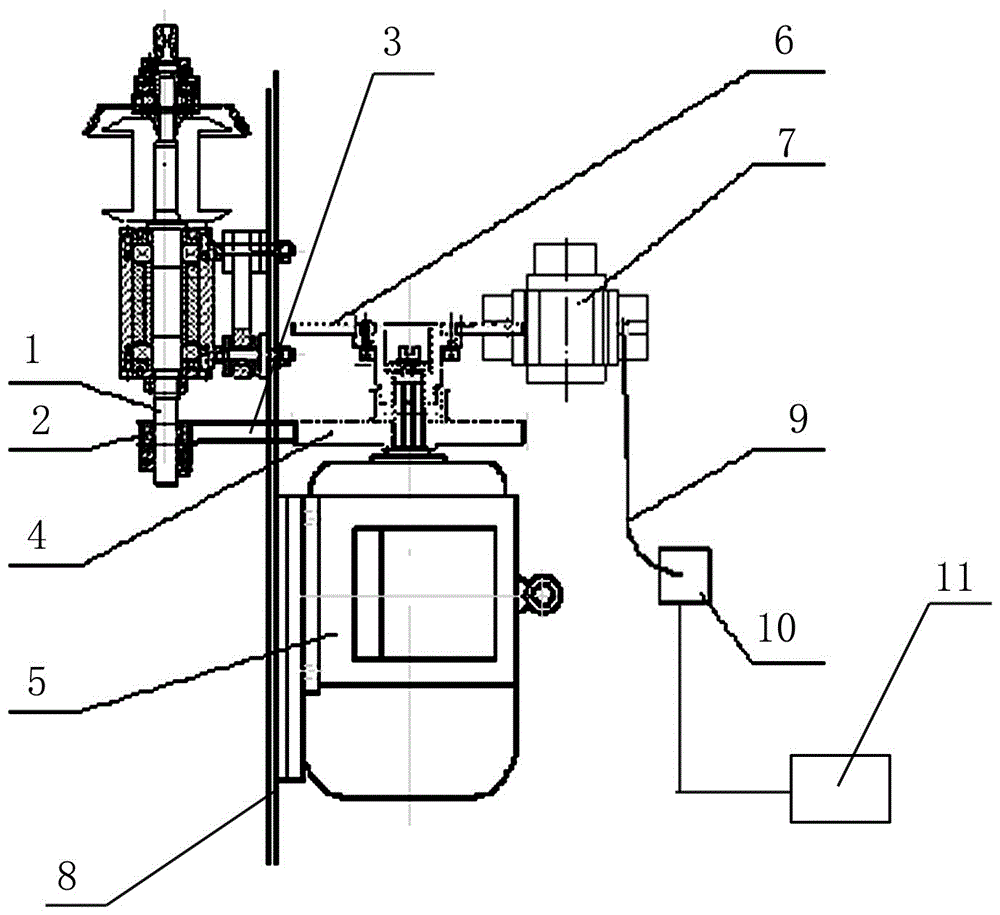

[0008] exist figure 1 Among them, the present invention provides a motor braking device for an outer winding machine, which includes a motor 5, a horizontal synchronous pulley I4 is connected to the output shaft of the motor 5, and a synchronous pulley II2 is provided on the side of the synchronous pulley I4. The synchronous pulley Ⅱ2 is set on the outer winding main shaft 1, and the synchronous belt 3 is used as the transmission connection between the synchronous pulley Ⅰ4 and the synchronous pulley Ⅱ2. There is a brake disc 6 on the upper part of the synchronous pulley Ⅰ4, and the brake disc 6 A brake cylinder 7 is installed on one side, the brake cylinder 7 is connected with a gas pipe 9, one end of the gas pipe 9 is connected with the brake cylinder 7, and the other end of the gas pipe 9 is equipped with a solenoid valve 10 connected with a PLC controller 11, PLC controller 11 is used to control the air intake and outlet of the solenoid valve 10, so as to realize the autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com